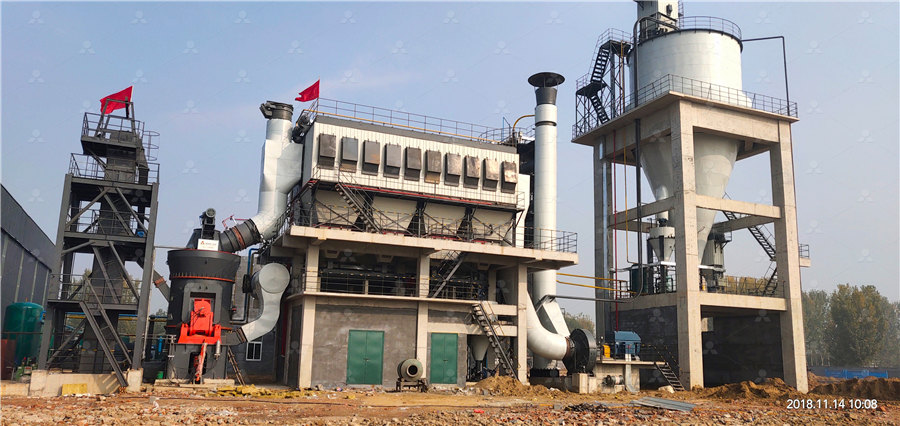

Mining highefficiency energysaving mill

.jpg)

Helping to reduce mining industry carbon emissions: A stepby

2022年3月30日 High Pressure Grinding Rolls (HPGR) circuits have the potential to reduce the Mining Industry’s CO 2 emissions by up to 345 megatonnes/year, or 435% when compared 2021年4月19日 Regarding this background, this article describes the feasibility of mine to mill optimization from three aspects: (1) different energy efficiencies between drillingblasting and(PDF) Feasibility and necessity of mine to mill Methods to increase capacity, decrease energy consumption and prolong lifter and liner life are needed The variable interaction involved in slurry transportation should first be understood ITP Mining: Improving Energy Efficiency in SAG Mills2016年3月20日 Energy efficiency improvement programs in mining are widespread and target all aspects of mining These include capturing waste heat, managing electricity demand, mine Energy efficiency in mining: a review with emphasis on the role of

.jpg)

EnergyEfficient Comminution: Best Practices and Future Springer

2017年11月2日 In openpit mines, improvements in mill performance have been achieved by increasing the energy intensity of blast patterns, thereby reducing the size of feed to the mill A 2024年7月9日 Helping to reduce mining industry carbon emissions: A stepbystep guide to sizing and selection of energy efficient high pressure grinding rolls circuitsEnergy Efficiency CEEC (Coalition for Eco Efficient Comminution)2024年11月26日 A MinetoMill optimization strategy is critical for improving mining operations in several key areas By integrating cuttingedge technologies mining operations can unlock the howtoleverageaiinminingmineralsmetals2023年10月20日 By implementing minetomill optimization using the realtime Xray fluorescence (XRF) sensorbased ore sorting technology, the overall grade of mined ore can Improving Sustainability in Mining Operations Through the

Plant Automation for EnergyEfficient Mineral Processing

2017年11月2日 Mineral processing is one of the most energyintensive stages of the overall mining beneficiation chain, with an increasing share of the industry footprint This chapter energy in mining, small improvements in comminution technologies can lead to relatively large savings in both energy consumption and GHG emissions For example, a 5% incremental improvement in energy efficiency across comminution could result in greenhouse gas emissions reductions of more than 30M tonnes of CO 2e2MINING ENERGY CONSUMPTION 年1月17日 Grinding mills are infamous for their extremely low energy efficiency It is generally accepted that the energy required to produce new mineral surfaces is less than 1% of the electricity consumed Breaking down energy consumption in industrial 2018年10月1日 SLW: Another example of improving wear life for increased mill performance, including reduced specific energy consumption, is given in a paper by Sever Ciutina (Metso MLS) and RJSoriano (Senior Improving energy efficiency in comminution

.jpg)

Grinding down energy consumption in comminution MINING

2019年6月21日 The grinding action (attrition), vertical arrangement, and finer media size distribution means that Vertimills offer an average energy saving of 3050% compared with ball mills, while SMDs offer Energy saving ball mill Product description Commonly used equipment in the beneficiation production line includes energysaving ball mills,highefficiency energysaving cone ball mills, magnetic separators, flotation machines, etc Energysaving ball mill is the key equipment for crushing materials after being crushedEnergy saving ball mill Rhyther Mining2021年3月23日 New ball mill drive system with the prototype energysaving SMH motor [37] Startup of the LSPMSM SMH1732T motor with a filled ball mill after two hours of downtime: (a) active power, (b Energy Efficiency Analysis of Copper Ore Ball Mill Drive SystemsA highlevel study into mining energy use for the key mineral commodities of the future consuming close to 40% of total energy contains a single piece of equipment—the grinding mill—that is typically the largest single a 5% incremental improvement in energy efficiency across comminution could result in greenhouse gas emissions MINING ENERGY CONSUMPTION 2021 CEEC (Coalition for Eco

