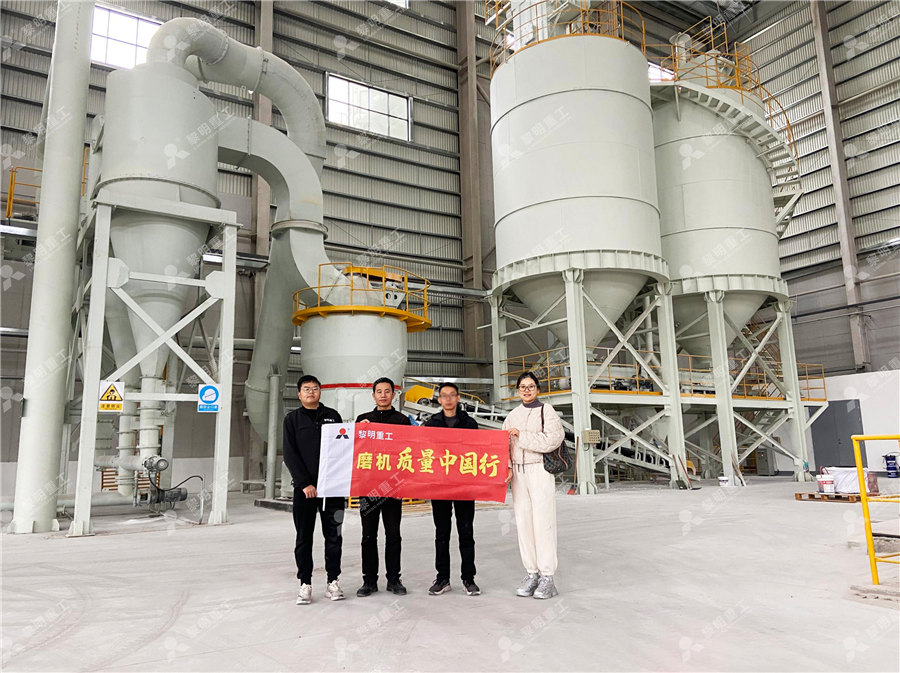

Machine for grinding lithium carbonate

.jpg)

Lithium Processing Systems and Equipment Bepex

Bepex has been supplying processing technology for lithium carbonate or lithium hydroxide production since the early 1990s Now, with lithium producers straining to fulfill ever increasing demand, Bepex is pioneering systems to streamline Impurity removal from the salar brine is a critical step in the process flowsheet for production of batterygrade lithium Our MaxRTM technology provides the most advanced method in the Lithium processing technology Complete solutions that FLSmidthThe Mikro ACM® Air Classifying Mill SF is used to grind lithium carbonate and produce the specific particle size distribution required for use in high performance Lithium Ion Batteries Ultrafine lithium powders used in Lithium Ion battery Lithium Carbonate Milling Hosokawa Micron Powder 2019年8月23日 Subsurface brines trapped in the Earth’s crust are major source material for lithium carbonate These sources are less expensive to mine than from rock such as Lithium Processing Equipment, Process Flow, Cases JXSC Machine

.jpg)

Lithium handling Carmeuse Systems

As the demand for batterygrade lithium continues to grow, Carmeuse Systems is at the ready to support lithium producers by providing lime slaking equipment and dry chemical handling systems to meet your operational needs Commercial Veolia has a wide range of evaporation and crystallization system designs specific for lithium processing Lithium Products: Lithium Hydroxide (LiOH), Lithium Carbonate (Li2CO3), Lithium Lithium Processing Solutions Services Veolia Water It has the ability to ultrafine grind raw materials with lowmelting points to sizes of a few μm The machine can be manufactured to correspond with GMP, CIP/SIP standards, making it a suitable machine for grinding a wide variety of materials HOSOKAWAMICRON CORPORATIONThe Mikro ACM® Air Classifying Mill SF is used to grind lithium carbonate and produce the specific particle size distribution required for use in high performance Lithium Ion Batteries Ultrafine lithium powders used in Lithium Ion battery Lithium Carbonate Compounds Hosokawa Micron

.jpg)

