Ore mill model t1600

.jpg)

Wet Pan MillWet Pan MillThe Nile Machinery Co, LtdThe Nile

Wet pan mill grinds ores by wheel drive First, power is transferred from the motor to the reducer, then to the horizontal axis, and finally to the grinding wheel The wheels can be rotated around China 1600 Wet Pan Mill wholesale Select 2024 high quality 1600 Wet Pan Mill products in best price from certified Chinese Raw Material Mill manufacturers, High Speed Mill suppliers, 1600 Wet Pan Mill MadeinChinaGold Ore Mill Double Wheel Wet Gold Mill Type 1600 Ore Mill Equipment , Find Complete Details about Gold Ore Mill Double Wheel Wet Gold Mill Type 1600 Ore Mill Equipment,Gold Ore Mill Gold ore mill double wheel wet gold mill type 1600 ore mill Find your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, ) on DirectIndustry, the industry specialist for your professional purchasesOre mill, Ore grinding mill All industrial manufacturers

1600 1500 1400 model wet pan mill for gold ore equiped with

Oil, Gas Mining » Mineral Processing » Grinding Mills » 1600 1500 1400 model wet pan mill for gold ore equiped with grinding roller grinding base and gear in Zhengzhou, Henan, China Professional gold ore Grinding equipment wet pan mills 1600 1500 models fine output size less than 200 mesh in Zhengzhou, Henan, China Trusted Seller Contact the seller forProfessional gold ore Grinding equipment wet pan mills 1600 high efficiency 1600 model wet pan mill 12tph capacity grinding gold ore with grinding roller base and gear in Zhengzhou, Henan, China Trusted Seller Contact the seller forhigh efficiency 1600 model wet pan mill 12tph capacityApplication: Mainly used for gold, silver, lead, zinc, tantalum niobium ore, molybdenum, copper, tin ore, etc The wet pan mill is the full name of the wet pan grinding mill, gold pan mill, or Wet Pan Mill JXSC Machinery

.jpg)

Wet Pan Mill Zoomjo Group

Wet pan mill is the best equipment to replace ball mill because of its low investment, high output, easy use and maintenance, and quick cost recovery It is used for the material recrushing At Bellian Mining Machinery, we specialize in crafting advanced solutions for ore crushing, sand making, and grinding processes Whether it's efficiently crushing ores, creating highquality Ore Crushing, Sand Making, Grinding Machinery Bellian Mining It is almost impossible to describe, let alone do justice to, the variety of processes that have been used to mill ore The importance of mills cannot be understated since no money was made until the minerals were stripped of their metal Winning the Metal: Ore Mills of the West Western 2018年10月1日 The impact of ore variability on process performance was observed at the OK Tedi mine in Papua New Guinea, where the variations in feed ore hardness (Bond work index 5–16 kWh/t) and in feed size distributions caused the SAG mill throughput to fluctuate between 700 and 3000 t/h (Sloan et al, 2001)Quantifying variability of ore breakage by impact ScienceDirect

Population balance model approach to ball mill optimization in iron ore

3 BALL MILL MODEL The population balance model may be expressed by Equation (1): > @ ¦ i1 1 i b ij m j j i j i S Ht dt d H m t (1) where: S i (t) is the size discretized selection function for 2017年2月1日 PDF This work focuses on the characterization of heat generation during dry fracture by direct impact of a tantalum ore Moreover, an attempt was made Find, read and cite all the research Heat generation model in the ballmilling process of a tantalum ore2013年4月1日 The ballmill data were analyzed by means of the orespecific breakage distribution function determined from pendulum tests and a multisegment ballmill model, enabling a scaleup relationship to (PDF) Multicomponent AG/SAG mill model ResearchGate5 new feed fi discharge pi recycle classification grate high energy impact low energy impact breakage Figure 4 Conceptual model of a SAG mill The model utilises the concept that breakageModelling and Simulation Techniques Applied for Optimisation of

