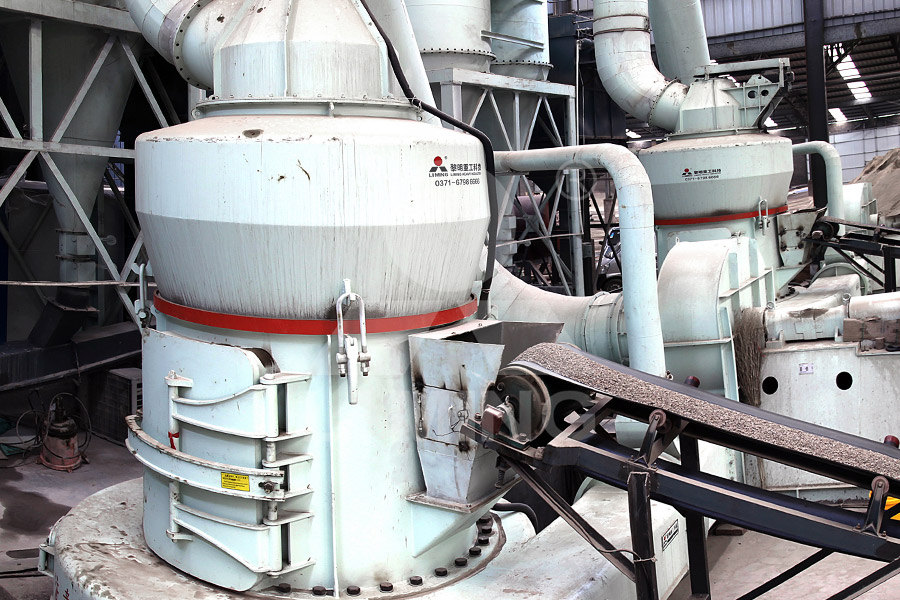

Firstlevel fly ash grinding machine

.jpg)

How to Process Fly Ash and What Is It Used for? Fote Machinery

Depending on the discharge method, there are dry fly ash and wet fly ash Dry fly ash is sold well as an admixture for cement production The wet fly ash has to be dried to have economic value The wet fly ash is fed into a rotary dryerwith burners After passing through the dryer, the dried material is discharged onto a 展开deep grinding of quicklime, cement, gypsum, aggregate (fly ash), so that the fineness of the specific surface area of 4000 cm 2/ g or more, promote more active ingredients to participate FLY ASH AAC BLOCK PLANTAAC BLOCK The first step of the fly ash processing system is taking ash from the silo and sending it into the elevator in front of the grinding mill after feeding by the feeder and electronic weighing Then the fly ash will be fed into powder concentrator Fly Ash Processing Plant Cement Equipment Fly Ash Grinder is a hightech milling equipment developed by Weifang Jinghua Powder Engineering Equipment Co, Ltd specifically for processing fly ash, This grinder utilizes China Fly Ash Grinder Manufacturer, Supplier JINGHUA

.jpg)

Investigation on grinding impact of fly ash particles and its

2019年6月1日 The OPC and fly ash samples are taken as control sample and compared with ball milled ground fly ash, to examine the effect of grinding process on fly ash particles How to process fly ash? The fly ash processing system is composed of dryer, elevator, silo, grinding mill, fan, powder concentrator, dust collector, pipeline device, etc The system structure is simple, the layout is compact, the process How to Process Fly Ash and What Is It Used forFly ash is a fine powder that is a byproduct of burning pulverized coal in electric generation power plants Fly ash is a pozzolan, a substance containing aluminous and siliceous material that forms cement in the presence of waterFly Ash NETZSCH Grinding Dispersing2023年12月13日 Ball mills play an indispensable role in transforming the heavy fluegas residues, also known as fly ash or coal ash You can use a ball mill to transform this material into a lightweight aggregate that can be mixed into Using Ball Mills for Fly Ash Processing Economy Ball Mill

.jpg)

