Quick lime nickel cobalt vertical mill

.jpg)

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

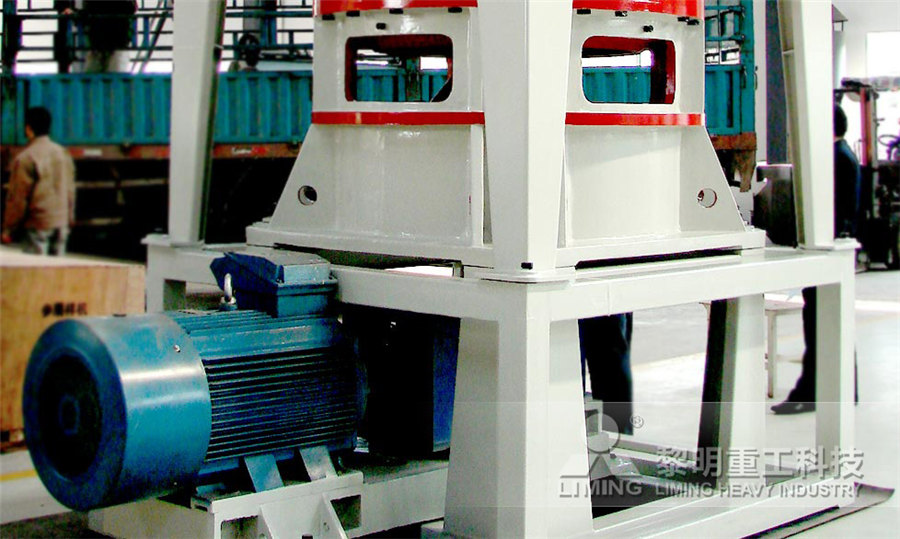

MPS vertical mill from Pfeiffer is the ideal allrounder Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, and many other materialsMVR vertical roller mill (conventional drive) ready2grind modular system; MPS ReferencesVertimill® is an energy efficient grinding machine They tend to grind more efficiently than, for example, ball mills with feeds as coarse as 6 mm to products finer than 20 microns This Vertimill® MetsoLM series vertical milling machine can be widely used in such industries as cement, power, metallurgy, stone industry, nonmetallic mineral It is used to grind granular and powdered LM Series Vertical Mill Liming Heavy Industry

.jpg)

Large scale equipment for quick lime powder production

It has been the first to launch a large vertical roller mill, LM series vertical roller mill, suitable for quicklime grinding processing This equipment integrates crushing, drying, grinding, and 2014年1月1日 Operational differences from nickel H 2 reduction are: (1) cobalt “seed” is made by precipitation from cobaltous diamine solution using sodium cyanide catalyst and sodium sulfide particle nucleation sites, (2) cobalt reduction is slightly faster than nickel reduction and the resulting cobalt particles are slightly larger and more irregular due to particle agglomeration, Nickel and Cobalt Production ScienceDirectNickel Slag Grinding Plant Materials: Nickel Slag Main Equipment: GRMSS Slag Vertical Mill Matching Equipment: belt feeder + vibrating screen + slag vertical mill + hot stove + dust collector + finished product warehouse Steel Slag Vertical Lime Kiln CHAENGCarmeuse Systems can engineer a complete slaking solution tailored to your site needs using the Metso VERTIMILL® vertical ball mill slaker This, along with our patented lime feed arrangement specifically designed for the Metso Verticall Ball Mill Slaker Carmeuse Systems

.jpg)

