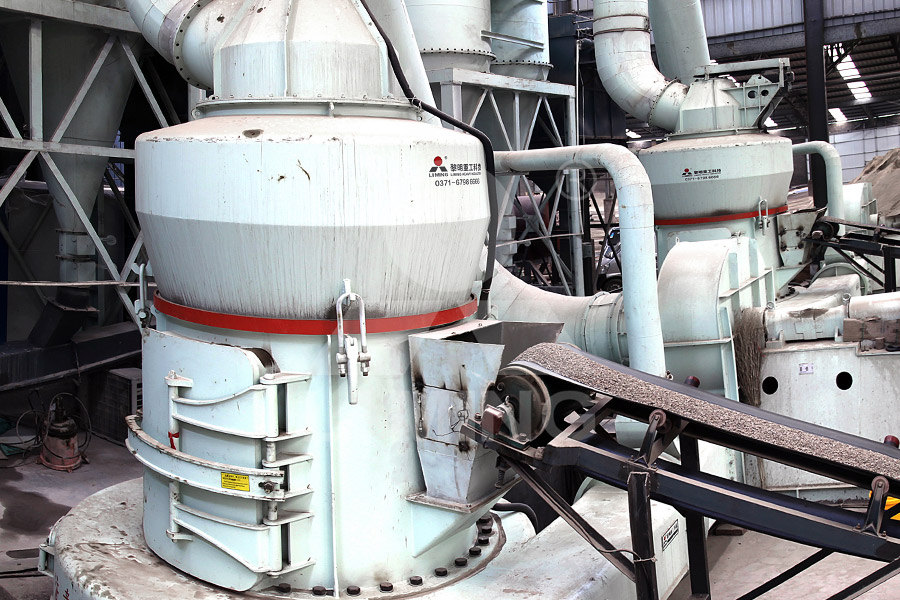

Nordberg hydraulic barite grinding mill

Nordberg MP 1000 and MP 800 Series Cone Crushers

Metso’s Nordberg MP Series cone crushers put that goal within easy reach MP stands for maximum power, and no similarlysized conventional crusher can match the performance of 2020年1月13日 15′ x 19′ Nordberg Ball Mill, 3000 HP Motor Drive, 4000 Volt, 180 RPM, Dual Fawick Clutch, Spare Pinion Equip yourself with the gold standard Components Inclusions 15′ X 19′ NORDBERG BALL MILL, 3000 HPThe world’s most popular modern cone crusher Nordberg® HP, is going through an evolution Efficiency is the key to meet aggregates and mining industries needs such as maximum Nordberg® HPe Series™ cone crushers Metsothe new Nordberg MP®1250 cone crusher Designed for increased capacity, reduced maintenance and increased reliability The MP1250 comes to market at a time when MP1250 Cone crusher Metso Automation PDF Catalogs

Cone crusher Nordberg® MP1250 Metso Corporation

The cone crusher availability is further enhanced by the hydraulic clearing system With a large vertical stroke, material can fall easily and this provides consistent stroke capabilities HP100™ cone crusher delivers less downtime and increased operator confidence Dualacting hydraulic tramprelease cylinders are used to let the crusher pass tramp iron and to provide a Nordberg® HP100™ cone crusher MetsoFind out all of the information about the Metso Corporation product: cone crusher Nordberg® HP900™ Contact a supplier or the parent company directly to get a quote or to find out a Cone crusher Nordberg® HP900™ Metso Corporation779 行 It is critical to choose the right parts and components to keep your crushing efficient with less downtime And this is what we aim to do, provide comprehensive support for your HP Spare Parts Suit Nordberg HP Cone Crusher GTEK MINING

.jpg)

Nordberg Manufacturing Company Wikipedia

By that time, Nordberg had been manufacturing mineral and rock crushing equipment, screens, grinding mills, and hoists, heavy duty diesel and gas turbines, railroad maintenance Hydraulic setting and console Motor and Drive Included Lubrication System Included Operating Frame Skid frame with access walkways and stairs * OptionalNORDBERG HP200 CONE CRUSHER Nelson Machinery2015年6月19日 We can calculate the steel charge volume of a ball or rod mill and express it as the % of the volume within the liners that is filled with grinding media 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Mill Steel Charge Volume CalculationMill Steel Charge Volume Calculation 911MetallurgistBarite Grinding Mill: The crushed barite is then sent to a grinding mill where it is pulverized into a fine powder Common types of grinding mills for barite include ball mill, R series raymond mills, YGM Raymond mills, MTW raymond mills, and ultrafine millsBarite Grinding Mill plant Baichy

