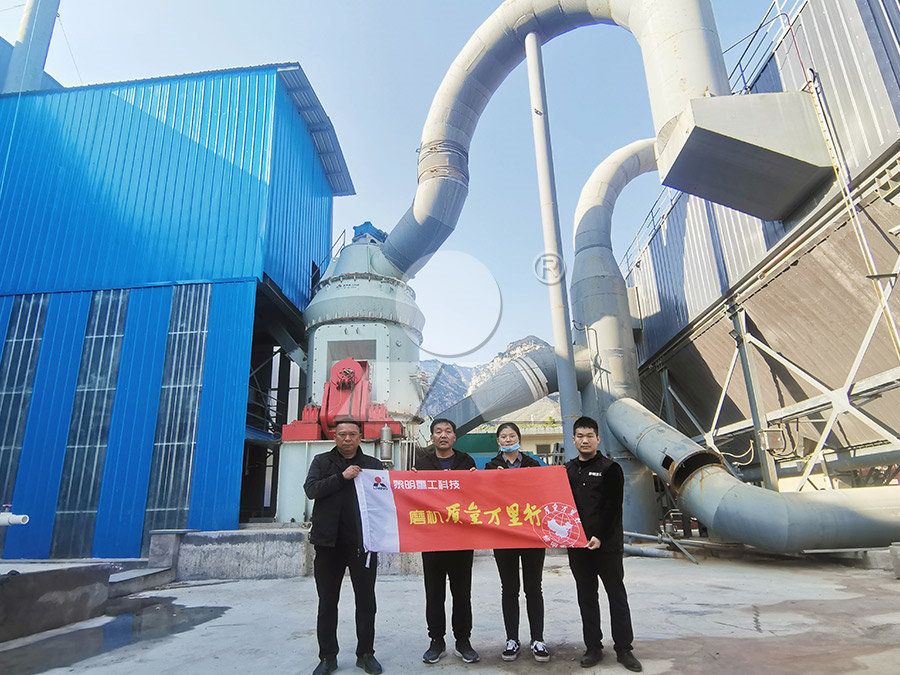

Model of mineral powder vertical mill

.jpg)

A multicomponent model for the vertical spindle mill

2016年3月10日 A multicomponent model of vertical spindle mill is developed • Interlinked comminution and classification operations in the mill are simulated • Particle size distributions 2015年3月1日 A new mechanistic model for vertical spindle mills (VSM) has been developed by Julius Kruttschnitt Mineral Research Centre (JKMRC) at the University of Queensland Unlike Modelling of vertical spindle mills Part 1: Submodels for of a laboratory scale vertical stirred mill using a Bond ball mill An energybased population balance model was developed to analyze the response in product size resulting from changing PREDICTING THE PRODUCT PARTICLE SIZE DISTRIBUTION FROM Vertical roller mill (VRM) is an established technology in cement and slag grinding applications and Boliden and Gebr Pfeiffer have been collaborating on the application of this technology in Vertical Roller Mills used for the comminution of mineral ores

.jpg)

Modeling and simulation of vertical roller mill using population

The application of vertical roller mills (VRMs) for ore grinding is a part of the strategies against rising energy consumption (Reichert et al, 2015) The VRM technology was introduced in the 2016年9月1日 Vertical roller mills (VRM) are widely used to grind, dry, and select powders from various materials in the cement, electric power, metallurgical, chemical, and nonmetallic oreOperational parameters affecting the vertical roller mill 2020年9月1日 A vertical stirred mill model, based on the Population Balance Model (PBM) technique, has recently been developed and validated using extensive data from pilot scale Mechanistic modeling and simulation of a batch vertical stirred Los molinos verticales de rodillos (VRM), son máquinas muy utilizadas para moler materia prima en fábricas dedicadas a la extracción y procesamiento de minerales Cualquier máquina Parámetros para el Proceso de Molienda en Molinos Verticales

.jpg)

A multicomponent model for the vertical spindle mill

2016年3月10日 A new model of VSMs has been developed which enabled interlinked simulation of comminution and classification operations that occur in the mill The multicomponent Vertical stirred mill is a fine grinding equipment that covers mills are smaller size, less auxiliary equipment required, more simple system and more options of processing methods Powder flow behaves continuously Providing the best Vertical Stirred Mill Mineral Processing Equipment2015年3月15日 Vertical Agitated Media Mill modeling has become subject of a research project due to its potential application as a secondary grinding mill as well as regrind and pellet feed preparation projectsVertical Agitated Media Mill scaleup and simulation of 80mm The raw materials are mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The vertical roller mill grinds the marital to D 85 of 90µm The ground product is calcined in a preheater to 850900℃ After calcination, the materials enter to a rotary kiln and heated to 1450℃ to become clinkerModeling and simulation of vertical roller mill using population