Grinding Fly Ash Process and Equipment with Vertical Milling

The new vertical milling machine grinding fly ash technology has advantages in addition to the general mill, but also has the following characteristics: (1)Improved Design of vertical milling 2023年2月20日 Fly ash (FA) is a solid, fine powder that constitutes a byproduct obtained when coal, biomass, municipal solid waste or a mixture of these are combusted This review article A critical review on mechanochemical processing of fly ash and fly 2024年8月29日 Over the last decade, there has been a substantial increase in the amount of construction waste, leading to growing societal and environmental concerns around the recycling of this refuse Concrete waste is one of the most significant forms of construction waste As a result, in order to examine the influence of recycled coarse aggregate (RCA) on concrete, this Enhancing Sustainable Concrete Production by Utilizing Fly Ash 2022年5月11日 The employees of the United Grinding Group – over 2500 strong characters with their own history – make us successful Our brands and companies make us what we are: one of the leading manufacturers of precision machines for grinding, eroding, laser machining, combination machining and measuringSix Tips for Optimizing the Performance of Your Grinding Machine

.jpg)

The Optimization of Calcareous Fly AshAdded

2018年1月28日 Many authors have shown that replacing 4060% fly ash can result in high strength development and high resistance to alkalisilica reaction, freezing and thawing, chlorideion penetration, sulfate Find here Fly Ash Brick Making Machine, Fly Ash Brick Press Machine manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Fly Ash Brick Making Machine, Fly Ash Brick Press Machine, Fly Ash Bricks Machine across IndiaFly Ash Brick Making Machine Fly Ash Brick Press Machine Concrete Cement After grinding, the fly ash can be used as a partial substitute for concrete raw materials Different incorporation of fly ash will affect the hardening level, strength, dry shrinkage and other characteristics of concrete, with an ideal content of 40%Fly Ash Processing Plant Cement Equipment Manufacturing2016年10月18日 The aim of this work was to observe the impact of the milling technique employed by the DESI 11 disintegrator on the properties of fly ash This type of mill is a highspeed pin mill with two The effect of highspeed grinding technology on the properties of fly ash

.jpg)

Synchronous hotpressed metakaolinfly ash based geopolymer

2024年11月15日 A comparative experiment was contrived to analyze the impacts of hightemperature curing and synchronous hotpressed curing of metakaolinfly ash geopolymer, examining how the siliconaluminum ratio, alkali equivalent, and curing time influence the compressive strength and hydration products of synchronous hotpressed cured metakaolinfly 2021年9月1日 The dispersion of fly ash in water results in an alkaline pH from 10 to 13 At high pH, the fly ash becomes negatively charged allowing the removal of heavy metal ions by precipitation and electrostatic adsorption from water (Cho et al, 2005) Fly ash can be modified or transformed into new materials for heavy metal ions adsorptionFly ash properties, characterization, and applications: A reviewIndia's leading and largest manufacturer of fly ash brick plant, block making machine, concrete block making machine, paver plant, dry mix mortar plant etc Reg Office 296 297, Phase ll , Dediasan, Modhera Road, India's first largest fly ash Fly Ash Brick and Block Making Machine manufacturer In IndiaFly ash can be used as prime material in many cementbased products, such as poured concrete, concrete block, and brick One of the most common uses of fly ash is in Portland cement concrete pavement or PCC pavement Road construction projects using PCC can use a great deal of concrete, and substituting fly ash provides significant economic Fly Ash NETZSCH Grinding Dispersing 분쇄 분산 사업부

Fly Ash Processing Plant Superfine Final Product

Fly Ash Processing Process There are different equipment configurations and processes for grinding fly ash On the market, ultra fine ball mill grinding, Raymond mill grinding, and vertical roller mill grinding all exist SINOMA Our Product Automatic Fly Ash Bricks Making Machine Belt Type Model: ABM 6 Conveyor Belt System; 10 Bricks Model: ABMH: 8 Ultra Belt System; 12 Bricks:Model:ABMH 8 SP Ultra DX Belt SystemFully Automatic Flyash Bricks Machine BennyManufacturer of Automatic Flyash Brick Making Machines Fly Ash Bricks Making Machines, The first step of the fly ash processing system is taking ash from the silo and sending it into the elevator in front of the grinding mill after feeding by Automatic Flyash Brick Making Machines Fly Ash 2021年5月5日 A grinding machine is a production machine tool used in the manufacturing industry in which the grinding wheel is attached in the tool post and the workpiece is fixed to the work table and when the operation starts it removes the unwanted material to get the desired surface finish, correct size, and accurate shape of the workpieceGrinding Machine: Definition, Parts, Working Principle, Operation