Roll Crusher Clirik Barite grinding mill

The motor and the reducer are linked by a distancelimited hydraulic coupling to prevent power Roll crusher is suitable for a wide range of materials with compressive strength less than 250Mpa can be used for grinding, such as: Overview HGM series threering (fourring) micro grinder is a new type of ultrafine powder processing equipment, which is based on many years of mill production experience, absorbing Swedish advanced mechanical technology manufacturing technology, after more than 20 tests and improvementsHGM Threering Grinding Mill vanguardtecThe crushed barite small pieces are sent to the silo by elevator and then evenly and quantitatively sent to the grinding chamber of the mill by the vibrating feeder for grinding Stage 3: Grading The powder classifier classifies the ground materials, and the unqualified powder is classified by the classifier and returned to the main machine for regrindingBarite Aggregate Processing JXSC MachineThe Limestone powder ultrafine grinding mill was made by Clirik in 2016 This is a professional processing of limestone powder grinding machines The fineness of the finished product can be adjusted between 325 mesh and 3000 mesh Limestone Powder Ultrafine Grinding Mill has HGM80, HGM90, HGM100, HGM125,HGM1680 five modelsLimestone Powder Ultrafine Grinding Mill

Halliburton Barite Grinding Plant Construction Mouat, Inc

Mouat provided all design, procurement, construction and project management associated with the project including site prep, the design and installation of the process equipment, and the design and construction of the mill building and warehouse This barite grinding plant, the largest in North America, covers 66,000 square feet including the 2016年1月10日 On a 11’6” x 22’0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and discharge trunnions during startup of the mill System monitors including pressure switches and flow monitors are provided, along with temperature sensors Ball Mill Trunnion Bearing Lube System 911MetallurgistEfficient Grinding Mechanism: These mills utilize a robust and efficient grinding mechanism, typically a ball mill or a vertical roller mill The grinding media, such as steel balls or roller shells, rotate and crush the barite minerals, resulting in fine powdersPortable barite grinding mills: Versatile and efficient solutions911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and prioritization of variables Metallurgists Mineral Processing Engineers 911Metallurgist

Phosphate Mineral Powder Grinding Mill SBM

2021年11月3日 Phosphate Rock Processing Process Phosphate ore processing and production processes mainly include three processes: crushing, grinding, and beneficiation In the crushing process, the threestage closed The term "grinding", as used in this bulletin, refers to the size reduction of material by tumbling it, together with media, in a rotating horizontal cylinder The media may be steel balls, rods or rock pebbles Energy is consumed in keeping the Nordberg Grinding Mills Ball Rod and Pebble PDFCrushing equipment, grinding equipment, screening equipment and mineral processing equipmentProducts Clirik Barite grinding millBarite Grinding Mill 989 likes Shanghai Clirik Machinery Co,Ltd is the professional barite grinding mill manufacturer, devoted to the barite powder grinding process more than 10 yearsBarite Grinding Mill Facebook

Barite Grinding Production Line TAYMACHINERY

The barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, 2023年3月15日 LM Vertical Grinding Mill integrates crushing, drying, grinding, separating and transport The structure is simple while the layout is compact Its occupational area is about 50% of that of the ballmilling system The LM grinding mill can also be arranged outdoors, which greatly reduces the investment costLM Vertical Grinding Mill SBM Mill CrusherBarite Roller Mill Our Roller Mills are highly efficient in the grinding of Barite Designed to provide completely automatic operation, the Williams Roller Mill includes micrometer control of the finished product Learn more about how Roller Mills from Williams Patent Crusher can contribute to your barite grinding projectBarite Grinding Mills Barite Crushers Williams Crusher\n \n FHWA Hydraulic Toolbox \n Hydraulic Toolbox Version 43Note: Hydraulic Toolbox Version 43 was released internally to FHWA staff as a Beta version for testingVersion 44 implements Version 43 features as well as additional functionalityVersion 43 will not see an external releaseHydraulic Toolbox Version 42Build Date August 18,2014Ads Page nordberg hydraulic 4 1 4 manual

.jpg)

Designed to perform Select™ Horizontal Grinding Mills Metso

Grinding Mills Metso Outotec Select™ horizontal grinding mills redefine design and selection simplicity to provide classleading availability, reliability and productivity Select simplicity Metso Outotec Select™ horizontal grinding mills redefine selection through a simplified process Preengineered mill designs can be specified by aHigh grinding efficiency:High grinding efficiency and low energy consumption, saving 40% 50% power consumption compared to ball millSpecial structure design of grinding roller and grinding table, large diameter of grinding roller, large grinding area, hydraulic automatic pressure deviceLUM series superfine vertical roller grinding mill15' x 19' Nordberg Ball Mill, 3000 HP Motor Drive, 4000 Volt, 180 RPM, Dual Fawick Clutch, Spare Pinion Equip yourself with the gold standard 16045345313 SKU: L01211 Category: Grinding Mills Description Description 15′ x 15′ X 19′ NORDBERG BALL MILL, 3000 HP2016年6月3日 IsaMills, Tower Mill and Verti Mill Ultrafine Grinding in a Tower Mill The Tower Mill is a vertical “stirred” ball/pebble mill recently introduced in the Western Hemisphere This device offers a significant power savings on wet Tower Mill Operating Work Index 911Metallurgist

.jpg)

