11kw ore grinding mill

Metso Vertimills

The Vertimill® is capable of handling feed sizes up to 6 mm and grinding to a product size of less than 20 microns, and has standard mill sizes ranging from 15HP (11kW) to 4500HP (3352 China Mine Impact Mill wholesale Select 2024 high quality Mine Impact Mill products in best price from certified Chinese Mine manufacturers, Steel Mill suppliers, wholesalers and factory Mine Impact Mill MadeinChina2021年6月22日 Metso Outotec will deliver multiple energyefficient Vertimill® VTM3000 stirred mills to Ferrexpo in Ukraine These vertical grinding mills will be the largest of their kind to be Metso Outotec to supply multiple Planet Positive Vertimill® Customized grinding mill parts including heads, shells, trunnions and liners, main bearings, gears and pinions, and more! Metallic, PolyMet™, Megaliner™, Rubber and Orebed™ mill liners for all mill types Whether old or new, we can Grinding mills for mining and minerals processing

.jpg)

Mining Processing Equipment Gold Ore Grinding Ball Mill High

Type: Ball Mill Motor Type: AC Motor Motor Power: 11kw Rotationl Speed: 351 R/Min Application: Mine Materials: All Kinds of MineralsChina Gold Grinding Mill Machine wholesale Select 2024 high quality Gold Grinding Mill Machine products in best price from certified Chinese Machine For Metal manufacturers, Machine Gold Grinding Mill Machine MadeinChinaWe have designed 300+ ore crushing and grinding projects for users in more than 40 countries and regions around the world Sand production line with an output of 800 tons per hour Ore Crushing, Sand Making, Grinding Machinery Bellian Mining China Gold Mill Machine wholesale Select 2024 high quality Gold Mill Machine products in best price from certified Chinese Machine Supplies manufacturers, Z Machine suppliers, Gold Mill Machine MadeinChina

7TOCS.jpg)

