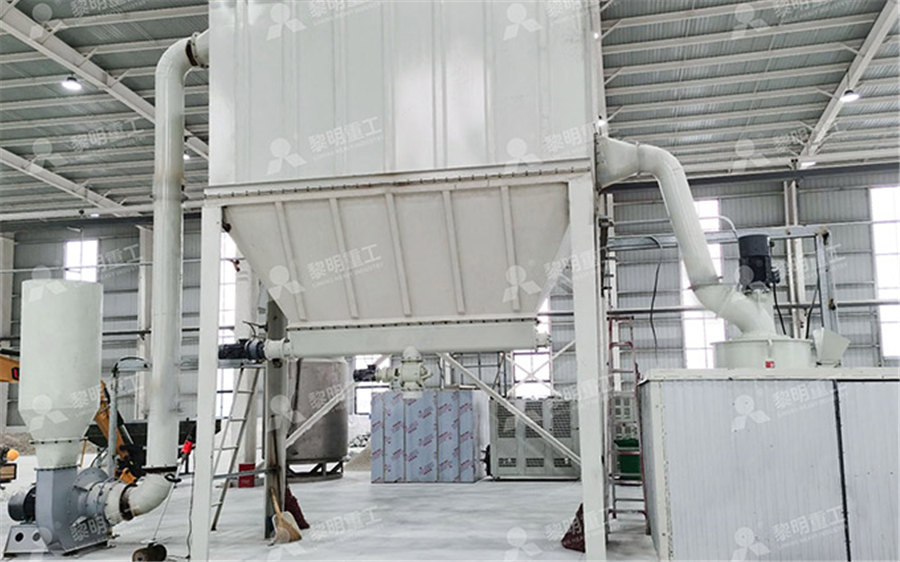

Vertical ore mill output 35T H

RECENT DEVELOPMENTS IN COARSE GRINDING USING VERTICAL

Vertical mills can operate at higher volumetric load (6085%v/v) than ball mills (3545%v/v), which then leads to higher productive throughput capacity (tph/m3) Fig 2 shows that that savings for Vertical roller mill (VRM) is an established technology in cement and slag grinding applications and Boliden and Gebr Pfeiffer have been collaborating on the application of this technology in Vertical Roller Mills used for the comminution of mineral ores2015年3月15日 Verticalrollermills (VRM) are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principle Results of extensive test Research of iron ore grinding in a verticalrollermill2014年10月20日 Results from sampling carried out on the Vertical Mill circuit demonstrated that the reduction ratio was approximately 20, considering a F80 of 604 m and a P80 of 30 m The Regrind of metallic ores with vertical mills: An overview of the

.jpg)

Operational parameters affecting the vertical roller mill

2017年4月1日 Pilot plant test results with various ores showed that low energy consumption feature of vertical roller mills is applicable to the ore industry Grinding test results for zinc ore 2019年4月16日 The paper demonstrates why the Loesche VerticalRollerMill (VRM) is a serious alternative to conventional grinding technologies and where the limitations of the system are (PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM2012年9月1日 Mills (VRM) installations and summarises the main benefits of the dry compressive Loesche grinding technologies in Airflow and OverflowMode Some of these Latest Installations And Developments Of Loesche Vertical Roller 2024年1月17日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or Parameters for the Grinding Process in Vertical Mills Using

FLS Tower Mill A vertical leap in fine grinding

The FLS Tower Mill (FTM) reduces energy and media consumption, while minimising water usage in secondary and tertiary wet grinding of minerals The tower mill is a robust, proven 2017年4月1日 Pilot plant test results with various ores showed that low energy consumption feature of vertical roller mills is applicable to the ore industry Grinding test results for zinc ore Operational parameters affecting the vertical roller mill Vertical stirred mill is a fine grinding equipment that covers advantages of low rotation speed, high reliability and long life cycle Since it is operated with wet grinding method, the mill requires no cooling system due to the low speed Vertical Stirred Mill Mineral Processing Equipment2015年3月15日 A test campaign with a pilot scale vertical mill was carried out with five different ore samples to elaborate a simple and robust methodology to scaleup vertical mills and perform simulationsVertical Agitated Media Mill scaleup and simulation

.jpg)

Vertical Stirred Ball Mills – ZJH minerals

21, Adopting The vertical spiral stirred mill to grinding the gold ore, and the same time leaching operation, can extract gold economically with low cost and high gold recovery 22, Applied for the second stage ore grinding, the fine grinding of 2014年11月1日 Vertical mill simulation applied to iron ores November 2014; Journal of Materials Research and a coarse sample of iron ore was tested in a pilot scale grinding circuit with a vertical millVertical mill simulation applied to iron ores ResearchGateUltrafine Vertical Mill Discharge fineness: 1503000 mesh Feed size: 20 mm Output: 120 T/HUltrafine Vertical MillLimestone ultrafine vertical mill is a high quality ores material powder grinding mill +17 [ protected] language >Shibang Industry Technology Group, Shanghai Ultrafine Powder Tech Co, Ltd Output: 120 T/H Product features: High output, low energy consumption, high intelligent control system, Limestone Ultrafine Vertical Mill