.jpg)

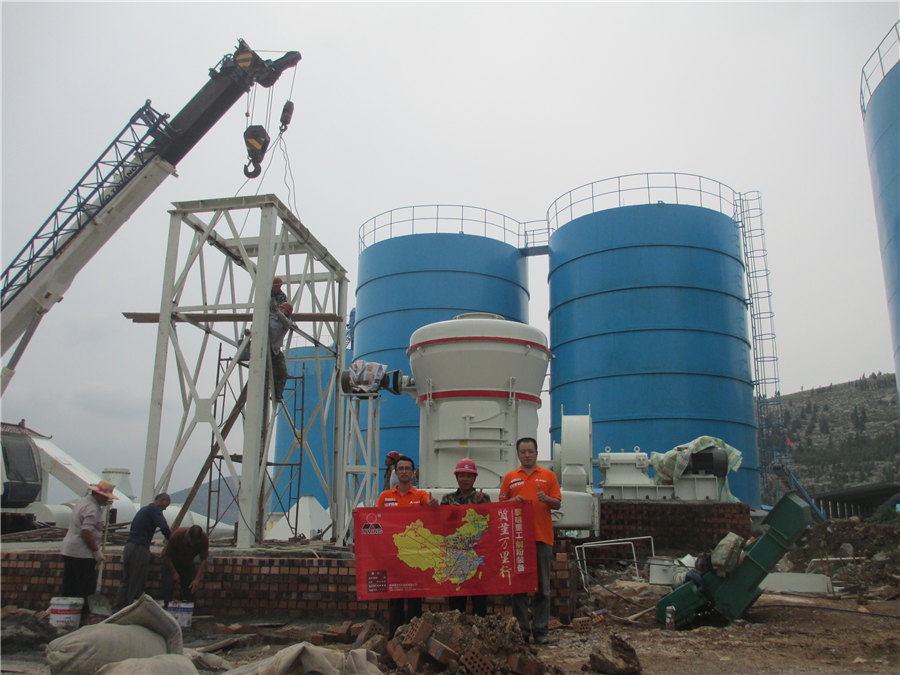

SBM Ore Ultrafine Grinding Mill

HGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM ultrafine grinding mill, 2013年4月1日 Two types of mills commonly found in the minerals processing industry are ball and semiautogenous (SAG) mills, which use both ore and steel balls as grinding media (Wei and Craig, 2009b)In the case of a ball mill the ore is crushed before it enters the mill, whereas a SAG mill receives runofmine (ROM) ore directly (Stanley, 1987)A SAG mill in a singlestage Analysis and validation of a runofmine ore grinding mill circuit 2022年5月23日 Grinding experiments were conducted in a laboratoryscale stirred mill on a lowgrade PGE bearing chromite ore HighPressure Grinding Rolls (HPGR) product of −1 mm was used as feed material to (PDF) Modeling and application of stirred mill for the coarse The Ban Houayxai mine (BHX) is a relatively lowgrade, lowcost, open pit goldsilver deposit in Laos operated by Phu Bia Mining, a subsidiary of PanAust The ore production rate at BHX is 45 Mt/a, with direct tipping to a semiautogenous grinding/ball mill circuit with a carboninleach process plant Approximately 100 000 oz of gold is produced per annumThe operation is Predicting Mill Ore Feed Variability Using Integrated Geotechnical

.jpg)

How to choose a suitable ore powder grinding mill?