Ball Mills Manufacturer JXSC

The energysaving ball mill reduces power consumption while maintaining high efficiency, ideal for costeffective grinding in mining and industrial applications Grate Ball Mill The grate ball mill allows efficient discharge of materials, reducing overgrinding, making it ideal for coarse materials in mining and mineral processingDOI: 101016/jpowtec202110056 Corpus ID: ; Highefficiency and energyconservation grinding technology using a special ceramicmedium stirred mill: A pilotscale studyHighefficiency and energyconservation grinding technology 2021年11月1日 A pilotscale grinding technology of ceramic medium stirred mill was proposed in this study Based on the specific productivity and grinding efficiency, the appropriate grinding parameters were Highefficiency and energyconservation grinding technology 2022年3月30日 In neither application was the HPGR principally chosen for its energy efficiency and almost a further 20 years had to pass before the Mining Industry saw the first full scale HPGRBall mill installation at Cerro Verde (Vanderbeek et al, 2006), which was chosen due to the 15% energy saving it provided compared to the SAGBall mill alternativeHelping to reduce mining industry carbon emissions: A stepby

.jpg)

Energy efficiency for the mining industry Doing more with less

520% savings in energy and utility usage Motor / Drive system assessments and solutions Motors account for around 29% of onsite mining energy loss es ABB has a simple, methodical appraisal process to identify and realize energy savings opportunities through the proper sizing and maintenance of motors, premium efficiency motors,2024年6月27日 Gold ball mills offer costeffective solutions for grinding materials due to their low operating costs and high efficiency Investing in these machines reduces labor expenses while increasing material throughput, ultimately leading to improved profitability for mining operations Environmental Considerations and Mitigation Measures5 Tips to Improve Efficiency Using a Gold Ball Mill Miningpedia2022年1月1日 A pilotscale grinding technology of ceramic medium stirred mill was proposed in this study Based on the specific productivity and grinding efficiency, the appropriate grinding parameters were ascertained as follows: material ball ratio of 07, ceramic ball medium size ratio (10 mm: 15 mm: 20 mm = 3:2:5), stirring speed of 110 rpm, grinding concentration of 50%, Highefficiency and energyconservation grinding technology using 2023年1月1日 Download Citation Ball mill energy efficiency optimization techniques: A review Ball mills are essential machinery in the mining industry, thermal powerproducing companies, and cement Ball mill energy efficiency optimization techniques: A review

Energy efficiency in mining: a review with emphasis on the role

2016年3月20日 Energy efficiency in mining: (Levesque et al, 2014, Kecojevic et al, 2014) Such high energy intensive operations are not acceptable from a sustainability or cost standpoint, grinding and diesel equipment used in material handling were identified as the operations presenting the greatest energy savings potential (DOE, By adjusting the gradation of the steel balls, the size and amount of the discharge fineness can be changed The highefficiency and energysaving ball mills produced by our company are all supported by rolling bearings instead of bearing bushes and sliding bearings Compared with the coaxial pad sliding beaning supported energy saving is 2030%Ball MillGrinding EquipmentHongji Mine Machinery2010年1月1日 SAG specifi c energy of mines A, B and C relative to the published Newmont Mining plant database (Veillette and Parker, 2005) Efficiency, economics, energy and emissionsemerging criteria for The ball mill is an important grinding equipment in the industrial field, its main function is to grind large materials into fine particles by rolling or rubbing, which improves the efficiency of the subsequent processingBall mills are mainly used in cement production, silicate products, new building materials, refractory materials, chemical fertilizers, ferrous and nonferrous metal Energy Saving High Energy Ball Mills For Sale JXSC Machine

.jpg)

High pressure grinding rolls provide energy savings

2019年8月15日 High pressure grinding rolls provide mine owners with proven energy savings, grappling with increasing economic and ecological pressures to reduce their energy consumption For full functionality of this site it is necessary to enable JavaScriptEnergysaving Ball Mills: Investing in energysaving ball mill designs, such as vertical roller mills or jet mills, can provide significant energy savings compared to traditional ball mills Noise control and energysaving retrofitting are essential for improving the operational efficiency and environmental impact of ball millsNoise control and energysaving retrofitting of ball mills[Introduction] : An overflow ball mill with rolling bearings, high efficiency and energy saving [Capacity] : Up to 160t/h [Improvement] : Rolling bearings replace slipping bearings to reduce friction; easy to start; saving 2030% of energyCylinder EnergySaving Overflow Ball Mill Xinhai The round mill has the features of high efficiency and energy saving, high output, no loss of mineral powder, and full utilization of effective resources Structure Structure of Wet Pan Mill Wet Pan Mill Online Consultant Henan Forui Gold Round Mill/Wet Pan Mill Henan Forui

