Calcium carbide mud mill quotation Xinyang puffing furnace

.jpg)

A 90 MW CALCIUM CARBIDE FURNACE PROCESS AND

This paper describes the scaleup for a furnace design rated at 90 MW active (real) power for calcium carbide production The basis for the scaleup is Carbide Industries‱ (CI) well established 50 MW furnace and process in LouisChina Calcium Carbide Furnace wholesale Select 2024 high quality Calcium Carbide Furnace products in best price from certified Chinese Solid Carbide manufacturers, Lime Equipment Calcium Carbide Furnace MadeinChinaThis paper describes the scaleup for a furnace design rated at 90 MW active (real) power for calcium carbide production The basis for the scaleup is Carbide Industries’ (CI) well A 90 MW CALCIUM CARBIDE FURNACE Semantic ScholarHatch has worked with partner Carbide Industries (CI) to scale up CI’s circular 3electrode furnace to a rectangular 6electrode closed furnace design with double the capacity of the previous A STEP CHANGE IN CALCIUM CARBIDE PRODUCTION TECHNOLOGY

.jpg)

A 90 MW CALCIUM CARBIDE FURNACE MECHANICAL DESIGN

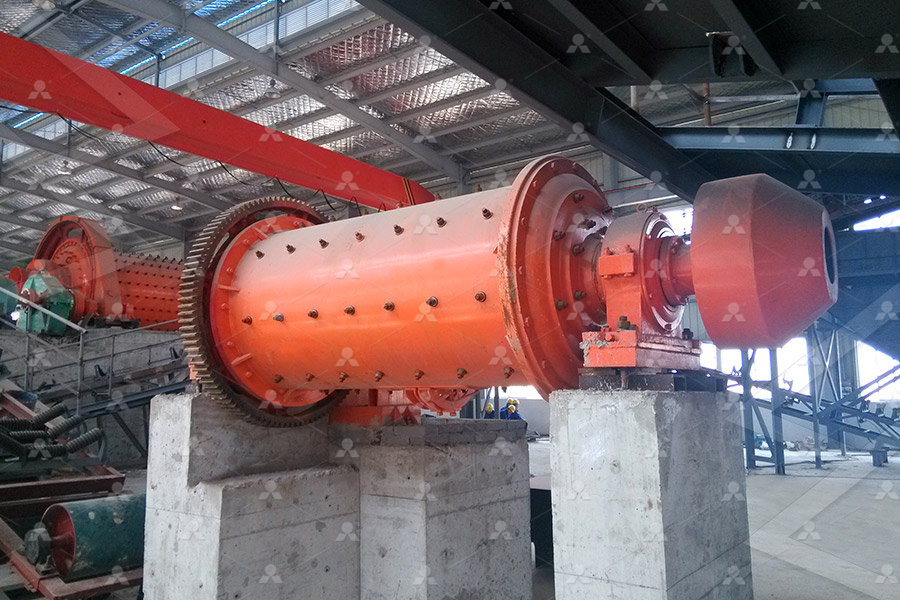

The scaledup calcium carbide furnace is a rectangular sixinline electrode design with an overall size of 287 m x 81 m x 71 m The furnace is equipped with a watercooled roof (cover) that 2022年2月1日 The aim of this paper is to: (i) propose a new type of calcium carbide production method and analyze the relationship between the input and output energy transfer and loss, Energy and exergy analysis of a new calcium carbide2023年2月1日 Aims at improving the utilization rate of red mud and preparing a lowcost grouting material for underground engineering, the ultrafine red mud was adopted to prepare a Preparation and curing method of red mudcalcium carbide slag The potential for eruptions is an ever present danger in calcium carbide furnace operation Environmental demands dictate that any new furnace must be closed The 90 MW furnace A 90 MW CALCIUM CARBIDE FURNACE – MECHANICAL DESIGN

.jpg)