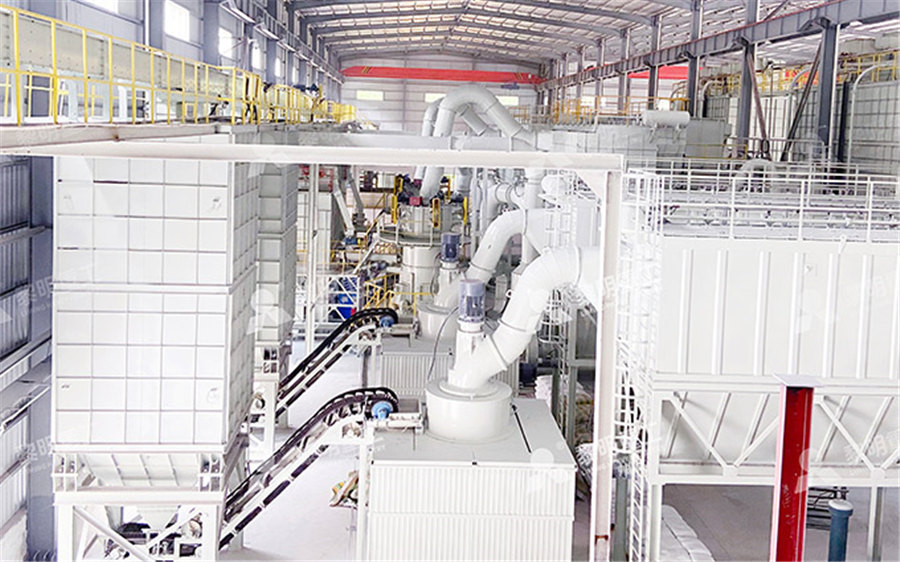

Reliable YGM big capacity 11kw raymond grinding mill manufacture

Reliable Ygm Big Capacity 11kw Raymond Grinding Mill Manufacture , Find Complete Details about Reliable Ygm Big Capacity 11kw Raymond Grinding Mill Manufacture,Reliable Ygm Big CITIC HIC has engineered and provided 6 AG mills of Ø122m×11m (28000kW gearless drive) and 6 overflow discharge ball mills of Ø79×136m (2×9000kW gear drive) for Sino Iron Project Grinding Mills Mineral Processing Equipment CITIC HIC1 All the main components of Ascend wet pan mill adopt famous Chinese or internation Brand With motor LUAN or Siemens brand, bearing ZWZ or Timken brand, Steel Shanghai Bao Steel, we are determined to ensure our customer Gold Ore Grinding Wet Pan Mill Machine Ascend2018年4月20日 The first two Grinding Efficiency Measurement examples are given to show how to calculate Wio and Wioc for single stage ball mills Figure 1 The first example is a comparison of two parallel mills from a daily operating report Mill How to Measure Grinding Efficiency 911Metallurgist

High Pressure Grinding Roll and Magnetic Separation for Energy

2024年5月31日 This paper presents an industrial verification test, adding a high pressure grinding roll and magnetic separation operation after the thirdstage fine crushing operation to reduce the particle size of ball mill feed and improve the processing capacity of grinding operation The optimal process parameters of high pressure grinding roll and magnetic separation were Mobile grinding mill for ore 2 Loesche has developed a mobile ore grinding plant, the OGPmobile, to demonstrate the benefits of Loesche grinding technology The OGPmobile offers potential customers and their experts a convincing way of becoming acquainted with Loesche grindingMobile grinding mill for ore Loesche2023年9月25日 A Canadian iron ore producer has awarded Metso an order for two powerful Vertimill 4500 grinding mills to be delivered in 3Q24 for in excess of 10 million euros The Vertimill stirred grinding mill technology is globally recognised as a leading solution for energyefficient grindingMetso to supply two grinding mills to iron ore producer in Canada2015年10月15日 Learn how to calculate the grinding capacity of your ball mill with 911 Metallurgist This guide provides essential formulas, insights, and tips to optimize your milling process and enhance production efficiencyCalculate Ball Mill Grinding Capacity 911Metallurgist

.jpg)

Ball Mill JXSC Mineral

High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits Ball milling is a grinding method that reduces the product into a controlled final grind and a uniform size, usually, Find your large mill easily amongst the 47 products from the leading brands (Fritsch GmbH, Liming, LONGI, ) on DirectIndustry, the industry specialist for your professional purchasesLarge mill, Large grinding mill All industrial manufacturersGrinding Mills: Ball Mill Rod Mill Design PartsCommon types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed herePhotographs of a glass ended laboratory ball mill show Grinding Mills 911MetallurgistDepending on the application, ore grinding can take place in a ball mill, SAG or AG mill, towe r mill, rod mill or HPGR Empowering the future of mining FLS is a leading, full flowsheet minerals processing supplier to the global mining industryFlexible, efficient grinding systems – FLS

.jpg)

Definition of Mill Diameter D, Mill Length L, and

Ore comminution practices have undergone significant changes since 1990 The overwhelming majority of mining operations have used and continue to use conventional technologies such as cone and jaw 2016年7月8日 UNTIL THE THIRD THEORY OF COMMINUTION of "Work Index" method of determining crushing and grinding mill size was introduced, there was no way of accurately 911 Metallurgist is a trusted resource for Equipment Sizing: Crusher or Grinding MillThe maximum feed size is 30 mm and the output size is 007406 mm wet pan mill is particularly suitable for grinding rock gold ore which c [ protected] +86; 0086 ; Home; Wet pan mill grinding machine Sinogomine Industrial Technology Co,LtdGold Mining Ball mills are widely used in ferrous and nonferrous metal mines, nonmetallic mines, cement, refractory materials, chemical industry, electric power, aluminum industry, building materials, and grinding operations in glass, ceramics, steel slag, fly ash and other industries Generally, the feed partied size of the ball mill is required to be less than 25mm, and more crushing and less Ball MillGrindingProductsHongji Mine Machinery

.jpg)