efficiency energy limestone quarries grinding Mining Quarry

2013年4月4日 A full set of energysaving grinding machine wet processing equipment 5 tons limestone quarries for aggregates production high efficiency ball mill (hebm) limestone grinding energy – kefid Hotsale Products: stone 2023年7月4日 It has the advantages of simple structure, stable operation, high efficiency, energy saving, and convenient maintenance It is widely applied in the crushing and grinding of metal and nonmetallic ores The product particle size can be less than 5 mm or finerRoller Mill SpringerLinkPDF On Jun 20, 2018, VI Golik and others published Energy Saving in Mining Production energy efficiency and the which can be efficiently leached out upon the assistance of highenergy (PDF) Energy Saving in Mining Production ResearchGate2024年8月23日 Here are some main features of the energysaving ball mill: Energysaving Ball Mill Features High efficiency and energy saving: By improving the structural design of the ball mill and selecting highquality materials, the energysaving ball mill can improve working efficiency while reducing energy consumption, and the energysaving effect can Energysaving Ball Mill VS Cement Ball Mill JXSC Mineral

.jpg)

Fact sheet Energy use in the steel industry

energy management systems ensure efficient use and recovery of energy throughout the steelmaking process for use within the steelworks boundary or exported from the site Improvements in energy efficiency have led to reductions of about 60% in energy required to produce a tonne of crude steel since 1960, as demonstrated in Figure 1 Realisation of energy saving potential at mining enterprises on the basis of optimal intramill filling Svetlana Starykh1*, Irina Minakova1, Natalia Derkach1, Maksim Taranenko2, and Denis Ermolaev2 1Federal State Budgetary Educational Institution of Higher Education «SouthWest State University», 94, 50 let Oktyabrya st, Kursk, , RussiaRealisation of energy saving potential at mining enterprises on Wet ball mill is a kind of energysaving industrial grinding mill which adopts rolling bearings and has high efficiency Wet grid mining ball mill processing capacity can reach 160 tons per hour It usually grinds coarser oresWet Ball Mill Mining, Industrial/Horizontal Ball Mill, Wet Grid Ball energy in mining, small improvements in comminution technologies can lead to relatively large savings in both energy consumption and GHG emissions For example, a 5% incremental improvement in energy efficiency across comminution could result in greenhouse gas emissions reductions of more than 30M tonnes of CO 2e2MINING ENERGY CONSUMPTION 2021

Breaking down energy consumption in industrial

2017年1月17日 Grinding mills are infamous for their extremely low energy efficiency It is generally accepted that the energy required to produce new mineral surfaces is less than 1% of the electricity consumed 2018年10月1日 SLW: Another example of improving wear life for increased mill performance, including reduced specific energy consumption, is given in a paper by Sever Ciutina (Metso MLS) and RJSoriano (Senior Improving energy efficiency in comminution2019年6月21日 The grinding action (attrition), vertical arrangement, and finer media size distribution means that Vertimills offer an average energy saving of 3050% compared with ball mills, while SMDs offer Grinding down energy consumption in comminution MININGEnergy saving ball mill Product description Commonly used equipment in the beneficiation production line includes energysaving ball mills,highefficiency energysaving cone ball mills, magnetic separators, flotation machines, etc Energysaving ball mill is the key equipment for crushing materials after being crushedEnergy saving ball mill Rhyther Mining

Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems

2021年3月23日 New ball mill drive system with the prototype energysaving SMH motor [37] Startup of the LSPMSM SMH1732T motor with a filled ball mill after two hours of downtime: (a) active power, (b A highlevel study into mining energy use for the key mineral commodities of the future consuming close to 40% of total energy contains a single piece of equipment—the grinding mill—that is typically the largest single a 5% incremental improvement in energy efficiency across comminution could result in greenhouse gas emissions MINING ENERGY CONSUMPTION 2021 CEEC (Coalition for Eco The energysaving ball mill reduces power consumption while maintaining high efficiency, ideal for costeffective grinding in mining and industrial applications Grate Ball Mill The grate ball mill allows efficient discharge of materials, reducing overgrinding, making it ideal for coarse materials in mining and mineral processingBall Mills Manufacturer JXSCDOI: 101016/jpowtec202110056 Corpus ID: ; Highefficiency and energyconservation grinding technology using a special ceramicmedium stirred mill: A pilotscale studyHighefficiency and energyconservation grinding technology

Highefficiency and energyconservation grinding technology

2021年11月1日 A pilotscale grinding technology of ceramic medium stirred mill was proposed in this study Based on the specific productivity and grinding efficiency, the appropriate grinding parameters were