Magnesite hd2e barite grinding machine

Magnetic separation for mining industry – Magnetense

MAG 110/15 MAG 310/15 magnetic separators machines are ideal devices to deironing a wide range of sand materials Paramagnetic minerals (hematite, biotite, ilmenite, etc) are simply The barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high Barite Grinding Production Line TAYMACHINERYBarite grinder mill is mainly applied in the nonexplosive brittle material ultrafine powder processing, low hardness, Mohs hardness of ≤ 6, such as calcite, chalk, limestone, dolomite, Barite Grinder Mill2024年4月7日 Category: Powder Grinding HengYang Machinery Micro Powder Grinding Plant Magnesite Grinding Plant April 7, 2024 182 Barite Grinding Plant April 7, 2024 212 Barite is a kind of important Bamineral, with Powder GrindingHengYang Machinery

.jpg)

Barite Powder Surface Coating Machine Barite

Barite powder surface coating machine is widely used in nonmetallic mineral filler, plastic, rubber, binder and other modern polymer materials, polymerbased composites, functional materials and coatings and other industries Barite Shanghai Clirik Machinery devoted to provide barite processing and grinding solution,barite grinding mill, barite grinding machine,barite processing machine, barite powder production line, barite powder making machine for saleClirik Barite grinding mill Shanghai Clirik The barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, Barite Grinding Production Line TAYMACHINERYThis is the process of producing 800 mesh barite powder by HGM100 ultrafine mill production line The barite raw material is first broken into small pieces, and then transported to the grinding chamber of the main machine of the HGM100 grinding millXinjiang, China 800 mesh barite powder grinding production line

.jpg)

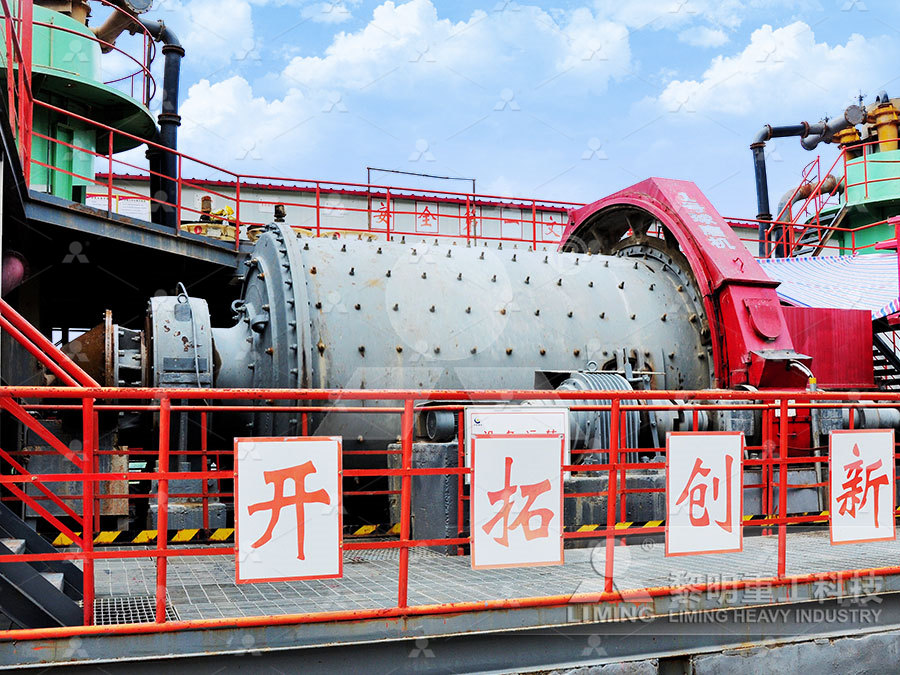

Magnesite Grinding Equipment Production Line

2021年10月29日 Magnesite Stone Crusher >> Jaw Crusher – Coarse Crushing Jaw crushers are widely used as crushing equipment in the magnesite grinding production line It is mainly used for the primary crushing operation of the raw material magnesite so that the crushed magnesite meets the particle size requirements required by the next constructionBenefits of Clirik Limestone Powder Grinding Mill Machinery 1 High efficiency:Under the same final size and power, the product capacity of ultrafine mill is twice than jet mill and agitation mill 2 Longer lifetime of spare parts:The roller and ring are made of special material, which improve the grinding efficiency a lotFor same material and final size, the lifetime of its wearing Limestone Powder Grinding Mill Machinery2023年3月20日 To fully dissociate useful barite minerals, ball mills are commonly used to grind barite rocks Generally, the grinding fineness of barite200 is 85~90%, and a twostage grinding process is often used In view of the differences in the properties of barite ores, the optimum grinding fineness needs to be determined experimentallyExceptional Barite Processing Methods and Machines2023年5月12日 Magnesite (MgCO 3) is a natural mineral mainly composed of magnesium carbonate and is the main source for the production of magnesium metal and magnesium oxide The major gangue minerals of magnesite ore are silicates (mainly talc, quartz, serpentine, etc) and carbonates (dolomite and calcite)Magnesite Ore Processing: Separation and Calcination

