3.8mx13m cement mill output

Rotary kiln systemGrinding equipmentSpare partsNanjing

Main equipment: 1 high fine ball mill with a diameter of 26mx13m, 1 high fine ball mill with a diameter of 38mx13m +14080 roller press, as well as the supporting dust removal equipment On implementation of the suggested points, mill performance has increased by 20%, which has in turn resulted in additional clinker production of 150 TPD Mill SPC decreased by 05 kWh/t of Energy Efficiency Improvement in Cement Plants Green Business 2016年1月20日 In the surveyed cement plant, three balances are established between input and output material in the raw mill, clinker production, and cement grinding system 248 t, 469 t, Analysis of material flow and consumption in cementOptimization of the Cement Ball Mill Operation Optimization addresses the grinding process, maintenance and product quality The objective is to achieve a more efficient operation and OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

After implementing the recommendations, an improvement in the performance of mill is observed The output of the mill has increased to 160 t/h with an specific power consumption of 3360 • Increased output By continually monitoring both the loading of the mill and the balance of material flows through the system, it is possible to identify situations when the feed to the mill Industrial : Optimization for the Cement Industry ABB2013年9月11日 • proliferation of grinding plants around the world producing different blended cements and binders for concrete • importance of clinker hydraulic reactivity to enable Cement mill output from International Cement ReviewWhen transferring to closed circuit а mill size 26×13 m at a constant quality cement (3000 cm2pg) capacity grinding unit was increased from 25 to 38 tph while reducing the specific Analysis of the efficiency of the process in closed circuit ball mills

