What is limestone grinding

What is Limestone Grinding Mill SBM Mill Crusher

2023年5月15日 A limestone grinding mill is a machine that grinds and powderizes limestone It is very useful in the manufacture of cement, glass, steel and other industrial products that require finely ground limestone Limestone A limestone grinding machine is a piece of equipment designed to grind limestone into a fine powder It is used in various industries, including construction, agriculture, and manufacturing How does Limestone Grinding Machine Work and What to These limestone mills are designed to operate at 3 to 4 PSI (02 to 03 bar) and 250°F (120°C) to inject the limestone directly into the Circulating Fluidized Bed (CFB), thus eliminating costly material handling, storage, and drying equipmentLimestone Mills Williams Crusher2022年8月26日 Limestone grinding mill is composed of grinding host, grading screening, product collection and other parts The host adopts the overall cast base structure and can adopt the shock absorption foundationWhich Grinding Mill Is Suitable For Processing

Grinding Technology of Limestone With Ball Mills

The document discusses grinding technology for limestone using ball mills It covers: 1 The properties and applications of limestone powder 2 Wet and dry grinding processes 3 Different types of grinding circuits including classical ball Limestone can be made into limestone powder by treatment of limestone crusher and limestone grinding mill Limestone powder can produce quicklime by calcination Quicklime can be widely used for desulfurization in power plants, LIMESTONE CRUSHING GRINDING ball mills supplier2023年9月19日 What is a limestone grinding mill? A limestone grinding mill is a machine used for grinding limestone into powder It is a mechanical device that grinds materials into powders by friction, crushing, and grinding to meet the Limestone Grinding Mill That You Need To Know2023年2月28日 To make limestone rock into powder, a grinding process is required This blog will share with you limestone grinding machines and problems that should be paid attention to in the limestone powder grinding plants to Necessary Matters About Limestone Powder Grinding

5 Limestone Grinding Mills to Maximize Limestone Grinding

2023年3月24日 To meet the increasing demand for highquality limestone products, the limestone grinding plant and grinding mills have been developed to enhance the efficiency of 2024年1月18日 Limestone is the primary raw material for manufacturing cement, lime, and carbide and is an essential flux limestone in the metallurgical industry Highquality limestone, after ultrafine grinding, is widely used in the How to choose a limestone grinding mill SANDMINE#3 Polished Limestone Finish for a Sense of HighEnd Refinement Achieving smooth polished limestone can require grinding with successively finer diamond grit pads or compounds Sometimes, oxalic acid or a crystallizing compound is General Types of Limestone Finishes Stone CenterLimestone specific weight = 27 g/cm3 SO3 Effects The clinker SO3 content has been recognized as having an impact on grindability High Chrome Cast Iron Grinding Balls Data supplied by ME International (1990) Data based on steel Everything you need to know about clinker/cement

.jpg)

What is the grinding of limestone? SageTips

Limestone powder ground from natural limestone rock is also called Heavy Calcium Carbonate, or Ground Calcium Carbonate (GCC) (Kotaite in the United States) The grinding process of heavy calcium carbonate can be divided into coarse crushing, medium and fine crushing, powder grinding, grading and powder collection2024年11月7日 What is Limestone Flour? Limestone flour is a finely ground powder derived from limestone, a sedimentary rock primarily composed of calcium carbonate (CaCO3) It is created by crushing and grinding limestone into a powder with a particle size ranging from a few microns to several hundred micronsLimestone flour finds applications in various industries, What Is Limestone Flour And Why You Should Be Using It2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and Limestone crushing technology and equipment SBM Ultrafine 2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s energy budget Overall Energy Use of Fine Grinding in Mineral Processing

.jpg)

9 Different Minerals Used as Abrasives ThoughtCo

2019年3月6日 Polishing Abrasives Three natural abrasives are commonly used for polishing and cleaning metal: enamel finishes, plastic, and tile Pumice is a stone, not a mineral, a volcanic product with a very fine grain Its hardest mineral is quartz, so Limestone Grinding Process The limestone grinding process mainly includes two types: Open circuit process: the process of material passing through the mill as finished product for the next step of operation; Closed circuit process: when the material discharged from grinding mill after one or several levels of separation, the fine particles are used as the finished product, and the Which Grinding Mill Is Suitable For Processing Limestone?2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcLimestone Ultrafine Mill Machine SBM Ultrafine Powder HOME > APPLICATIONS > MINERALS > LIMESTONE GRINDING Limestone Grinding The main application for limestone is as hydrated lime (calcium hydroxide) for mortar or plaster preparation On a smaller scale, lime is additionally used as a fertilizer, for wastewater treatment or as an additive in the food industry (for example as a neutralizing agent or acidityLIMESTONE GRINDING Bauermeister Size Reduction Equipment

