Heavy calcium powder crushing parts

Heavy calcium carbonate grinding, surface modification

2024年7月10日 Heavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing using calcite, chalk, marble and other minerals as raw materials It has the characteristics of wide raw material sources, high whiteness, low oil absorption value, good 2023年9月19日 Heavy calcium carbonate (heavy calcium) is made by directly crushing natural limestone, calcite, etc, by mechanical methods (Raymond mill or ultrafine vertical grinding mill and other grinding equipment) Its production Calcium carbonate milling process SBM Ultrafine Here is a detailed introduction to the main equipment involved in the production of ultrafine heavy calcium powder: 1 Crushing equipment: Before grinding, the calcium carbonate raw material Production and processing equipment for ultrafine heavy calcium 2024年8月23日 Among them, the dry process is generally used to produce heavy calcium carbonate products with d97≥35μm The main crushing equipment includes Raymond mill, impact mill, dry stirred mill, air flow mill, Heavy calcium carbonate dry production process and

.jpg)

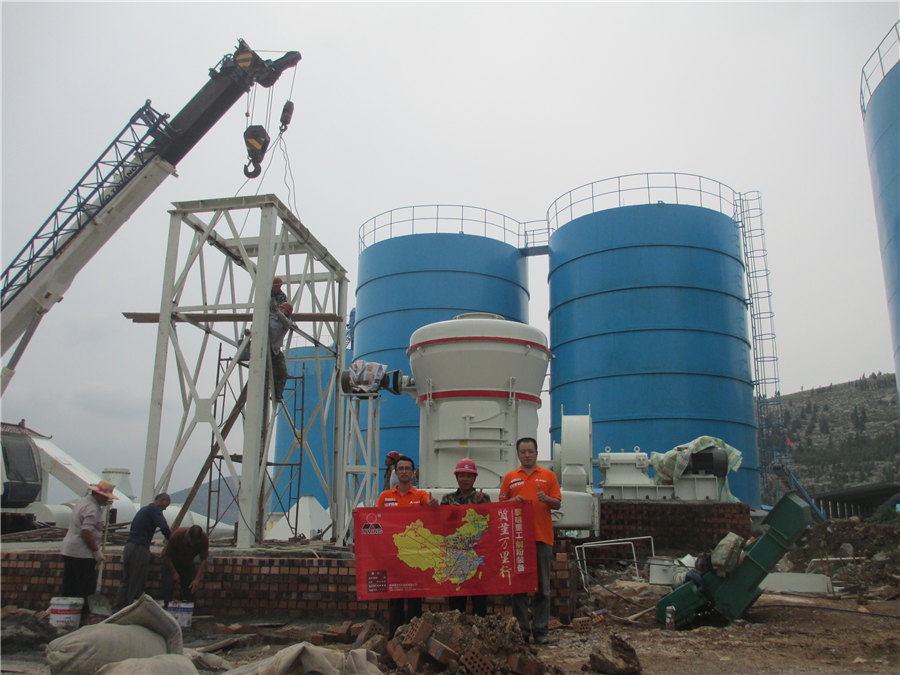

The heavy calcium powder production equipment(capacity: 6

2016年12月6日 Fengli Machinery designed 68 tons 400 mesh heavy calcium powder production technology and equipment selection: The first stage: Crushing Natural carbonate minerals Limestone can be directly crushed to obtain heavy calcium carbonate According to the different grinding fineness, there are four different specifications in the industry: single flight, double flight, three flight, and four flight, which are used Limestone Ultrafine Grinding MillThe calcium carbonate grinding production line provides an efficient, environmentally friendly, and stable solution for the production of calcium carbonate powder, meeting the needs of different Calcium Carbonate Grinding Production Line TAYMACHINERY2021年12月20日 Heavy machinery is primarily used during the dry processing phase, when calcium carbonate manufacturing processes focus on reduction through milling, crushing, and screening, whereas air classification is generally Calcium Carbonate Manufacturing Process and