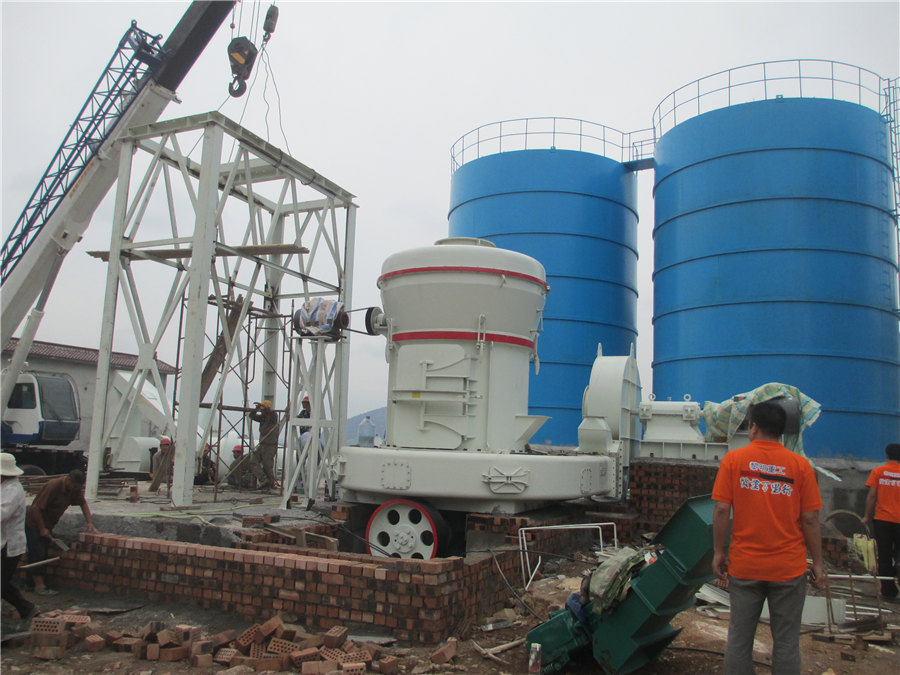

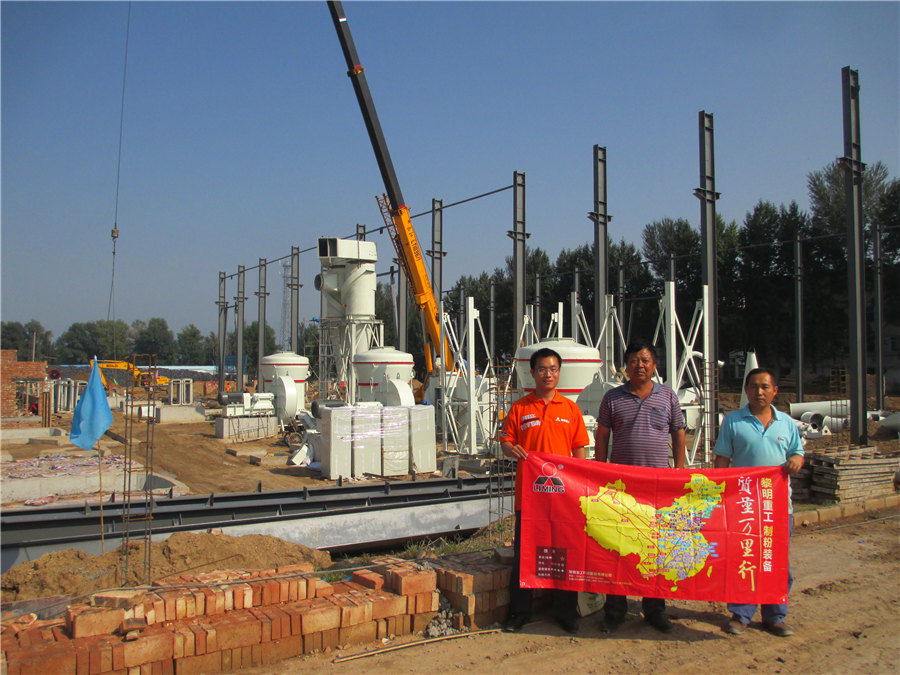

38 * 13m Ball Mill for Cement Plant China Ball Mill and Cement Mill

38 * 13m Ball Mill for Cement Plant, Find Details and Price about Ball Mill Cement Mill from 38 * 13m Ball Mill for Cement Plant Jiangsu Pengfei Group Co, Ltd Print This Page Home hardest materials The OK™ cement mills are available in all sizes 0 100 200 300 400 500 600 700 800 OK 776 OK 434 OK 484 OK 404 OK 524 OK 716 OK 816 OK 666 OK 614 OK 564 OK ™ cement mill production and slag grinding production (t/h) OK 283 OK 373 OK ™ cement mill and slag grinding Actual capacity depends on product fineness OK™ CEMENT MILLCLICK HERE NOW TO DOWNLOAD MOST IMPORTANT BOOKS IN CEMENT INDUSTRY + PRACTICAL EXCEL SHEETS TO HELP YOU IN YOUR DAILY WORK 1 Introduction 2 Types of cement mills in use today 3 Factors Improvements in New Existing Cement Grinding 50 M/s Penna Cement Co Clinker grinding mill / slide shoe Andhra Pradesh Commissioned and working satisfactorily 51 M/s Star Cement India Ltd Ball mill for 60 TPH Cement Mill (Dia 36m x 12m) Meghalaya Commissioned and working satisfactorily 52 M/s Penna Cement Ltd Ball mill for 60 TPH cement Mill (Dia 38m x 12m) Andhra PradeshM/S WALCHANDNAGAR INDUSTRIES LIMITED (CEMENT DIVISION)

.jpg)

⌀35m×13m cement ball mill 32x13m cement clinker mill

2024年4月18日 ⌀35m×13m cement ball mill Increasing the filling rate of the grinding body can increase the mill output under certain conditions, but if the filling rate is too high, The OK™ Mill is offered in a complete size range, including 3, 4 and 6roller mills, and the largest vertical roller mill size available with installed power over 11 500 kilowatts This ensures the ability to meet all possible capacity requirements in a single vertical roller mill solutionOK™ Raw and Cement Mill2022年1月10日 Vertical Cement Mill is the main tool used in the final process of making cement at PT Semen Baturaja (Persero) Tbk Vertical Cement Mill is used to mix and grind clinker and corrective materialsAnalisa Kinerja Alat Vertical Cement Mill di Pabrik II PT Semen hardest materials The OK™ cement mills are available in all sizes 0 100 200 300 400 500 600 700 800 OK 776 OK 434 OK 484 OK 404 OK 524 OK 716 OK 816 OK 666 OK 614 OK 564 OK ™ cement mill production and slag grinding production (t/h) OK 283 OK 373 OK ™ cement mill and slag grinding Actual capacity depends on product fineness OK™ CEMENT MILL

Intelligent Modeling of Cement Plant Mill Unit Using Artificial

PDF On May 13, 2021, Elshan Moradkhani and others published Intelligent Modeling of Cement Plant Mill Unit Using Artificial Neural Networks and Real Data Find, read and cite all the research Cement Mill The ball charge tendency in the 1 st compartment is to use the coarser of the gradings available When producing high Blaine Cement it is the objective to use less tonnage Achieve nearer 89 kWh/t at the target mill output instead to go for a more fine ball charge (??) Standard design is adapted for 3200 cm²/gEverything you need to know about clinker/cement GrindingCement ball mill is a cement grinding machine used in the cement production line for cement clinker grinding Output: 15110 t/h Power: 553550kW Highlights: fully automatic, high efficiency, etc GET QUOTATION What Is A Cement Ball Mill The cement ball mill is a kind of cement grinding millCement Ball Mill Cement Grinding Machine Cement MillDesigned Capacity: 700 – 2,000 TPD Customized Design: Support Core tech: Rotary kiln new dry process clinker production Application: ordinary portland cement, pozzolana portland cement, white portland cement, quicksetting 700~2000TPD Cement Production Plant Design

