Where is the limestone crusher smelting waste slag crushing needed

.jpg)

Slag Aggregate an overview ScienceDirect Topics

Slag aggregates are obtained by crushing of smelter slag or by special treatment of fireliquid slag melt (molten slag aggregates) Currently there are many types of concrete that are developed and used in construction that include metallurgical slags both as a binding component and as fillersLimestone can be crushed and used to build roads The waste slag from the blast furnace can also be used for this purpose Most limestone is obtained by quarrying, where the rock isLimestone [GCSE Chemistry only] Uses of limestone BBC2020年8月2日 The ferrochromium production company states that a slag that is rich in chromium content is obtained after smelting chromite ores This slag is crushed into small particles and Use of waste ferrochromium slag as aggregate in concreteThe limestone aggregates crushing generally has four steps: coarse crushing, sencondary crushing, sand making and screeningLimestone Aggregate Crushing JXSC Machine

.jpg)

Limestone – Its Processing and Application in Iron and IspatGuru

2017年7月7日 The first process takes place at limestone mines where the mined ore undergo crushing and screening for the separation of the different size fractions of the ore In the iron ‘slag’ generally refers to ground, granulated, iron blast furnace slag – with the descriptors to be explained and developed in this technical note In a general sense, the term ‘slag’ refers to a Ground Slag Properties, Characterisation and UsesSlag from steel mills in ferrous smelting is designed to minimize iron loss, which gives out the significant amount of iron, following by oxides of calcium, silicon, magnesium, and aluminium As the slag is cooled down by water, several Slag Wikipedia2015年6月1日 The results impact how slag waste is disposed, how slag waste piles are treated, and if and how slag is used as a resource for construction or environmental applications In Characteristics and environmental aspects of slag: A review

Limestone and Crushed Rock Department of Energy

The following lists the inputs and outputs for limestone and other crushed rock mining and processing Key inputs and outputs are: Inputs Electricity Fuels Water Outputs Dust Waste Williams Patent Crusher is committed to designing and manufacturing the most durable and efficient limestone crusher machines on the market We’ve held that commitment for over 150 years Additionally, since the mid1980s, we’ve Limestone Mills Limestone Crushers Pulverizers2022年2月26日 Blast furnace slag can be processed into the following materials by various processes In China, blast furnace slag is usually processed into water slag, slag gravel, expanded slag and slag beadsWater slag is the process of What is Blast Furnace Slag and How to Process It?If the gold item you are planning on smelting contains silver, copper or zinc, the level of heat necessary for smelting will be lower Another option for gold smelting is a 1,200watt microwave It is necessary that the magnetron in the Everything You Need to Know About the Process of

.jpg)

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesNomenclature and Terminology James G Speight PhD, DSC, in Asphalt Materials Science and Technology, 2016 1516 Slag Slag aggregates are obtained by crushing of smelter slag or by special treatment of fireliquid slag melt (molten slag aggregates) Currently there are many types of concrete that are developed and used in construction that include metallurgical slags both Slag Aggregate an overview ScienceDirect Topics2006年4月27日 This study highlights regional variation in the composition of ironsmelting slag produced in England prior to the medieval period and attempts to link slag composition to the type of ore smelted(PDF) Regional variation in bloomery smelting slag of2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of the comminution The Complete Guide to Primary Crushing, Secondary Crushing,

.jpg)

