200 mesh coal powder mill size 200 mesh coal powder mill size 200 mesh coal powder mill size

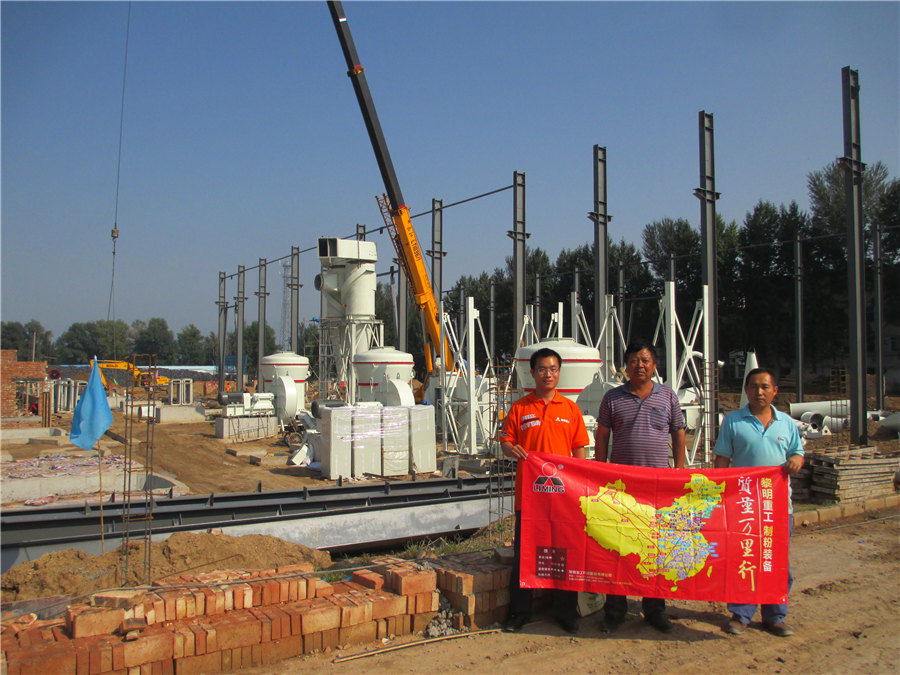

200 mesh coal powder mill/coal powder preparation production line

A 200 mesh coal powder mill, also known as a coal powder preparation production line, is an industrial system that grinds coal into fine powder with a particle size of 200 mesh or smaller The production of 200 mesh coal powder requires the selection of an appropriate vertical mill that meets the specific requirements of the application The choice of vertical mill should be based Choosing the right vertical mill for 200 mesh coal powder Limestone sand powder preparation in India Output size:2040, 4070, 70140 mesh fine graded sand and 200 mesh fine powderLM170Mcoal mill, 200mesh, D85, 30tphLIMING HEAVY A 200 mesh coal powder mill, also known as a coal powder preparation production line, is an industrial system that grinds coal into fine powder with a particle size of 200 mesh or smaller This powder is then used for various applications, such as combustion in power plants, steelmaking in blast furnaces, or as a component in cement and other industrial processes200 mesh coal powder mill/coal powder preparation production

.jpg)

Pulverized Coal Pipe Testing and Balancing Storm Technologies,

68% passing 200 mesh On average, the pipes were about 65% passing 200 mesh, short of our standard of 75% minimum passing 200 mesh on a mass weighted average basis The actual data are shown in Figure 6 Coal pipe F9 on pulverizer B was the only pipe that met the original plant fuel specification guarantee of2023年11月20日 HGM series ultrafine grinding mill is used by customers to grind pulverized coal, with an output of 5tph, and a finished powder fineness of 200 mesh It is +17200 mesh coal pulverizer grinding mill delivery siteTypically a mill will be controlled so that 70% of the coal powder it produces will pass through a 200 mesh, indicating a particle size of less than 75 microns Operation of coal mills is affected by both the moisture content and volatiles content of the coal and so will vary from coal to coal, therefore coal processing must normally be tuned to a particular type of coalCoal Mill an overview ScienceDirect TopicsDesired Coal Properties Feed Size Total Moisture Grindability (HGI) Abrasiveness Prod Fineness thru 200 Mesh Standard Screen Typical Air to Coal Ratio at 100% Mill Load Specific Power @ 100% Mill Load Typical Conditions CrusherDryer Mill PA Fan Total StartUp Time NoiseMill Only Approx Dimensions Mill Dia (D) Mill Length (L)A Comparison of Three Types of Coal Pulverizers Babcock Power