FLY ASH AAC BLOCK PLANTAAC BLOCK PLANTPRODUCTSDongyue Machinery

deep grinding of quicklime, cement, gypsum, aggregate (fly ash), so that the fineness of the specific surface area of 4000 cm 2/ g or more, promote more active ingredients to participate in the reaction, improve the strength of autoclaved aerated blocks, and because of deep grinding, the slurry prepared by raw materials is more viscous, more favorable to the stability of pouringFly Ash Brick Making Machine Buy Fly Ash Brick Making Machine at best price of Rs by Chirag Industry Also find product list from verified suppliers with contact number ID: 88 This machine is not only to process edge Fly Ash Brick Making Machine IndiaMARTHardic Engineering striving hard to achieve an eminent and unshakable position in the industry, we, hardic engineering, shape up and fabricate quality equipment as desired by our clients we are a prominent manufacturer, exporter, supplier and trader for fly ash paver block bricks, sand mix miller, color mixer , vibrating table vibrating screen machine, magnetic drum Fly Ash Brick Machinery ManufacturersFly ash grinding mill is based on the fly ash and waste fuel from powder plants as the main materials to produce a variety of wall tilesIt’s an environmentally friendly building milling project in modern society Fly ash grinding mill is used sand or other slag or ash as raw material, mixing with lime, gypsum and aggregate, the billet preparation, pressing, such as steam curing mill is Fly ash grinding mill

Mechanical activation of power station fly ash by grinding

2016年3月7日 Power station fly ash has good application possibilities mainly in the construction industry, nevertheless, significant amount is landfilled due to their relatively low reactivity and heterogeneity2023年3月16日 This study reports the preparation of geopolymers with a mechanical performance similar to that of cement at room temperature by ground fly ash mixed with a small amount of cement The grinding time of fly ash raw materials was 0,20,40 and 60 min, respectively The influence of the grinding degree of the fly ash on the properties and the Influence of different grinding degrees of fly ash on properties TASA Fettling/ Flash Grinding MachineTasa Micro is an Indian special purpose machine tool Manufacturer that has developed high precision machine tools for inTASA Flash Grinding/ Fettling Machine YouTubePDF On Jan 1, 2015, Rui fang Li and others published Grinding Fly Ash Process and Equipment with Vertical Milling Machine Find, read and cite all the research you need on ResearchGateGrinding Fly Ash Process and Equipment with Vertical Milling Machine

.jpg)

Geotechnical and microstructural analysis of highvolume fly ash

3 天之前 The specific gravity of flyash is an essential physical property to consider when figuring out how it can be used in geotechnical engineering Fly ash's porous structure and popcornlike particles cause this effect, which causes to degrade quickly under loading or compaction [85]4 天之前 To improve the reactivity of fly ash, a novel ultrafine fly ash (UFFA) was produced by mechanically separating the ultrafine fractions of Class F fly ash to make fly ash highly reactive At a low replacement level of 5 %–15 % by cement weight, it shows improvement in the strength of the concrete and decreases permeability compared to regular fly ash concretesA study on the effective utilization of ultrafine fly ash and silica IDEAL APE strip shears for the burrfree and rightangled cutting of strips as the first step for a highquality strip join Grinding machines IDEALSMH or, as may apply, SMP grinding machines for machining the weld of strips with a width of up to 320 mm Worldwide sales and service IDEALWerk German Headquarters Martin Schulte +49 2941 206 Type BAS 300 flash butt welding machines IDEAL Werk2015年2月28日 Benefits of dried fly ash: Dry fly ash can be directly mixed in to the final product, PPC Capacity of the grinding mill does not need to be increased to get enhanced production Advantages of fly ash drying plant in power plant premises: Wet fly ash can be easily sourced since, abundantly available with nearby TPPs Logistics of wet and dry Fly ash drying technology Indian Cement Review

.jpg)

