Active silicon micro powder mill

Silicon Powder Properties Produced in a Planetary Ball Mill as a

2020年1月15日 In this study a metallurgical grade silicon quality was milled in a planetary ball mill and the properties of the powder were investigated as a function of grinding time, grinding The invention discloses a production process of active silicon micropowder, which comprises the following steps: crushing raw materials, carrying out primary classification treatment, carryingCNA Production process of active silicon micropowder 2021年8月23日 Angular silicon micropowder is an irregularly angular silicon micropowder obtained by grinding the raw material of silicon micropowder The main production equipment Production Technology and Application of Silicon MicropowderThis study demonstrates that vibrationassisted micromilling is a valuable technique for producing silicon components at scales ranging from a few microns with a nanometric surface finish with A comprehensive experimental investigation into vibration

.jpg)

Silicon carbide micropowder jet mill Google Patents

the silicon carbide micro powder jet mill comprises a feeder, a stirring frame, a material conveying groove, a screw, a first motor, a second motor, a hopper, an air compressor, a2023年5月24日 The reaction ball milling selfassembly approach can not only efficiently reducing nanoSiO 2 but also assemble the asformed nanoSi particles into compact micro/nanoSi Reaction ball milling selfassembly derived micro/nanoSi flakes as 2019年10月7日 In this study, we have used highenergy ball milling in an inert gas atmosphere to synthesize SiNCs and study their photophysical properties The induced accumulation of high strain, quantum confinement and possibly Photophysical properties of ball milled silicon 2023年8月23日 This study examines how the microstructure, thermal conductivity, and hardness of a highsilicon–aluminum composite are affected by different ball milling times We exposed the powder to various durations of ball Effect of Ball Milling Time on the Microstructure and

.jpg)

Microstructural Characteristics and Electrochemical Performance

2023年9月11日 The ballmilled Si powders with a silicontoethanol ratio of 1:9 showed the best electrochemical performance, displaying an initial coulombic efficiency of about 90% and a 2020年10月1日 In this study a metallurgical grade silicon quality was milled in a planetary ball mill and the properties of the powder were investigated as a function of grinding time, grinding Silicon Powder Properties Produced in a Planetary Ball Mill as a 2023年6月3日 Different types of silicon micro powder modification effects are also different Among them, spherical silicon micro powder has good liquidity It is easy to combine with the modifier during the modification process And the Surface modification method of silicon micro powderSBM micro powder grinding mill is a highly efficient industrial grinding mill, its finished products: 3253000 mesh; it's capacity: 0245t/h +17 [ protected] language >Shibang Industry Technology Group, Shanghai Micro Powder Grinding Mill

.jpg)

Top 5 productspecific milling technologies used in

2017年7月7日 New technology allows for the high wear components, particularly the classifier, to be made in silicon carbide or a completely cast aluminum oxide wheel, providing thousands of hours of service life when processing abrasive 2022年11月5日 Fuji et al reported that the powder surface can be activated by a mild ball milling treatment at very low rotation speeds without sufficient pulverization and silane coupling agents [17]The cleavages of siloxane bonds (Si–O–Si) on the silica particle surface could be confirmed because of the friction between the balls and particles even under mild milling, resulting in the Surface modification of silica powder by mild ball millingSilicon powder, max particle size 45 micron, weight 200 g, purity 995%; CAS Number: ; Synonyms: SI; Linear Formula: Si at SigmaAldrichSilicon powder, max particle size 45 micron, 200g, purity 995 Silicon is a semimetal with properties of metals and nonmetals that is not only used as a basic material in the electronics industry as an excellent semiconductor, but is also used in many other areas, eg as a basic material in silanes, polysilicon and in part in refractory materials, welding wires, in order to specifically change their propertiesSilicon micro powder PCC Thorion

Kaolin Ultrafine Grinding Mill SBM Ultrafine Powder Technology

2021年8月3日 HGM Micro Powder Mill Product Fineness: 3002500 mesh refractory bricks and silicon aluminum wool The voids have a certain adsorption effect on some of the more active and harmful components in the cable material, which can improve the insulation of 2016年1月1日 Request PDF Preparation of microsize flake silver powder by planetary ball mill Flake silver powder with controllable particle size and specific surface area was prepared using planetary ball Preparation of microsize flake silver powder by planetary ball millThe transformation in particle micromorphology and size of Ag was carried out by planetary ball mill (QM1SP2) in a agate jar using agate balls of 2–6 mm diameter Figure 1 shows a schematic diagram of the planetary ball mill [6] During the preparation process of flake silver powders by planetary ball mill, every time the ball mill adoptsPreparation of microsize flake silver powder by planetary ball mill2024年9月27日 Explore Hosokawa Micron Powder Systems for advanced size reduction and powder processing solutions across Wednesday, February 21st, 2024 4:00 AM to 4:45 AM EST To produce the best possible active materials for Battery Materials Processors Are Supercharging the Introducing the NEW Hosokawa SFW Air Classifying MillHome Hosokawa Micron Powder Systems

.jpg)

