Tail limestone dry separation

.jpg)

Expanding Applications in Dry Triboelectric Separation of Minerals

the separating particles and continual triboelectric charging by carbon‐mineral collisions provides for a multistage separation and results in excellent purity and recovery in a single‐pass unit The high belt speed also enables very high throughputs, up to 40 tonnes per hour on a single 2020年6月16日 Density segregation on dry separators can be achieved in two ways: (1) using minimum fluidization velocity differences and (2) using terminal velocity difference between Study of Dry Mineral Separation Behavior in Dry Density Separators2023年10月1日 Dry mineral processing methods are classified broadly into size reduction (comminution) and separation Dry separation uses forces generated by gravity, centrifuges, A comprehensive review and recent advances in dry mineral 2024年5月27日 The paint shops of two plants belonging to a wellknown German automotive group will be completely converted to dry separation with limestone powder in the near future Limestone Powder Saves 17 Million Liters of Water

Recent advances in process and materials for dry desulfurization of

Limestone and lime are predominantly utilized in the desulfurization process within circulating fluidized bed boilers at the forefront of furnaces Under hightemperature conditions, limestone 2022年10月1日 The thermal treatment of limestone (mainly CaCO 3) to produce lime (CaO) is a major contributor to CO 2 emissions and the literature on decarbonising the lime industry is Decarbonising the lime industry: Stateoftheart ScienceDirectdry stack tailings tend to exit the filtration unit near the maximum dry density (based on the Standard Proctor density) and slightly wet of optimum At these conditions, the tailings can haveDry Stack Tailings – Design Considerations IQPC Corporate2022年7月15日 In the last 20 years many mining projects around the world have applied a tailings deposition technology named “dry stacking of filtered tailings” at tailings storage Practical Experience of Filtered Tailings Technology in Chile MDPI

.jpg)

Determining Water Transport Kinetics in Limestone by Dual

With this aim in mind, here we show how cavity ringdown spectroscopy (CRDS) can be used to monitor both the moisture content and dynamics in small samples of limestone (ca ≤5 g), a 2022年1月20日 The separation performance of varied particle sizes indicated poor separation efficiency Particle distribution rates in clean coal increase with particle size, and the presence ofGravity separation by falcon concentrator an over from 4098 to 4979 in flaggy limestone and silica can be reduced from 3766 to 1362 in variegated limestone, therefore, the flaggy limestone can be used directly after benefication in cement manufacturing and variegated limestone can be used by proper blending with massive limestone Fig1 Graphical representation of the result of depressantDepressants for Calcite and Silica Flotation Studies of Limestone2020年6月30日 In the present study, gravity separation of speiss (674 g/㎤) and limestone (27 g/㎤) was investigated using a vibrating 1 mmzirconia ball (56 g/㎤) bed as a medium(PDF) The Gravity Separation of Speiss and Limestone Granules

.jpg)

Air Separation Unit an overview ScienceDirect Topics

21st European Symposium on Computer Aided Process Engineering Chao Fu, Truls Gundersen, in Computer Aided Chemical Engineering, 2011 6 Conclusion The air separation unit is the most important factor for the power penalties related to CO 2 capture from fossil fuel based power plants using oxycombustion In a conventional cryogenic air separation unit, the actual power 2021年9月9日 Why Choose ST Equipment Technology For Your Dry Minerals Separation Equipment? Located in Needham, Massachusetts, we’ve created a triboelectric separator that separates minerals according to their tribocharging susceptibility, ie, how particles respond when electrically charged by contact in an electric fieldDifferent types of separation methods for minerals2023年6月17日 Introduction Ferruginous manganese ore deposits, typically with 15–35 wt% Mn, or with low Mn:Fe ratios (eg Mn/Fe of ∼05–2), are problematic for manganese alloy makers and thus manganese ore miners (Kivinen et al Citation 2010)Olsen et al (Citation 2007) state that the production of standard ferromanganese alloy with 78% Mn requires raw materials with Full article: Demonstration of dry magnetic separation to upgrade 2023年4月28日 The EcoDryScrubber separates paint overspray using finely ground limestone powder and highly efficient HEPA12 filters in just one filter stage Watch: EcoDryScrubber – paint booth efficiency through dry separation By Dürr, sponsor partner T09:04:00+01:00Watch: EcoDryScrubber – paint booth efficiency through dry separation