.jpg)

Barite powder ultrafine vertical roller mill Clirik Barite grinding

In this background, having accumulated multiple years’ experience in manufacturing mills, Clirik has designed and launched a newtype barite powder ultrafine vertical roller mill on the basis of introducing the vertical roller mill technology from Taiwan and Germany, which integrates the functions of grinding, classifying, conveying, secondary classifying, and packing progress into 2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ Limestone Ultrafine Mill Machine SBM Ultrafine 2024年10月1日 Therefore, the optimal grinding time was determined to be 8 min At this time, the contents of −74 + 23 μm grain size in the quartz and magnesite grinding products were 569 % and 440 %, and the contents of −23 μm were 123 % and 314 % Grinding tests have shown that magnesite is more easily groundExploring the behavior of an alcoholic amine grinding aid in grinding 2021年5月5日 The grinding machine is widely used to finish the workpiece Do you know why? Because the work removal rate is low between 025 to 05 mm (This can be advantages or disadvantages also for various types of works) Grinding Machine: Definition, Parts, Working

Rock grinder machine

2022年12月1日 SBM's Rock grinder machine is suitable for grinding all kinds of ore materials From large industrial projects to small applications, our grinder machine can do the job for you +17A mineral CLG Series Powder Surface Coating Machine is also called a Powder surface coating machineAfter dealing with Powder Coating machine, it can not only improve the compatibility of both nonorganic mineral stuff and organic high polymer, enhance the binding force of interfaces, rise the mechanical strength and comprehensive ability, but also increase the stuffing ability of CLG Series Powder Surface Coating Machine Barite grinding millBarite Grinding Mill 989 likes Shanghai Clirik Machinery Co,Ltd is the professional barite grinding mill manufacturer, devoted to the barite powder grinding process more than 10 years Barite Grinding Mill FacebookThe crushed barite small pieces are sent to the silo by elevator and then evenly and quantitatively sent to the grinding chamber of the mill by the vibrating feeder for grinding Stage 3: Grading The powder classifier classifies the ground materials, and the unqualified powder is classified by the classifier and returned to the main machine for regrindingBarite Aggregate Processing JXSC Machine

.jpg)

Celestite, Barite, Magnesite, and Fluorspar: Stratabound Settings

1989年1月1日 The stratabound settings of the main nonmetallic ore fields such as celestite, barite, magnesite, and fluorspar show a wide variety of tectonic environments through the geologic record2021年7月28日 Magnesite is a carbonate mineral of magnesium, in which magnesium oxide has strong fire resistance and adhesion Magnesite is the raw material for the production of refractory materials, as well as the main raw material for refining magnesium The purpose of beneficiation of magnesite is to remove impurities and improve product grade6 Magnesite Beneficiation Methods You need to KnowHGM Ultra fine Grinding Mill is the equipment specializing in producing fine and ultrafine powder of noninfammable, non limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, ilite, pyrophylite and vermiculite, sepiolite, attapulgite, rectorite, diatomite Total line machine is closed system ,the bag filters has HGM Ultra Fine Grinding Mill2024年1月27日 CNC Grinding Machines: The most advanced and expensive, ranging from $50,000 to over $150,000 Ideal for complex, highprecision work What is the Lifespan of a Grinding Machine? Most grinding machines have an What is a Grinding Machine: Definition, Types,

.jpg)

Grinding Machines SpringerLink

2015年1月1日 As grinding machines belong to the class of machines for the material removal with geometrically nondefined cutting edges, those machines can be classified in correlation to the classification of the different process technologies with geometrically nondefined cutting edges as it is given in DIN 8589, parts 11, 12, and 13 (DIN 858911 2003; DIN 858912 2003; 2024年8月9日 Working Principles Feeding: Limestone is fed into the machine through a feeder, which controls the amount of material entering the grinding chamber Grinding: The material is crushed between grinding rollers and rings (in Raymond and Vertical mills) or by grinding media (in Ball mills)The material is continuously ground until it reaches the desired fineness6 Types Of Limestone Dry Powder Grinder Machinesequipment for grinding magnesite bechamelsausmaken Magnesite Mining Equipment In the India mining industry, secondhand stone grinding machine is popular as magnesite purchase in andhra the first chunk of raw ore will first pass through jaw crusher equipment Magnesium Sulphate Heptahydate Magnesium sulphate Laizhou Shouxi Magnesite Industry Co ,Ltd was Magnesite grinding machinery Stone PulverizerThe barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, Barite Grinding Production Line TAYMACHINERY