Coal Pulverizer – Power Plant Pall Corporation

Many coal pulverizer designs do not incorporate any filtration in their lube circuits The pulverizers that do not incorporate filtration use coarse filtration such as 40micron cleanable mesh or 200micron cleanable, stacked disk filters Such OEMsupplied filtration is often unable to keep up with the inherently high ingression ratecoal passing through 200 mesh (75 µm) is weighed and about 60% passing through 200 mesh For low volatile coals, the fineness passing between Standard ASTM Sieves of 200, 100 and 50 mesh size were used for the study 15 Mill Wear and Ash Content in Raw CoalA Study on 500 MW Coal Fired Boiler Unit’s Bowl Mill US Mesh Size (or US Sieve Size) is defined as the number of openings in one square inch of a screen Know More! Powder Compounds; Cream Compounds; Liquid Compounds; Recharge Additive; Parts Separating Systems; Which is smaller 100mesh or 200mesh? 200 meshes are smaller than 100 meshesMesh Size, Mesh to Micron Comparison chart Kramer Industries IncParticle Size / Mesh Conversion Chart Particle Size US Std Sieve Tensile Bolt Cloth Market Grade Inches Microns Std Sieve Opening In Inches Mesh TBC Opening Mesh MG Opening Inches Microns Inches Microns 01570 4000 5 01575 5 01590 4039 01320 3350 6 01319 6 01318 3348 01110 2820 7 01102 7 01080 2743 00937 []Particle Size / Mesh Conversion Chart Powder Technology

Pulverised Coal an overview ScienceDirect Topics

Predating the development of pulverized coal firing came the development of pulverizers used in the processing of minerals In preparing coal, or other materials, in sizes approximating talcum powder or finer (eg, coal produced at >70% 50 mesh), two fundamental methods apply: impaction and attrition [13]In addition to this, a comparison of different mesh sizes is shown for you WhatsApp:+86 sale@xxdahan ABOUT The D50 of our 400 mesh polishing powder is 20 microns Mesh size The division of the Screen mesh number and particle size comparison This Coal Powder Making Plant in Bhutan utilizes our CLRM1300 Raymond grinding mill to achieve 80400 mesh coal powder production with high capacity Equipment: HGM Series Ultrafine Grinding Mill; Feeding size: 200325 SBM Ultrafine Powder Technology Industrial 2011年8月1日 Adequate fineness for both western and eastern fuels (Powder River Basin or bituminous) is a minimum of 75% to 80% passing 200 mesh and zero to 01% remaining on a 50 mesh screen (Figure 10)Pulverizers 101: Part I POWER Magazine

vertical roller mill, vertical coal mill, vertical slag mill, superfine

Vertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill, vertical coal mill, 25TPH LM1700 Coal Grinding Mill Capacity: 2025T/H Output size: 200 mesh Calcium carbonate ultrafine vertical mill Capacity: 8T/H Output size: 3253000 meshFuel preparation for a pc boiler occurs in a mill, where coal is typically reduced to 70% through a 200mesh (74μm) screen Figure 2 shows a particlesize distribution from a bowlmill grinder typically used in power plants A typical utility specification for particle size distribution of the coal is that 70% of the mass should pass through a 200mesh screen, which is equivalent to 70% Pulverized Coal Boiler an overview ScienceDirect Topics2011年10月1日 Reducing the pulverized coal particle size (in 7212% passing 140 mesh (105 µm) and 5576% passing 200 mesh (74 µm) These are note the expanded range of mill operation Improved Coal Fineness Improves Performance, Reduces EmissionsMany mesh sizes were historically given in the number of holes per inch; Standard Mesh Tensile Bolting Cloth Mill Grade Market Grade US Tyler Mesh Opening Wire Mesh Opening Wire Mesh Opening Wire 560: 022: 5600: 35 200: 200: 230: 00029:Mesh (scale) Wikipedia