Preparation and curing method of red mudcalcium carbide slag

2023年5月1日 A low carbon geopolymer (RCFG) was developed from the 100% solid wastes including red mud (RM), calcium carbide slag (CS), GGBS and FA in this study The effect of DDA 149853 describes a process in which calcium carbide is produced by blowing lime and coke dust into a plasma jet and then quenching and separating the finegrained product This A process for the production of calcium carbide and a shaft Calcium carbide, also known as calcium acetylide, is a chemical compound with the chemical formula of Ca C 2Its main use industrially is in the production of acetylene and calcium cyanamide [3]The pure material is colorless, while pieces of technicalgrade calcium carbide are grey or brown and consist of about 80–85% of CaC 2 (the rest is CaO (calcium oxide), Ca 3 P Calcium carbide Wikipedia2014年5月1日 Calcium carbide is a basic raw material for producing acetylene gas, using the following reaction [2]: (1) CaC 2 + 2 H 2 O → C 2 H 2 + Ca (OH) 2 Calcium carbide is manufactured from lime (CaO) and carbonaceous material (petroleum coke or metallurgical coke) in a electric arc furnace at 1800–2200 °C, according to the following equation [3]: (2) CaO + 3 Dust removal and purification of calcium carbide furnace offgas

Strength development and microstructure of sustainable

2022年11月21日 The increased production of industrial waste accompanies global industrialization The discharge and storage of industrial wastes seriously pollute the natural environment and limit the development of related industries [1]Red mud (RM), also known as bauxite residue, is a category of industrial waste produced from alumina plants2022年11月1日 Strength development and microstructure of sustainable geopolymers made from alkaliactivated ground granulated blastfurnace slag, calcium carbide residue, and red mud November 2022 Construction Strength development and microstructure of sustainable 2023年5月1日 The commercial alkali activators could account for more than 50% of the cost for producing geopolymers Thus, to lower the carbon footprint of geopolymer by avoiding the utilization of energyintensive commercial alkali activators, a novel ecofriendly geopolymer was synthesized from 100% solid wastes comprising red mud (RM), calcium carbide slag (CS), Preparation and curing method of red mudcalcium carbide slag 2 Carbide Industries LLC, 4400 Bells Lane, Louisville, Kentucky, USA 40211; srobinson@carbidellc fsizemore@carbidellc ABSTRACT Scalingup a 50 MW, 3electrode, round calcium carbide furnace, to a 90 MW, 6electrode, rectangular closed furnace configuration presents a number of mechanical design challenges as well as opportunitiesA 90 MW CALCIUM CARBIDE FURNACE MECHANICAL DESIGN

.jpg)

Enhanced thermal performance of calcium carbide furnace dust

2023年7月1日 Enhanced thermal performance of calcium carbide furnace dustbased formstable composite phase change materials for highefficient utilization of thermal energy Author links open overlay panel Yue Luo a b, Chongchong Li a, Feng Zhang a, Ji Tao a, Xiaoxiang He a, Xiang Lu c, Zhengke Li d, Ruitao Peng a Show more2021年2月25日 When the work point at 12,000 A and 1200 s, as the electrode immersion ratio increases from 025 to 075, the average temperature in calcium carbide electric furnace decreases by 71% However, the reduction of effective heating region with the electrode immersion ratio growth causes, the output of calcium carbide decreasedAnalysis and optimization about electromagneticstemperature 2006年3月1日 Calcium carbide can be synthesized from limestone and petroleum coke in a furnace employing direct heating by solar radiation The proposed technological process, based on the firing of an initial Calcium carbide synthesis using a solar furnace ResearchGate2024年1月2日 As one of the industries that guarantee the basic life of people, the calcium carbide industry permeates people's daily necessities [1, 2]However, heavy pollution limits its largescale and longterm operation [3]Further converting the carbide furnace gas (CFG, which is rich in H 2 and CO and has a molar fraction of over 95%, with small amounts of H 2 O and CO Achieving significant carbon emission reduction by chemical

Calcium Carbide Furnace MadeinChina

China Calcium Carbide Furnace wholesale Select 2024 high quality Calcium Carbide Furnace products in best price from certified Chinese Solid Carbide manufacturers, Lime Equipment suppliers, wholesalers and factory on MadeinChinaIn the process for the production of calcium carbide by reacting excess coke with burnt lime in the presence of oxygen in an oxygen thermal furnace (17), coal is mixed as a starting material for coke and hydrated lime (Ca (OH) 2) or limestone (CaCO3) as a starting material for burned Lime, both in prebroken form, frees the mixture from adhering water (7) in a drying zone (5) at 80 to Process for the production of calcium carbide Google Patents2021年10月25日 In this study, DS from Taihu Lake, together with calcium carbide slag (CCS) and ground granulated blastfurnace slag (GGBS), was used as supplementary cementitious materials (SCM) to replace Recycling sediment, calcium carbide slag and ground granulated 114 Calcium Carbide Manufacturing 1141 General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100°C (3632 to 3812°F) in an electric arc furnace At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO+3C→CaC2 +CO114 Calcium Carbide Manufacturing US EPA

