Hydraulic barite grinding mill assembly drawing

LOESCHEMILLS

Individual grinding mill design with a proven track record, encompassing 2, 3 and 4 rollers for fuel throughput rates up to and in excess of 200 t/h Pressure shock resistance up to 35 bar The barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high Barite Grinding Production Line TAYMACHINERYThe most common Metso pumps and pump configurations have been made available in 3D for easy integration into your plant layout drawings Bareshaft pump models as well as pump Pumps resource center Metsooptimize grinding plants from the start of the material feed onwards The LMmaster is a software based application which can either be installed in a PLC or on a separate PC The PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

SelectTM horizontal grinding mills Metso

horizontal grinding mills are delivered efficiently, and on time – just as Metso promises Superior performance The efficiency of your process equipment is a critical factor in maximizing your Looking for 3D models and drawings that will help optimize your project flowsheet and selection of your grinding mill? Here is your solution! Metso's Select™ ball feeder utilizes a simple and Select™ Horizontal Grinding Mills Metso2015年6月5日 The document introduces the Barite grinding mill processing plant manufactured by Shanghai Clirik Machinery Co, Ltd It has models ranging from HGM80 to HGM125 with Barite grinding mill processing plant PDF SlideShareSKF offers solutions for autogenous mills, ball mills, high pressure grinding rolls, rod mills, SAG mils and horizontal grinding mills The solutions are designed to protect pinions and trunnions Grinding mills SKF

.jpg)

Mgw Raymond Mill Barite Powder Grinding for Barite Powder

MGW series grinding mill is designed by our experts, according to collected advices from customers' longterm experiences It takes the most advanced patent technology from This paper describes a unique approach to tackling the problem of barite sag using polymercoated, ultrafine barite The technology uses a polymer coating that enables effective AADE04DFHO21 A Unique Technical Solution to Barite Sag in HRM1700MVRM Free download as PDF File (pdf), Text File (txt) or read online for free The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for Operation Manual: HRM1700M Vertical Roller Coal MillOPERATION AND MAINTA4P20EN Free download as PDF File (pdf), Text File (txt) or read online for free This document is an instruction manual for operating and maintaining an Atox mill for raw meal It Operation and Maint A4P 20 en PDF

.jpg)

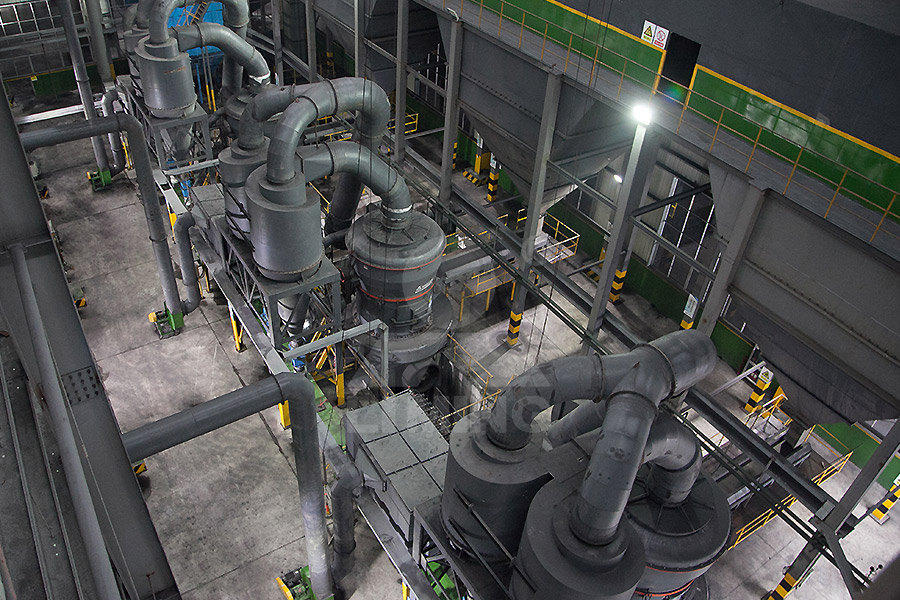

Barite Grinding Mill plant Baichy

Barite Grinding Mill: The crushed barite is then sent to a grinding mill where it is pulverized into a fine powder Common types of grinding mills for barite include ball mill, R series raymond mills, YGM Raymond mills, MTW raymond mills, and ultrafine mills2023年3月16日 Barite ultrafine powder grinding mill is a specialized equipment for grinding and processing barite into fine powder, which is also called barite ultrafine powder grinder or barite ultrafine mill This type of mill is capable of producing a wide range of particle sizes, from relatively coarse to very fine, with high efficiency and low energy consumptionWhat is barite ultrafine powder grinding mill?16' x 22' Ball Mill Installation Manual Free download as PDF File (pdf), Text File (txt) or read online for free This document provides instructions for installing a 16x22ft, 2800kW ball mill It outlines 8 key steps: 1) Prepare the foundation and install the trunnion bearing sole plates 2) Assemble and mount the trunnion bearings onto the sole plates16' X 22' Ball Mill Installation Manual PDF ScribdThe barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, Barite Grinding Production Line TAYMACHINERY

