1hbeswlvg micro powder grinding is B ultrasound or Xray

.jpg)

Ultrasonic vibration assisted grinding of hard and brittle linear

2017年4月1日 In this paper, a novel ultrasonic vibration assisted grinding (UVAG) technique was presented for machining hard and brittle linear microstructured surfaces The kinematics of 2024年3月14日 This process which creates a 2Doscilating trajectory of the work material during a grinding pass is referred to ultrasonic assisted grinding (UAG) Reports have shown that the Grindability Evaluation of Ultrasonic Assisted Grinding of Silicon 2014年7月8日 The experiment results demonstrate that grinding forces are significantly reduced by introducing ultrasonic vibration into conventional micro end grinding (CMEG) of silica glass; [PDF] Study on Effect of Ultrasonic Vibration on Grinding Force 2021年5月1日 Xray diffraction data strongly agrees with BET surface areabased particle size In this work, a submicron quartz powder produced by high energy grinding was used to Powder grinding and nanoparticle sizing: Sound, light and

.jpg)

Study on Effect of Ultrasonic Vibration on Grinding Force and

2014年7月8日 The experiment results demonstrate that grinding forces are significantly reduced by introducing ultrasonic vibration into conventional micro end grinding (CMEG) of silica glass;2010年1月1日 In this sense ultraprecision grinding is primarily used to generate high quality and functional parts usually made from difficult to machine materials The aim of ultraprecision Ultraprecision grinding ScienceDirect2023年2月22日 A new microgrinding process called ultrasonic vibrationassisted nanoparticle jet mist cooling (UNJMC) is innovatively proposed to solve the technical problem It combines Machinability of ultrasonic vibrationassisted microgrinding in 2017年4月29日 By adopting the method of combining highspeed grinding technology with ultrasonic vibration, abrasive wear forms of single cubic boron nitride (CBN) grains under Abrasive wear of a single CBN grain in ultrasonicassisted high

Material Removal Mechanism and Force Modeling in Ultrasonic

2023年10月27日 Microscale grinding mainly refers to the direct mechanical removal process using a microabrasive tool with a processing feature size of less than 50 μm [7] It has the 2023年8月22日 In this work, the UVAG and CG comparative trials with ultrahigh strength steels using white alumina (WA) and microcrystalline alumina (MA) wheels are conducted, aiming at Study on grinding performance during ultrasonic vibration 2023年10月1日 Visual feedback images that determine the next motion The red circles are powderdense areas, and the red points are the center of ones The blue circle is the area of 10 mm from the mortar centerRobotic Powder Grinding with a Soft Jig for 2016年2月22日 31 XRay Powder Diffraction (XRPD) 311 General Theory We will consider a parallel beam (plane wave) of monochromatic radiation , that is, with a single constant wavelength λ (if we think about a particle beam, as it is allowed by the De Broglie ambiguity, all particles travel parallel to each other and have the same speed and energy)XRay Powder Diffraction Characterization of Nanomaterials

.jpg)

Powder injection molding process for fabrication of piezoelectric

2018年6月22日 Figure 1 shows schematic diagram for the developed manufacturing process of micro PZT array As starting materials, PMMA sheet, PZT powder and polymeric binders are required Developed process consists six main steps; mold insert fabrication via LIGA (from the German Lithographi, Galvanoformung, Abformung) process, powder and binder mixing Xray powder diffraction (XRD) is a rapid analytical technique primarily used for phase identification of a crystalline material and can provide information on unit cell dimensions Determination of an unknown requires: the material, an instrument for grinding, and a sample holder Obtain a few tenths of a gram (or more) Xray Powder Diffraction (XRD)2020年8月1日 And the microgroove arrays were designed to U shape with bottom radius of 70 μm and depth of 110 μm Ultrahigh molecular weight polyethylene (UHMWPE) powders were used as raw material to fabricate microplastic parts with hydrophobic surface structures by micro ultrasonic powder moulding (microUPM)Fabrication of microplastic parts with a hydrophobic surface by micro 2011年8月1日 Request PDF Particle Grinding by HighIntensity Ultrasound: Kinetic Modeling and Identification of Breakage Mechanisms Highintensity ultrasound, is sought as a means to break particles A Particle Grinding by HighIntensity Ultrasound: Kinetic Modeling and