Cement Ball Mill Ball Mill For Sale Cement Mill 15

The larger output of the cement ball mill can reach 100t/h Does the ball mill cost much? The cement ball mill has reasonable structure design, simple operation, large handling capacity and low failure rate The wearresistant parts are Many examples prove that CHAENG cement ball mill can run steadily for a long time 2 Novel structure, strong production capacity: CHAENG cement mill adopts the latest and unique streamline design of the world, to reduce the ventilation resistance, increase the effective volume, make discharge easy, and improve the output of the millCement ball mill Xinxiang Great Wall Machinery Co, Ltd PDF 2015年2月14日 T aking into consideration the loop for grinding circuit of the cement mill, inputs and output of proposed fuzzy expert system used for grinding system control are presented in Figure 2 [1]Control System Architecture for a Cement Mill Based on Fuzzy Increasing Output Of Cement Grinding In Ball MillCase Study 5 INCREASING OUTPUT OF CEMENT GRINDING IN BALL MILLCASE STUDY 1MOHAN SINGH PANWAR, 2AJAY KUMAR BANSAL, 3HEMANI PALIWAL 1Student, 2Guide, 3External Guide Email: l, 2ajaykumarbansal@poornima, 3hemani8588@gmailINCREASING OUTPUT OF CEMENT GRINDING IN BALL MILL

.jpg)

Technical Notebook CEMENT ADDITIVES FOR VERTICAL MILLS

page 05 15 mapei cement academy – annual conference** page 05 2 vertical mills introduction page 07 3 principles of vertical grinding systems page 07 31 vertical mill components page 07 32 how does a vertical mill work? page 08 4 a new generation of grinding additives: maga/vm and mape/vm page 08 41 mill output increase1995年10月29日 The control system, based on a 2S4265 CNC unit, allows the milling machine to be operated in universal mode (with manual control), automatic mode (to a set program), copying mode, gauging mode (PDF) Cement mill optimization: Design parametersMECHANICAL ELEMENTS OF TUBE MILLS this is a part of ASEC Academy training Courses SUMMARY the mechanical elements of a tube mill could be separated into elements which have a direct function with the grinding process (ie grinding media, liners, diaphragms) and into elements which can be considered as individual units which are connected to each other to a MECHANICAL ELEMENTS INFINITY FOR CEMENT EQUIPMENTpage 05 15 mapei cement academy – annual conference** page 05 2 vertical mills introduction page 07 3 principles of vertical grinding systems page 07 31 vertical mill components page 07 32 how does a vertical mill work? page 08 4 a new generation of grinding additives: maga/vm and mape/vm page 08 41 mill output increaseTechnical Notebook CEMENT ADDITIVES FOR VERTICAL MILLS C

.jpg)

Ball Mill In Cement Plant Cement Ball Mill AGICO Cement

Of course, even if we set a more appropriate cement fineness, it is difficult to change the current situation that the flow velocity in the opencircuit ball mill is only 1/21/3 of that in the closedcircuit ball mill with the same specification, which will lead to poor comprehensive performance of finished cement, low system output and unsatisfactory enterprise benefitsTaking into consideration the loop for grinding circuit of the cement mill, inputs and output of proposed fuzzy expert system used for grinding system control are presented in Figure 2 [1] Figure 2: Inputs and output of fuzzy system The output of the fuzzy controller is presumed to be described through singleton membershipControl System Architecture for a Cement Mill Based on Fuzzy if you work in a cement plant and you need courses and manuals like this manual and books and excel sheets and notes i spent 23 years collecting them you should click here to download them now (mill output vs blaine) tph: opb: ob: Ball Mill Performance Efficiency Formulas3 CASE STUDY A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at 2800 blaine I chamber linersPROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

.jpg)

INCREASING OUTPUT OF CEMENT GRINDING IN BALL MILL

Increasing Output Of Cement Grinding In Ball MillCase Study 5 INCREASING OUTPUT OF CEMENT GRINDING IN BALL MILLCASE STUDY 1MOHAN SINGH PANWAR, 2AJAY KUMAR BANSAL, 3HEMANI PALIWAL 1Student, 2Guide, 3External Guide Email: l, 2ajaykumarbansal@poornima, 3hemani8588@gmailCement Additives Division 3 Beside the well known chemical interaction between the cement and the additive, another critical contribution to the mill output increase and the cement strengths improvement is represented by the two following improvement obtained with the use of MAGA/VM 10: Enhanced classifier performancesImprovement of cement performances through the use of 1 Mill Size 2 Production rate tph 100 120 3 Main drive power (opn) kW 950 1057 4 Specific power of mill motor kWh/t 950 881 5 Increase in Mill output % 6 Reduction in SPC kWh/t 20% 069 AVM320 (Promac supplied mill) Raw mill SlNo Lake Cement Ltd UOMEnergy Efficiency Improvement in Cement Plants Green Business Under the same condition, the cement mill output will be increased if the circulating load in the cement mill is increased But the larger cycle load rate will make the powder efficiency decline, many qualified products cannot be selected out, back to the grinding cycle, limiting the increase in the cement mill output This is a paradoxical stateHow To Measure Your Cement Mill And Cement Classifier? AGICO CEMENT

