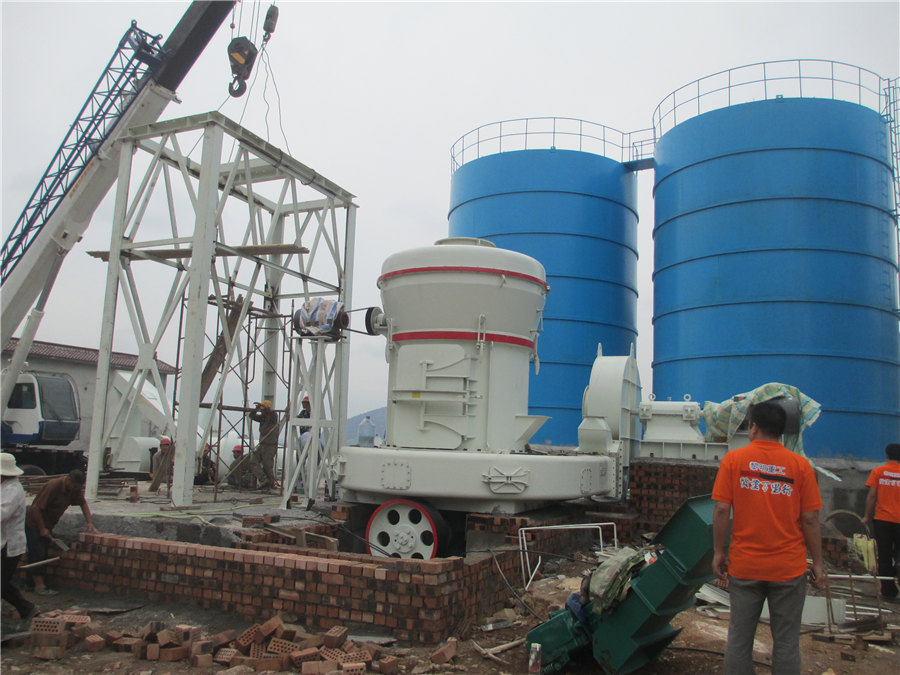

Expandable graphite powder making process process flow

.jpg)

Design of manufacturing process and production line for

This research work gives a detail description of designing a manufacturing process for expanded graphite based on the observation from patents and design a continuous production line for 2023年6月25日 EG are usually prepared from graphite intercalation compounds (GICs) formed via a intercalation process (the insertion of various chemical species (intercalant) between Highperformance expanded graphite from flake graphite by 2020年6月1日 For instance, Expandable graphite was prepared by a onestep process at room temperature, which might be suitable for synthesis of EG[14] Nevertheless, long reaction Rapid preparation of expanded graphite at low temperatureThe die molding process consists of the following stages: Die filling At this stage a controlled amount of the powder is fed into the die cavity Compaction Upper punch moves down and GRAPHITE MANUFACTURING PROCESS IDCOnline

Expanded Graphite an overview ScienceDirect Topics

The method for making graphite is expandable [34,53]: First, they mix natural graphite into nitric acid and sulfuric acid After 24 h, the reaction between the graphite plates and the acid passes 2010年4月28日 This article reports a new way to prepare expandable graphite using a hydrothermal method Natural flake graphite was added to a concentrated sulfuric acid and Preparation of expandable graphite using a hydrothermal method 2006年11月1日 In this work, a simple synthesis approach is suggested to achieve expanded graphite from natural graphite precursors via thermal treatment(PDF) Thermally expanded graphite: Synthesis, properties, and The traditional methods for preparing expanded graphite (EG) often require harsh conditions and take a long time resulting in a highcost and severe environmental pollution A simple, energy Rapid preparation of expanded graphite at low temperature

.jpg)

Expandable graphite Wikipedia

Expandable graphite is produced from the naturally occurring mineral graphite [1] The layered structure of graphite allows some molecules to be intercalated in between the graphite layers 2024年6月14日 The two main methods used to produce expanded graphite are thermal expansion and liquid phase expansion In the first process, graphite is intercalated using Effects of expanded graphite’s structural and elemental NGS fine expandable graphite powder grade Ex 200 95 40 (neutral pH) particle size approx 85 % finer than 200 mesh = 75 µm pH value of the flake surface 6 8 activation temperature approx 200 °C expansion volume at 1000 °C 40 cm³/g Expandable Graphite NGS2020年6月1日 As a result, simpler and more environmental friendly routes have recently been reported For instance, Expandable graphite was prepared by a onestep process at room temperature, which might be suitable for synthesis of EG[14] Nevertheless, long reaction times are required for this process, which limits its applicationRapid preparation of expanded graphite at low temperature