ORE HARDNESS PROPERTIES EVALUATION BASED ON

PROCESSING AND COMPLEX USAGE OF MINERAL RAW MATERIALS EURASIAN MINING 2022 No 2 pp 54–57 55 kWh/t; M ia is the Morrell index for coarse ore treatment in tumbling mills to the size P 80 > 750 μm , kWh/t; Mic is the M orrell index for ore treatment in cone and jaw crushers, kWh/t; Mih is the Morrell index for ore treatment in HPGR circuits, kWh/t; Mib is the 2022年1月1日 A pilotscale grinding technology of ceramic medium stirred mill was proposed in this study Based on the specific productivity and grinding efficiency, the appropriate grinding parameters were ascertained as follows: material ball ratio of 07, ceramic ball medium size ratio (10 mm: 15 mm: 20 mm = 3:2:5), stirring speed of 110 rpm, grinding concentration of 50%, Highefficiency and energyconservation grinding technology using 2018年4月8日 Referring to Table VI the L/D can be between 175 and 20 or even greater Referring to Table VII a 305 meter (10 foot) by 305 meter (10 foot) overflow ball mill with a 40 percent by mill volume ball charge, new liners and 50 mm (2″) balls draws 491 HP Using equation 5 there will be a loss of 055 Kw (074 Hp) per metric tonnes of ballsHow to Size Design a Regrind Ball Mill 911MetallurgistAs the main equipment in iron ore pelletizing plants, a damp mill is mainly used for the damp grinding of iron ore to provide materials for the pelletizing disc It can deal with iron ore with a water content of 813%, not only increasing the surface area of the ore particles but also making the ore fully mixed and ground to shorten the whole pelletizing processDamp Mill – Ball Grinding Machine Iron Ore Pelletizing Equipment

.jpg)

Energy conservation and consumption reduction in grinding

2023年11月1日 Grinding operation is the last preparation stage before beneficiation In this stage, the material undergoes the combined action of impact and grinding, so that the ore particle size is diminished and the qualified materials is provided for succeeding beneficiation operations [1, 2]Generally, the quality of the grinding product is also an important factor to determine the 2018年6月18日 Ore pretreatment methods for grinding: journey and prospects, Mineral Processing and Extractive Metallurgy Review, DOI: 101080/2018 To link to this article: https://doior g/10 Ore Pretreatment Methods for Grinding: Journey and ProspectsBall Mill, Raymond Mill, Ultrafine Mill manufacturer / supplier in China, offering MR Machinery High Quality Micro Powder Raymond Mill for Lron Ore Hot Sale, MR Machinery High Quality Micro Powder Raymond Mill for Lron Ore, Grinding Machine Grinding Mill MR Hot Sale Raymond Grinder Mill with CESGS Crushing Machine and so onBall Mill Manufacturer, Raymond Mill, Ultrafine Mill Supplier IVGrinding mill complete set VOur Services 24 hours online customer service, detailed and professional solution Skilled engineers, scene investigation, free customized program solution The purchase contract has a certain reputation Kaolin grinding mill Hengtu Machinery

}@~3SRDG`IA1KP_ICWAA.jpg)

Grinding Mills Mineral Processing Equipment CITIC

3 The maximum ball loading capacity of AG mill is calculated at 3% of effective mill volume, while the SAG mill with ball loading capacity at 15% of mill volume 4 The operating speed is usually 75% of critical speed of mill, the variable The wet pan mill is named by the diameter of roller Φ1300,Φ 1350,Φ 1400,Φ 1500,Φ 1600 is suitable for selection of iron ore, molybdenum ore ,lead ore ,zinc ore, antimony ore and so on Φ 850, Φ 900, Φ 1000,Φ 1100,Φ 1200 is suitable for selection of gold ore Above all, 1200a type is the most popular and widely use Advantages of wet Gold Ore Wet Pan Mill XKJ Groupoperation (1) Structure parameters of grinding mill, including its specifications, model, aspect ratio, ore discharging method, and liner form (2) Various working parameters of grinding mill, including fraction of critical speed for grinding mill, filling rate for grinding mill, grinding concentration,grindingcycleload,etc(3)AndgrindOre Grinding Methods and Process of Ore GrindingThe Tower mill is a vertical stirred grinding mill which can be used in both dry and wet grinding applications from the AMIRA P336 project “Methods and Benefits of Fine Grinding Ores” (progress reports 1993,1994) Summaries of the results are presented in Tables 2 to 4TOWER FINE MILLING EXPERIENCE AT MOUNT ISA MINES