2023年10月17日 Type of Ore powder grinding mil 1 Raymond mill Raymond mill feed particle size ≤30mm, production capacity 8176 tons/day, production fineness 80325 mesh, the main transmission device adopts sealed gearbox pilotscale mills (042 m diameter), and surveys in a fullscale industrial (52 m diameter) mill It is first demonstrated that the successful application of the model required recognizing the nonnormalizable nature of the breakage function of the particular Optimization of Solids Concentration in Iron Ore Ball Milling 2017年9月1日 The transitional change on the implementation of iso 14001: 2015 in Copper Ore Mill Case studyThe transitional change on the implementation of 2019年9月1日 Developing a stepwise approach to simulate a hammer mill through the Whiten model the adherence for a gold ore September 2019 REM International Engineering Journal 72(3):535542Developing a stepwise approach to simulate a hammer mill

.jpg)

Modelplant mismatch detection and model update for a runofmine ore

Nonlinear mill model The milling circuit model is based on phenomenological equations and consists of separate modules for the feeder, mill, Xms 0 50 947 Holdup of solid ore in the mill [m 3] Xmf 0 50 354 Holdup of ne ore in the mill [m 3] POPULATION BALANCE MODEL APPROACH TO BALL MILL OPTIMIZATION IN IRON ORE GRINDING* Patrícia Mundim Campos Faria1 Luís Marcelo Tavares 2 Raj K Rajamani 3 Abstract The process of particle size reduction by grinding is inherently inefficient and involves high capital and operating costs In particular, ball milling is one of the POPULATION BALANCE MODEL APPROACH TO BALL MILL OPTIMIZATION IN IRON ORE 2013年4月1日 DOI: 101016/JMINENG201210009 Corpus ID: ; Analysis and validation of a runofmine ore grinding mill circuit model for process control @article{Roux2013AnalysisAV, title={Analysis and validation of a runofmine ore grinding mill circuit model for process control}, author={Johan D le Roux and Ian Keith Craig and D G [PDF] Analysis and validation of a runofmine ore grinding mill 2023年9月1日 A typical coarse ore stockpile (Fig 1) is fed from either a fixed or moving conveyor with primary crushed (minus ∼ 250 mm) rock to build up a pile above one or more fixed discharge feeders or draw pointsThese feeders discharge onto one or more belt conveyors that in turn each feed an autogenous grinding (AG) or semi autogenous grinding (SAG) millA 3D cellular automata ore stockpile model ScienceDirect

Vertical mill simulation applied to iron ores ResearchGate

2014年11月1日 The model previously implemented in Modsim™ has been successfully applied to represent the vertical mill operated with different ores2011年2月1日 Request PDF Understanding fine ore breakage in a laboratory scale ball mill using DEM DEM models of fine grinding in ball and stirred mills have to date almost entirely focused on the motion Understanding fine ore breakage in a laboratory scale ball mill using PDF On Jan 1, 2011, W M Jansen and others published Tracerbased minemill ore tracking via process hold ups at Northparkes mine Find, read and cite all the research you need on ResearchGate(PDF) Tracerbased minemill ore tracking via 2019年1月30日 Mill power models have been used in a variety of ways in industrial practice since power directly equates to throughput and fineness of ground product We first start with HoggFuerstenau Power Model and show how this model successfully predicted the power draw of many grinding mills in several mining operations Then, we show how this model was on the The Evolution of Grinding Mill Power Models Mining,

(PDF) A mechanistic model of SAG mills ResearchGate

2014年1月1日 Figure 8Comparison of measured (symbols) and predicted size distributions (lines) from milling of copper ore in a 6´x 2´ pilotscale AG mill (Carvalho and Tavares, 2014) The assumption that 2023年1月11日 The Craftsman T1600 may be just the right mower for you From its robust power to its durable construction, this lawn mower has all the bells and whistles of a topoftheline model – at an affordable price In this review, we’ll take an indepth look at the Craftsman T1600, from specs and performance to pricing and what accessories are Craftsman T1600: Review, Price, Specs Attachments Farm Sun the mill, the sump and hydrocyclone is described brie y in Section 2 The model uses ve states to represent the constituents of charge in the milling circuit The states are rocks, solids, nes, balls and water Rocks are ore too large to be discharged from the mill, whereas solids are ore that can be discharged from the millAnalysis and validation of a runofmine ore grinding mill circuit 2001年1月1日 Download Citation A strategy to minimise ore grade reconciliation problems between the mine and the mill Major discrepancies between mine estimates and estimates from plant metallurgical A strategy to minimise ore grade reconciliation problems between the

