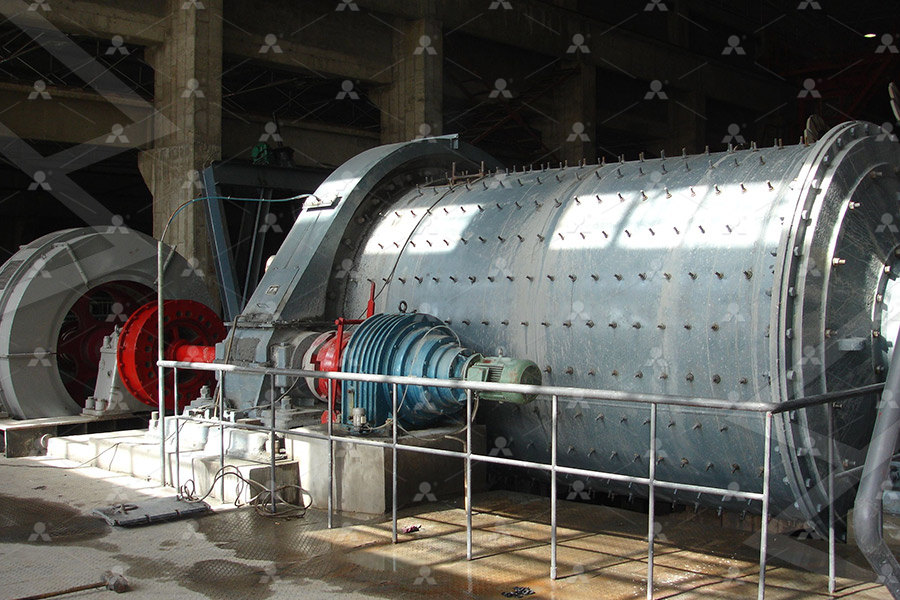

Bluestone grinding machine model working principle and schematic diagram

.jpg)

Structural illustration of the grinding machine model

Analysis about the grinding principle error shows that this method is a feasible way for many complex surface component formation The structural illustration of the grinding machine isThe document discusses 14 types of grinding machines including bench, hand, pedestal, portable, flexible, and precision grinders Precision grinders include cylindrical, plunge cut, form, 14 Types of Grinding Machines (Working, Diagram PDF)To achieve this method, firstly, based on the analysis of the geometric topology features of the riblet surface, an engineered CBN grinding wheel with spiral arrangement of abrasive particles The schematic diagram of the grinding techniqueA grinding machine is a material removal machine having geometrically nondefined, bonded cutting edges and rotational or linear relative movement between tool and workpiece The Different Types of Grinding Machine IJRPR

Schematic diagram of the grinding machine and instrumentation

Figure 2 shows the schematic diagram of the grinding machine and instrumentation used The tests were carried out for 15 different grinding conditions, using 5µm as the lowest depth ofGrinding is the process of removing metal by the application of abrasives which are bonded to form a rotating wheel When the moving abrasive particles contact the workpiece, they act as GRINDING MACHINES Carnegie Mellon UniversityWorking Principle of Grinding Machine The grinding machine works on the principle of the grinding process This is a machining process in which finishing work is carried out on the Types of Grinding Machine: Parts, Working Principle Grinding Working Principle of Grinding Machine Grinding machines employ a rotating abrasive wheel that removes material from the workpiece through abrasion The grinding wheel is composed of Grinding Machine: Learn its working, types, and applications

.jpg)

Milling Machine: Definition, Parts, Operation,

2022年7月4日 Milling Machine Definition: The milling machine is a type of machine which removes the material from the workpiece by feeding the work past a rotating multipoint cutterThe metal removal rate is higher very high as the 2023年11月22日 Tips for Mastering Schematic Diagrams Standardize Symbols: Always use standardized symbols for components to ensure that your schematics are universally understood; Label Clearly: Consistent and clear labeling helps Understanding Schematic Diagrams: a 2022年10月6日 Working principle and Diagram of SEM A scanning electron microscope works on the principle of targeting a focused beam of electrons moving with high kinetic energy on a specimen Model: Type: Used Price: Scanning Electron Microscope (SEM) Diagram, How It Works, Internal Schematic and Block Diagram Let’s take a closer look what’s inside the 555 Timer and explain how it works in each of the three modes Here’s the internal schematics of 555 Timer which consists of 25 transistors, 2 diodes and 15 resistors555 Timer IC – Working Principle, Block Diagram, Circuit Schematics

.jpg)