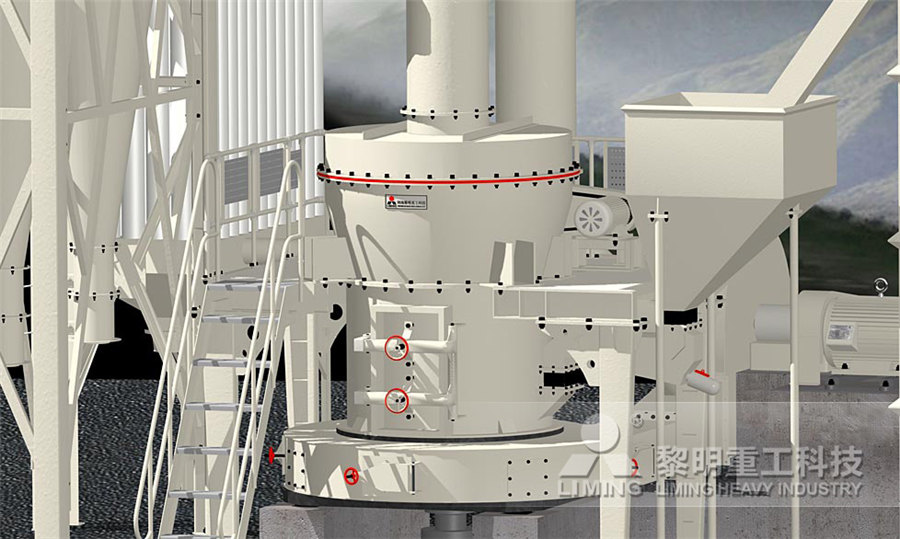

Steel Slag Processing Plant Equipment Selection Eastman Rock Crusher

2023年12月27日 Steel slag uniformly enters the jaw crusher through a vibrating feeder for coarse crushing treatment After coarse crushing, the steel slag enters the vibrating screen for screening into materials of different particle sizes If it does not meet the particle size requirements, the materials will return to the crusher machine for crushing‘slag’ generally refers to ground, granulated, iron blast furnace slag – with the descriptors to be explained and developed in this technical note In a general sense, the term ‘slag’ refers to a waste material separated from metals during the smelting or refining of an ore in a blast furnace ‘Slags’ are formed during the smelting orGround Slag Properties, Characterisation and Uses2016年5月16日 Reduce, reuse, and recycle are important techniques for waste management These become significant for improving environmental and economic condition of industries Integrated steel industries are generating huge amounts of steel slag as waste through the blast furnace and Linz–Donawitz (LD) process Presently, these wastes are disposed by dumping in Sustainable Approaches for LD Slag Waste Management in Steel 2023年2月15日 Secondary crushing — cone crusher Yes, fuel (coke) and flux (limestone) Usually, smelting 1 ton of pig iron requires a total of 23 tons of raw materials including 1520 tons of iron ore, 0406 tons of coke and 0204 Iron Ore Crushing Experts for South Africa Fote

.jpg)

The SPL Waste Management Challenge in Primary

2021年3月16日 By Alton Tabereaux, Contributing Editor Spent potlining (SPL) disposal is one of the largest environmental waste management challenges confronting worldwide primary aluminum smelters due to its toxicity The 2019年9月3日 The treatment of laterites has been a research hotspot in extractive metallurgy over the past decades Industrially, the pyrometallurgical treatment of laterites is mostly accomplished with a well (PDF) Nickel Laterite Smelting Processes and SomeThere slag crusher jaw crusher, impact crusher, cone crusher, mobile crusher There slag mill ball mill, Raymond mill, vertical mill, jet mill and so on Kefid machinery is a professional production crusher and milling machine manufacturers, and its products have been exported to the world more than 180 countries and regionsSteel Slag Crusher and Grinding Mill Mining, Crushing, A jaw crusher is generally used as a primary crusher in a crushing circuit Product is fed into the top of the jaw crusher by an vibrating grizzly feeder The eccentric rotating drive shaft causes theSIZE REDUCTION BY CRUSHING METHODS By ResearchGate

Limestone Crusher Machine: Boost Quarrying Mining Operations

Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3) and is widely used in various industries, such as mining industry, metallurgy industry, and construction industryMore and more customers are paying attention to this industry and invest into limestone crushers and have made great achievements2024年7月10日 3How to crush limestone? The first step in crushing limestone is primary crushing This is usually done using a jaw crusher, which breaks the larger rocks into smaller pieces Jaw crushers have a fixed jaw and a moving jaw The moving jaw exerts force on the rock to crush it against the fixed jawChoosing the right primary crusher for limestone crushing Baichy22 Jun 2024; A slag crusher plant is an industrial facility that processes slag, a byproduct of metal smelting, into usable materials Slag is typically a hard, brittle material that can be difficult to break down, so slag crusher plants use specialized equipment to Slag Crusher Plant CM Mining Machinery2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceCrushing in Mineral Processing 911Metallurgist

Using SteelSmelting Slag as a Raw Material Component in the

Using SteelSmelting Slag as a Raw Material Component in the Production of Asphalt Concrete Dmitry Kuznetsov1*, Marina Vysotskaya1, and Albert Burgonutdinov2 1Belgorod State Technological University VG Shukhov, Kostukova str, 46, , Belgorod, Russia 2 Perm National Research Polytechnic University, Komsomolsky Prospect, 29, , Perm, Russia2024年1月11日 The equipment for the coarse crushing is the jaw crusher, the medium crushing system uses the impact crusher, and the fine crushing system uses the sandmaking machine 1 Jaw crusher When processing limestone, Limestone Crushing And SandMaking Plant2020年2月27日 Scientists who observed this chemical reaction conducted laboratory experiments to try to increase the amount of CO 2 that could be captured by slag Crushing up the slag into fine powder, adding lots of water, The Surprising Science of Slag2017年7月7日 Limestone is also a very important industrial mineral Its chemical properties make it a valuable mineral for a wide range of industrial/manufacturing uses Limestone is also one of the vital raw materials used in production of iron and steel Limestone, by definition, is a rock that contains at least 50 % of CaCO3 in the form of calcite by weightLimestone – Its Processing and Application in Iron and