Limestone Texas Beyond History

Hard limestone rocks were also used for grinding stones (manos/handstones as well as grinding slabs), but harder stones, such as granite and other metamorphic rocks, were preferred When limestone was the only rock available, that is 2024年1月18日 Limestone has been widely used in human civilization history due to its wide distribution and easy lime, and carbide and is an essential flux limestone in the metallurgical industry Highquality limestone, after ultrafine How to choose a limestone grinding mill SANDMINELimestone mining involves underground mining techniques that comprises of drilling, blasting Great mining is mainly considered by mining companies product equipments like as Aluminum, copper, gold, mercury, etc All mining suppliers Limestone extraction – underground mining Clinker is the primary material of cement, and it is called as semifinished product Clinker is a granulated material made of raw meal powder obtained by grinding limestone and clay together by sintering the raw meal in a rotary furnace at 1400°C1500°C degrees Produced clinker’s mineralogical structure effects clinker’s grinding energyWhat is Clinker? The Relationship Between Clinker Phases and Grinding

.jpg)

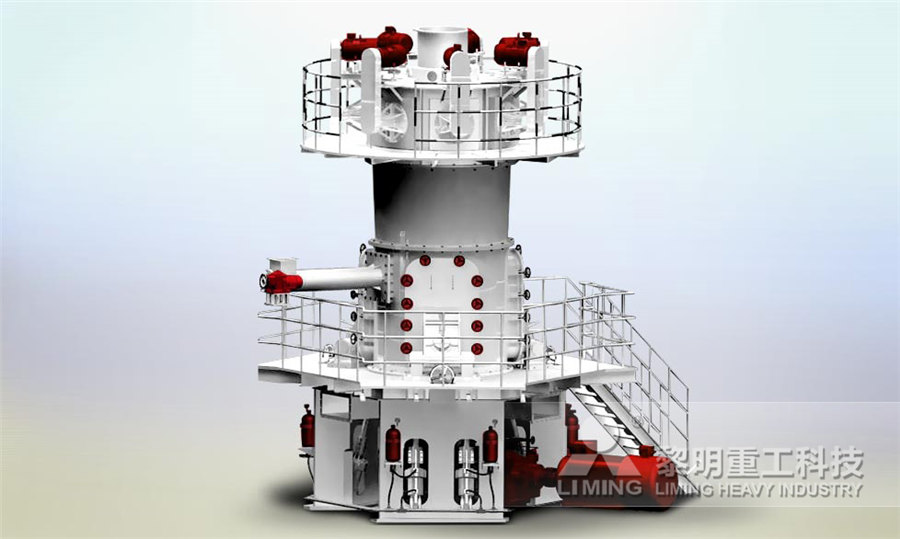

Limestone Ultrafine Grinding Mill

Limestone ultrafine grinding mill can process fine limestone powder, fineness: 1503000 mesh adjustable It has stable operation, good performance +年2月26日 Regardless of the grinding wheel, though, all grinding processes use abrasive particles to “grind” away material from a workpiece’s surface When a workpiece is exposed to a grinding wheel, some of its material will rub off With that said, grinding is often used to both remove material from workpieces as well as polish workpiecesMilling vs Grinding: What's the Difference? OneMonroeLimestone Grinding Purpose: Grinding is used to remove deep scratches, stains, or unevenness on the surface Process: Diamond abrasive pads grind down the stone, resulting in a smooth and level surface Best For: Floors with significant damage or uneven areas that require restorationLimestone Floor Grinding Sydney Geova Stone Solutions2022年4月20日 After limestone is mined from limestone rock, it is crushed to form limestone particles, namely stone and sand Or further grinding to form limestone powder, which is widely used in building materials, highways, metallurgy, chemical industry and other industriesLimestone crushing and grinding production line SBM Ultrafine

.jpg)

What is the difference between crushing and grinding?

2020年9月7日 Misunderstanding of Lubricating Oil Used in Raymond Mill As a common grinding plant, Raymond Mill can be used in fine powder making of barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement and phosphate rock, and other Nonflammable and explosive minerals, chemicals, 2024年11月23日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by Cement Extraction, Processing, Manufacturing BritannicaRaymond Roller Mills are available with grinding ring diameters ranging from 30120 in / 760 fineness from a wide variety of material Typical material processed Clay, Fire Clay, Bentonite, Kaolin, Barytes, Gypsum, Limestone, Raymond Roller Mill airswept vertical ringroll2024年11月22日 portland cement, binding material in the form of a finely ground powder, usually gray, that is manufactured by burning and grinding a mixture of limestone and clay or limestone and shaleThe inventor Joseph Aspdin, of England, patented the basic process in 1824, naming it for the resemblance of the cement when set to portland stone, a limestone from the Isle of Portland cement Manufacturing, Composition, Uses Britannica