Ore Grade Reconciliation Techniques A Review ResearchGate

2015年1月1日 "A New Model to Improve Ore Grade Reconciliation between the Exploration Model and the Mine", Proceedings of Mine Planning and Equipment Selection (MPES) Conference, Fremantle, Western Australia Energies 2021, 14, 1786 2 of 14 size [11] The cost of the energy used in comminution represents 50 ÷ 60% of the entire ore processing costs [12]Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems2018年7月1日 A hybrid nonlinear model predictive controller (HNMPC) is developed for a runofmine ore grinding mill circuit A continuoustime grinding mill circuit model is presented with a hydrocyclone cluster as the primary classifier The discretetime component is the switching of hydrocyclones in the hydrocyclone clusterHybrid nonlinear model predictive control of a runofmine ore 2020年5月25日 In this paper, we develop a state space model of semiautogenous (SAG) mill systems, which is of great significance to the mineral processing controlA Dynamic Model for a Class of SemiAutogenous Mill Systems

Winning the Metal: Ore Mills of the West Western

It is almost impossible to describe, let alone do justice to, the variety of processes that have been used to mill ore The importance of mills cannot be understated since no money was made until the minerals were stripped of their metal 2018年10月1日 The impact of ore variability on process performance was observed at the OK Tedi mine in Papua New Guinea, where the variations in feed ore hardness (Bond work index 5–16 kWh/t) and in feed size distributions caused the SAG mill throughput to fluctuate between 700 and 3000 t/h (Sloan et al, 2001)Quantifying variability of ore breakage by impact ScienceDirect3 BALL MILL MODEL The population balance model may be expressed by Equation (1): > @ ¦ i1 1 i b ij m j j i j i S Ht dt d H m t (1) where: S i (t) is the size discretized selection function for Population balance model approach to ball mill optimization in iron ore 2017年2月1日 PDF This work focuses on the characterization of heat generation during dry fracture by direct impact of a tantalum ore Moreover, an attempt was made Find, read and cite all the research Heat generation model in the ballmilling process of a tantalum ore

(PDF) Multicomponent AG/SAG mill model ResearchGate

2013年4月1日 The ballmill data were analyzed by means of the orespecific breakage distribution function determined from pendulum tests and a multisegment ballmill model, enabling a scaleup relationship to 5 new feed fi discharge pi recycle classification grate high energy impact low energy impact breakage Figure 4 Conceptual model of a SAG mill The model utilises the concept that breakageModelling and Simulation Techniques Applied for Optimisation of HGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM ultrafine grinding mill, SBM Ore Ultrafine Grinding Mill2013年4月1日 Two types of mills commonly found in the minerals processing industry are ball and semiautogenous (SAG) mills, which use both ore and steel balls as grinding media (Wei and Craig, 2009b)In the case of a ball mill the ore is crushed before it enters the mill, whereas a SAG mill receives runofmine (ROM) ore directly (Stanley, 1987)A SAG mill in a singlestage Analysis and validation of a runofmine ore grinding mill circuit

(PDF) Modeling and application of stirred mill for the coarse

2022年5月23日 Grinding experiments were conducted in a laboratoryscale stirred mill on a lowgrade PGE bearing chromite ore HighPressure Grinding Rolls (HPGR) product of −1 mm was used as feed material to The Ban Houayxai mine (BHX) is a relatively lowgrade, lowcost, open pit goldsilver deposit in Laos operated by Phu Bia Mining, a subsidiary of PanAust The ore production rate at BHX is 45 Mt/a, with direct tipping to a semiautogenous grinding/ball mill circuit with a carboninleach process plant Approximately 100 000 oz of gold is produced per annumThe operation is Predicting Mill Ore Feed Variability Using Integrated Geotechnical