.jpg)

Lesson Explainer: Extracting Iron Nagwa

Example 4: Describing the Use of Limestone in a Blast Furnace What is the purpose of adding limestone to a blast furnace? The limestone decomposes and the products of that reaction convert impurities into slag The limestone decomposes (an exothermic reaction), heating up the furnace The limestone reduces the iron ore to iron2022年6月15日 Waste slag is different from mines The main application fields of mines are construction, roads, houses and other construction projects, so certain quality standards need to be met If Waste slag is used as raw material, its hardness and strength should also be guaranteed What are the sand making and crushing equipment for Waste slag?What crushing equipment is needed to process Waste slag and So I just want to make sure I understand this process and that I'll be going about it the right way There are 6 "raw" ores to be mined directly These ores should then be crushed, creating crushed ores (as well as crushed stone that needs to be dealt with) The crushed ores should then be floated into chunks The chunks should then be sorted into 11 intermediate oresAngel + Bobs smelting Do I understand all this right?2011年10月27日 Slags also arise from other processes, particularly the smelting of nonferrous metals, but these materials can be very different and each needs to be studied individually Moreover, in colloquial English an even wider range of materials such as clinker, ash and even colliery waste is sometimes referred to as “slag”Basics of slag production Article on the slag industry from Global Slag

.jpg)

Crushed Slag Eco English Wiki

2023年2月19日 Crushed Slag is the result of crushing Slag in either a Stamp Mill or a Jaw Crusher WiKi ECO Eco site Eco on Steam Eco Discord Eco Mods Due to being a byproduct of the Smelting process and functions the same as any other crushed rock Jaw Crusher: Crushed Slag x5 Slag x20 Mining Level 1 05 150 05 Used in Recipes None 2013年5月8日 Fig 1 Limestone Dolomite is a common rockforming mineral It is a calcium magnesium carbonate with a chemical composition of CaCO3MgCO3 It is the primary component of the sedimentary rock known as dolostone and the metamorphic rock known as dolomitic marbleLimestone and Dolomite and their Use in Iron and Steel PlantWilliams Patent Crusher is committed to designing and manufacturing the most durable and efficient limestone crusher machines on the market We’ve held that commitment for over 150 years Additionally, since the mid1980s, we’ve Limestone Mills Limestone Crushers Pulverizers2022年2月26日 Blast furnace slag can be processed into the following materials by various processes In China, blast furnace slag is usually processed into water slag, slag gravel, expanded slag and slag beadsWater slag is the process of What is Blast Furnace Slag and How to Process It?

Everything You Need to Know About the Process of

If the gold item you are planning on smelting contains silver, copper or zinc, the level of heat necessary for smelting will be lower Another option for gold smelting is a 1,200watt microwave It is necessary that the magnetron in the 2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each StageNomenclature and Terminology James G Speight PhD, DSC, in Asphalt Materials Science and Technology, 2016 1516 Slag Slag aggregates are obtained by crushing of smelter slag or by special treatment of fireliquid slag melt (molten slag aggregates) Currently there are many types of concrete that are developed and used in construction that include metallurgical slags both Slag Aggregate an overview ScienceDirect Topics2006年4月27日 This study highlights regional variation in the composition of ironsmelting slag produced in England prior to the medieval period and attempts to link slag composition to the type of ore smelted(PDF) Regional variation in bloomery smelting slag of

The Complete Guide to Primary Crushing, Secondary Crushing,

2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of the comminution 2023年12月27日 Steel slag uniformly enters the jaw crusher through a vibrating feeder for coarse crushing treatment After coarse crushing, the steel slag enters the vibrating screen for screening into materials of different particle sizes If it does not meet the particle size requirements, the materials will return to the crusher machine for crushingSteel Slag Processing Plant Equipment Selection Eastman Rock Crusher‘slag’ generally refers to ground, granulated, iron blast furnace slag – with the descriptors to be explained and developed in this technical note In a general sense, the term ‘slag’ refers to a waste material separated from metals during the smelting or refining of an ore in a blast furnace ‘Slags’ are formed during the smelting orGround Slag Properties, Characterisation and Uses2016年5月16日 Reduce, reuse, and recycle are important techniques for waste management These become significant for improving environmental and economic condition of industries Integrated steel industries are generating huge amounts of steel slag as waste through the blast furnace and Linz–Donawitz (LD) process Presently, these wastes are disposed by dumping in Sustainable Approaches for LD Slag Waste Management in Steel