.jpg)

what is the use of limestone limestone grinding mill hcm

Limestone bases on Calcium Carbonate (CaCO3) Lime and limestone is widely applied as construction material and industrial material Limestone can be processed into building stones or be baked into quick lime, and then add water to make slaked lime The lime slurry and lime putty can be used as coating material and adhesive2022年11月28日 Grinding is a type of finishing process in mechanical processing, with less machining and high precision It is widely used in the machinery manufacturing industry The heattreated and quenched carbon tool steel and carburized and quenched steel parts often have a large number of regularly arranged grinding cracks on the surface that is basically What is Grinding Process How It Works Different Types of Grinding2018年8月30日 Limestone powder is a byproduct of the limestone quarry, and it has been used in cementbased materials for many years In 1938, Bessey [6] first reported that CaCO 3 could react with cement to form calciumcarboaluminate The formation of calciumcarboaluminate was influenced by the amount and fineness of LS, but it had little effect on the compressive A review on use of limestone powder in cementbased materials 2019年11月11日 Limestone: A sedimentary rock and the most commonly used rock type for crushed stone in the United States One of the most versatile rocks for construction, limestone is able to be crushed easily, making it a primary rock used in readymix concrete, road construction, and railroads It is widely available in quarries across the countryThe Complete Guide to Crushed Stone and Gravel

Limestone Types, Properties, Composition, Formation, Uses

2023年10月21日 Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO3) in the form of mineral calcite or aragoniteIt is one of the most common and widely distributed rocks on Earth, with a wide range of uses in various industries and natural settings Limestone forms through the accumulation and compaction of marine organisms, primarily the Calcination is the process of heating a solid material in order to cause chemical separation of its components The diversity of chemical separation lends calcination to accomplishing a range of objectives, from the removal of chemically bound (crystalline) water, to the volatilization of contaminants from a source material, thermal decomposition, and even phase changesWhat is Calcination? FEECO International Inc2016年10月12日 The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is shown in Fig 25 and the actual layout in 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, Closed Circuit Grinding VS Open Circuit GrindingLimestone grinding, polishing and sealing services Palm Beach Marble Restoration and Tile top of page 5616356585 5618006235 "The Natural Stone Experts" WHO WE ARE WHAT WE DO SERVICES Marble Grinding,Polishing,Sealing; Granite Grinding,Polishing,Sealing; Natural Stone Restoration;Limestone Grinding , Polishing , Sealing Palm Beach Marble and

General Types of Limestone Finishes Stone Center

#3 Polished Limestone Finish for a Sense of HighEnd Refinement Achieving smooth polished limestone can require grinding with successively finer diamond grit pads or compounds Sometimes, oxalic acid or a crystallizing compound is Limestone specific weight = 27 g/cm3 SO3 Effects The clinker SO3 content has been recognized as having an impact on grindability High Chrome Cast Iron Grinding Balls Data supplied by ME International (1990) Data based on steel Everything you need to know about clinker/cement Limestone powder ground from natural limestone rock is also called Heavy Calcium Carbonate, or Ground Calcium Carbonate (GCC) (Kotaite in the United States) The grinding process of heavy calcium carbonate can be divided into coarse crushing, medium and fine crushing, powder grinding, grading and powder collectionWhat is the grinding of limestone? SageTips2024年11月7日 What is Limestone Flour? Limestone flour is a finely ground powder derived from limestone, a sedimentary rock primarily composed of calcium carbonate (CaCO3) It is created by crushing and grinding limestone into a powder with a particle size ranging from a few microns to several hundred micronsLimestone flour finds applications in various industries, What Is Limestone Flour And Why You Should Be Using It

.jpg)

Limestone crushing technology and equipment SBM Ultrafine

2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and 2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s energy budget Overall Energy Use of Fine Grinding in Mineral Processing2019年3月6日 Polishing Abrasives Three natural abrasives are commonly used for polishing and cleaning metal: enamel finishes, plastic, and tile Pumice is a stone, not a mineral, a volcanic product with a very fine grain Its hardest mineral is quartz, so 9 Different Minerals Used as Abrasives ThoughtCoLimestone Grinding Process The limestone grinding process mainly includes two types: Open circuit process: the process of material passing through the mill as finished product for the next step of operation; Closed circuit process: when the material discharged from grinding mill after one or several levels of separation, the fine particles are used as the finished product, and the Which Grinding Mill Is Suitable For Processing Limestone?

.jpg)

Limestone Ultrafine Mill Machine SBM Ultrafine Powder

2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcHOME > APPLICATIONS > MINERALS > LIMESTONE GRINDING Limestone Grinding The main application for limestone is as hydrated lime (calcium hydroxide) for mortar or plaster preparation On a smaller scale, lime is additionally used as a fertilizer, for wastewater treatment or as an additive in the food industry (for example as a neutralizing agent or acidityLIMESTONE GRINDING Bauermeister Size Reduction Equipment