.jpg)

Coal Mill Manufacturers Powder Making Machine Price

Phrase one: raw material crushing Coal blocks will be crushed to 15mm50mm fineness by crusher Phrase two: drying and grinding 1Coal material with low moisture will be sent to the storage hopper by the elevator, and than the feeder will send the material to the main mill for grinding The hot air in the mill will dry the coal This will reduce drying cost 2For high Our vertical coal mill is designed to enhance the process, maximizing energy efficiency Home; Products compact equipment, low dust emission, and efficient combustion of coal powder Working Principle Fineness of pulverized coal (200 mesh pass %) 80: Coal moisture content (%) ≤1: Main motor Power (kW) 55: 110: 132: 180: 250250: 315 HighEfficiency Vertical Coal Mill Enhancing Coal PulverizationMESH and MICRON SIZES cinnamon (ground) 70 to 200 clay 01 to 2 coal dust 1 to 100 coffee (ground) 5 to 400 : concrete dust 3 to 100 copier dust (household) 005 to 100 dust mites 100 to 300 : eye of a needle 1230 flour (wheat milled) 25 to 212 gelatin powder 5 to 90 giardia cysts 8 to 14 : ginger (ground) 25 to 40 human hair MESH and MICRON SIZES Industrial SpecCustomer case—Vietnam clean coal powder production line With the emergence of vertical roller mills, there has been an upsurge of clean energy pulverized coal replacing traditional boiler coal in various places In July 2022, a Vietnamese Energysaving and Efficient Vertical Roller Mill Fote

Mesh and Micron Sizes Chart ISM Industrial Spec

A 100mesh screen has 100 openings per inch, and so on As the number indicating the mesh size increases, the size of the openings and thus the size of particles captured by the screen decreases Higher mesh numbers = smaller 2018年11月19日 However, The power consumption of the mill increases with the fineness of the powders There is always an optimal particle size for a boiler, and thus the coal powder size measurement is critical to keep the high efficiency of the boiler and favorable dynamic performance of millsDigital holographic sizer for coal powder size distribution China Powder 200 Mill wholesale Outlet Size: 80325 Mesh 1 / 6 Favorites Grinding Rock Gold Grinding Hammer Mill for Gold Crushing Plant Coal Stone Gold Ore Hammer Crusher Mill for Powder Making Output Size 13 mm US$ 850900 / Set 1 Set (MOQ)Powder 200 Mill MadeinChina2021年6月1日 This was mainly due to the sparseness of coarse coal powder, leading to a low probability of coal powder larger than 200 μm to be captured by the measurement system Although the obvious difference of PCF for mill D and B can be revealed with SAD directly, R 90 results and distribution curves were still with deviations comparing to the sieving methodOnline measurement of pulverized coal fineness on a 300

Grinding mill, MTW European Type Trapezium Mill, LM Vertical

LM Vertical Coal Mill MW Micro Powder Mill LUM Series Superfine Vertical Roller Grinding Mill SOLUTION Coal Powder Processing Slag Powder Making Limestone Ore Powder Power Plant Output size:200 mesh, D85 Capacity:45tph ABOUT USGet the perfect consistency for your nutraceutical products with our powder mesh sizes guide Learn about the importance of particle size We use cookies This website uses cookies in order to enhance the overall user experience Take a look at our Cookies Policy for more informationPowder Mesh Sizes Nutraceuticals Group25 grams/24 € 100 grams/43 € 500 grams/93 € 1000 grams/125 € 5 kg/248 € Please contact us for quotes on larger quantities !!! Activated Carbon Micron Powder Size: 200 MeshActivated Carbon Micron Powder, Size: 200 MeshDownload scientific diagram Particle size distribution of pulverized coal from publication: Effect of Particle Size on Flow Mode and Flow Characteristics of Pulverized Coal This paper reports Particle size distribution of pulverized coal