For Sale: Heavy Calcium Carbonate Crushing Process Equipment

The Heavy Calcium Carbonate Crushing Process: Customized Crushing: The equipment for sale is designed specifically for the crushing of heavy calcium carbonate It can handle a variety of 2023年10月10日 Developing a simple and efficient crushing process and controlling the particle size and shape of the product are the keys to obtaining highquality ultrafine calcium carbonate and improving its economic benefits Typical processes and equipment for ultrafine grinding the heavy calcium carbonate in the method for producing a heavy calcium carbonate slurry, may be calcite crystal heavy calcium carbonate Further, in a preferred embodiment of the present invention, the method for producing a heavy calcium carbonate slurry has a volume average particle diameter of 00001 Y to 00001 Y and 00 1 to 04 ⁇ m, and the heavy calcium Dispersant for the wet grinding of heavy calcium carbonate2023年11月8日 The HGM125L highend calcium oxide ultrafine powder grinding production line equipped with SBM micro powder technology has been put into use, bringing customers unexpected high energy efficiency and high profits! Highend calcium oxide ultrafine powder making

Application of filter press in heavy calcium carbonate industry

2024年2月26日 Ground calcium carbonate, referred to as heavy calcium carbonate GCC, is nontoxic, tasteless, good in color, high in whiteness, and stable in chemical properties It is mainly used in plastics, papermaking, rubber, cables, paint 2024年7月12日 Due to the relatively high impurities, the whiteness of heavy calcium carbonate is generally 89% to 93%, and very few products can reach 95%; The purity of light calcium carbonate products is relatively high, so the whiteness is generally 92% to 95%, and some products can reach 96% to 97% 7 Specific surface area The specific surface area of Heavy calcium and light calcium, 10 essential differences2024年11月1日 In this study, the ceramic cores were printed with heavy calcium carbonate (HCC, CaMg(CO 3) 2) powder as raw material and Al powder as additive by binder jetting (BJ)The ceramic cores were impregnated with nanoZrO 2 dispersion solution and then sintered at high temperature to prepare the ceramic cores with low sintering shrinkage The effects of Significantly improved sintering shrinkage of heavy calcium Heavy calcium powder: using highquality limestone as raw material, it is processed into white powder by lime mill Light calcium powder: limestone and other raw materials are burned to generate lime (the main component is calcium oxide) and carbon dioxide, and then water is added to digest the lime to generate lime milk (the main component is Light Calcium Superfine Vertical Mill

.jpg)

The difference between light calcium and heavy calcium

2023年11月15日 The granular form of heavy calcium can promote fluidity, and the amount added is not limited If more than 25 parts of calcium carbonate are added to the PVC pipe formula, it is best to use heavy calcium from the perspective of fluidity 12 Price The processing of heavy calcium is mainly achieved through mechanical crushing and grinding2023年4月27日 3 Heavy calcium is made from natural ore crushing Light calcium is produced artificially It has a large amount of application in coatings 4 Heavy calcium is stable, but relatively light calcium is easy to settle 5 Light calcium is better at settling But the oil absorption is greater than heavy calcium The price is generally more The difference between calcium carbonate heavy and calcium 2021年8月5日 Heavy calcium powder for paper industry – heavy calcium carbonate (heavy calcium powder) for papermaking: 325 mesh, whiteness requirement: 95%, calcium carbonate content: 98% Calcium carbonate plays an important role in the paper industry It can ensure the strength and strength of paper Whiteness, and low costCalcite Industrial Ultrafine Powder Grinder2022年11月12日 calcium carbonate powder is an important inorganic Drying (moisture content below 03%), cooling, crushing and sieving to produce light calcium carbonate finished products Its CaCO3 → CO2 The raw material for wet grinding calcium by grinding method is heavy calcium carbonate or calcite with whiteness> 93 degrees and Calcium Carbonate Heavy Request for Quotation ChemBK

.jpg)

Customize Suitable Calcium Carbonate Plant DASWELL

The core part of calcium carbonate plant, the grinding mills of Daswell, whether ball mills with classifier or wet grinding mills, can produce ground calcium carbonate powder in various particle sizes from fine to ultra fine GCC powder Various calcium carbonate powder production capacity available According to customer’s needs, Daswell can Heavy Calcium Carbonate(Powder) It is manufactured crushing and screening limestone We can produce various size of particle from superfine ground product to granular product to adapt various use It is mainly used for rubber, resin, and paint 【Uses】Lime Processed Product ListProduct InformationYabashi 2024年3月21日 Heavy calcium carbonate is physical grinding and crushing of marble, limestone, dolomite and calcite through Raymond mill, vertical mill, ball mill and other equipment to obtain 1003000 mesh powder, and the sedimentation volume is smaller than that of light calcium carbonate ApplicationGeneral Introduction of Calcium Carbonate Powder ChemicalBookProduct name:Calcium carbonate Form: powder Specification: 325mesh 1250mesh Colors: white CAS No:471341 Calcium carbonate Packing and shipping: 25kgs/bag, 1 ton/ton bag, or as required Ports of delivery are Tianjin, Qingdao, and Dalian port Calcium carbonate Storage: Storage in a ventilated lowtemperature dry warehouseWholesale/Bulk Calcium Carbonate, Heavy and Light Calcium Carbonate Powder

