VSI8518 pyrochlore steelmaking plant steel slag mill vertical mill Raymond mill

.jpg)

Sbm VSI8518 Hydraulic Vertical Shaft Impact Crusher Plant,

SBM VSI Series vertical slag crushing machine is designed by reputed German expert of SBM and every index is in world's leading standard It incorporates three crushing types and it can The JOYAL VSI Crusher VSI8518 (sand making machine) is widely used to produce sand and stone for highway, highspeed railway, city project, hydropower dam constructions, and Verticalshaft impact crusher VSI8518 DirectIndustrySteel slag below 5mm enters the grinding system and is ground by the GRMSS series steel slag vertical roller mill The produced steel slag powder has a specific surface area of 400500 Steel Slag Grinding Plant CHAENG2007年3月1日 Pilot plant trials successfully demonstrated the viability of recycling million of tons of steel plant dusts and sludge that are now typically land filled, and typically converting them An overview of utilization of slag and sludge from steel industries

Comprehensive utilization of steel slag: A review ScienceDirect

2023年5月15日 This paper summarized the comprehensive utilization status of steel slag in building materials, agriculture, wastewater treatment, marine engineering, ceramics, and CO 2 The GRMSS steel slag vertical mill of CHAENG is a kind of special equipment for grinding industrial waste such as steel slag and water slag into powder Capacity: 200,0001,500,000t/a Steel Slag Vertical Mill CHAENGAfter meeting the grinding grain size requirements and reducing the iron content in the steel slag, the advantages of vertical grinding immediately show: high output, low power consumption, How is the steel slag vertical mill grinding process?2007年11月1日 With over 2000 MPS vertical roller mills in use around the world today for grinding cement raw material, coal, clinker, granulated blast furnace slag (GBFS), pozzolana, MPS vertical roller mills for slag and slag cements

.jpg)

Pelletizing steel mill desulfurization slag ScienceDirect

2002年7月1日 Each year, 50,000 tons of this slag is produced at one particular steelmaking plant This material can be beneficiated so that it can be utilized as blast furnace feed, but it is 2020年10月15日 Capturing CO 2 by steel slag (SS) via mineralization is regarded to be an excellent choice due to the high basicity of the slag In this paper, recent research on the steel Cotreatment of Waste From Steelmaking Processes: Steel Slag Output: 100 kg/h 180 kg/h Motor power: 30 kWFineness of the final powder is welldistributed, 99% of them can pass through the screen, other milling machines are hard to approachRaymond mill conmission equipment adopt Raymond mill, Raymond grinding mill All industrial Raymond mill is mainly used for fine grinding barite, fluorite, rare earth, marble, bauxite, manganese ore, iron ore, copper ore, slag, granite, barite, dolomite, bentonite, limestone , Kaolin and other ores and aggregates are We Raymond Mill JXSC Machinery

An overview of utilization of slag and sludge from steel industries

2007年3月1日 Integrated steel plants utilize mostly five materials such as raw materials, air, water, fuel and power to produce steel During the production of steel, 2–4 t of wastes are being generated per tonne of steel producedThe various solid wastes in the form of slags and sludges that are emerged from steel plants are blast furnace slag, blast furnace flue dust and sludge, The steel slag ball mill is one of the main equipment for grinding and processing It has stable operation, good grinding effect and obvious economic benefit The emergence of steel slag ball mill meets the needs of steel slag plant for processing steel slag grinding, and also enables the rational use of steel slag and avoids waste of resourcesSteel Slag Ball Mill Quality Ball Bill Supplier Provide Best PriceVertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plantVertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one It can be widely used in cement, electric power, metallurgy, chemical industry, nonmetallic ore, and other industriesVertical raw mill Cement PlantRelease time 18/12/2014 Clirik Newest super fine HGM100 vertical powder grinding mill See detailsvertical roller mill clirikultrafine vertical mill, Raymond vertical

Raymond Mill at Best Price in India India Business Directory

Mild steel pin (raymond mill), capacity(kg/hr): 100; Raymond Mill,Raymond Roller Mill,Raymond Mill Machine,Raymond Mill Plant; Grinding Mill Raymond Mill,Vertical Roller Mill,Milling Machine Manufacturer; Show More Videos V Related Category Vertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills that satisfy the cement user’s demandsNevertheless, the two types of mills have their distinctive meritsCement grinding Vertical roller mills VS ball millsThey can also be used to prepare feed for systems producing ultrafine materials, such as a Raymond Vertical mill, ball mill or JetStream Classifier system The mill provides efficient control of product size with minimal power, resulting in a flexible, costeffective production Standard sizeRaymond Roller Mill airswept vertical ringrollSince 2007, SINOMALY has begun to develop and manufacture vertical slag mill, which has been successfully applied in the market, with a output range from 45t/h to 300t/h that can satisfy the slag powder production lineSlag Mill Vertical Slag Mill Provider SINOMALY