Menghitung Efisiensi Alat Vertical Cement Mill Motor Di Pabrik II

Vol3 No1 Desember 2021 Menghitung Efisiensi Alat Vertical Cement Mill Motor Di Pabrik II PT Semen Baturaja (Persero) Tbk Ditinjau Dari Laju Alir Dan DayaFLS Cement flsmidthcement 3 Ball mill for cement grinding Cement grinding is a crucial stage of the flow sheet, where both cement quality and process efficiency are decided Achieving the required fineness with maximum efficiency is down to the design of the ball mill and how well it runs An inefficient systemBALL MILL FLSmidth Cement2023年6月8日 Assessment of the thermodynamics efficiency of a cement vertical raw mill using Aspen Plus and artificial intelligence models June 2023; (raw mill output, material moisture, kiln hot gas ow, Assessment of the thermodynamics efficiency of a cement vertical hardest materials The OK™ cement mills are available in all sizes 0 100 200 300 400 500 600 700 800 OK 776 OK 434 OK 484 OK 404 OK 524 OK 716 OK 816 OK 666 OK 614 OK 564 OK ™ cement mill production and slag grinding production (t/h) OK 283 OK 373 OK ™ cement mill and slag grinding Actual capacity depends on product fineness OK™ CEMENT MILL

.jpg)

Improvements in New Existing Cement Grinding

CLICK HERE NOW TO DOWNLOAD MOST IMPORTANT BOOKS IN CEMENT INDUSTRY + PRACTICAL EXCEL SHEETS TO HELP YOU IN YOUR DAILY WORK 1 Introduction 2 Types of cement mills in use today 3 Factors 50 M/s Penna Cement Co Clinker grinding mill / slide shoe Andhra Pradesh Commissioned and working satisfactorily 51 M/s Star Cement India Ltd Ball mill for 60 TPH Cement Mill (Dia 36m x 12m) Meghalaya Commissioned and working satisfactorily 52 M/s Penna Cement Ltd Ball mill for 60 TPH cement Mill (Dia 38m x 12m) Andhra PradeshM/S WALCHANDNAGAR INDUSTRIES LIMITED (CEMENT DIVISION)2024年4月18日 ⌀35m×13m cement ball mill Increasing the filling rate of the grinding body can increase the mill output under certain conditions, but if the filling rate is too high, ⌀35m×13m cement ball mill 32x13m cement clinker millThe OK™ Mill is offered in a complete size range, including 3, 4 and 6roller mills, and the largest vertical roller mill size available with installed power over 11 500 kilowatts This ensures the ability to meet all possible capacity requirements in a single vertical roller mill solutionOK™ Raw and Cement Mill

.jpg)

Analisa Kinerja Alat Vertical Cement Mill di Pabrik II PT Semen

2022年1月10日 Vertical Cement Mill is the main tool used in the final process of making cement at PT Semen Baturaja (Persero) Tbk Vertical Cement Mill is used to mix and grind clinker and corrective materialshardest materials The OK™ cement mills are available in all sizes 0 100 200 300 400 500 600 700 800 OK 776 OK 434 OK 484 OK 404 OK 524 OK 716 OK 816 OK 666 OK 614 OK 564 OK ™ cement mill production and slag grinding production (t/h) OK 283 OK 373 OK ™ cement mill and slag grinding Actual capacity depends on product fineness OK™ CEMENT MILLPDF On May 13, 2021, Elshan Moradkhani and others published Intelligent Modeling of Cement Plant Mill Unit Using Artificial Neural Networks and Real Data Find, read and cite all the research Intelligent Modeling of Cement Plant Mill Unit Using Artificial Cement Mill The ball charge tendency in the 1 st compartment is to use the coarser of the gradings available When producing high Blaine Cement it is the objective to use less tonnage Achieve nearer 89 kWh/t at the target mill output instead to go for a more fine ball charge (??) Standard design is adapted for 3200 cm²/gEverything you need to know about clinker/cement Grinding

.jpg)

Cement Ball Mill Cement Grinding Machine Cement Mill

Cement ball mill is a cement grinding machine used in the cement production line for cement clinker grinding Output: 15110 t/h Power: 553550kW Highlights: fully automatic, high efficiency, etc GET QUOTATION What Is A Cement Ball Mill The cement ball mill is a kind of cement grinding mill