An investigation of performance characteristics and energetic

2020年8月12日 output temperature were obtained and coal powder samples as Vertical Coal Mill Ghalandari et al 2021), coal (Tontu 2020), iron ore (Reichert et al 2015), zinc ore (van Drunick 2023年2月28日 the barium carbonate ore vertical mill has the advantages of high efficiency, stability, and controllable crushing fineness, and is suitable for the crushing and processing of barium carbonate ore and other materials +17 [ protected] Barium carbonate ore vertical mill2015年3月10日 Within the scope of the study ore grinding performance of the vertical roller mill was investigated with mobile pilot plant In this context, chalcopyrite ore of a plant having rod and ball milling circuit was ground under different operating modes eg, air swept and overflow, and process conditions, then samples were collected around the systemCopper ore grinding in a mobile vertical roller mill pilot plant2022年6月24日 The vertical ore grinder is a mill for processing many nonmetallic ores The vertical ore grinder has high output, controllable powder fineness, environmental protection and energy saving So let's take a look at the advantages and characteristics of Guilin Hongcheng HLM vertical ore grinder hlm vertical ore grinder case site, welcome to leave a message or Advantages of vertical ore grinder

(PDF) Performance Evaluation of Vertical Roller Mill

2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement mined that is used as ore consumption but also increase outputHCM Machinery has whole production line for Raymond Mill, Vertical Roller Mill, Micro Powder Mill Welcome to Guilin HCM Machinery Official WebSite! mkt@hcmilling Home (current) New upgrade of traditional Raymond mill 135t/h DETAILS Manganese ore industry Carbon industry Refractory industry INQUIRY NEWS FOCUS Grinding Mills, Ultrafine Mills, Powder Processing Equipment2021年11月8日 Illite ore industrial grinding mill machine can grind illite into powder up to 3000 mesh, including ultrafine mill, vertical mill, Raymond mill, wet mill, etc +17 [ protected]Illite Ore Industrial Grinding Mill Machine SBM 2014年10月20日 Rio Paracatu regrind circuit Santos Júnior et al (2011) presented some data on the Paracatu Vertical Mill circuit process, as well as its comparison to the plant's conventional ball millRegrind of metallic ores with vertical mills: An overview of the

LM Vertical Roller Mill, Vertical Mill Manufacturer

Vertical roller mill is used to pulverize materials like limestone, coal, feldspar, calcite, fluorite, talc, iron ore, copper ore, phosphate rock, graphite, quartz, slag, etc Material can be pulverized into 80400Mesh with this millFind out all of the information about the Dec Group product: jet mill MC DecJet® 200 Output Min: 1 kg/h (2 lb/h) Max: 40 kg/h (88 lb/h) Description vertical for ore micronization jet mill MC DecJet® 50 vertical micronization jet mill MC DecJet® 100Jet mill MC DecJet® 200 Dec Group vertical / for ore / Figure 3: Relationship between feed size (F80) and Bond efficiency factor (Huang et al, 2019) VERTICAL POWER MILL (VPM) – PRINCIPLE OF OPERATION Declining ore grades and more complex ore bodies, as well as waste management and global net zero initiatives, lead to a clear trend for high tonnage yet energy efficient grindingRECENT DEVELOPMENTS IN COARSE GRINDING USING VERTICAL The vertical roller mill integrates crushing, drying, grinding, and conveying +17 [ protected] Output: 120 T/H Product features: high production and efficiency, It can produce a variety of different highquality ore powders The Dolomite Ultrafine Vertical Roller Mill

Vertical Roller Mill (VRM)SinomaLiyang Heavy Machinery Co, Ltd

Vertical Roller Mill (VRM) we have developed a variety of VRMs for handling materials such as manganese ore, bauxite, heavy calcium carbonate, leadzinc tailings, iron tailings and tungsten tailings stable performance, high output, and low construction investment2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Copper ore grinding in a mobile vertical roller mill pilot plantThese lowgrade ores with complex compositions have a large number of constituent minerals and significant differences in their physical and chemical properties, which seriously affects the VERTICAL ROLLER MILL TECHNICAL DETAILSVertical cement mill has high grinding efficiency and low power consumption (20% – 30% less than ball mill) The granularity of the feeding material is larger(VRM cement mill is 80mm120mm, cement ball mill is less than or Vertical Cement Mill Cement Clinker Grinding