Characteristics of Recycled Micro Powder Produced Using Construction

2021年7月11日 Six different recycled micro powders were prepared by grinding the construction wastes that composed of concrete, tile, brick, and concrete Experimental researches on their physical and chemical properties, particle size distribution, chemical composition and strength activity index were investigated and compared with the characteristics of cement, slag powder 2016年8月31日 Xray diffraction is one of the most powerful methods for the analysis of crystalline materials In particular, singlecrystal Xray diffraction (SXD ; see Chap 9) is the definitive method for determining threedimensional crystal structures, yielding accurate atomic coordinates and thermal parameters from which quantities such as molecular geometry and An Overview of Powder Xray Diffraction and Its Relevance to 2007年11月1日 The experiment shows micro deformation mechanism of ceramic material in twodimensional ultrasound grinding is twin grain boundary and grainboundary sliding for Al2O3, and it is crystal dislocation of enhanced phase, matrix grain boundary sliding, coordination deformation of intergranular second phase as well as its deformation mechanism for nano Research on MicroMechanism of Nanocomposite Ceramic in Two Evaluation of laboratory powder Xray microdiffraction for applications in the fields of cultural heritage and forensic science Using throughtransmission midwave infrared vision and aircoupled ultrasound for artwork inspection: a case study on Xray powder microdiffraction for routine analysis of paintings

Dry Grinding Carbonated UltrasoundAssisted Water Leaching

2021年11月1日 a) Xray diffractogram and b) SEM micrograph of the recovered Li 2 CO 3 (roasting temperature = 600 °C, roasting time = 30 min, grinding time = 25 min, CO 2 flow rate = 100 mL/min, ultrasound frequency = 40 kHz, leaching time = 3 h, evaporative crystallization temperature 95 °C); c) Xray diffractogram and d) SEM micrograph of the acid leaching Three‐dimensional density measurements of ultra low density materials by X‐ray scatter using confocal micro X‐ray fluorescence spectroscopy XRay Spectrometry, Vol 41, Issue 4, pMicro Xray fluorescence in materials characterization Powder 2000年4月1日 The use of ultrasound during the tableting of pharmaceutical powders is a new concept However, in the metallurgy, plastic, and ceramic industries, ultrasoundassisted compression of materials has Principles and application of ultrasound in pharmaceutical powder 2021年5月13日 A new powder production method has been developed to speed up the search for novel alloys for additive manufacturing The technique involves an ultrasonically agitated cold crucible installed at (PDF) Novel Cold Crucible Ultrasonic Atomization Powder Production

CFB石灰石脱硫剂制备96.jpg)

Research on Material Removal Mechanism of C/SiC Composites in

2020年4月19日 C/SiC composites are the preferred materials for hotend structures and other important components of aerospace vehicles It is important to reveal the material removal mechanism of ultrasound 2022年12月1日 In this study, the suspensionassisted totalreflection Xray fluorescence analysis of ores was improved using the wet grinding procedure to produce ultrafine suspended powder mixed with internal standard solution in aqueous mediaThe advantages of the proposed technique were demonstrated by the example of the determination of S, Fe, Ni, and Cu in Improvement of suspensionassisted total reflection Xray 2014年7月8日 Ultrasonic vibration assisted micro end grinding (UAMEG) is a promising processing method for micro parts made of hard and brittle materials First, the influence of ultrasonic assistance on the mechanism of this processing technology is theoretically analyzed Then, in order to reveal the effects of ultrasonic vibration and grinding parameters on grinding [PDF] Study on Effect of Ultrasonic Vibration on Grinding Force 2023年10月1日 Robotic powder grinding would solve this problem, but it is a challenging task for robots, as it requires observing the powder state and generating appropriate motionsRobotic Powder Grinding with AudioVisual Feedback for

Powder injection molding process for fabrication of piezoelectric

2018年2月27日 Powder injection molding process has been developed for a costeffective fabrication of micro PZT array in diagnostic 2D array ultrasound transducer2015年5月5日 Finally, by taking the PCBs with 010 and 015 mm microhole arrays as the microcavity inserts, utilizing ultrahighmolecule weight polyethylene powder with the average particle size of about Mechanical drilling of PCB micro hole and its application in micro MIC will be closed for the holidays on the following days: Tuesday, December 24 th – Closed at 3:00pm Wednesday, December 25 th Thursday, December 26 th Friday, December 27 th Saturday, December 28 th Tuesday, December 31 st MIC Medical Imaging X Ray, Ultrasound, MRI, More2020年4月19日 C/SiC composites are the preferred materials for hotend structures and other important components of aerospace vehicles It is important to reveal the material removal mechanism of ultrasound vibrationassisted Research on Material Removal Mechanism of C/SiC

