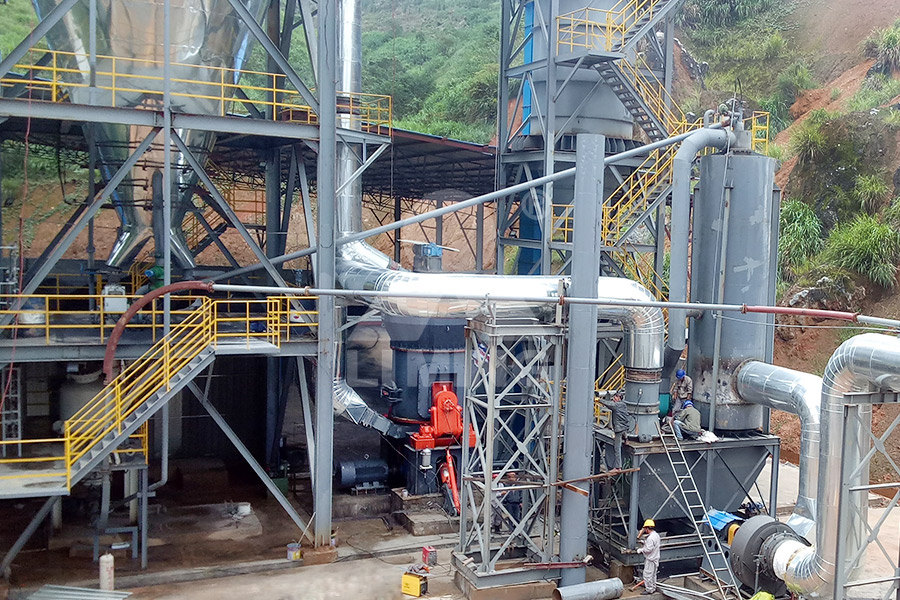

Graphite ore Mining and deep processing

.jpg)

Graphite Ore Processing: Optimal Processes and Equipment

Different graphite ores are suitable for different processing flowsheets Natural graphite, according to crystal diameter, is usually divided into: 1 Amorphous graphite (crystal diameter less than 1 μm) 2 Crystalline graphite (crystal diameter greater than 1 μm) Crystalline graphite, often referred to as generally refers to flake 展开2019年9月1日 Hence, this study extensively describes a current purification method for producing highquality graphite material with impurities reaching about 10–100 mg/kg, Purification, application and current market trend of natural 2017年4月24日 Graphite extraction is based on the degree of weathering of the ore rock and the proximity of the ore to the surface Around the world, graphite is mined using two techniques: How Is Graphite Extracted? Sciencing2023年2月1日 This work systematically introduces the progress in the comprehensive utilization of graphite resources, which mainly involve three essential deepprocessing material products: Recent progress in the research and development of natural

A Review of Graphite Beneficiation Techniques: Mineral Processing

2016年2月18日 Graphite ore is mostly beneficiated using flotation separation techniques The increasing demand for highgrade graphite products with up to 9999% carbon has resulted in 2022年2月15日 The LCA includes the production process of active anode material consisting of natural graphite for traction batteries (cradletogate) based on industrial primary data The Life cycle assessment of natural graphite production for lithium 2024年6月27日 Openpit mining is the favoured method of extraction, particularly for deposits near the surface, with underground mining used for deeper deposits Once extracted, the ore Focus on: Graphite, a Crucial Clean Energy Mineral2023年9月7日 A procedure based on acid extraction using a mixture of conc sulfuric and nitric acids (8:1) to recover graphite attached to rock pieces of the vein contact zones of graphite Sustainable mining of natural vein graphite via acidextraction

Network optimization for optimal product mix decisions in a

whole complex production process with sensitivity analysis and scenario analysis, are scarce Therefore, this study aims to develop a novel general mathematical model for the mineral 2023年2月7日 Highspeed photographic tests show that the dynamic crushing process of the graphite ore rock can be divided into five stages, which are compaction, crack initiation, crack Dynamic response characteristics and damage rule of graphite ore 2022年11月1日 An understanding of graphite ore characteristics Graphite is an increasingly important commodity for the development of nextgeneration lithium ion batteries An understanding of graphite ore and how its variations perform Building a picture of graphite from deposit The extracted graphite is then picked through the hand tools and carried out for further processing Underground mining Underground mining is undertaken to access the deepest ores Various methods, such as drift mining, hard rock Graphite extraction method open pit, underground