Analysis and Optimization of Grinding Performance of Vertical

2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters2020年9月1日 Vertical stirred mills are now widely used in the minerals industry and the increasing variety of models from different manufacturers and number of new units installed worldwide are evidence of Mechanistic modeling and simulation of a batch vertical stirred mill 2021年7月1日 Vertical stirred mills may be classified according to the speed of the stirrer in two groups: gravityinduced or fluidized mills [[1], [2], [3]]In the gravityinduced mills, the stirrer, generally of the screw type, turns so that the grinding charge exhibits an ascending convective motion at the center, descending from the edges of the screw and close to the mill shell, owing Predicting the effect of operating and design variables in 2017年4月1日 The scaleup and simulation model used here is based on the population balance modeling technique using the Herbst Fuerstenau scaleup procedure for ball mills, adapted for vertical stirred mills The model was originally validated with extensive data from pilot scale vertical stirred mill tests (Mazzinghy et al, 2012, Mazzinghy et al, 2013 Vertical stirred mill scaleup and simulation: Model validation

Operational parameters affecting the vertical roller mill

2016年9月1日 Vertical roller mill (VRM) is a largescale grinding equipment, which is used to grind raw materials from block/granule into powder Due to harsh production environment and inconsistent raw 2019年3月3日 This study investigated a mathematical model for an industrialscale vertical roller mill(VRM) at the Ilam Cement Plant in Iran The model was calibrated using the initial survey's data, and the Modeling and simulation of vertical roller mill using population 2016年3月10日 A new model of VSMs has been developed which enabled interlinked simulation of comminution and classification operations that occur in the mill The multicomponent models incorporate the effects of size and ash distribution in coal feed, air and coal flow rate and power drawn by the millA multicomponent model for the vertical spindle mill2022年5月31日 The vertical roller mill (VRM), including powder separation and crushing subsystems, is used extensively for intermediate crushing of minerals in several industries such as cement, electric power, and chemical Compression crushing is also the main crushing mechanism in the VRM, but there is also shear force between grinding roller and particlesAnalysis of vertical roller mill performance with changes in

.jpg)

Talc Ultra Fine Powder Grinding Mill

2021年8月13日 Ultra Fine Powder Mill; Vertical Roller Mill; PE Jaw Crusher; Gypsum Industrial Ultrafine Powder Mill Machine; China Shanxi annual production of 30,000 tons of anchoring agent powder project; Light Calcium HLM vertical roller mill is an advanced powder making equipment which is designed based on the world advanced We would like to recommend you the optimal grinding mill model to ensure you get the desired Guilin HongCheng Best HLM Vertical Roller Mill Manufacturer and SBM high quality calcium carbonate ultrafine powder vertical mill is widely used in many fields +17 [ Mining and minerals: Calcium carbonate ultrafine powder vertical mill is used in mining and mineral industry to produce ultrafine powder Model: CLUM Payment methods: Accepted Delivery Terms: FOB, CFR, CIF, EXW Calcium Carbonate Ultrafine Powder Vertical Mill2014年11月1日 The model previously implemented in Modsim™ has been successfully applied to represent the vertical mill operated with different ores Mineral (CETEM), Rio de Janeiro, RJ, Brazil c Centro Vertical mill simulation applied to iron ores ResearchGate

.jpg)

Vertical MillMill Powder Tech Solutions

Features Treatment:Grinder Material Properties:Oily、NonOily Fineness:3mm ~ 30mesh Capacity:20kg ~ 300kg Production Methods:Single MachineModels: HGM ultrafine grinding mill, CLUM vertical roller mill, LXMC ultrafine wet stirring mill etc Send us an Inquiry If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hoursSBM Ore Ultrafine Grinding Mill2019年8月1日 The stress model developed by Kwade et al is likewise based on the characteristic values of stress energy and stress frequency [37], [38], [39] The model assumes a maximum kinetic collision energy between the grinding media based on the assumption that the stirrer tip speed is equal to the velocity of the grinding mediaMill, material, and process parameters – A mechanistic model LM series vertical mill is a new type of milling equipment with advanced technology, Vertical Mineral Mill Series; LMN Vertical Slag Mill Series; LMM Vertical Coal Mill Series; LM(Y) Premilling Vertical mill; LMX(GX) Fine powder vertical mill; Models: LM130K: LM150K: LM170K: LM190K: LM220K: LM280K: Plate diameter(mm) 1300: 1500: 1700:LM series vertical mill

.jpg)

A multicomponent model for the vertical spindle mill Semantic

2016年3月10日 Semantic Scholar extracted view of "A multicomponent model for the vertical spindle mill" by C E Özer et al International Journal of Mineral Processing; View via Publisher espacelibraryuqau Save to Library Save Powder Technology 2018; 14Types of Mineral Powder Grinding Mills 1 Ball Mill The ball mill is one of the most common types of mineral powder grinding mills It works on the principle of impact and attrition: Vertical Roller Mill Vertical roller mills are advanced versions of the traditional ball millsThe role of mineral powder grinding mills in industrial productionThe LM Vertical Grinding Mill, launched by ZENITH, integrates five functions of crushing, grinding, powder selection, drying and material conveying It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protectionVertical Mill Shanghai Zenith Companyof 80mm The raw materials are mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The vertical roller mill grinds the marital to D 85 of 90µm The ground product is calcined in a preheater to 850900℃ After calcination, the materials enter to a rotary kiln and heated to 1450℃ to become clinkerModeling and simulation of vertical roller mill using population