Optimization of proportions and solidification mechanism of all

2024年5月23日 ash (CFBFA), red mud (RM) and calcium carbide slag (CS)The solidi cation mechanism of the ternary paste was studied from both macroscopic mechanical properties and microscopic ex2021年1月1日 It is of particular important to optimize the feed of calcium carbide (CaC 2) production by improving the productivity and reducing the energy consumptionIn this present paper, a transient mathematical model was established to analyze the effects of feed on heat and mass transfer characteristics of CaC 2 electric furnace The model was adopted to study the Influence of feed architecture on heat and mass transfer in calcium Calcium Carbide Furnaces The Union Carbide Co, one of the group of companies which were later incorporated into what is now Union Carbide Corp, was formed in 1898 to manufacture calcium carbide by the electric furnace process dis covered by Thomas L Willson and Maj J T Morehead a few years earlierHollow Electrode System For Calcium Carbide Furnaces Springer2023年5月16日 Calcium Carbide Calcium Carbide (CaC2) consists of about 8085% CaC2 and appears grey or brown in colour In steel making, it is used in the desulphurization of pig iron, cast iron and steel, also as a deoxidizer at ladle treatment facilities Click here to Calcium carbide MineralLoy

Kinetic analysis about the CO 2 capture capacity of lime mud from

2020年8月5日 Lime mud, a kind of industrial waste that produced in paper mill, was proposed as CO2 sorbent in calcium looping process The carbonation performance of the lime mud was investigated in a dual 2024年10月29日 In this study, different dosages of Calcium Carbide Slag (CCS) were used to modify Red Mud (RM), including partially replacing RM with blast furnace slag (GGBS) prior to CCS modification Thereafter, the influence of CCS on the fluidity and mechanical properties of the resultant cementitious mixtures was quantitatively evaluatedPreparation and Performance Assessment of Calcium Carbide 2020年5月13日 3 OffGas Waste Heat Potential The applied offgas data for the process design (mass flow and temperature) are shown in Figure 2The fluctuation in mass flow and temperature of the offgas between melting and Off‐Gas Waste Heat Recovery for Electric Arc Furnace 114 Calcium Carbide Manufacturing 1141 General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100°C (3632 to 3812°F) in an electric arc furnace At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO+3C→CaC2 +CO114 Calcium Carbide Manufacturing US EPA

.jpg)

Dust removal and purification of calcium carbide furnace offgas

2014年5月1日 A large amount of CO contained in calcium carbide furnace offgas can be recycled and used as an important raw material for C1 (one carbon) industrial chemical manufacturingThis Letter presents data on the synthesis of calcium carbide (CaC 2) using a large solar furnace with a power of 1000 kW Calcium carbide is widely used in various fields of technology, but mostly as the initial reactant in the production of acetylene and calcium cyanamide Acetylene (C 2 H 2) is formed in the course of calcium carbideCalcium Carbide Synthesis Using a Solar Furnace2014年5月1日 DOI: 101016/JJTICE201308008 Corpus ID: ; Dust removal and purification of calcium carbide furnace offgas @article{Jiang2014DustRA, title={Dust removal and purification of calcium carbide furnace offgas}, author={Ming Jiang and ZhongHua Wang and Ping Ning and Senlin Tian and Xiaofeng Huang and YangWei Bai and Yan Shi and Dust removal and purification of calcium carbide furnace offgas2019年10月26日 The solidification and stabilization of calcium carbide residue (CCR) using granulated blast furnace slag was investigated in this study CCR binding in hydrated slag was explored by Xray Utilization of Calcium Carbide Residue Using Granulated Blast Furnace

.jpg)