Focus on: Graphite, a Crucial Clean Energy Mineral

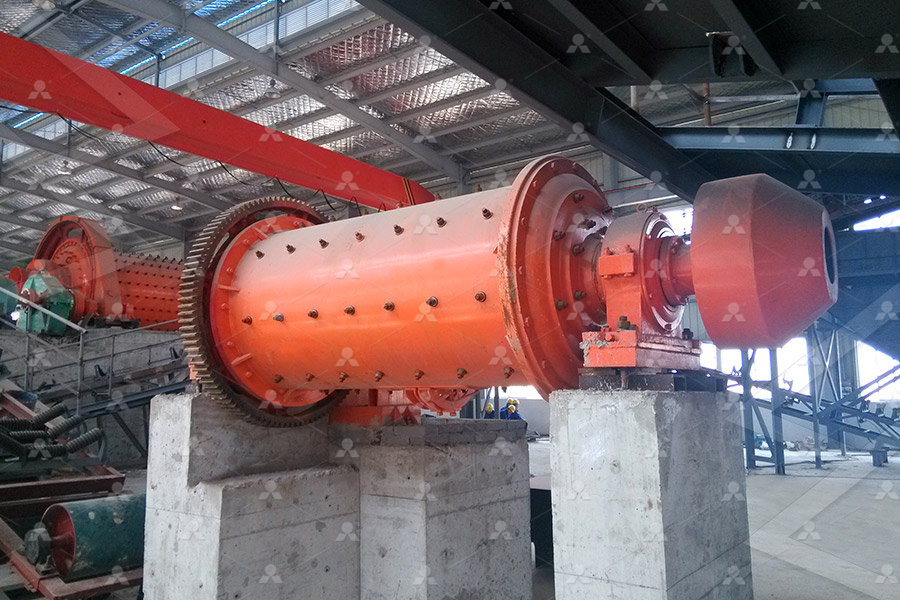

2024年6月27日 Openpit mining is the favoured method of extraction, particularly for deposits near the surface, with underground mining used for deeper deposits Once extracted, the ore undergoes processing, involving crushing, grinding, and flotation, which uses the hydrophobic nature of graphite to separate it from other minerals2021年2月22日 Lecture by Swati Sharma, IIT Mandi Graphite ore, graphite mining, froth floatation, jigging, communitionGraphite Ore Processing YouTube2015年1月1日 Mining of graphite veins developing a deep learningbased image processing strategy The results demonstrate that CT allows for the 3D visualisation of graphite ores and provides valid Graphite deposit types, their origin, and economic significance2024年1月23日 Because the electric separation method has small production capacity and low efficiency, the mineral separation effect is not as good as flotation, and it is rarely used in mineral processing plants 03 Graphite ores purification method When deep processing graphite ores, the grade of graphite concentrate needs to be increased to above 99%Graphite Ores Types and Mineral Processing and Xinhai Mining

A Review of Graphite Beneficiation Techniques: Mineral Processing

2016年2月18日 Graphite ore is mostly beneficiated using flotation separation techniques The increasing demand for highgrade graphite products with up to 9999% carbon has resulted in the development of various approaches to remove impurities even to parts per million range2024年3月17日 This paper proposes a graphite ore image classification and recognition method based on fused multiscale features, firstly, the input image is preprocessed by better initialization improvement; secondly, a deep convolutional layer performs feature extraction on the incoming preprocessed data, and the deep convolutional will run on a perchannel basis and mix the Graphite Ore Grade Classification Algorithm Based on Multi2019年9月1日 Graphite is a mineral exclusively composed of sp 2 p z hybridized carbon atoms with πelectrons, which is found in metamorphic and igneous rocks [1]It is an extremely soft slice and has a very low specific gravity [2], [3]Graphite is a good conductor of heat and electricity [4], [5] and has a high regular stiffness and strength Graphite (plumbago) can sustain its firmness Purification, application and current market trend of natural graphite Reserve: 110Mt (16% TGC) Graphite Ore Reserve Resource: 1,036Mt (12% TGC) Graphite Mineral Resource Life of mine: 50 years Mining: Simple, low strip, open pit mining Processing: Conventional crushing, grinding, flotation, filtration, drying, screening and bagging Plant capacity: 2Mtpa ore throughput yielding ~350ktpa graphiteBalama Graphite Operation Syrah Resources

.jpg)