.jpg)

Raymond Mill

The Raymond mill, also called Raymond roller mill, combines grinding, classifying, and if necessary, drying, in one machine to produce precisely sized powders to meet exact production specificationsIt is an efficient fine grinding 2024年9月4日 alwepo, Raymond Mill is an industrial equipment used to grind raw materials into fine powder This equipment is commonly used in industries such as mining, metallurgy, chemistry, and construction materials Its efficient What is Raymond Mill? How Does It Work? alwepoFig2 Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimationVertical roller mill for raw Application p rocess materialsRelease time 18/12/2014 Clirik Newest super fine HGM100 vertical powder grinding mill See detailsvertical roller mill clirikultrafine vertical mill, Raymond vertical

Fly Ash Processing Plant Ball Mill, Raymond Mill, EPC Project

Fly ash is generally a solid waste generated by the incineration boilers in thermal power plants, coalfired power plants, paper mills, and chemical factories, as well as the collection of ash from dust collectors It consists of tiny ash particles emitted during the combustion of fuel, primarily coal, with particle sizes typically ranging from 1 to 100 micrometersA vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal Energysaving and Efficient Vertical Roller Mill Fote MachineryRaw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by Raw mill Cement PlantChina Raymond Mill wholesale Roller Vertical Limestone Raymond Grinding Mill for Sale US$ / Set 1 Set (MOQ) Henan Shanky Machinery Co, Ltd Gongyi Hengchang Metallurgical Building Material Equipments Plant Diamond Raymond Mill MadeinChina

.jpg)

2 µm 5 µm Loesche

a Loesche mill, with a grinding track diameter of only 11 metres, was used as long ago as 1935 However, the breakthrough in grinding this type of material on the vertical roller mill did not take place until the beginning of the 1990’s 1935 The first Loesche mill for grinding cement clinker, an LM 11, was commissioned in Joao Pessao, BrazilThe document discusses Gebr Pfeiffer AG's MPS vertical roller mills for grinding slag and their effectiveness It notes that since 1980, an MPS 3750 C mill in Hannover has been producing cement with 4080% slag content Currently an 2006 Slag Grinding With MPS Vertical Roller MillsRaymond pulverizing and classification equipment has been setting the standards in size reduction since 1887, serving many types of mineral processing industries Our portfolio includes not only the Raymond Roller Mill but the Raymond Imp™ Mill, Raymond Bowl Mill, Raymond Vertical Mill, Raymond Ultra Fine Mill and others Reliable SolutionsRAYMOND® ROLLER MILLS PDF4PROGrinding Mill, Raymond Mill, Ball Mill manufacturer / supplier in China, offering Big Capacity Stone Quarry Plant Used Calcium Carbonate Gypsum Limestone Quartz Graphite Calcite Feldspar Fluorite Impact Crusher, Hot Sale Dolomite Pyrophyllite Mineral Phosphorite Marble Perlite Sepiolite Silica Powder Jaw Crusher Price with High Efficient Capacity, Low Cost Calcite Raymond mill; Superfine grinding mill; Vertical roller mill

.jpg)

Vertical Cement Mill

AGICO Cement provides vertical cement mill, vertical roller mill used for cement manufacturing, powerful grinding and homogenization, customdesign cement mill, onschedule delivery Skip to content +86 2011年10月26日 Steel slag is a byproduct of the steelmaking and steel refining processes Multiserv Ltd, Harsco Corporation, which performs slag processing operations at the Mittal Steel Plant, Indiana, was the source for the EAF ladle (L) slag The Edward C Levy Co, which operates at the Whitesville Steel Mill, supplied The EAF(L) slagChemical, Mineralogical, and Morphological Properties of Steel Slag 2023年9月21日 Common types of grinding mills include ball mill, Raymond mill, vertical roller mill and ultrafine mill, each with unique advantages for specific applications Sand Making Machine The sand making machine, also known as Vertical Shaft Impactors, is a specialized equipment used for producing artificial sand from rocksA Comparative Analysis: Vertical Roller Mill Vs Ball MillRaymond Roller Mill Free download as PDF File (pdf), Text File (txt) or read online for free roller millRaymond Roller Mill PDF Mill (Grinding) Steel