.jpg)

The advantages of ultrafine vertical mill in the processing and

2023年3月21日 Application of ultrafine vertical mill in the processing and production of ultrafine heavy calcium Considering the diversified needs of heavy calcium powder products, the “CLUM ultrafine vertical mill + secondary (or tertiary)” classification process is often used in the design of vertical grinding powder engineering systems There are two reasons:The ultrafine grinding of heavy calcium powder is essential to improve its application range and performance 1 Introduction Heavy calcium powder, also known as calcium carbonate, is a commonly used filling material in the industries of plastics, rubber, paper, paint, and pharmaceuticals The particle size of heavy calcium powder directly UltraFine grinding processing method and flow of heavy calcium powder 2024年6月7日 It can produce 325mesh2500mesh product fineness at one time, from coarse powder to superfine powder, and the fineness of the finished product can reach D97≤5μm At the same fineness, compared with ball mill , impact mill, jet mill and stirring mill, ring roller mill has higher production efficiency, lower energy consumption and lower production costRoller Mill Calcium Carbonate Production Line4、 Heavy calcium powder for waterbased paint industry heavy calcium carbonate (heavy calcium powder) 800 mesh or 1000 mesh for waterbased paint, whiteness: 95%, calcium carbonate: 96%, calcium carbonate is more widely used in the waterbased coating industry, It can make the paint nonsedimentation, easy to disperse, good gloss and other characteristics, China Heavy Calcium Carbonate Manufacturers, Suppliers, Factory

Limestone Ultrafine Grinding Mill

Limestone ultrafine grinding mill can process fine limestone powder, fineness: 1503000 mesh adjustable It has stable operation, Limestone can be used to produce Portland cement and to produce coated heavy calcium carbonate products for highend papermaking Various transmission parts must be fastened and reliable, HCH1395 heavy calcium(GCC) ultrafine mill is a new generation of largescale highefficiency heavy calcium(GCC) micropowder grinding mill independently developed by HCMilling(Guilin Hongcheng) It draws on the working principle of the traditional ring roller mill and improves the shape, size and quantity matching of the grinding rollersNews Application of HCH1395 Heavy Calcium(GCC) Ultrafine Buy Calcium Carbonate (CaCO3) Technical Grade 1Kg Powder online today! Product details of Calcium Carbonate (CaCO3) Technical Grade 1Kg Powder Calcium Carbonate CaCO3 TECHNICAL GRADE 1 Kilogram Ready to use Calcium Carbonate (CaCO3) Technical Grade 1Kg 2020年12月10日 In the past, due to the limitation of crushing equipment, heavy calcium carbonate could not reach this fineness Now, the particle size of heavy calcium carbonate can fully meet the needs, even finer than light calcium 【Technical analysis】How to choose “industrial

.jpg)

CNA Heavy calcium carbonate modifier Google

CNA CN70A CN7A CNA CN A CN A CN A CN 7 A CN7 A CN 7A CN A CN A CN A Authority CN China Prior art keywords calcium carbonate component heavy calcium vinyl hydrogen Prior art date Legal The following provides an overview on how, and why, to pelletize a fine powder Why Pelletize Fine Powder? Anyone working with bulk solids in the form of a fine powder can attest to the numerous challenges it can present Through pelletizing, however, these challenges can be transformed into benefits, including: Cleaner Handling FlowabilityHow to Pelletize a Fine Powder FEECO International IncCalcium carbonate has the molecular formula of CaCO 3 and the molecular weight of 1000924 g/mol It is a common substance found in rock in all parts of the world, and is the main component of the shells of many marine organisms such as snails and conches It is the main ingredient in eggshells of birds and pearls obtained from oystersCalcium Carbonate an overview ScienceDirect TopicsNote: This specification is just referencing, any changes are subject to the products Shanghai clirik machinery co, LTD Should you have any questions on our powder grinder; micro powder grinder; industrial powder grinder; fine powder grinder; powder grinder series; powder grinder machineease do not hesitate to contact us Phone: ;86Heavy calcium carbonate micro powder grinderHeavy calcium