Raymond Mill TAYMACHINERY

The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a 2021年10月26日 HGM superfine powder grinding mill The newly designed grinding roller grinding ring grinding curve improves the grinding efficiency The production capacity is 40% higher than that of jet mills and stirring mills, and the energy consumption is only 30% of that of jet mills Equipped with multihead cage type powder concentratorGraphite Grinding Machine Powder Mill EquipmentThe hammer mill (also called HM series coarse powder mill) is one kind of new high efficient grinding machine This mill is mainly used for coarse powder and small size of sand producing The output size can reach more than 90% of 03mmHammer mill for sale, hydraulic hammer mill, hammer mill in 2021年10月13日 The fluorite fine powder grinding mill is an industrial ore milling equipment independently developed and produced by SBM The equipment includes two series of HGM ultra fine grinding mill and CLUM vertical roller mill, both of which can grind nonmetallic ore powder of 1503000 meshFluorite Fine Powder Grinding Mill SBM Ultrafine Powder

.jpg)

YGM160 High Pressure Grinding Mill Baichy Heavy Industry

YGM160 MILL QUOTATION; Name Model Specification Power (KW) Qty (set) High pressure suspension roller mill production line: YGM160: Milling system: Main Grinding Mill: 132: 1: Classifier: 15: Blower: 132: Cyclone powder collector / Bag type dust collector / Connected pipes / Crusher: Jaw crusher PEX250x750: 22: 1: Accessory equipment: Bucket Barite Ultra Fine Powder Mill is an ultrafine powder mill independently developed by us The grinding fineness can reach 3000 meshes and is suitable for more than 1000 minerals (Mohs hardness less than 7) It is widely used in the fields of chemicals, construction, coatings, plastics, etcHot Sale Barite Ultra Fine Powder Mill Shanghai Clirik Based on electrical energy consumption, the test made at 50 percent solids yielded the best results In this test 169 kilowatthours of energy were required per ton of feed, compared with 190 kilowatthours per ton of barite when grinding a barite ATTRITION GRINDING MILL 911Metallurgist2021年8月2日 HGM barite grinding mill: 745 micron(2002500 mesh); D97=5 micron YGM barite Raymond mill: 61333 micron(30325 mesh); D90=30 micron CLUM barite vertical roller mill: 205 micron(6003000 mesh); D50=2 micron D97=4 micron Barite Grinding MillsBarite Ore Grinding MillCLIRIK Machinery

.jpg)

Mill Steel Charge Volume Calculation 911Metallurgist

2015年6月19日 We can calculate the steel charge volume of a ball or rod mill and express it as the % of the volume within the liners that is filled with grinding media 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Mill Steel Charge Volume CalculationBarite Grinding Mill: The crushed barite is then sent to a grinding mill where it is pulverized into a fine powder Common types of grinding mills for barite include ball mill, R series raymond mills, YGM Raymond mills, MTW raymond mills, and ultrafine millsBarite Grinding Mill plant BaichyThe motor and the reducer are linked by a distancelimited hydraulic coupling to prevent power Roll crusher is suitable for a wide range of materials with compressive strength less than 250Mpa can be used for grinding, such as: Roll Crusher Clirik Barite grinding millOverview HGM series threering (fourring) micro grinder is a new type of ultrafine powder processing equipment, which is based on many years of mill production experience, absorbing Swedish advanced mechanical technology manufacturing technology, after more than 20 tests and improvementsHGM Threering Grinding Mill vanguardtec

Barite Aggregate Processing JXSC Machine

The crushed barite small pieces are sent to the silo by elevator and then evenly and quantitatively sent to the grinding chamber of the mill by the vibrating feeder for grinding Stage 3: Grading The powder classifier classifies the ground materials, and the unqualified powder is classified by the classifier and returned to the main machine for regrindingThe Limestone powder ultrafine grinding mill was made by Clirik in 2016 This is a professional processing of limestone powder grinding machines The fineness of the finished product can be adjusted between 325 mesh and 3000 mesh Limestone Powder Ultrafine Grinding Mill has HGM80, HGM90, HGM100, HGM125,HGM1680 five modelsLimestone Powder Ultrafine Grinding MillMouat provided all design, procurement, construction and project management associated with the project including site prep, the design and installation of the process equipment, and the design and construction of the mill building and warehouse This barite grinding plant, the largest in North America, covers 66,000 square feet including the Halliburton Barite Grinding Plant Construction Mouat, Inc2016年1月10日 On a 11’6” x 22’0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and discharge trunnions during startup of the mill System monitors including pressure switches and flow monitors are provided, along with temperature sensors Ball Mill Trunnion Bearing Lube System 911Metallurgist

Portable barite grinding mills: Versatile and efficient solutions

Efficient Grinding Mechanism: These mills utilize a robust and efficient grinding mechanism, typically a ball mill or a vertical roller mill The grinding media, such as steel balls or roller shells, rotate and crush the barite minerals, resulting in fine powders911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and prioritization of variables Metallurgists Mineral Processing Engineers 911Metallurgist