Expanded Graphite an overview ScienceDirect Topics

The method for making graphite is expandable (K 2 HPO 4 3H 2 O–NaH 2 PO 4 2H 2 O–Na 2 S 2 O 3 5H 2 O–H 2 O) in expanded graphite through an impregnation process with an adsorption capacity of 8071 wt% The phase change temperature, latent heat, The graphite powder was dried in a vacuum oven at 70 °C for 20 h, 3 天之前 Expandable graphite (EG) is a special form of flake graphite that contains strongly acidic intercalated anions The industrialscale preparation of EG primarily involves chemical oxidation Flake graphite loses electrons under the oxidation of strong agents such as KMnO 4 , HNO 3 , and H 2 O 2 ( Chua et al, 2012 , Sorokina et al, 2007 ), typically represented as C n + Experimental exploration of methanecoal dust explosion Due to the layered structure of graphite, atoms or small molecules can be introduced between the carbon layers (intercalation) During this process a socalled expandable graphite salt or GIC (Graphite Intercalation Compound) is produced Outstanding expandable graphite grades have a high proportion of intercalated layersEXPANDED PROCESSED EXPANDED GRAPHITEGraphite powder process smoothing agent, a pair of heater 5,2, singlelayer flat plate rolling method single layer flat plate rolling, with 156 graphite plate and density 17 graphite plate service life can be separated by 3 months, it is this incomparable advantage, graphite powder process (4) no burr; Copper electrode in the processing is completed, graphite products has been widely Graphite powder process FRANLI

Graphite Flakes/Powder CGT Carbon

Expandable graphite powder Expandable graphite powders are made from natural flake graphite treated by chemical or electrochemical processes They can expand 150250 times in volume at high temperature with large surface area, high surface energy, good flexibility, resilience and plasticity etc Natural highpurity graphite powderExpandable graphite is produced through a process of subjecting flake graphite to high temperature treatment This versatile material has a wide range of applications, including its use in the production of graphite paper, fireproof adhesive tape, and for sealing purposes in various industries, such as the battery industryExpandable GraphiteGraphite Sourcepro2024年9月20日 2 Impact crusher The impact crusher can process materials with a side length of 100500 millimeters or less, with a maximum pressure resistance of 350 MPA It has the advantages of a large crushing ratio and with cubic material particles This machine is widely used in building materials, ore crushing, railways, highways, energy, transportation, cement, mining, How Does The Graphite Grinding Plant Process?2006年11月1日 PDF Results obtained in synthesis of thermally expanded graphite by chemical and electrochemical methods with sulfuric and nitric acids are Find, read and cite all the research you need on (PDF) Thermally expanded graphite: Synthesis, properties, and prospects

Effects of expanded graphite’s structural and

2024年6月14日 In the first process, graphite is intercalated using hydrogen peroxide to oxidise the graphite, followed by sulfuric or nitric acid intercalation to form expandable graphite 9particles together with their internal porosity During the foaming process the pitch tends to coat the outside surface of the expanding graphite flakes It also bonds them together The graphite foam prepared with 5 wt% expandable graphite had a bulk density of 0249 g cm3, a compressive strength of 046 MPa and a thermal conductivity of 21 Graphite foam from pitch and expandable graphite University Expandable graphite (EG) is a special form of flake graphite that contains strongly acidic intercalated anions The industrialscale preparation of EG primarily involves chemical oxidation Flake graphite loses electrons under the oxidation of strong agents such as KMnO 4 , HNO 3 , and H 2 O 2 (Chua et al, 2012, Sorokina et al, 2007), typically represented as C n + Experimental exploration of methanecoal dust explosion 2023年11月30日 Highlights Ca/Zn‐ stearate, expandable graphite developed by a safe hydrothermal process Comprehensive analysis indicates improved thermal stability Safe stabilization of eco‐friendly (PDF) Utilizing a blend of expandable graphite and calcium/zinc