%3C1PGHL[2}HK_]YT.jpg)

6 Magnetic Separation Springer

6 Magnetic Separation Drytype magnetic drum separator Source: AL Mular and RB Bhappu (Eds), Mineral Processing Plant Design, Society of Mining Engineers AIME, New York, 1980, p 475 Reproduced with the permission of the Society for Mining, Metallurgy, and Exploration 2020年6月16日 Mineral dry density separation behavior (mineral beneficiation) involves segregation of high density particles and low density particles in the feed, ie, in nutshell, mineral dry density beneficiation is density segregation in physics terms In dry beneficiation, this density segregation is achieved using air as fluidized medium Density segregation on dry separators Study of Dry Mineral Separation Behavior in Dry Density SeparatorsDry separation is fully automatic and almost 100% effective, with maximum energy efficiency Effective principle The Eco DryScrubber removes paint overspray in a single filter stage using finely powdered limestone and highly efficient HEPA12 filtersEcoDryScrubber – Efficient dry separation Dürr durr2022年9月9日 Dry permanent magnetic separators have been widely used in the mineral and coal processing industries due to their simple operation and high separation efficiency These tools not only discard some amount of bulk Dry Permanent Magnetic Separator: Present Status

.jpg)

EcoDryScrubber: fully automatic solution Dürr

2020年8月5日 Dry overspray separation was a real innovation in 2010 The EcoDryScrubber technology, the company uses the paintsaturated limestone from the dry filters as a desulfurization additive for its own power plant – proof Dry methods such as electrostatic separation may be of interest of the bauxite industry for the preconcentration of bauxite prior to the Bayer process Electrostatic separation methods that utilize contact, or triboelectric, charging is particularity interesting because of their potential to separate aDRY BENEFICIATION OF BAUXITE MINERALS USING A TRIBOELECTROSTATIC Dry Stack; Fieldstone; Heritage; Laurel Cavern; Ledgestone; Ledgestone; Limestone; River Rock; Stack Ledge; Tuscan Ridge; Weather Ledge; (Limestone) Dove Tail FLATS Large Box quantity + Eldorado Stone Marquee 24 (Limestone) Dove Tail CORNERS Eldorado Stone Marquee 24 (Limestone) Dove Tail2020年1月2日 Separation and Purification Technology Volume 230, 2 January 2020, The semidry method combined the advantages of dry and wet methods, Simultaneous absorption of NO x and SO 2 in oxidantenhanced limestone slurry Environ Prog Sustainable Energy, 33 (4) (2015), pp 11711179 Google ScholarSeparation and Purification Technology ScienceDirect

FACTORS EFFECTING EFFICIENCY PREDICTION OF LIMESTONE

2022年8月28日 Semi dry limestone method 6090 The developed process model comprises the following three steps: (1) metal ion separation of pulp mill wastewater to produce KClO4, Mg(OH)2, and Ca(OH)2; (2) 1995年1月1日 PDF This paper describes some industrial applications of magnetic separation in Swedish mineral industry Recent studies on magnetic treatment of Find, read and cite all the research you Recent Activities in Magnetic Separation in SwedenThis paper reviews the need for, and potential of, dry technologies in mineral processing, and considers the problems that will have to be solved for such technologies to be economic The need for water in conventional mineral processing is reviewed, together with the advantages and disadvantages of operating wet and dry A wide range of dry processing techniques have been The Potential for the Dry Processing of Ores AusIMM2020年6月21日 where x is the particle size, x t the cut size and k represents a coefficient for the sharpness of cut Also for the deflector wheel separators, the model by Molerus [] was appliedIt was later improved by Rumpf [], Senden [12, 13], Schubert [] and finally by Husemann []As a simplification, all these models assume a steady state process, for which the classification Dynamics of Separation Characteristics of Sieving and Flow