Support Software Drivers Active Silicon

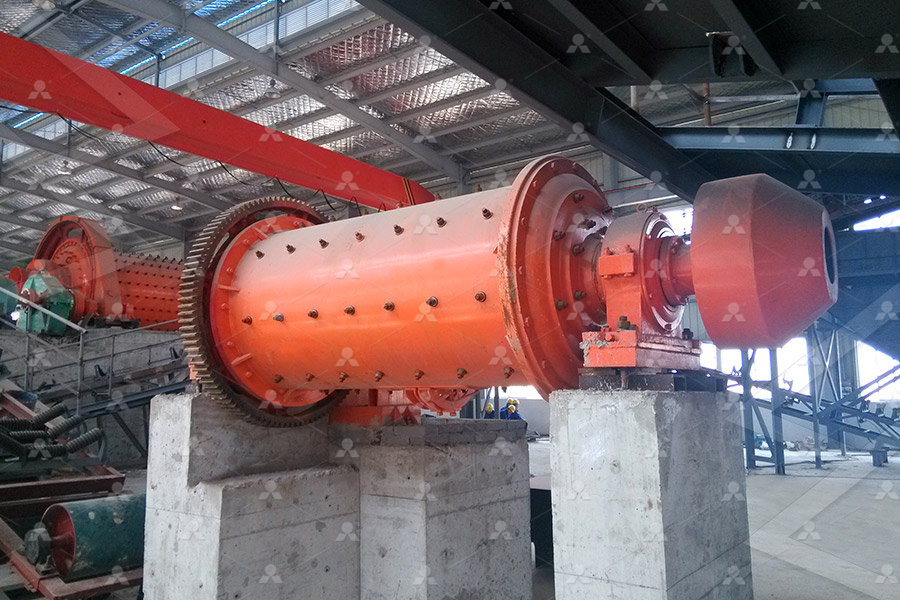

Company Profile Active Silicon, a Solid State plc group company, is a specialist manufacturer of imaging products and embedded vision systems We provide cameras and camera electronics for image data transmission, frame grabbers for data acquisition, and embedded systems for imaging processing and machine control2012年3月1日 Spherical and monodisperse microsilver powder, a kind of silver powder with controllable size and high tap density, was prepared by using silver nitrate as metal source, ascorbic acid as Synthesis and characterization of spherical and monodisperse micro The utility model discloses a micro silicon powder ball mill, which comprises a base, wherein the surface of the top end of the base is provided with a machine body for micro silicon powder ball milling, the surfaces of two side walls of the periphery of the base are provided with clamping grooves for connection, clamping blocks for auxiliary support are clamped and connected in CNU Micro silicon powder ball mill Google Patents2021年7月21日 In order to explore the impact of different ball milling technical parameters on the grain size of nano silicon powder, this paper adopted the orthogonal experimental design in combination with fitting analysis, and set the agitator shaft speed of the ball mill and the milling time as the influence factorsThe Impact of Ball Milling Process Parameters on the Preparation

Polymerderived silicon carbide micro powders through selective

2021年6月15日 Silicon carbide (SiC) ceramics have become a significant specialty material for advanced applications such as gasturbine, nuclear power, semiconductor, and aerospace industries because of their high thermal conductivity and resistance thermal shock, corrosion resistance, chemical inertness, and abrasion resistance [[1], [2], [3]]Recent interest in China Micro Silicon Powder wholesale Select 2024 high quality Micro Silicon Powder products in best price from certified Chinese Powder Can manufacturers, Powder Material suppliers, wholesalers and factory on MadeinChinaMicro Silicon Powder MadeinChina2019年10月15日 Silicon and composite characterization The elemental analysis of Silgrain® as a starting material is shown in Table 1As Silgrain® is a metallurgical grade of Si, some impurities are expected SiliconCarbon composite anodes from industrial battery grade silicon FRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding stations is designed for a broad range of applications and ideally suited for lossfree grinding down to a final fineness of 100 nm of hard, mediumhard and brittle materials Depending on the desired final fineness, the Planetary Micro Mill PULVERISETTE 7 premium line / Description

What Are The Uses Of Silica Powder?Professional Silicon Micro Powder

Silicon micro powder is a nontoxic, tasteless and pollutionfree inorganic nonmetallic material, which is made of natural quartz (SiO2) or fused quartz (amorphous SiO2 of natural quartz after high temperature melting and cooling) through crushing, grinding, flotation, pickling purification, highpurity water treatment and other processesSilicon micropowder is made of natural quartz (SiO 2) or fused quartz (amorphous SiO 2 after high temperature melting and cooling of natural quartz) after crushing, ball milling (or vibration, jet milling), flotation, pickling purification, highpurity water treatment, etc The micro powder processed by this technology Silicon micropowder is a nonmetallic material that is odorless, Application, processing technology and development trend of silicon powderMicro Powder Equipment (Ningbo) Co, Ltd: We're wellknown as one of the leading jet mill, pulverizer, full ceramic grading wheel, pulse bag filter, electronic control system manufacturers and suppliers in China Please feel free to buy China Jet Mill, Pulverizer, Full Ceramic Grading Wheel 2024年8月8日 In this process, a powder mixture is placed in a rotating drum, along with grinding media such as balls The kinetic energy imparted by the balls' motion breaks the powder into smaller pieces, making it a critical technique in Ball Mill Success: A StepbyStep Guide to Choosing