.jpg)

Graphite manufacturing process SubsTech

2023年12月13日 The resulted powder is conditioned according to the particles size distribution (screening) The last step of powder preparation process is blending the powder with a binder Coal tar pitch, petroleum pitch or synthetic resins are used as binders The powder preparation process is presented in the scheme below to topHPMS Graphite expandable graphite is manufactured from natural crystalline graphite flake through an intercalation chemical process The expandable graphite is low in density and halogenfree The expansion temperature starts at 150 to 220 °C, and the expansion volume can be as high as 350 times its original volumeExpandable Graphite Flakes HPMS Graphite2023年10月22日 Yang et al produced an expandable graphite (EG)/cellulose nanofiber (CNF)/polyethylene oxide (PEO) composite material that relied on this exfoliation process At a ratio 95:5:3 the material exhibited an electrical conductivity of 1226 S cm –1 and a thermal conductivity 3023 W m –1 K –1 Comparison of the Synthesis, Properties, and Applications of Graphite Unexpanded graphite on the left side and the same quantity of graphite, expanded on the right side Expandable graphite is produced from the naturally occurring mineral graphite [1] The layered structure of graphite allows some molecules to be intercalated in between the graphite layers Through incorporation of acids, usually sulfuric acid graphite can be converted into Expandable graphite Wikipedia

Graphite foam from pitch and expandable graphite University

particles together with their internal porosity During the foaming process the pitch tends to coat the outside surface of the expanding graphite flakes It also bonds them together The graphite foam prepared with 5 wt% expandable graphite had a bulk density of 0249 g cm3, a compressive strength of 046 MPa and a thermal conductivity of 21 This is typically the first stage of the particle size separation and selection process 4 Vibration and Sieving After the powder is milled in the centrifuge system and the larger and heavier particles are separated, the next step in the graphite manufacturing process is to subject the powder to a vibration and sieving operationGraphite Manufacturing Process Flowchart MWI, Inc2021年11月24日 Graphene, which is made up of singlelayer sp2 graphite, has stimulated the interest of researchers in a variety of application fields, including electronics, pharmaceuticals, and chemicals, due to its superior properties Largescale production of graphene is essential for the material to be viable and widely used One of the most efficient methods of accomplishing Recent advances of the graphite exfoliation processes and 2021年12月24日 Graphene is a unique attractive material owing to its characteristic structure and excellent properties To improve the preparation efficiency of graphene, reduce defects and costs, and meet the growing Graphene Synthesis: Method, Exfoliation

.jpg)

Process flow from graphite to grapheneoxide

Download scientific diagram Process flow from graphite to grapheneoxide from publication: Removal of heavy metal ions from pharmaeffluents using grapheneoxide nanosorbents and study of their Natural Expandable Graphite Powder Natural mineral graphite is very heat conductive and thermal diffusive It has many favorable qualities and is an environmentally friendly raw material that is used for leads, recarburiser, coatings, refractory products, lubricants and in the powder metallurgy industryGraphite Powder GES Europe GmbHSince the material needs to spend a certain amount of time in each temperature zone, it takes up to several weeks for a part to enter the oven and come out as plain carbon graphite The diagram above shows a microscopic view of “green” carbon graphite The diagram above shows carbon graphite that has been sent through the baking processFrom Powders to Parts: CARBON Graphite MANUFACTURING Process So the ore beneficiation process goes: raw orecrushing processmilling processflotation processdewatering processdrying processpowder making processclassifying process and packing process Cryptocrystalline graphite ore beneficiation process in Kayserberg, Austria includes the direct powder making dry process and flotation wet processGraphite ore flotation processing flow chart

.jpg)