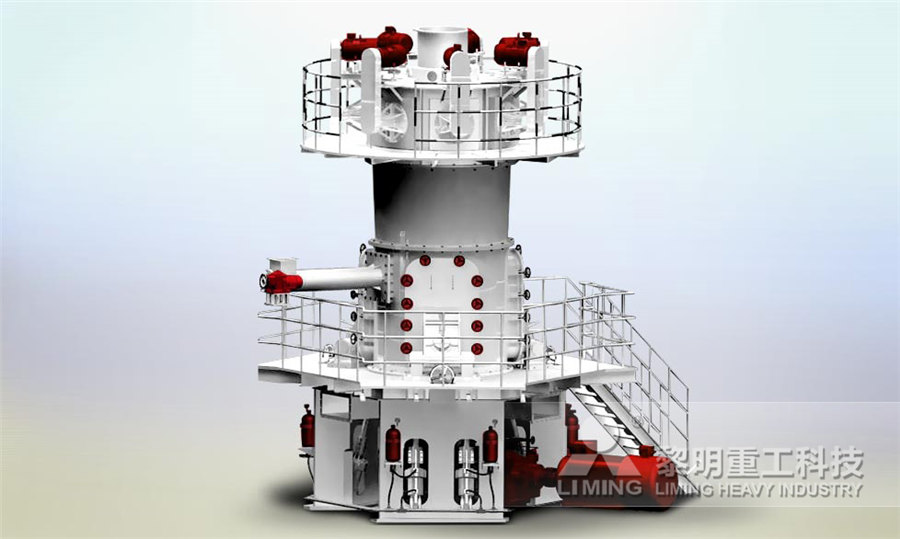

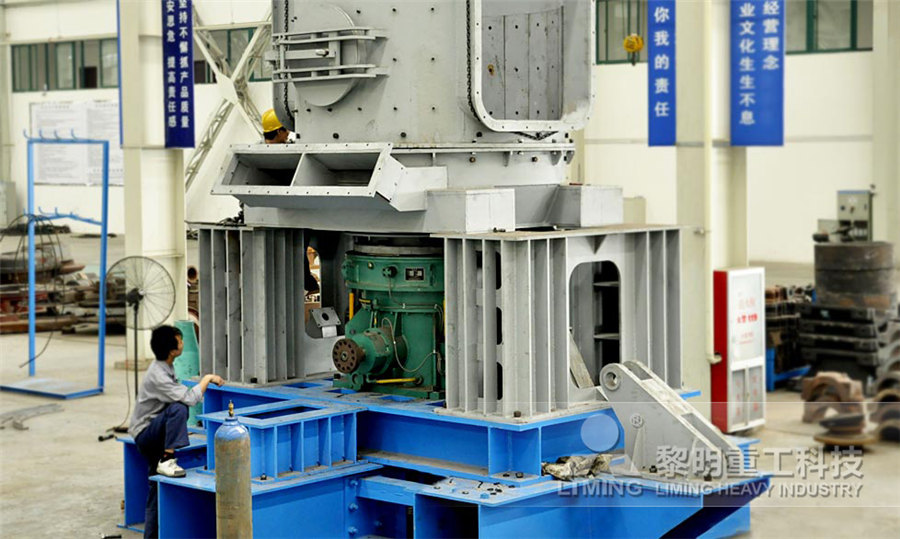

Chalk Micro Powder Mill SBM Ultrafine Powder

2021年9月30日 The chalk micro powder mill is independently developed and produced by SBM It mainly includes 3 types, namely HGM ultrafine grinding mill (1503000 meshes), CLUM vertical mill (1503000 meshes), and wet stirring 2021年2月25日 Xray computed tomography (CT) can reveal the internal details of objects in three dimensions nondestructively In this Primer, we outline the basic principles of CT and describe the ways in Xray computed tomography Nature Reviews Methods PrimersJune 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process: 2017年11月16日 Laser powder bed fusion offers many advantages over conventional manufacturing methods, such as the integration of multiple parts that can result in significant weightsavings The increased design freedom that layerwise manufacture allows has also been seen to enhance component performance at little or no added cost For such benefits to be Using Laser Ultrasound to Detect Subsurface Defects in Metal