Hot press sintering machine and schematic diagram of sintering

Download scientific diagram Hot press sintering machine and schematic diagram of sintering process from publication: Preparation and characterization of ultrathin dicing blades with different 2020年8月12日 This document discusses grinding machines It provides an overview of the working principle, specifications, purposes and types of grinding The main types are surface grinding, cylindrical grinding, centerless grinding, and tool and cutter grinding It describes the parts of a grinding machine and grinding wheel sizes and shapesGrinding machine PPT Free Download SlideShareGrinding Machine: Working Principle, Parts, Types and Applications Last Updated on Mar 6 Schematic of Surface Grinding Process we can study the types with functions of grinding machines that are responsible for the operations with the grinding machine diagrams or images The list also contains some of the commonly used in the machine Grinding Machine: Learn its working, types, and applications2023年9月12日 Locksmiths can use plasma cutting machines to drill holes in secure areas when customers are locked out In a CNC (Computer Numerical Control) cutting system, you don’t need to touch the material All you have to do is draw the shape you want to cut on the computer and the cutting process will be automated 1 Working PrincipleUnderstanding Plasma Cutting Machine Principle MachineMFG

.jpg)

Lathe Machine Schematic Diagram

2017年12月12日 Understanding a lathe machine’s workings is essential for those wanting to operate one or construct their own Thankfully, lathe machine schematic diagrams provide a comprehensive overview of how a lathe works and how its various components interact By studying these diagrams, technicians can better understand how to use and maintain a lathe slotting machine,without any thought of the cons equences of such planningIn such cases,it is impossible to achieve good surface finishes,as the vibrations from the milling machine or jerks from the reversal of the shaper stroke,etcare transmitted to the grinding machineChatter marks can be found on the ground surface,which are due to theseINSTRUCTION MANUAL FOR PRECISION SURFACE GRINDER 2024年4月18日 Key learnings: Solar Cell Definition: A solar cell (also known as a photovoltaic cell) is an electrical device that transforms light energy directly into electrical energy using the photovoltaic effect; Working Principle: The working Solar Cell: Working Principle Construction 2022年7月4日 As you can see the above diagram of Shaper machine, The tool is hold by Ram and workpiece is fixed over table When we switch on the power the ram reciprocates with respect to the table that means the cutting tool cuts Shaper Machine: Definition, Parts, Working

Schematic diagram of the working principle of MPS

Download scientific diagram Schematic diagram of the working principle of MPS medium speed coal mill [1] from publication: Fault Diagnosis of Coal Mill Based on Kernel Extreme Learning Machine Download scientific diagram Schematic diagram representing the working principle of the SPS machine from publication: Microstructural evaluation of WC and steel dissimilar bilayered composite Schematic diagram representing the working principle of the SPS machine In the plunge grinding machine the grinding wheel moves radially towards the substance 4 Creep Feed Grinding Machine The creep feed grinding machine eliminates a full chunk of the substance through the grinding wheel all at once This machine greatly reduces the manufacturing time 5 Centerless Grinding Machine The centerless grinding Cylindrical Grinding Machine: Types, Process Working Principle2019年5月9日 Hydrocyclone is mainly used in mineral processing for: ① Heavy medium cyclone is a common heavy medium separation equipment ② As grading equipment in the grinding circuit, especially as fine grinding grading equipment ③ Slurry will be desliming, concentration Hydrocyclone structure:Hydrocyclone Working Principle Schematic DiagramJXSC

.jpg)

Guide to Centerless Grinding Machine: Advantages, Working Principle

2023年5月18日 A centerless grinding machine is a machine tool that uses CNC technology to grind the surface of a workpiece using grinding tools Most grinders use highspeed rotating grinding wheels for grinding, while a few use other grinding tools such as oilstones, abrasive belts, and free abrasives for processing, such as honing machines, ultraprecision machining The working of an xray machine can be easily explained with the help of a functional block diagram Generally, an xray machine consists of 10 blocks The working of each block is given below: 1 High Voltage Source The main purpose of using a high voltage source control to power an xray machine is to allow the proper operation of the xray Working Principle of XRay Machine StudiousGuy2024年10月4日 More simply, a schematic diagram is a simplified drawing that uses symbols and lines to convey important information For example, if you are taking the subway you may see a “map” showing you all the stations along a subway line, but that map will not show all the roads and buildings you may pass along the wayWhat Is a Schematic Diagram? ThoughtCo2012年6月1日 Basic kinetic and energy models of the grinding process are described and the most commonly used control strategies are analyzed and discussed +1 Figures uploaded by Vladimir MonovGrinding in Ball Mills: Modeling and Process Control

.jpg)

Schematic diagram of the cylindrical grinding process

Download scientific diagram Schematic diagram of the cylindrical grinding process from publication: Measuring strain during a cylindrical grinding process using embedded sensors in a workpiece A G6 (SKD11): its carbon content is between 14 and 16, and the chromium content is between 1100 and 13pared with other alloys, the content of Mo and V has higher hardness (it can reach Hardness range 58°60°), What is Slitting Machine,Working Principle of The Download scientific diagram (a) schematic of XRD working principle with an example of the obtained pattern; (b) schematic of the in situ cell developed by Chianelli and coauthors [25]; (c (a) schematic of XRD working principle with an Download scientific diagram Spiral jet milling working principle and system schematic from publication: A detailed CFD analysis of flow patterns and singlephase velocity variations in spiral Spiral jet milling working principle and system schematic

.jpg)