Development of calcium coke for CaC2 production using calcium carbide

2020年9月21日 A type of calcium coke was developed for use in the oxythermal process of calcium carbide production The calcium coke was prepared by the copyrolysis of coking coal and calcium carbide slag, which is a solid waste generated from the chloralkali industry The characteristics of the calcium cokes under different conditions were analyzed experimentally 2022年11月21日 Calcium carbide residue (CCR) is a high alkaline byproduct generated from acetylene gas factories [23] Given its abundant calcium hydroxide (Ca(OH) 2) content, it has been widely reported as alkali activator combined with pozzolanic materials such as ground granulated blastfurnace slag (GGBS) and fly ash to prepare a cementfree binderStrength development and microstructure of sustainable 2024年8月30日 Calcium carbide residue (CCR) is a solid byproduct discharged during acetylene gas production through the hydrolysis of calcium carbide (CaC 2) [13]It mainly consists of Ca(OH) 2 and exhibits a high alkalinity (pH ≥12) [14]Currently, the landfill is the principal disposal way for CCR [15], which occupies valuable land resources and basifies the soil and Compressive strength and gel structure improvement in the high A large amount of CO contained in calcium carbide furnace offgas can be recycled and used as an important raw material for C1 (one carbon) industrial chemical manufacturing The key to the recovery is the removal of dust and gaseous impurities from the offgas For this purpose, an industrial device has been used for removing the dustDust removal and purification of calcium carbide furnace offgas

.jpg)

Calcium carbide Wikipedia

Calcium carbide, also known as calcium acetylide, is a chemical compound with the chemical formula of Ca C 2Its main use industrially is in the production of acetylene and calcium cyanamide [3]The pure material is colorless, while pieces of technicalgrade calcium carbide are grey or brown and consist of about 80–85% of CaC 2 (the rest is CaO (calcium oxide), Ca 3 P 2014年5月1日 Calcium carbide is a basic raw material for producing acetylene gas, using the following reaction [2]: (1) CaC 2 + 2 H 2 O → C 2 H 2 + Ca (OH) 2 Calcium carbide is manufactured from lime (CaO) and carbonaceous material (petroleum coke or metallurgical coke) in a electric arc furnace at 1800–2200 °C, according to the following equation [3]: (2) CaO + 3 Dust removal and purification of calcium carbide furnace offgas2022年11月21日 The increased production of industrial waste accompanies global industrialization The discharge and storage of industrial wastes seriously pollute the natural environment and limit the development of related industries [1]Red mud (RM), also known as bauxite residue, is a category of industrial waste produced from alumina plantsStrength development and microstructure of sustainable 2022年11月1日 Strength development and microstructure of sustainable geopolymers made from alkaliactivated ground granulated blastfurnace slag, calcium carbide residue, and red mud November 2022 Construction Strength development and microstructure of sustainable

Preparation and curing method of red mudcalcium carbide slag

2023年5月1日 The commercial alkali activators could account for more than 50% of the cost for producing geopolymers Thus, to lower the carbon footprint of geopolymer by avoiding the utilization of energyintensive commercial alkali activators, a novel ecofriendly geopolymer was synthesized from 100% solid wastes comprising red mud (RM), calcium carbide slag (CS), 2 Carbide Industries LLC, 4400 Bells Lane, Louisville, Kentucky, USA 40211; srobinson@carbidellc fsizemore@carbidellc ABSTRACT Scalingup a 50 MW, 3electrode, round calcium carbide furnace, to a 90 MW, 6electrode, rectangular closed furnace configuration presents a number of mechanical design challenges as well as opportunitiesA 90 MW CALCIUM CARBIDE FURNACE MECHANICAL DESIGN2023年7月1日 Enhanced thermal performance of calcium carbide furnace dustbased formstable composite phase change materials for highefficient utilization of thermal energy Author links open overlay panel Yue Luo a b, Chongchong Li a, Feng Zhang a, Ji Tao a, Xiaoxiang He a, Xiang Lu c, Zhengke Li d, Ruitao Peng a Show moreEnhanced thermal performance of calcium carbide furnace dust 2021年2月25日 When the work point at 12,000 A and 1200 s, as the electrode immersion ratio increases from 025 to 075, the average temperature in calcium carbide electric furnace decreases by 71% However, the reduction of effective heating region with the electrode immersion ratio growth causes, the output of calcium carbide decreasedAnalysis and optimization about electromagneticstemperature

Calcium carbide synthesis using a solar furnace ResearchGate

2006年3月1日 Calcium carbide can be synthesized from limestone and petroleum coke in a furnace employing direct heating by solar radiation The proposed technological process, based on the firing of an initial 2024年1月2日 As one of the industries that guarantee the basic life of people, the calcium carbide industry permeates people's daily necessities [1, 2]However, heavy pollution limits its largescale and longterm operation [3]Further converting the carbide furnace gas (CFG, which is rich in H 2 and CO and has a molar fraction of over 95%, with small amounts of H 2 O and CO Achieving significant carbon emission reduction by chemical