Chapter 11 Overview and principles of powder diffraction

The easiest way to understand the structural information contained in powder diffraction, and historically one of the first ways in which diffraction was described, is via the well known Bragg equation (Bragg, 1913), which describes the principle of Xray diffraction in terms of the reflection of Xrays by sets of lattice planes To understand the concept of a lattice plane, first imagine a ① Integrated design, less comprehensive investment The machine integrates crushing, grinding, powder selection, conveying, and packaging The system is simple, and the layout is compact The floor area is about 50% of the ball mill system, and it can be arranged in the open air, greatly reducing investment costsStone Powder Making Machine2020年8月20日 The ultrasound generated in the measuring head is transported into the test part through a coupling medium, usually a type of water Good coupling is important for effective testing The ultrasound penetrates the test piece and echoes of the ultrasonic waves are created by reflections on the back wall6 important methods for crack testing in nondestructive testingUltrasonication is an efficient means for the wetmilling and microgrinding of particles Besides dispersing and deagglomerating, the wet milling is an important application of Hielscher ultrasonic devices In particular for the manufacturing of superfinesize slurries, ultrasound has many advantages, when compared with common size reduction equipment, such as: colloid mills Ultrasonic WetMilling and MicroGrinding Hielscher Ultrasonics

Robotic Powder Grinding with a Soft Jig for

2023年10月1日 Visual feedback images that determine the next motion The red circles are powderdense areas, and the red points are the center of ones The blue circle is the area of 10 mm from the mortar center2016年2月22日 31 XRay Powder Diffraction (XRPD) 311 General Theory We will consider a parallel beam (plane wave) of monochromatic radiation , that is, with a single constant wavelength λ (if we think about a particle beam, as it is allowed by the De Broglie ambiguity, all particles travel parallel to each other and have the same speed and energy)XRay Powder Diffraction Characterization of Nanomaterials2018年6月22日 Figure 1 shows schematic diagram for the developed manufacturing process of micro PZT array As starting materials, PMMA sheet, PZT powder and polymeric binders are required Developed process consists six main steps; mold insert fabrication via LIGA (from the German Lithographi, Galvanoformung, Abformung) process, powder and binder mixing Powder injection molding process for fabrication of piezoelectric Xray powder diffraction (XRD) is a rapid analytical technique primarily used for phase identification of a crystalline material and can provide information on unit cell dimensions Determination of an unknown requires: the material, an instrument for grinding, and a sample holder Obtain a few tenths of a gram (or more) Xray Powder Diffraction (XRD)

.jpg)

Fabrication of microplastic parts with a hydrophobic surface by micro

2020年8月1日 And the microgroove arrays were designed to U shape with bottom radius of 70 μm and depth of 110 μm Ultrahigh molecular weight polyethylene (UHMWPE) powders were used as raw material to fabricate microplastic parts with hydrophobic surface structures by micro ultrasonic powder moulding (microUPM)2011年8月1日 Request PDF Particle Grinding by HighIntensity Ultrasound: Kinetic Modeling and Identification of Breakage Mechanisms Highintensity ultrasound, is sought as a means to break particles A Particle Grinding by HighIntensity Ultrasound: Kinetic Modeling and 2021年7月11日 Six different recycled micro powders were prepared by grinding the construction wastes that composed of concrete, tile, brick, and concrete Experimental researches on their physical and chemical properties, particle size distribution, chemical composition and strength activity index were investigated and compared with the characteristics of cement, slag powder Characteristics of Recycled Micro Powder Produced Using Construction 2016年8月31日 Xray diffraction is one of the most powerful methods for the analysis of crystalline materials In particular, singlecrystal Xray diffraction (SXD ; see Chap 9) is the definitive method for determining threedimensional crystal structures, yielding accurate atomic coordinates and thermal parameters from which quantities such as molecular geometry and An Overview of Powder Xray Diffraction and Its Relevance to

.jpg)

Research on MicroMechanism of Nanocomposite Ceramic in Two

2007年11月1日 The experiment shows micro deformation mechanism of ceramic material in twodimensional ultrasound grinding is twin grain boundary and grainboundary sliding for Al2O3, and it is crystal dislocation of enhanced phase, matrix grain boundary sliding, coordination deformation of intergranular second phase as well as its deformation mechanism for nano Evaluation of laboratory powder Xray microdiffraction for applications in the fields of cultural heritage and forensic science Using throughtransmission midwave infrared vision and aircoupled ultrasound for artwork inspection: a case study on Xray powder microdiffraction for routine analysis of paintings