SIGRATHERM ® Highly Conductive Expanded Graphite Powder

What is expanded graphite powder? Expanded graphite powder – also known as flexible graphite powder, exfoliated graphite powder, expanded natural graphite powder or just graphite powder – is produced from purified natural graphite flakes The graphite flakes are mixed with a highly oxidizing acid to form an intercalation compound which is Modern graphite manufacture commences with a high molecular weight hydrocarbon, often natural pitch or a residue of crude oil distillation, which is first converted to coke by heating in the absence of air This is long and complex process, usually taking several weeks to performOpen Knowledge Wiki Manufacturing and Production of Graphite The XPS process utilizes a continuous extrusion process to create slabs of foam An example of a XPS process is shown below, showing the addition of a powder (via masterbatch) being performed at the initial step of extrusion Additives introduced — Figure 1 — There are several ways of making EPS foamsPolystyrene Insulation Rvalue Enhancements Using Graf+® Graphite There are many kinds of artificial graphite and different production processes In a broad sense, all graphite materials obtained by carbonization of organic matters and treated by high temperature after being treated with graphite can be collectively referred to as artificial graphiteIn the narrow sense, artificial graphite usually refers to the massive solid materials prepared by Graphite Production Process Artificial graphite FRANLI

.jpg)

Expandable Graphite NGS

NGS fine expandable graphite powder grade Ex 200 95 40 (neutral pH) particle size approx 85 % finer than 200 mesh = 75 µm pH value of the flake surface 6 8 activation temperature approx 200 °C expansion volume at 1000 °C 40 cm³/g 2020年6月1日 As a result, simpler and more environmental friendly routes have recently been reported For instance, Expandable graphite was prepared by a onestep process at room temperature, which might be suitable for synthesis of EG[14] Nevertheless, long reaction times are required for this process, which limits its applicationRapid preparation of expanded graphite at low temperatureThe method for making graphite is expandable (K 2 HPO 4 3H 2 O–NaH 2 PO 4 2H 2 O–Na 2 S 2 O 3 5H 2 O–H 2 O) in expanded graphite through an impregnation process with an adsorption capacity of 8071 wt% The phase change temperature, latent heat, The graphite powder was dried in a vacuum oven at 70 °C for 20 h, Expanded Graphite an overview ScienceDirect Topics3 天之前 Expandable graphite (EG) is a special form of flake graphite that contains strongly acidic intercalated anions The industrialscale preparation of EG primarily involves chemical oxidation Flake graphite loses electrons under the oxidation of strong agents such as KMnO 4 , HNO 3 , and H 2 O 2 ( Chua et al, 2012 , Sorokina et al, 2007 ), typically represented as C n + Experimental exploration of methanecoal dust explosion

EXPANDED PROCESSED EXPANDED GRAPHITE

Due to the layered structure of graphite, atoms or small molecules can be introduced between the carbon layers (intercalation) During this process a socalled expandable graphite salt or GIC (Graphite Intercalation Compound) is produced Outstanding expandable graphite grades have a high proportion of intercalated layersGraphite powder process smoothing agent, a pair of heater 5,2, singlelayer flat plate rolling method single layer flat plate rolling, with 156 graphite plate and density 17 graphite plate service life can be separated by 3 months, it is this incomparable advantage, graphite powder process (4) no burr; Copper electrode in the processing is completed, graphite products has been widely Graphite powder process FRANLIExpandable graphite powder Expandable graphite powders are made from natural flake graphite treated by chemical or electrochemical processes They can expand 150250 times in volume at high temperature with large surface area, high surface energy, good flexibility, resilience and plasticity etc Natural highpurity graphite powderGraphite Flakes/Powder CGT CarbonExpandable graphite is produced through a process of subjecting flake graphite to high temperature treatment This versatile material has a wide range of applications, including its use in the production of graphite paper, fireproof adhesive tape, and for sealing purposes in various industries, such as the battery industryExpandable GraphiteGraphite Sourcepro

How Does The Graphite Grinding Plant Process?

2024年9月20日 2 Impact crusher The impact crusher can process materials with a side length of 100500 millimeters or less, with a maximum pressure resistance of 350 MPA It has the advantages of a large crushing ratio and with cubic material particles This machine is widely used in building materials, ore crushing, railways, highways, energy, transportation, cement, mining, 2006年11月1日 PDF Results obtained in synthesis of thermally expanded graphite by chemical and electrochemical methods with sulfuric and nitric acids are Find, read and cite all the research you need on (PDF) Thermally expanded graphite: Synthesis, properties, and prospects