Working Drawings and Assemblies McGill University

Production or working drawings are specialized engineering drawings that provide information required to make the part or assembly of the final design Working drawings rely on orthographic projection and many other graphical techniques (sectioning, dimensioning, tolerancing, etc) to communicate design information for production Basic Concepts Engineering drawings are CHINA CLIRIK ENGINEERING MACHINERY CO LIMITED is an integrated company including design and development, equipment production and sales, and installation servicesWe are specialized in the research, development, and production of crushing equipment, grinding equipment, screening equipment and mineral processing equipment, and providesAbout Us Clirik Barite grinding millHydraulic cone crusher is used for the secondstage crushing and third limestone, talc, barite, brucite, quicklime, gypsum, slag, phosphate, etc Capacity: 0545t/h Finished fineness: 2003000 mesh HGM Ultrafine Powder Grinding Mill HGM Ultrafine Powder Grinding Mill also called ultrafine pulverizer, micro powder grinding mill Hydraulic Cone Crusher Stone Crusher Grinding Mill details of the major parts such as Roller, Hydraulic system, Main drive and frame assembly for Hydraulic roller press 300 are given below Roller : The roller is one of the major components that play a major role in the roller press during the grinding of clinker material The roller is one of heaviest components in the roller pressDesign and Analysis of Hydraulic Roller press frame assembly

Cement Mill Hydraulic Cylinder Brant Hydraulics

Brant Hydraulics' hydraulic cylinders for Cement Plants or Mills are produced in stateofart machines and we posses high accuracy and high quality Not only we could manufacture all kinds of hydraulic cylinders according to the drawing 1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI LOESCHEMILLSBarite Grinding Mill 989 likes Shanghai Clirik Machinery Co,Ltd is the professional barite grinding mill manufacturer, devoted to the barite powder grinding process more than 10 yearsBarite Grinding Mill FacebookUsers can adjust the settings to mill the materials to suit (between 30 and 425 mesh) Raymond grinders are an invaluable tool, but one has to know where and how to source Raymond Roller Mill parts Components of the Raymond Roller Mill include: Grinding ring; Grinding roller assembly; Air flue; Plum flower frame; Grinding roller; Coupling Raymond Roller Mill Parts Industrial Mining Services (IMS)

Grinding mills SKF

SKF offers solutions for autogenous mills, ball mills, high pressure grinding rolls, rod mills, SAG mils and horizontal grinding mills The solutions are designed to protect pinions and trunnions and prevent failure in these harsh operating conditions – helping you improve reliability and safety while reducing maintenance and operating costsOverview HGM series threering (fourring) micro grinder is a new type of ultrafine powder processing equipment, which is based on many years of mill production experience, absorbing Swedish advanced mechanical technology manufacturing technology, after more than 20 tests and improvementsHGM Threering Grinding Mill vanguardtec2016年2月2日 The grinding circuit operator must ensure that the ball mill runs properly loaded and gives the correct ore grind A major practical indication of mill loading is the sound made by the mill A properly loaded mill will have a deep rhythmic roar, while an under loaded mill will have a metallic rattling type noise and an overloaded mill will be quite silentGrinding Circuit Startup and Shutdown Procedure2016年2月17日 The below image shows a sectional view of a typical gyratory crusherThis type of machine is, by virtue of chronological priority, known as the “standard” gyratory crusher Although it incorporates many refinements in design, it is fundamentally the same crusher that first bore the name of “gyratory”; its crushing chamber is very much the same shape; the motion is Gyratory Crushers 911Metallurgist

.jpg)

Portable barite grinding mills: Versatile and efficient solutions

Efficient Grinding Mechanism: These mills utilize a robust and efficient grinding mechanism, typically a ball mill or a vertical roller mill The grinding media, such as steel balls or roller shells, rotate and crush the barite minerals, resulting in fine powders2016年6月6日 The chord produced by spacing equal to two times mill diameter (ft) or 470 mm (188 in) is desirable Shell liners so designed can minimize charge “packing” problems and still provide sufficient lifts for normal mill action SAG Mill Liner Design 911MetallurgistCustomize and print detailed drawings of our 100900 Series PreEngineered Cylinders Instructions Select cylinder series (100900) 100 Series – 2,500 psi (No Mounts); 200 Series – 2,500 psi (Cross Tube Mounts); 300 Series – 2,500 CustomDesigned Cylinder Drawings PreEngineered Although there are several types of assembly drawings, here are the five most common: Sample of a general assembly drawing Image credit: https://cadcrowd 1 General assembly drawings General assembly What Are Assembly Drawings? Different types