Breaking down energy consumption in industrial grinding mills

2017年1月17日 Other process activities, such as spraying the ore with water for dust control or the fact that runofmine ore moisture is approximately 2%5% are not generally considered (Bleiwas, 2012a)Advantages of Gold Grinding Machine 1 The grinding wheels of the wet pan mill mix up the mineral and stone and produce ore pulp while pressing and rubbing the ores 2 The ores and water are evenly mixed, which can make the pulp density and other indexes stable 3Good Price Gold Grinding Machine Manufacturers Discount Gold Grinding 911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and prioritization of variables Metallurgists Mineral Processing Engineers 911MetallurgistWet Pan Mill also known as amalgamation grinding mill, gold grinder mill, which is a versatile ore grinding pan mill for wet materials It’s the best replacement for a mediumsmall capacity ball mill, owing to the excellent performance for wet crushing, small investment, and high output, widely used for separating gold, iron, molybdenum, lead, zinc, antimony, and so onWet Pan Mill JXSC Mineral

Gold Ore Grinding Wet Pan Mill Machine Ascend

1 All the main components of Ascend wet pan mill adopt famous Chinese or internation Brand With motor LUAN or Siemens brand, bearing ZWZ or Timken brand, Steel Shanghai Bao Steel, we are determined to ensure our customer 2018年4月20日 The first two Grinding Efficiency Measurement examples are given to show how to calculate Wio and Wioc for single stage ball mills Figure 1 The first example is a comparison of two parallel mills from a daily operating report Mill How to Measure Grinding Efficiency 911Metallurgist2024年5月31日 This paper presents an industrial verification test, adding a high pressure grinding roll and magnetic separation operation after the thirdstage fine crushing operation to reduce the particle size of ball mill feed and improve the processing capacity of grinding operation The optimal process parameters of high pressure grinding roll and magnetic separation were High Pressure Grinding Roll and Magnetic Separation for Energy Mobile grinding mill for ore 2 Loesche has developed a mobile ore grinding plant, the OGPmobile, to demonstrate the benefits of Loesche grinding technology The OGPmobile offers potential customers and their experts a convincing way of becoming acquainted with Loesche grindingMobile grinding mill for ore Loesche

.jpg)

Metso to supply two grinding mills to iron ore producer in Canada

2023年9月25日 A Canadian iron ore producer has awarded Metso an order for two powerful Vertimill 4500 grinding mills to be delivered in 3Q24 for in excess of 10 million euros The Vertimill stirred grinding mill technology is globally recognised as a leading solution for energyefficient grinding2015年10月15日 Learn how to calculate the grinding capacity of your ball mill with 911 Metallurgist This guide provides essential formulas, insights, and tips to optimize your milling process and enhance production efficiencyCalculate Ball Mill Grinding Capacity 911MetallurgistHigh energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits Ball milling is a grinding method that reduces the product into a controlled final grind and a uniform size, usually, Ball Mill JXSC MineralFind your large mill easily amongst the 47 products from the leading brands (Fritsch GmbH, Liming, LONGI, ) on DirectIndustry, the industry specialist for your professional purchasesLarge mill, Large grinding mill All industrial manufacturers

Grinding Mills 911Metallurgist

Grinding Mills: Ball Mill Rod Mill Design PartsCommon types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed herePhotographs of a glass ended laboratory ball mill show Depending on the application, ore grinding can take place in a ball mill, SAG or AG mill, towe r mill, rod mill or HPGR Empowering the future of mining FLS is a leading, full flowsheet minerals processing supplier to the global mining industryFlexible, efficient grinding systems – FLS