14 Types of Grinding Machines (Working, Diagram PDF)

The document discusses 14 types of grinding machines including bench, hand, pedestal, portable, flexible, and precision grinders Precision grinders include cylindrical, plunge cut, form, internal, centreless, surface, universal, and tool/cutter grinders Details are provided on the working and applications of each type of grinder2023年6月14日 Lathe is a machine tool commonly used in all industrial applications Now, a machine tool is powerdriven and designed to move a sharp cutting tool against a rigidly held workpiece material or vice versa to remove material from the workpiece In this article, we will discuss the definition, parts, working principle, and types of lathe machinesLathe Machine: Learn the Working with Parts and Applications2021年10月21日 Hello friends In this article, I am going to explain the key aspects of a cylindrical grinding machine (eg parts, types, uses, etc) The cylindrical grinding machine is basically a type of grinding machine like a surface grinding machine, tool and cutter grinding machine, centerless grinding machine, etc So let's get startedCylindrical Grinding Machine: Working, Parts, Types, Uses2023年2月22日 Read also: ElectronBeam Machining (EBM): Working Principle, Advantage, Limitation and Design A DC power supply in the range of 525 volt Maintains current densities, which for most of the applications are 158 A/mm2 of the active machined surface Machines having current capacities as high as 40,000 A and has low has 5 AR availableElectrochemical Machining (ECM): Process, Working Diagram

Surface Grinding Machine: Types, Parts Working Procedure

The grinding disc is not confined to a cylindrical form and is able to come up with a multitude of possibilities That will be useful for moving various geometries in accordance with the objects Read More :Types of Grinding Machine Types of Cylindrical Grinding Machine Types of CNC Machine Types of Planer Machine Types of Slotting MachineSection 7: Best Practices for CNC Machine Schematic Diagrams Techniques for organizing and labeling schematic diagrams Importance of documentation and keeping schematic diagrams up to date Section 8: Future Developments in CNC Machine Schematic Diagrams Overview of emerging technologies and advancements in schematic diagrams for CNC machinesThe Ultimate Guide to Understanding CNC Machine Schematic Diagrams2022年7月4日 Milling Machine Definition: The milling machine is a type of machine which removes the material from the workpiece by feeding the work past a rotating multipoint cutterThe metal removal rate is higher very high as the Milling Machine: Definition, Parts, Operation, 2023年11月22日 Tips for Mastering Schematic Diagrams Standardize Symbols: Always use standardized symbols for components to ensure that your schematics are universally understood; Label Clearly: Consistent and clear labeling helps Understanding Schematic Diagrams: a

.jpg)

Scanning Electron Microscope (SEM) Diagram,

2022年10月6日 Working principle and Diagram of SEM A scanning electron microscope works on the principle of targeting a focused beam of electrons moving with high kinetic energy on a specimen Model: Type: Used Price: How It Works, Internal Schematic and Block Diagram Let’s take a closer look what’s inside the 555 Timer and explain how it works in each of the three modes Here’s the internal schematics of 555 Timer which consists of 25 transistors, 2 diodes and 15 resistors555 Timer IC – Working Principle, Block Diagram, Circuit SchematicsDownload scientific diagram Hot press sintering machine and schematic diagram of sintering process from publication: Preparation and characterization of ultrathin dicing blades with different Hot press sintering machine and schematic diagram of sintering 2020年8月12日 This document discusses grinding machines It provides an overview of the working principle, specifications, purposes and types of grinding The main types are surface grinding, cylindrical grinding, centerless grinding, and tool and cutter grinding It describes the parts of a grinding machine and grinding wheel sizes and shapesGrinding machine PPT Free Download SlideShare

FYEFEPS2HDZ49G5Z0[B.jpg)

Grinding Machine: Learn its working, types, and applications

Grinding Machine: Working Principle, Parts, Types and Applications Last Updated on Mar 6 Schematic of Surface Grinding Process we can study the types with functions of grinding machines that are responsible for the operations with the grinding machine diagrams or images The list also contains some of the commonly used in the machine 2023年9月12日 Locksmiths can use plasma cutting machines to drill holes in secure areas when customers are locked out In a CNC (Computer Numerical Control) cutting system, you don’t need to touch the material All you have to do is draw the shape you want to cut on the computer and the cutting process will be automated 1 Working PrincipleUnderstanding Plasma Cutting Machine Principle MachineMFG2017年12月12日 Understanding a lathe machine’s workings is essential for those wanting to operate one or construct their own Thankfully, lathe machine schematic diagrams provide a comprehensive overview of how a lathe works and how its various components interact By studying these diagrams, technicians can better understand how to use and maintain a lathe Lathe Machine Schematic Diagramslotting machine,without any thought of the cons equences of such planningIn such cases,it is impossible to achieve good surface finishes,as the vibrations from the milling machine or jerks from the reversal of the shaper stroke,etcare transmitted to the grinding machineChatter marks can be found on the ground surface,which are due to theseINSTRUCTION MANUAL FOR PRECISION SURFACE GRINDER