Slag Mill

Vertical Slag Mill; Ball Mill; Coalwater Slurry Ball Mill; Raw Material Ball Mill; Cement Ball Mill; Coal Ball Mill; Slag Mill; Rod Mill for Beneficiation; Rotary Kiln; Cement Plant, Slag Grinding Plant, Steel Mill: Capacity: 1178 t/h: Motor Power: 95 YGM Industrial Raymond Mill Discharge fineness: 80600 mesh Feed size: 35 mm Output: 0435 t/h Materials: Calcite, limestone, wollastonite, gypsum, potassium feldspar, kaolin, bentonite, barite, phosphate rock, manganese ore, quartz stone, marble and other materials with Mohs hardness below 7YGM Industrial Raymond MillWe can provide different types of vertical roller mills in different industries such as cement, steel, and mining The production capacity is 30250 t/h More>>cement plant,ball mill,vertical mill,rotary kiln,slag grinding mill Output: 100 kg/h 180 kg/h Motor power: 30 kWFineness of the final powder is welldistributed, 99% of them can pass through the screen, other milling machines are hard to approachRaymond mill conmission equipment adopt Raymond mill, Raymond grinding mill All industrial

.jpg)

Raymond Mill JXSC Machinery

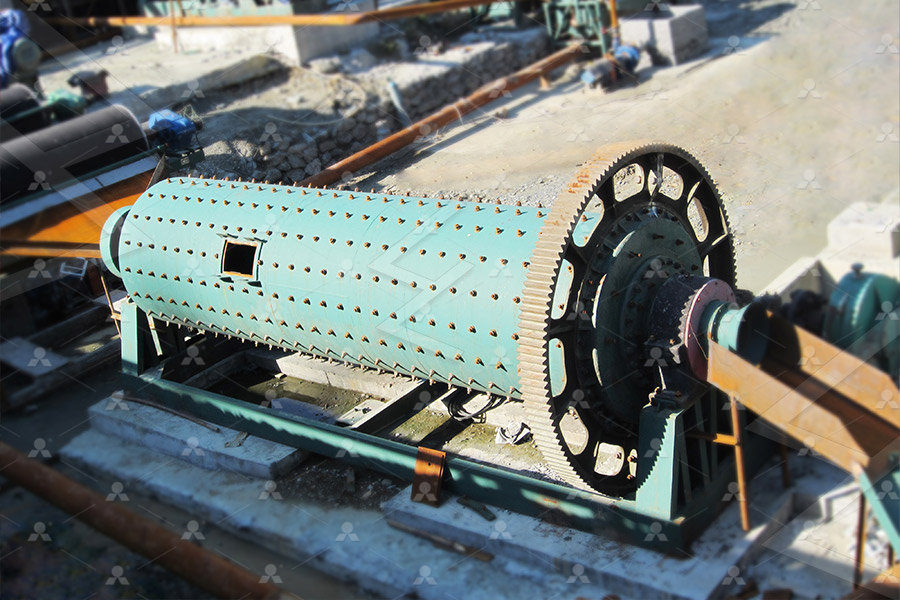

Raymond mill is mainly used for fine grinding barite, fluorite, rare earth, marble, bauxite, manganese ore, iron ore, copper ore, slag, granite, barite, dolomite, bentonite, limestone , Kaolin and other ores and aggregates are We 2007年3月1日 Integrated steel plants utilize mostly five materials such as raw materials, air, water, fuel and power to produce steel During the production of steel, 2–4 t of wastes are being generated per tonne of steel producedThe various solid wastes in the form of slags and sludges that are emerged from steel plants are blast furnace slag, blast furnace flue dust and sludge, An overview of utilization of slag and sludge from steel industriesThe steel slag ball mill is one of the main equipment for grinding and processing It has stable operation, good grinding effect and obvious economic benefit The emergence of steel slag ball mill meets the needs of steel slag plant for processing steel slag grinding, and also enables the rational use of steel slag and avoids waste of resourcesSteel Slag Ball Mill Quality Ball Bill Supplier Provide Best PriceVertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plantVertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one It can be widely used in cement, electric power, metallurgy, chemical industry, nonmetallic ore, and other industriesVertical raw mill Cement Plant

vertical roller mill clirikultrafine vertical mill, Raymond vertical

Release time 18/12/2014 Clirik Newest super fine HGM100 vertical powder grinding mill See detailsMild steel pin (raymond mill), capacity(kg/hr): 100; Raymond Mill,Raymond Roller Mill,Raymond Mill Machine,Raymond Mill Plant; Grinding Mill Raymond Mill,Vertical Roller Mill,Milling Machine Manufacturer; Show More Videos V Related Category Raymond Mill at Best Price in India India Business DirectoryVertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills that satisfy the cement user’s demandsNevertheless, the two types of mills have their distinctive meritsCement grinding Vertical roller mills VS ball millsThey can also be used to prepare feed for systems producing ultrafine materials, such as a Raymond Vertical mill, ball mill or JetStream Classifier system The mill provides efficient control of product size with minimal power, resulting in a flexible, costeffective production Standard sizeRaymond Roller Mill airswept vertical ringroll

Slag Mill Vertical Slag Mill Provider SINOMALY

Since 2007, SINOMALY has begun to develop and manufacture vertical slag mill, which has been successfully applied in the market, with a output range from 45t/h to 300t/h that can satisfy the slag powder production line