Towermill Vertical Agitated Media Mill Pharmaceutical Process

TowerMill Vertical Agitated Media Mill Agitated Media Mill for wet dry grinding of ores and minerals Nippon EIRICH, Japan, supplies the TowerMill, a vertical agitated media mill for wet grinding in the fineness range from 45 µm to 150 µmQUICK LIME AND BYPRODUCTS Metallurgical The largest use of lime is in steel manufacturing, where it serves as a flux to remove impurities (silica, phosphorus, and sulfur) Lime is used in basic oxygen furnaces and electric arc furnaces, as well as in secondary refiningQUICK LIME AND BYPRODUCTS PEC Consulting GroupThe first example of using an agitated vessel and grinding media for comminution was in 1922 when Szegvari stirred a gallon can full of pebbles to rapidly disperse a sulphur suspension [19]This was developed into the first ‘stirred ball mill’ by Klein and Szegvari in 1928 [20]This prototype was refined into the Attritor mill, a low tip speed (3–5 m/s [21]) vertical pin mill which Semi Autogenous Grinding Mill ScienceDirect Topics2024年1月1日 Operational differences from nickel H 2 reduction are: (1) cobalt “seed” is made by precipitation from cobaltous diamine solution using sodium cyanide catalyst and sodium sulfide particle nucleation sites, (2) cobalt reduction is slightly faster than nickel reduction and the resulting cobalt particles are slightly larger and more irregular due to particle agglomeration, Nickel and Cobalt ScienceDirect

vertical roller mill, vertical coal mill, vertical slag mill, superfine

Vertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill, vertical coal mill, and ultrafine vertical mill48*76m Cement Clinker Nickel Zinc Oxide Metallurgy Lime Vertical/Rotary Kiln US$ / Piece 1 Piece (MOQ) Jiangsu Pengfei Group Co, Quick Lime Plant Active Lime Construction Machinery Vertical Shaft 200250tpd Kiln Vertical Mill; Vertical Machine Center; Vertical Wall; Vertical Casting Machine; Ceramic Kiln;Vertical Lime Kiln MadeinChinaActive lime vertical kiln equipment supporting Calcination of limestone Qualified limestone goes to the top of the preheater through the belt conveyor, and the material is introduced into the body of the preheater from the silo at the top of the preheater through the discharge chute, and at the same time, the hightemperature flue gas from the rotary kiln preheats the material to 600°C Vertical Shaft Lime Kiln for Cement PlantLime Calcination Plant Solution As a professional provider of lime calcination solutions, we can provide onestop lime calcination kiln solutions for lime production enterprises in various industries, including lime rotary kilns or lime Lime Calcination Plant Solution, Lime Production

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

Quicklime preparation Gebr Pfeiffer

Quicklime lumps are ground and classified in Pfeiffer MPS vertical roller mills The fineness of the white fine limes can be set within wide limits (006 to 01 mm) In downstream Pfeiffer lime hydrators, water is added to quicklime, thus PDF On Mar 11, 2019, Sait Kursunoglu and others published Hydrometallurgical Processing of Nickel Laterites—A Brief Overview On The Use of Solvent Extraction and Nickel/Cobalt Project For The (PDF) Hydrometallurgical Processing of Nickel Table 1 Principal nickel and nickeliferous minerals in nickel sulfide deposits Formula Nickel content (%) Nickel minerals Primary Pentlandite (Ni,Fe)9S8 25}41 Millerite NiS 65 Heazelwoodite Ni3S2 73 Geradorffite (Ni,Co,Fe)AsS 15}35 Nickeline NiAs 44 Awaruite NiFe 25}75 Secondary Violarite Ni2FeS4 33}40 Bravoite (Ni,Fe)S2 17}24 Haapalaite 4(Fe NICKEL AND COBALT ORES: FLOTATION 911 MetallurgistC BALL MILL SLAKERS Ball mill slakers are an adaptation of ball mills, which originally were designed for wet and dry grinding, to lime slaking Two types of ball mills are used for slaking, horizontal and vertical Ball mill slakers are generally used where: the capacity required is too large for other types of slakersAn Overview of Lime Slaking and Factors That Affect the Process