Limestone Powder Saves 17 Million Liters of Water

2024年5月27日 The paint shops of two plants belonging to a wellknown German automotive group will be completely converted to dry separation with limestone powder in the near future The process saves 17 million liters of water and around 17,400 MWh of energy per year This reduces carbon dioxide emissions by more than 5000 tonsLimestone flue gas desulphurization (FGD) units are wellproven and costeffective ANDRITZ provides novel scrubber system (FGDplus) that maximizes SO2 and dust removal while keeping energy inputs to a minimum ANDRITZ Wet flue gas cleaning, limestone FGD Andritz2009年1月1日 138 00066 99686 tail Series of experiments have been performed on hematite/limestone and Upgrading this product to 44,00% B2O3 was carried out by dry magnetic separation By OPTIMIZATION OF SHAKING TABLE AND DRY 2015年4月1日 The main hypotheses are related to usability of dry selective crushing and in situ separation of oil shale and limestone in the mine to support effective management of calorific value and backfilling(PDF) Wet separation processes as method to

Limestone Beneficiation ST Equipment Technology (STET)

Many countries around the world have abundant cement grade limestone deposits But in cases where access to cement grade limestone is expensive or limited (for example – located in environmentally sensitive areas), a dry limestone beneficiation process such as STET can assist in generating a longterm supply of highgrade limestone from lower grade varieties2023年10月11日 Limestone air dry separation process in Colombia with our DF75 from 04mm to our machine separates 64 microns to customer material requirement for quality coDF 75 COLOMBIA LIMESTONE 64 MICRONS SEPARATION2016年2月26日 Request PDF Novel Methods for Separation of Gangue from Limestone and Coal using Multispectral and Joint ColorTexture Features Ore sorting is a useful tool to remove gangue material from the Novel Methods for Separation of Gangue from Limestone and Magnetic Separation 21 Introduction The differences in magnetic susceptibility can be utilized to separate a valuable mineral from its gangue through the magnetic separation method Similar to other materials, minerals are generally classified into three main categories, namely diamagnetic, paramagnetic, and ferromagneticChapter 2 Magnetic Separation Springer

.jpg)

Summary of research progress on industrial flue gas

2022年1月15日 Separation and Purification Technology Volume 281, 15 January 2022, Summary of research progress on industrial flue gas desulfurization technology Similarities between lime and limestone in wet—dry scrubbing Chem Eng 2002年1月1日 The dry process has been applied to many minerals including gypsum, salt, phosphates, talc, magnesite, diamonds, limestone, potassium, gold, coal, uranium and copper Dry Particle Separation A Contribution to Sustainable ProcessingThe MAGQUIP SUPRSEP Rare Earth Roll Separator is a permanent, highintensity roll magnet for the separation and/or upgrading of dry granular paramagnetic material in the 75 microns to 10 mm size range Standard range consists of various configurations including, single, double, and triple stage separators with standard diameters of 100, 150, 300 mm Roll magnetRare Earth Roll Separators (RERS) Magquip2022年1月20日 The separation performance of varied particle sizes indicated poor separation efficiency Particle distribution rates in clean coal increase with particle size, and the presence ofGravity separation by falcon concentrator an over

Depressants for Calcite and Silica Flotation Studies of Limestone

from 4098 to 4979 in flaggy limestone and silica can be reduced from 3766 to 1362 in variegated limestone, therefore, the flaggy limestone can be used directly after benefication in cement manufacturing and variegated limestone can be used by proper blending with massive limestone Fig1 Graphical representation of the result of depressant2020年6月30日 In the present study, gravity separation of speiss (674 g/㎤) and limestone (27 g/㎤) was investigated using a vibrating 1 mmzirconia ball (56 g/㎤) bed as a medium(PDF) The Gravity Separation of Speiss and Limestone Granules 21st European Symposium on Computer Aided Process Engineering Chao Fu, Truls Gundersen, in Computer Aided Chemical Engineering, 2011 6 Conclusion The air separation unit is the most important factor for the power penalties related to CO 2 capture from fossil fuel based power plants using oxycombustion In a conventional cryogenic air separation unit, the actual power Air Separation Unit an overview ScienceDirect Topics2021年9月9日 Why Choose ST Equipment Technology For Your Dry Minerals Separation Equipment? Located in Needham, Massachusetts, we’ve created a triboelectric separator that separates minerals according to their tribocharging susceptibility, ie, how particles respond when electrically charged by contact in an electric fieldDifferent types of separation methods for minerals