.jpg)

vertical roller mill, vertical slag mill, vertical coal mill, Superfine

vertical roller mill, widely used in minerals grinding process of metallurgy, building materials, slag and nonmetallic ore Divided into: vertical coal mill, vertical slag mill, Output size: LM353N: Water slag, gypsum: 5560T/H: 400 SSa: 25TPH LM1700 Vertical Coal Mill Equipment:Vertical Roller Mill Brand SINOMALY Product origin Liyang, Jiangsu, China Delivery time 7 months Supply capacity 10800tph 1 The vertical roller mill is a highefficiency and energysaving grinding equipment widely used in preparing raw materials and clinker, grinding slag, ore, industrial silicon, calcium carbide slag and coal gangue in the cement industry and in coal Supply Vertical Roller Mill Customized Factory SINOMALY 2014年10月1日 Request PDF Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot PlantSBM high quality calcium carbonate ultrafine powder vertical mill is widely used in many fields +17 [ protected] Output: 120 T/H Product features: 1 copper and other minerals These powders are then used in various applications such as Calcium Carbonate Ultrafine Powder Vertical Mill

LM Series Vertical Mill LIMING(Shanghai)

LM series vertical mill is one advanced mill adopted top technology of domestic and abroad, Ore Mill; Model LM 192K LM 222K LM 242K LM 272K LM 273K LM 312K LM 313K LM 342K LM 343K LM 373K LM Best input moisture <4%: Input material moisture (drying required) <15%: Output fineness:LM series vertical mill is an efficient grinding equipment which combines electricity, chemical,ceramics, glass, nonmetal ores,etc It can also grind water slag, ore slag, stove slag, coal slag, cement, quarts,etc Tel: 0086371 Output Fineness: Final Product Moisture: Input Size (mm) Best Input Moisture: Input MoistureLM Vertical MillGreat Wall CompanyRequest PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermillVertical stirred mill is a fine grinding equipment that covers advantages of low rotation speed, high reliability and long life cycle Since it is operated with wet grinding method, the mill requires no cooling system due to the low speed Vertical Stirred Mill Mineral Processing Equipment

.jpg)

Vertical Agitated Media Mill scaleup and simulation

2015年3月15日 A test campaign with a pilot scale vertical mill was carried out with five different ore samples to elaborate a simple and robust methodology to scaleup vertical mills and perform simulations21, Adopting The vertical spiral stirred mill to grinding the gold ore, and the same time leaching operation, can extract gold economically with low cost and high gold recovery 22, Applied for the second stage ore grinding, the fine grinding of Vertical Stirred Ball Mills – ZJH minerals2014年11月1日 Vertical mill simulation applied to iron ores November 2014; Journal of Materials Research and a coarse sample of iron ore was tested in a pilot scale grinding circuit with a vertical millVertical mill simulation applied to iron ores ResearchGateUltrafine Vertical Mill Discharge fineness: 1503000 mesh Feed size: 20 mm Output: 120 T/HUltrafine Vertical Mill

.jpg)

Limestone Ultrafine Vertical Mill

Limestone ultrafine vertical mill is a high quality ores material powder grinding mill +17 [ protected] language >Shibang Industry Technology Group, Shanghai Ultrafine Powder Tech Co, Ltd Output: 120 T/H Product features: High output, low energy consumption, high intelligent control system, 2020年8月12日 output temperature were obtained and coal powder samples as Vertical Coal Mill Ghalandari et al 2021), coal (Tontu 2020), iron ore (Reichert et al 2015), zinc ore (van Drunick An investigation of performance characteristics and energetic 2023年2月28日 the barium carbonate ore vertical mill has the advantages of high efficiency, stability, and controllable crushing fineness, and is suitable for the crushing and processing of barium carbonate ore and other materials +17 [ protected] Barium carbonate ore vertical mill2015年3月10日 Within the scope of the study ore grinding performance of the vertical roller mill was investigated with mobile pilot plant In this context, chalcopyrite ore of a plant having rod and ball milling circuit was ground under different operating modes eg, air swept and overflow, and process conditions, then samples were collected around the systemCopper ore grinding in a mobile vertical roller mill pilot plant

.jpg)

Advantages of vertical ore grinder

2022年6月24日 The vertical ore grinder is a mill for processing many nonmetallic ores The vertical ore grinder has high output, controllable powder fineness, environmental protection and energy saving So let's take a look at the advantages and characteristics of Guilin Hongcheng HLM vertical ore grinder hlm vertical ore grinder case site, welcome to leave a message or