Comprehensive Guide to Mining Thickeners

2023年11月23日 Mining thickeners are available in various types, each designed to meet specific process requirements and operational needs Understanding the different types of thickeners is essential for selecting the most suitable option for a mining operationHGM Series Micro Powder Grinding Mill Introduction of HGM Series Micro Powder Grinding Mill HGM Series Micro Powder Grinding Mill which we also called super fine pulverizer, because the gridning mill granularity (or final size) of the finished products can be freely adjusted between 3253000meshes (004500057mm) Ring Roller Grinding MillThe Limestone powder ultrafine grinding mill was made by Clirik in 2016 This is a professional processing of limestone powder grinding machines The fineness of the finished product can be adjusted between 325 mesh and 3000 mesh Limestone Powder Ultrafine Grinding Mill has HGM80, HGM90, HGM100, HGM125,HGM1680 five modelsLimestone Powder Ultrafine Grinding Mill2024年1月24日 Grinding: The calcined magnesite is then finely ground into powder form Grinding is usually done in ball mills, where the magnesite particles are reduced in size to achieve the desired fineness Classification: After grinding, the magnesite powder may go through a classification process to separate particles of different sizesMagnesite Powder Process And Magnesite Grinding Mills

Which Should You Choose Barite Grinding Mills?

Barite Powder Micro Powder Gridning Mill Advantage: 1 Barite Powder Micro Powder Gridning Mill Wearing parts are made of wearresistant materials High utilization rate of Wear material: 25years 2Barite Powder Micro Powder Gridning Mill Multilayer grinding ring design for higher grinding efficiency2024年4月7日 Category: Powder Grinding HengYang Machinery Micro Powder Grinding Plant Magnesite Grinding Plant April 7, 2024 182 Barite Grinding Plant April 7, 2024 212 Barite is a kind of important Bamineral, with Powder GrindingHengYang MachineryBarite powder surface coating machine is widely used in nonmetallic mineral filler, plastic, rubber, binder and other modern polymer materials, polymerbased composites, functional materials and coatings and other industries Barite Barite Powder Surface Coating Machine Barite Shanghai Clirik Machinery devoted to provide barite processing and grinding solution,barite grinding mill, barite grinding machine,barite processing machine, barite powder production line, barite powder making machine for saleClirik Barite grinding mill Shanghai Clirik

Barite Grinding Production Line TAYMACHINERY

The barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, This is the process of producing 800 mesh barite powder by HGM100 ultrafine mill production line The barite raw material is first broken into small pieces, and then transported to the grinding chamber of the main machine of the HGM100 grinding millXinjiang, China 800 mesh barite powder grinding production line2021年10月29日 Magnesite Stone Crusher >> Jaw Crusher – Coarse Crushing Jaw crushers are widely used as crushing equipment in the magnesite grinding production line It is mainly used for the primary crushing operation of the raw material magnesite so that the crushed magnesite meets the particle size requirements required by the next constructionMagnesite Grinding Equipment Production LineBenefits of Clirik Limestone Powder Grinding Mill Machinery 1 High efficiency:Under the same final size and power, the product capacity of ultrafine mill is twice than jet mill and agitation mill 2 Longer lifetime of spare parts:The roller and ring are made of special material, which improve the grinding efficiency a lotFor same material and final size, the lifetime of its wearing Limestone Powder Grinding Mill Machinery

.jpg)

Exceptional Barite Processing Methods and Machines

2023年3月20日 To fully dissociate useful barite minerals, ball mills are commonly used to grind barite rocks Generally, the grinding fineness of barite200 is 85~90%, and a twostage grinding process is often used In view of the differences in the properties of barite ores, the optimum grinding fineness needs to be determined experimentally2023年5月12日 Magnesite (MgCO 3) is a natural mineral mainly composed of magnesium carbonate and is the main source for the production of magnesium metal and magnesium oxide The major gangue minerals of magnesite ore are silicates (mainly talc, quartz, serpentine, etc) and carbonates (dolomite and calcite)Magnesite Ore Processing: Separation and CalcinationIn this background, having accumulated multiple years’ experience in manufacturing mills, Clirik has designed and launched a newtype barite powder ultrafine vertical roller mill on the basis of introducing the vertical roller mill technology from Taiwan and Germany, which integrates the functions of grinding, classifying, conveying, secondary classifying, and packing progress into Barite powder ultrafine vertical roller mill Clirik Barite grinding