.jpg)

200 mesh coal powder mill/coal powder preparation production

A 200 mesh coal powder mill, also known as a coal powder preparation production line, is an industrial system that grinds coal into fine powder with a particle size of 200 mesh or smaller This powder is then used for various applications, such as combustion in power plants, steelmaking in blast furnaces, or as a component in cement and other industrial processes68% passing 200 mesh On average, the pipes were about 65% passing 200 mesh, short of our standard of 75% minimum passing 200 mesh on a mass weighted average basis The actual data are shown in Figure 6 Coal pipe F9 on pulverizer B was the only pipe that met the original plant fuel specification guarantee ofPulverized Coal Pipe Testing and Balancing Storm Technologies, 2023年11月20日 HGM series ultrafine grinding mill is used by customers to grind pulverized coal, with an output of 5tph, and a finished powder fineness of 200 mesh It is +17200 mesh coal pulverizer grinding mill delivery siteTypically a mill will be controlled so that 70% of the coal powder it produces will pass through a 200 mesh, indicating a particle size of less than 75 microns Operation of coal mills is affected by both the moisture content and volatiles content of the coal and so will vary from coal to coal, therefore coal processing must normally be tuned to a particular type of coalCoal Mill an overview ScienceDirect Topics

A Comparison of Three Types of Coal Pulverizers Babcock Power

Desired Coal Properties Feed Size Total Moisture Grindability (HGI) Abrasiveness Prod Fineness thru 200 Mesh Standard Screen Typical Air to Coal Ratio at 100% Mill Load Specific Power @ 100% Mill Load Typical Conditions CrusherDryer Mill PA Fan Total StartUp Time NoiseMill Only Approx Dimensions Mill Dia (D) Mill Length (L)Many coal pulverizer designs do not incorporate any filtration in their lube circuits The pulverizers that do not incorporate filtration use coarse filtration such as 40micron cleanable mesh or 200micron cleanable, stacked disk filters Such OEMsupplied filtration is often unable to keep up with the inherently high ingression rateCoal Pulverizer – Power Plant Pall Corporationcoal passing through 200 mesh (75 µm) is weighed and about 60% passing through 200 mesh For low volatile coals, the fineness passing between Standard ASTM Sieves of 200, 100 and 50 mesh size were used for the study 15 Mill Wear and Ash Content in Raw CoalA Study on 500 MW Coal Fired Boiler Unit’s Bowl Mill US Mesh Size (or US Sieve Size) is defined as the number of openings in one square inch of a screen Know More! Powder Compounds; Cream Compounds; Liquid Compounds; Recharge Additive; Parts Separating Systems; Which is smaller 100mesh or 200mesh? 200 meshes are smaller than 100 meshesMesh Size, Mesh to Micron Comparison chart Kramer Industries Inc

Particle Size / Mesh Conversion Chart Powder Technology

Particle Size / Mesh Conversion Chart Particle Size US Std Sieve Tensile Bolt Cloth Market Grade Inches Microns Std Sieve Opening In Inches Mesh TBC Opening Mesh MG Opening Inches Microns Inches Microns 01570 4000 5 01575 5 01590 4039 01320 3350 6 01319 6 01318 3348 01110 2820 7 01102 7 01080 2743 00937 []Predating the development of pulverized coal firing came the development of pulverizers used in the processing of minerals In preparing coal, or other materials, in sizes approximating talcum powder or finer (eg, coal produced at >70% 50 mesh), two fundamental methods apply: impaction and attrition [13]Pulverised Coal an overview ScienceDirect Topics