Towards sustainable extraction of technology materials

2021年9月21日 The potential benefit of such an approach has been illustrated in the case of iron ore mining, although limited to ore extraction and not including the processing stages, by using a carbon The company has more than 30 years of experience in graphite mining and processing, deep processing of graphite and related key technical forces, with an annual ore processing capacity of more than 15 million tons, medium and high carbon flake graphite capacity of more than 50000 tons, spherical graphite capacity of more than 10000 tons, stone processing capacity of more Qingdao Jinhui Graphite Co, LtdHighpurity graphiteGraphene Graphite Ore Grade Classification Algorithm Based on Multiscale Fused Image Features Jionghui Wang1(B), Yaokun Liu2, Xueyu Huang2,3, and Shaopeng Chang2 1 Minmetals Exploration Development Co Ltd, Beijing , People’s Republic of China wangjh@minmetals 2 School of Software Engineering, Jiangxi University of Science and Graphite Ore Grade Classification Algorithm Based on Multi2024年1月23日 Because the electric separation method has small production capacity and low efficiency, the mineral separation effect is not as good as flotation, and it is rarely used in mineral processing plants 03 Graphite ores purification method When deep processing graphite ores, the grade of graphite concentrate needs to be increased to above 99%Graphite Ores Types and Mineral Processing and Xinhai Mining

Life cycle assessment of natural graphite production for lithium

2022年2月15日 The authors identified the graphite mining process of graphite in ecoinvent as an approximation from lime mining This is the reason why they completed the missing process steps for graphite mining from Pehnt et al and combined them with the LCI data of further processing from ecoinvent (Jungbluth, 2008)913 Mineral Deposits, Ore Deposits, and Mining A mineral deposit is a place in Earth’s crust where geologic processes have concentrated one or more minerals at greater abundance than in the average crust An ore deposit is a mineral deposit that can be produced to make a profit9 Ore Deposits and Economic Minerals – Mineralogy2023年1月1日 Compared to nearsufrace mining, deep underground mining is associated with challenges such as high temperatures, humidity, airborne dust, rockbursts, largescale cavings, mud rushes, rockfalls and airblasts, mining induced seismicity, the intersection of hazardous gases (eg, methane from the rock mass and toxic gases from blasting and diesel engines) Moving towards deep underground mineral resources: Drivers, Tuxingsun Mineral Mining provides comprehensive solutions for graphite ore mining, beneficiation, and processing We offer a wide range of services, from exploration and mine development to mineral processing and refining Our experienced team utilizes cuttingedge technologies and equipment to deliver highquality results for our clientsGraphite Ore: A Comprehensive Guide to Mining, Beneficiation,

Mining our green future Nature Reviews Materials

2021年5月24日 A mixture of graphite, lithium, The debate about mining our deep ocean, as alternative to terrestrial sources, Ore Geology Reviews 130, (2021)2023年11月9日 Hot Coke Natural ores aren’t the only source of graphite, though Methods for producing synthetic graphite have been around since the 1890s, and while they produce extremely highpurity Mining And Refining: Graphite Hackaday2018年12月5日 Spatially explicit life cycle analyses may be a useful tool to capture indirect impacts of mining, mineral processing supply chains and Ilves E and Ali S (2022) Deep‐sea nodules versus land ores: A comparative Mining and biodiversity: key issues and research The graphite ore mining production line plays a crucial role in efficiently extracting and processing graphite, ensuring its availability for various industrial, technological, and consumer applications The versatility and unique properties of graphite make it Graphite Ore Mining Production Line TAYMACHINERY

.jpg)

Graphite in Mozambique Mining Technology

2024年8月23日 Mozambique accounts for 6% of global production, with the largest producers being China, Madagascar, Mozambique and Brazil Exports of graphite from Mozambique declined by 4217% in 2023 over 2022, with the highest share being exported to China Mozambique’s graphite exports are expected to grow at a CAGR of 1264% between 2023 2023年4月30日 Quantitative mineralogical information on key properties of graphite was obtained by developing a deep learningbased image processing strategy The results demonstrate that CT allows for the 3D visualisation of graphite ores and provides valid and reliable quantitative to vitrinite in coal from the Gemudi mining area in Minerals Special Issue : Graphite Minerals and Graphene MDPIMexican underground mining operations are 100–400 m below the surface, measured on the angle of the vein Some of the older mines in Sri Lanka reached depths in excess of 450 m on a vertical plane For many years, mining operations in Sri Lanka were primitive and ore extraction was slow and cumbersome The mines were mechanized after World Graphite Mining Processing Equipment Flow Chart JXSCElectric Vehicle (EV) sales have seen considerable growth in recent years, reaching 94% of global passenger vehicle penetration in 2021, and expected to triple by 2026Africa’s Growing Graphite Mining Potential SP Global