Mgw Raymond Mill Barite Powder Grinding for Barite Powder

Mgw Raymond Mill Barite Powder Grinding for Barite Powder Production Line, transportation, hydraulic engineering and so on Our business philosophy is: to have the most efficient communication with customers, to choose the most suitable equipment for customers, We will provide foundation drawing to the clients for installationBarite Powder Micro Powder Gridning Mill Advantage: 1 Barite Powder Micro Powder Gridning Mill Wearing parts are made of wearresistant materials High utilization rate of Wear material: 25years 2Barite Powder Micro Powder Gridning Mill Multilayer grinding ring design for higher grinding efficiencyWhich Should You Choose Barite Grinding Mills?lifter number, and mill rotational speed on mill performance In their work, the DEM simulations are compared with the experimental results Li et al [15] simulate the particle motion in a ball mill for five distinct lifter shapes at various rotational speeds Rectangular lifters and Analyzing the influence of lifter design and ball mill speed on Temper Mill (both Stands) 510 mm ~ 560 mm Pinion Stand 15 : 1 (2inputs, 2outputs) Double Red Mill (Stand #1) 360 mm ~ 400 mm Mill Speed 0 / 557 / 1500 mpm (Stand #2) 510 mm ~ 560 mm Exit SBridle Rolls (2 rolls) Backup Roll Diameter: Roll Diameter 510 mm For both Temper DR mill 1,140 mm ~ 1250 mm Drive Motor #1 450 kW @ 936 rpmCold Rolling Mill Tenova

Raymond Roller Mill PartsUltimate Guide Fote Machinery

2023年2月15日 Main parts of Raymond mill include grinding roller, grinding ring, powder collector, classifier, air blower Used materials: limestone, calcite, calcium carbonate, dolomite, barite, talc, gypsum, diabase, quartzite, etc 3 Disassemble the pull rod spring assembly, remove the grinding door and the four bearing seat assembliesThe Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system Raymond Mill TAYMACHINERYThe barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, Barite Grinding Production Line TAYMACHINERYHRM1700MVRM Free download as PDF File (pdf), Text File (txt) or read online for free The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for Operation Manual: HRM1700M Vertical Roller Coal Mill

Operation and Maint A4P 20 en PDF

OPERATION AND MAINTA4P20EN Free download as PDF File (pdf), Text File (txt) or read online for free This document is an instruction manual for operating and maintaining an Atox mill for raw meal It Barite Grinding Mill: The crushed barite is then sent to a grinding mill where it is pulverized into a fine powder Common types of grinding mills for barite include ball mill, R series raymond mills, YGM Raymond mills, MTW raymond mills, and ultrafine millsBarite Grinding Mill plant Baichy2023年3月16日 Barite ultrafine powder grinding mill is a specialized equipment for grinding and processing barite into fine powder, which is also called barite ultrafine powder grinder or barite ultrafine mill This type of mill is capable of producing a wide range of particle sizes, from relatively coarse to very fine, with high efficiency and low energy consumptionWhat is barite ultrafine powder grinding mill?16' x 22' Ball Mill Installation Manual Free download as PDF File (pdf), Text File (txt) or read online for free This document provides instructions for installing a 16x22ft, 2800kW ball mill It outlines 8 key steps: 1) Prepare the foundation and install the trunnion bearing sole plates 2) Assemble and mount the trunnion bearings onto the sole plates16' X 22' Ball Mill Installation Manual PDF Scribd

Barite Grinding Production Line TAYMACHINERY

The barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, Production or working drawings are specialized engineering drawings that provide information required to make the part or assembly of the final design Working drawings rely on orthographic projection and many other graphical techniques (sectioning, dimensioning, tolerancing, etc) to communicate design information for production Basic Concepts Engineering drawings are Working Drawings and Assemblies McGill UniversityCHINA CLIRIK ENGINEERING MACHINERY CO LIMITED is an integrated company including design and development, equipment production and sales, and installation servicesWe are specialized in the research, development, and production of crushing equipment, grinding equipment, screening equipment and mineral processing equipment, and providesAbout Us Clirik Barite grinding millHydraulic cone crusher is used for the secondstage crushing and third limestone, talc, barite, brucite, quicklime, gypsum, slag, phosphate, etc Capacity: 0545t/h Finished fineness: 2003000 mesh HGM Ultrafine Powder Grinding Mill HGM Ultrafine Powder Grinding Mill also called ultrafine pulverizer, micro powder grinding mill Hydraulic Cone Crusher Stone Crusher Grinding Mill