Fly ash processing process flow, fly ash equipment and

Fly Ash Processing Equipment: Baghouse filters or electrostatic precipitators for fly ash collection Drying and grinding machines for conditioning fly ash (rotary dryer, fluidized bed dryer, ball mill, vertical mill) Silos and storage containers for fly ash storage Pneumatic conveyors and other material handling equipment for fly ash handlingDescription: With over 50 years experience, ATA is a global leader in the provision of high end industrial air tools Our comprehensive portfolio offers a solution for every grinding and finishing application, optimizing process in terms of economic effeciency, reliability and safety Our customers comeFlash Grinding Machine Products Suppliers GlobalSpecable to grind fly ash to a fineness of 8800 cm2/g This study concluded that the grinding converts spherical fly ash particles to irregular and crushed shaped particles, increasing their reactivity Chindaprasirt et al6 separated fly ash into various levels of fineness by using an air classifier machine The results showed thatExperimental and SEM Analyses of Ground Fly Ash in ConcreteOur range includes Bricks Concrete Paver Machine, robotic, Automatic Fly Ash Brick Making Machine, Concrete Block Machine, Hollow solid block making hydraulics machine, Mosaic Tiles Machines In addition to these, we also offer Designer Vibro forming machines, Concrete Planetary Machines, Pan Mixture and Concrete Mixture MachinesAutomatic Flyash Bricks Machine Robotic Bricks Machine at

.jpg)

Enhancing Sustainable Concrete Production by Utilizing Fly Ash

2024年8月29日 Over the last decade, there has been a substantial increase in the amount of construction waste, leading to growing societal and environmental concerns around the recycling of this refuse Concrete waste is one of the most significant forms of construction waste As a result, in order to examine the influence of recycled coarse aggregate (RCA) on concrete, this 2022年5月11日 The employees of the United Grinding Group – over 2500 strong characters with their own history – make us successful Our brands and companies make us what we are: one of the leading manufacturers of precision machines for grinding, eroding, laser machining, combination machining and measuringSix Tips for Optimizing the Performance of Your Grinding Machine2018年1月28日 Many authors have shown that replacing 4060% fly ash can result in high strength development and high resistance to alkalisilica reaction, freezing and thawing, chlorideion penetration, sulfate The Optimization of Calcareous Fly AshAdded Find here Fly Ash Brick Making Machine, Fly Ash Brick Press Machine manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Fly Ash Brick Making Machine, Fly Ash Brick Press Machine, Fly Ash Bricks Machine across IndiaFly Ash Brick Making Machine Fly Ash Brick Press Machine

.jpg)

Fly Ash Processing Plant Cement Equipment Manufacturing

Concrete Cement After grinding, the fly ash can be used as a partial substitute for concrete raw materials Different incorporation of fly ash will affect the hardening level, strength, dry shrinkage and other characteristics of concrete, with an ideal content of 40%2016年10月18日 The aim of this work was to observe the impact of the milling technique employed by the DESI 11 disintegrator on the properties of fly ash This type of mill is a highspeed pin mill with two The effect of highspeed grinding technology on the properties of fly ash2024年11月15日 A comparative experiment was contrived to analyze the impacts of hightemperature curing and synchronous hotpressed curing of metakaolinfly ash geopolymer, examining how the siliconaluminum ratio, alkali equivalent, and curing time influence the compressive strength and hydration products of synchronous hotpressed cured metakaolinfly Synchronous hotpressed metakaolinfly ash based geopolymer 2021年9月1日 The dispersion of fly ash in water results in an alkaline pH from 10 to 13 At high pH, the fly ash becomes negatively charged allowing the removal of heavy metal ions by precipitation and electrostatic adsorption from water (Cho et al, 2005) Fly ash can be modified or transformed into new materials for heavy metal ions adsorptionFly ash properties, characterization, and applications: A review

Fly Ash Brick and Block Making Machine manufacturer In India

India's leading and largest manufacturer of fly ash brick plant, block making machine, concrete block making machine, paver plant, dry mix mortar plant etc Reg Office 296 297, Phase ll , Dediasan, Modhera Road, India's first largest fly ash Fly ash can be used as prime material in many cementbased products, such as poured concrete, concrete block, and brick One of the most common uses of fly ash is in Portland cement concrete pavement or PCC pavement Road construction projects using PCC can use a great deal of concrete, and substituting fly ash provides significant economic Fly Ash NETZSCH Grinding Dispersing 분쇄 분산 사업부