Ultrafine Grinding Mill, Micro Powder Grinding Mill Bellian

The Ultrafine Grinding Mill, also known as a Micro Powder Grinding Mill or Ultra Fine Powder Grinding Machine, is a highefficiency and lowconsumption grinding mill that is widely used in the powder processing of various materials Bellian Mining Machinery offers a range of Ultrafine Grinding Mills, including the Ultrafine Vertical Mill and Fine Powder Mill Grinder, designed to Ultrafine vertical mill is a highefficient industrial grinding mill, It can be widely used in largescale ultrafine dry powder processing of nonmetallic minerals such as calcite, marble, limestone, dolomite, barite, talc, kaolin, dolomite, Model: CLUM1425, CLUM1632, CLUM1736Ultrafine Vertical Mill SBM Ultrafine Powder Technology2024年1月1日 DOI: 101016/jmineng2023 Corpus ID: ; Scaleup of Vertical Wet Stirred Media Mill (HIGmill) via Signature Plots, Stress Analyses and Energy Equations @article{Altun2024ScaleupOV, title={Scaleup of Vertical Wet Stirred Media Mill (HIGmill) via Signature Plots, Stress Analyses and Energy Equations}, author={Okay Altun and Tolga Sert Scaleup of Vertical Wet Stirred Media Mill (HIGmill) via Signature HCM’s mineral powder vertical mill is the ideal equipment choice for ultrafine grinding of metallurgical solid waste Advantages and characteristics of HLM series mineral powder vertical mill 1 It integrates drying, grinding, screening and collection, and is [Conference News] HCM’s Vertical Mill Injects Green And Low

.jpg)

Modelling of vertical spindle mills Part 1: Submodels for

2015年3月1日 Part 1 of this paper presents the submodels of comminution and classification functions, commonly associated with industrial vertical spindle mill operation These submodels are logically integrated to model the Emill, MPS mill and CKP mill, which are A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal Energysaving and Efficient Vertical Roller Mill Fote Machinery2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Morrison, RD, Kojovic, T, Mineral comminution Finally, the ball mill model was (PDF) Performance Evaluation of Vertical Roller Mill in Cement Vertical stirred mill is a fine grinding equipment that covers mills are smaller size, less auxiliary equipment required, more simple system and more options of processing methods Powder flow behaves continuously Providing the best Vertical Stirred Mill Mineral Processing Equipment

.jpg)

Vertical Agitated Media Mill scaleup and simulation

2015年3月15日 Vertical Agitated Media Mill modeling has become subject of a research project due to its potential application as a secondary grinding mill as well as regrind and pellet feed preparation projectsof 80mm The raw materials are mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The vertical roller mill grinds the marital to D 85 of 90µm The ground product is calcined in a preheater to 850900℃ After calcination, the materials enter to a rotary kiln and heated to 1450℃ to become clinkerModeling and simulation of vertical roller mill using population 2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parametersAnalysis and Optimization of Grinding Performance of Vertical 2020年9月1日 Vertical stirred mills are now widely used in the minerals industry and the increasing variety of models from different manufacturers and number of new units installed worldwide are evidence of Mechanistic modeling and simulation of a batch vertical stirred mill

.jpg)

Predicting the effect of operating and design variables in

2021年7月1日 Vertical stirred mills may be classified according to the speed of the stirrer in two groups: gravityinduced or fluidized mills [[1], [2], [3]]In the gravityinduced mills, the stirrer, generally of the screw type, turns so that the grinding charge exhibits an ascending convective motion at the center, descending from the edges of the screw and close to the mill shell, owing 2017年4月1日 The scaleup and simulation model used here is based on the population balance modeling technique using the Herbst Fuerstenau scaleup procedure for ball mills, adapted for vertical stirred mills The model was originally validated with extensive data from pilot scale vertical stirred mill tests (Mazzinghy et al, 2012, Mazzinghy et al, 2013 Vertical stirred mill scaleup and simulation: Model validation 2016年9月1日 Vertical roller mill (VRM) is a largescale grinding equipment, which is used to grind raw materials from block/granule into powder Due to harsh production environment and inconsistent raw Operational parameters affecting the vertical roller mill 2019年3月3日 This study investigated a mathematical model for an industrialscale vertical roller mill(VRM) at the Ilam Cement Plant in Iran The model was calibrated using the initial survey's data, and the Modeling and simulation of vertical roller mill using population

A multicomponent model for the vertical spindle mill

2016年3月10日 A new model of VSMs has been developed which enabled interlinked simulation of comminution and classification operations that occur in the mill The multicomponent models incorporate the effects of size and ash distribution in coal feed, air and coal flow rate and power drawn by the mill