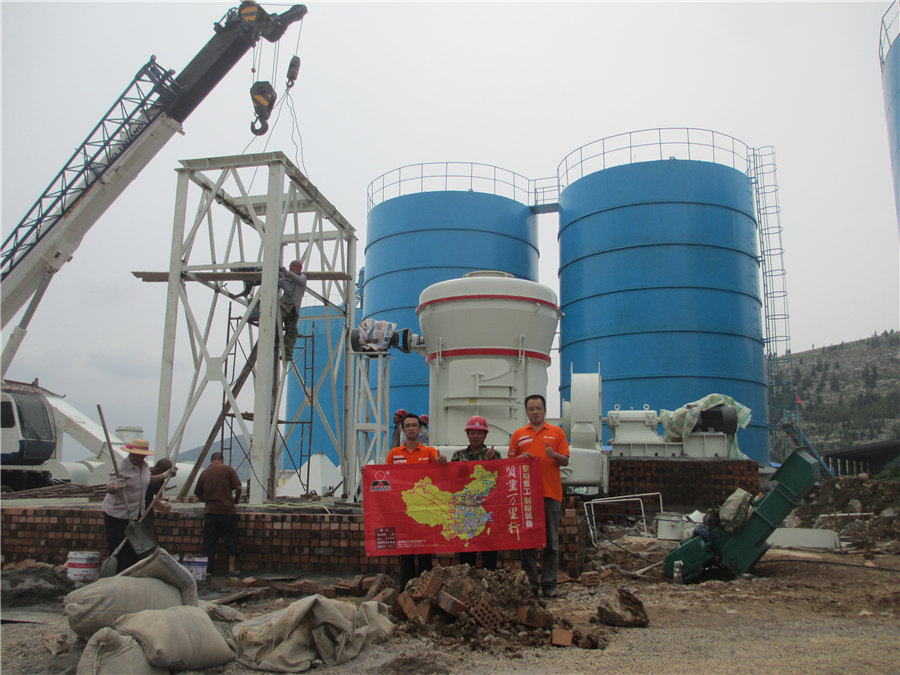

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)51.jpg)

Full article: Demonstration of dry magnetic separation to upgrade

2023年6月17日 Introduction Ferruginous manganese ore deposits, typically with 15–35 wt% Mn, or with low Mn:Fe ratios (eg Mn/Fe of ∼05–2), are problematic for manganese alloy makers and thus manganese ore miners (Kivinen et al Citation 2010)Olsen et al (Citation 2007) state that the production of standard ferromanganese alloy with 78% Mn requires raw materials with 2023年4月28日 The EcoDryScrubber separates paint overspray using finely ground limestone powder and highly efficient HEPA12 filters in just one filter stage Watch: EcoDryScrubber – paint booth efficiency through dry separation By Dürr, sponsor partner T09:04:00+01:00Watch: EcoDryScrubber – paint booth efficiency through dry separation 6 Magnetic Separation Drytype magnetic drum separator Source: AL Mular and RB Bhappu (Eds), Mineral Processing Plant Design, Society of Mining Engineers AIME, New York, 1980, p 475 Reproduced with the permission of the Society for Mining, Metallurgy, and Exploration 6 Magnetic Separation Springer2020年6月16日 Mineral dry density separation behavior (mineral beneficiation) involves segregation of high density particles and low density particles in the feed, ie, in nutshell, mineral dry density beneficiation is density segregation in physics terms In dry beneficiation, this density segregation is achieved using air as fluidized medium Density segregation on dry separators Study of Dry Mineral Separation Behavior in Dry Density Separators

.jpg)

EcoDryScrubber – Efficient dry separation Dürr durr

Dry separation is fully automatic and almost 100% effective, with maximum energy efficiency Effective principle The Eco DryScrubber removes paint overspray in a single filter stage using finely powdered limestone and highly efficient HEPA12 filters