.jpg)

How To Produce Silicon Powder? Introduction Of Silicon Grinding Mill

Industrial silicon powder is the basic raw material for organosilicon polymer synthesis in the silicone chemical industry, and it is also the main material for the production of silica sol; after industrial silicon powder is made into amorphous silicon, it is processed into monocrystalline silicon by Czochralski method The silicon wafer is the necessary semiconductor material in of mill types, operation parameters, characterization methods and qualities of silicon feed material [28, 32–42] The work presented in this paper aims at producing silicon powders with a variety of properties through wet mechanical milling of an Elkem ASA metallurgical grade silicon as the feed material to a planetary ball mill The powder Silicon Powder Properties Produced in a Planetary Ball Mill as a Dolomite micro powder grinding mill is a new type mining equipment for make micro powders with ring rollers It is a kind of fine powder and ultrafine powder processing equipment It is mainly applied to ultrafine powder processing of nonflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤9Dolomite Micro Powder Grinding Mill22 Silicon Carbide MicroPowder The silicon carbide micropowder is crushed silicon carbide block being processed by Ramon a milling machine, jet mill, ball mill and shaping machine into a micrometer level powder We now are providing SiC micro powder including Black and Silicon Carbide and Silicon Carbide Powder Sinosi

.jpg)

Surface modification ALPA micro silica powder (superfine

The reason is that the silane coupling agent and the silicon hydroxyl group on the surface of the quartz powder require high energy for shrinking and bonding, while the Al3+ and Ti3+ in the aluminate and titanate coupling agents have large radii and are easy to associate with the silicon hydroxyl group2020年6月18日 Using the ball mill to grind the recycled fine powder at different times to study the effect of physical excitation on the properties of the recycled fine powderStudy on Present Situation of Active Stimulation of Recycled Fine Powder2021年9月30日 HGM micro powder mill The micro powder mill adopts a newly designed grinding roller grinding ring grinding curve, which improves the grinding efficiency The production capacity is 40% higher than that of jet mills and mixers, and the energy consumption is only 30% of that of jet mills HGM micro powder mill is equipped with a multihead cage Chalk Micro Powder Mill SBM Ultrafine Powder Technology2023年6月3日 Different types of silicon micro powder modification effects are also different Among them, spherical silicon micro powder has good liquidity It is easy to combine with the modifier during the modification process And the Surface modification method of silicon micro powder

.jpg)

Micro Powder Grinding Mill

SBM micro powder grinding mill is a highly efficient industrial grinding mill, its finished products: 3253000 mesh; it's capacity: 0245t/h +17 [ protected] language >Shibang Industry Technology Group, Shanghai 2017年7月7日 New technology allows for the high wear components, particularly the classifier, to be made in silicon carbide or a completely cast aluminum oxide wheel, providing thousands of hours of service life when processing abrasive Top 5 productspecific milling technologies used in 2022年11月5日 Fuji et al reported that the powder surface can be activated by a mild ball milling treatment at very low rotation speeds without sufficient pulverization and silane coupling agents [17]The cleavages of siloxane bonds (Si–O–Si) on the silica particle surface could be confirmed because of the friction between the balls and particles even under mild milling, resulting in the Surface modification of silica powder by mild ball millingSilicon powder, max particle size 45 micron, weight 200 g, purity 995%; CAS Number: ; Synonyms: SI; Linear Formula: Si at SigmaAldrichSilicon powder, max particle size 45 micron, 200g, purity 995

.jpg)

Silicon micro powder PCC Thorion

Silicon is a semimetal with properties of metals and nonmetals that is not only used as a basic material in the electronics industry as an excellent semiconductor, but is also used in many other areas, eg as a basic material in silanes, polysilicon and in part in refractory materials, welding wires, in order to specifically change their properties2021年8月3日 HGM Micro Powder Mill Product Fineness: 3002500 mesh refractory bricks and silicon aluminum wool The voids have a certain adsorption effect on some of the more active and harmful components in the cable material, which can improve the insulation of Kaolin Ultrafine Grinding Mill SBM Ultrafine Powder Technology2016年1月1日 Request PDF Preparation of microsize flake silver powder by planetary ball mill Flake silver powder with controllable particle size and specific surface area was prepared using planetary ball Preparation of microsize flake silver powder by planetary ball millThe transformation in particle micromorphology and size of Ag was carried out by planetary ball mill (QM1SP2) in a agate jar using agate balls of 2–6 mm diameter Figure 1 shows a schematic diagram of the planetary ball mill [6] During the preparation process of flake silver powders by planetary ball mill, every time the ball mill adoptsPreparation of microsize flake silver powder by planetary ball mill

Home Hosokawa Micron Powder Systems

2024年9月27日 Explore Hosokawa Micron Powder Systems for advanced size reduction and powder processing solutions across Wednesday, February 21st, 2024 4:00 AM to 4:45 AM EST To produce the best possible active materials for Battery Materials Processors Are Supercharging the Introducing the NEW Hosokawa SFW Air Classifying Mill