Guide to Calcium Carbonate Grinding: Mills, Tips, and Uses

2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the mill Grinding: Use a bucket elevator to send the crushed small pieces of calcium carbonate to the silo, then use a vibrating feeder to send them 1 Importance of 1500 Mesh Heavy Calcium Carbonate Powder The 1500 mesh heavy calcium carbonate powder refers to a powder with a particle size of approximately 10 microns This ultrafine powder offers several advantages: Enhanced Whiteness and Purity The ultrafine powder has a higher degree of whiteness and purity, making it suitable for Processing of 1500 mesh heavy calcium carbonate powder with Heavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing method using calcite, chalk, marble and other ores as raw materials It has the characteristics of wide source of raw materials, high whiteness, low oil absorption value, good applicability and low pricNews Calcium powder processing machinery and equipment the heavy calcium carbonate in the method for producing a heavy calcium carbonate slurry, may be calcite crystal heavy calcium carbonate Further, in a preferred embodiment of the present invention, the method for producing a heavy calcium carbonate slurry has a volume average particle diameter of 00001 Y to 00001 Y and 00 1 to 04 ⁇ m, and the heavy calcium Dispersant for the wet grinding of heavy calcium carbonate

Highend calcium oxide ultrafine powder making

2023年11月8日 The HGM125L highend calcium oxide ultrafine powder grinding production line equipped with SBM micro powder technology has been put into use, bringing customers unexpected high energy efficiency and high profits! 2024年2月26日 Ground calcium carbonate, referred to as heavy calcium carbonate GCC, is nontoxic, tasteless, good in color, high in whiteness, and stable in chemical properties It is mainly used in plastics, papermaking, rubber, cables, paint Application of filter press in heavy calcium carbonate industry2024年7月12日 Due to the relatively high impurities, the whiteness of heavy calcium carbonate is generally 89% to 93%, and very few products can reach 95%; The purity of light calcium carbonate products is relatively high, so the whiteness is generally 92% to 95%, and some products can reach 96% to 97% 7 Specific surface area The specific surface area of Heavy calcium and light calcium, 10 essential differences2024年11月1日 In this study, the ceramic cores were printed with heavy calcium carbonate (HCC, CaMg(CO 3) 2) powder as raw material and Al powder as additive by binder jetting (BJ)The ceramic cores were impregnated with nanoZrO 2 dispersion solution and then sintered at high temperature to prepare the ceramic cores with low sintering shrinkage The effects of Significantly improved sintering shrinkage of heavy calcium

Light Calcium Superfine Vertical Mill

Heavy calcium powder: using highquality limestone as raw material, it is processed into white powder by lime mill Light calcium powder: limestone and other raw materials are burned to generate lime (the main component is calcium oxide) and carbon dioxide, and then water is added to digest the lime to generate lime milk (the main component is 2023年11月15日 The granular form of heavy calcium can promote fluidity, and the amount added is not limited If more than 25 parts of calcium carbonate are added to the PVC pipe formula, it is best to use heavy calcium from the perspective of fluidity 12 Price The processing of heavy calcium is mainly achieved through mechanical crushing and grindingThe difference between light calcium and heavy calcium2023年4月27日 3 Heavy calcium is made from natural ore crushing Light calcium is produced artificially It has a large amount of application in coatings 4 Heavy calcium is stable, but relatively light calcium is easy to settle 5 Light calcium is better at settling But the oil absorption is greater than heavy calcium The price is generally more The difference between calcium carbonate heavy and calcium 2021年8月5日 Heavy calcium powder for paper industry – heavy calcium carbonate (heavy calcium powder) for papermaking: 325 mesh, whiteness requirement: 95%, calcium carbonate content: 98% Calcium carbonate plays an important role in the paper industry It can ensure the strength and strength of paper Whiteness, and low costCalcite Industrial Ultrafine Powder Grinder