Lime use and functionality in sulphide mineral flotation: A review

2019年11月1日 At Vale's Thompson Mill (Canada) the predominant nickel and copper minerals are pentlandite and chalcopyrite, respectively Following bulk sulphide flotation, where soda ash is added as the pH modifier, sodium amyl xanthate as the collector and MIBC as the frother, slaked lime is added to depress the pentlandite and effect CuNi separation ( Farr, 1992 )Verticle Shaft Kiln Introduction In factory of lime calcination, where precision and efficiency are paramount, vertical shaft kilns (VSKs) stand as stalwart contributors to the chemical transformation of limestone into quicklime As an engineer navigating the intricacies of industrial processes, understanding the design, components, and operational aspects of VSKs becomes Vertical Shaft Kilns in Optimizing Lime Calcinationthe process requirements The mill residence times were 1 minute per mill The vapour seals on the nickel raffinate feed lines are achieved using viton rubber bellows Dry quicklime (CaO) powder is screwed into the vapour area of the vibrating mills from the storage silo using an extended screw inside the mill The quicklime reacts with theNOVEL DESIGN ASPECTS OF THE TATI ACTIVOX® PROJECT 2022年4月20日 Quicklime absorbs moisture or adds water to become slaked lime, the main component is calcium hydroxide Ca(OH) 2, used in environmental protection, Clum ultrafine vertical mill Fineness: 1503000mesh Yield: 120t/h see More >> GET IN TOUCH Tel: +86 WhatsApp: +86 Click to chat (Web)Limestone crushing and grinding production line SBM Ultrafine

Vertical Raw Mill CHAENG

The power consumption of raw material vertical mill system is 97Kwh/t lower than ball mill, that is to say: in one year, a 5000TPD cement plant can save energy in clinker grinding system: 97kWh/t * 5000t/d * 300d=14,550,000 kWh, that means the cement plant clinker grinding system can save 14,550,000 kWh electricity one year• Use of a vertical mill and gases passing through the mill to recover energy and to reduce the sulfur content in the gas In the mill, the gas containing sulfur oxide mixes with the calcium carbonate (CaCO 3) of the raw meal and produces calcium sulfate (gypsum ); • Selection of fuel source with lower sulfur content;World Bank DocumentVertical Roller Mill Vertical roller mills are mainly engaged in three major fields of coal powder, slag and nonmetallic ore Divided into: vertical coal mill, vertical slag mill, vertical roller mill, and ultrafine vertical mill (ultrafine powder processing) One machine is multipurpose, it can be used for grinding, grading, crushing, drying, etcvertical roller mill, vertical slag mill, vertical coal mill, Superfine New type TTHN vertical shaft kiln for lime production Output 100500t/d, particle size 3060/4080mm Lime shaft kiln with reasonable design and excellent performance for saleLime Shaft Kiln for Sale, Energyefficient Vertical Lime

.jpg)

Kalgoorlie Nickel Project Ardea Resources Limited

2023年6月30日 Ardea’s KNP hosts one of the largest nickelcobalt resources in the developed World, 854Mt at 071% Ni and 0045% Co for 61Mt of contained nickel and 386kt of contained cobalt (ASX release 30 June 2023), which places the Company in a prime position to provide essential supplies of ESGcompliant nickel and cobalt, along with other Critical Minerals such 2021年1月29日 The vertical roller mill used in the cement industry is a crucial piece of equipment that operates continuously and is essential for production However, Increase productivity of vertical roller mill using seven QC toolsVertical Kiln(Effective vol)(m³) 100500: output(t/d) 80400: Energy consumption(KJ/kglime) 910×41868: Coal consumption(kg/tlime) <130: Utilization factor(t/dm 3) ≥085: Activity degree(ml) ≥300: Calcium content of quicklime (%) ≥90: Overburning rate of quicklime (%) < 57: Quick lime consumption(t/t) 18: CO 2 concentration High Quality Vertical Lime Kiln for Sale2022年12月28日 Cobalt is a kind of magnetic hard metal with high melting point, high stability, high temperature resistance and corrosion resistance The material is an important raw material for the manufacture of superalloys, hard alloys, ceramic pigments, catalysts and batteries cobalt extraction frontend crushing grinding process Cobalt resources are mainly producedNew energy cobalt extraction frontend crushing grinding process

.jpg)