Graphite Mining in Canada: Everything You Need to Know

2022年3月4日 10 Canadian Graphite Mining Facts #1 Canada's graphite industry ranked as the 10th largest global producer with 12,000 tonnes of production in 2020, accounting for 12 per cent of production worldwide In years past, it has ranked consistently in the top five (NRC) #2 Canadian graphite shipments totalled 11,937 tonnes in 2020 (NRC)2022年3月22日 Graphite ore is an important nonmetallic mineral resource, which can only be used after processing Common graphite processing methods mainly include flotation method, gravity separation method, electric separation method, selective flocculation method, alkaliacid method, chlorination roasting method and high temperature roasting method Among them, 7 Common Graphite Processing Methods Xinhai Mining2019年8月16日 Mining, mineral processing and metal extraction are undergoing a profound transformation as a result of two revolutions in the making—one, advances in digital technologies and the other, availability of electricity from renewable energy sources at affordable prices The demand for new metals and materials has also arisen concurrently This necessitates Future of Mining, Mineral Processing and Metal Extraction Industry2022年11月1日 An understanding of graphite ore characteristics Graphite is an increasingly important commodity for the development of nextgeneration lithium ion batteries An understanding of graphite ore and how its variations perform Building a picture of graphite from deposit

.jpg)

Graphite extraction method open pit, underground

The extracted graphite is then picked through the hand tools and carried out for further processing Underground mining Underground mining is undertaken to access the deepest ores Various methods, such as drift mining, hard rock 2024年6月27日 Openpit mining is the favoured method of extraction, particularly for deposits near the surface, with underground mining used for deeper deposits Once extracted, the ore undergoes processing, involving crushing, grinding, and flotation, which uses the hydrophobic nature of graphite to separate it from other mineralsFocus on: Graphite, a Crucial Clean Energy Mineral2021年2月22日 Lecture by Swati Sharma, IIT Mandi Graphite ore, graphite mining, froth floatation, jigging, communitionGraphite Ore Processing YouTube2015年1月1日 Mining of graphite veins developing a deep learningbased image processing strategy The results demonstrate that CT allows for the 3D visualisation of graphite ores and provides valid Graphite deposit types, their origin, and economic significance

Graphite Ores Types and Mineral Processing and Xinhai Mining

2024年1月23日 Because the electric separation method has small production capacity and low efficiency, the mineral separation effect is not as good as flotation, and it is rarely used in mineral processing plants 03 Graphite ores purification method When deep processing graphite ores, the grade of graphite concentrate needs to be increased to above 99%2016年2月18日 Graphite ore is mostly beneficiated using flotation separation techniques The increasing demand for highgrade graphite products with up to 9999% carbon has resulted in the development of various approaches to remove impurities even to parts per million rangeA Review of Graphite Beneficiation Techniques: Mineral Processing 2024年3月17日 This paper proposes a graphite ore image classification and recognition method based on fused multiscale features, firstly, the input image is preprocessed by better initialization improvement; secondly, a deep convolutional layer performs feature extraction on the incoming preprocessed data, and the deep convolutional will run on a perchannel basis and mix the Graphite Ore Grade Classification Algorithm Based on Multi2019年9月1日 Graphite is a mineral exclusively composed of sp 2 p z hybridized carbon atoms with πelectrons, which is found in metamorphic and igneous rocks [1]It is an extremely soft slice and has a very low specific gravity [2], [3]Graphite is a good conductor of heat and electricity [4], [5] and has a high regular stiffness and strength Graphite (plumbago) can sustain its firmness Purification, application and current market trend of natural graphite

.jpg)

Balama Graphite Operation Syrah Resources

Reserve: 110Mt (16% TGC) Graphite Ore Reserve Resource: 1,036Mt (12% TGC) Graphite Mineral Resource Life of mine: 50 years Mining: Simple, low strip, open pit mining Processing: Conventional crushing, grinding, flotation, filtration, drying, screening and bagging Plant capacity: 2Mtpa ore throughput yielding ~350ktpa graphite