Limestone crushing technology and equipment SBM Ultrafine

2023年12月8日 The processing of limestone mainly includes crushing, grading and producing quick lime, hydrated lime, precipitated calcium carbonate, ultrafine (nano) calcium carbonate, carbon dioxide, Clum ultrafine vertical mill Fineness: 1503000mesh Yield: 120t/h see More >> GET IN TOUCH Tel: +86 WhatsApp: +86 Twin Shaft Lime Kiln Capacity: 300800t/d Fuel: Gas, pulverized coal, and more Features: Energysaving design ensures costeffective lime production Activity degree reaches an impressive 360400ml, guaranteeing highquality output Structure: Twin shaft design with interconnected chambers for optimal lime processing Advantages: Versatile fuel options Vertical Shaft Kiln Design Manufacture Cement VSK SolutionsLime Calcination Plant EPC solution for lime calcination CAPACITY: 50~1200TPD FUEL: coal gas, natural gas, and pulverized coal EQUIPMENT: vertical lime kiln (or rotary kiln), Raymond mill, jaw crusher, bucket elevator, separator, dust collector, etc Get QuoteLime Calcination Plant Lime Kiln Plant Output: 50–1200 TPD2014年1月1日 Operational differences from nickel H 2 reduction are: (1) cobalt “seed” is made by precipitation from cobaltous diamine solution using sodium cyanide catalyst and sodium sulfide particle nucleation sites, (2) cobalt reduction is slightly faster than nickel reduction and the resulting cobalt particles are slightly larger and more irregular due to particle agglomeration, Nickel and Cobalt Production ScienceDirect

.jpg)

Vertical Lime Kiln CHAENG

Nickel Slag Grinding Plant Materials: Nickel Slag Main Equipment: GRMSS Slag Vertical Mill Matching Equipment: belt feeder + vibrating screen + slag vertical mill + hot stove + dust collector + finished product warehouse Steel Slag Carmeuse Systems can engineer a complete slaking solution tailored to your site needs using the Metso VERTIMILL® vertical ball mill slaker This, along with our patented lime feed arrangement specifically designed for the Metso Verticall Ball Mill Slaker Carmeuse SystemsTowerMill Vertical Agitated Media Mill Agitated Media Mill for wet dry grinding of ores and minerals Nippon EIRICH, Japan, supplies the TowerMill, a vertical agitated media mill for wet grinding in the fineness range from 45 µm to 150 µmTowermill Vertical Agitated Media Mill Pharmaceutical Process QUICK LIME AND BYPRODUCTS Metallurgical The largest use of lime is in steel manufacturing, where it serves as a flux to remove impurities (silica, phosphorus, and sulfur) Lime is used in basic oxygen furnaces and electric arc furnaces, as well as in secondary refiningQUICK LIME AND BYPRODUCTS PEC Consulting Group

Semi Autogenous Grinding Mill ScienceDirect Topics

The first example of using an agitated vessel and grinding media for comminution was in 1922 when Szegvari stirred a gallon can full of pebbles to rapidly disperse a sulphur suspension [19]This was developed into the first ‘stirred ball mill’ by Klein and Szegvari in 1928 [20]This prototype was refined into the Attritor mill, a low tip speed (3–5 m/s [21]) vertical pin mill which 2024年1月1日 Operational differences from nickel H 2 reduction are: (1) cobalt “seed” is made by precipitation from cobaltous diamine solution using sodium cyanide catalyst and sodium sulfide particle nucleation sites, (2) cobalt reduction is slightly faster than nickel reduction and the resulting cobalt particles are slightly larger and more irregular due to particle agglomeration, Nickel and Cobalt ScienceDirectVertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill, vertical coal mill, and ultrafine vertical millvertical roller mill, vertical coal mill, vertical slag mill, superfine 48*76m Cement Clinker Nickel Zinc Oxide Metallurgy Lime Vertical/Rotary Kiln US$ / Piece 1 Piece (MOQ) Jiangsu Pengfei Group Co, Quick Lime Plant Active Lime Construction Machinery Vertical Shaft 200250tpd Kiln Vertical Mill; Vertical Machine Center; Vertical Wall; Vertical Casting Machine; Ceramic Kiln;Vertical Lime Kiln MadeinChina

Vertical Shaft Lime Kiln for Cement Plant

Active lime vertical kiln equipment supporting Calcination of limestone Qualified limestone goes to the top of the preheater through the belt conveyor, and the material is introduced into the body of the preheater from the silo at the top of the preheater through the discharge chute, and at the same time, the hightemperature flue gas from the rotary kiln preheats the material to 600°C