Hard Rock Lithium Processing SGS

Working with the lithium concentrate, SGS’ team uses a standardized flowsheet to produce high grade lithium products such as lithium carbonate or lithium hydroxide These are reagents for Cornish Lithium has worked with Grinding Solutions Ltd and Wardell Armstrong International, both based in Cornwall, together with Strategic Metallurgy, based in Perth Australia to complete concentrator test work on different samples of ore Processing Technology Cornish Lithium PlcThe primary crude lithium carbonate and the second crude product adhesion liquid contain impurities such as Na2SO4, and then are stirred with purified water at about 90 ° C, and the washing liquid is sent to the alkali, and after washing, Rotary Kiln used for Lithium carbonate to lithium Calcium Carbonate Modified Line Highspeed rotor pulverizer is used as the modified main machine to heat the air intake to keep the modified main machine at a suitable modification temperature, and the superfine heavy calcium (D97 Industrial Powder Grinding Machine Manufacturers,

.jpg)

How to mine lithium ore, mineral processing, crushing, grinding

2022年12月13日 The following is the process flow of lithium ore processing to obtain lithium carbonate: After the mining of lithium ore, the bulk material is first crushed by electromagnetic dressing equipment; Then under the action of belt conveyor, it is evenly sent to the grinding machine for deep grinding treatment; After grinding, lithium ore powder 2019年8月29日 As for the supply of lithium carbonate, there will be a gap in the supply and demand of global lithium carbonate by 2019 3 Lithium mining equipment Lithium ore beneficiation equipment includes crushers, ball mills, jigs, flotation machines, etc, as well as some auxiliary equipment to form a complete production lineThe 5 Most Useful Methods Of Lithium Mining BeneficiationLithium carbonate has a very wide range of applications in the production of secondary lithium salts and metal lithium products, and is the most critical product in the lithium industry In the current actual production process of lithium carbonate, its main production raw materials come from salt lake brine and ore extracts At present, in the production process of lithium carbonate News Process Flow Of Lithium Carbonate Vertical Roller Mill View lithium carbonate information, including dose, uses, sideeffects, renal impairment, pregnancy, breast feeding, May impair performance of skilled tasks (eg driving, operating machinery) Medicinal forms There can be variation in the licensing of different medicines containing the same drugLithium carbonate Drugs BNF NICE

Aspects of Spodumene Lithium Extraction Techniques MDPI

2024年9月30日 Lithium (Li), a leading cathode material in rechargeable Liion batteries, is vital to modern energy storage technology, establishing it as one of the most impactful and strategical elements Given the surge in the electric car market, it is crucial to improve lithium recovery from its rich mineral deposits using the most effective extraction technique In recent years, both 2022年7月5日 The three minerals, spodumene, petalite, and lepidolite, can be used for various purposes after beneficiation and concentrationThe cutoff grade and industrial grade of lithium deposits are divided into manual beneficiation and machine beneficiation, and the grade indicators are determined respectivelyThe division between manual and machine Lithium Processing Plant JXSC MachineLithiumIonenBatterien Maschinen Anlagen für die Produktion von LithiumIonenAkkus Kathode Anode Infos hier! Calcium Carbonate (GCC) Technical ceramic Hard Minerals Talc Graphite rounding for lithiumion batteries Grinding and classifying in one machine; Cool and contaminationfree grinding;Lithiumion batteries Hosokawa AlpineOur lithium processing capabilities are reinforced by a global team of scientists and engineers that design solutions for the production of high purity lithium System Designs Veolia has a wide range of evaporation and crystallization system designs specific for lithium processing Filtration and membrane, ion exchange, lithium brine concentrationLithium Processing Solutions Services Veolia Water

Spodumene: The Lithium Market, Resources and

2019年5月29日 The expected growth rate for lithium carbonate and lithium hydroxide is respectively 10% and 145% until 2025 , since they are two of the raw materials used for LiBs In 2016, lithium carbonate prices were reported to 2024年11月21日 The grinding and grading stage of lithium ore is to ensure that lithium minerals are fully dissociated from gangue mineral monomers Therefore, lithium ore extraction is inseparable from ore grinding, and the common Ball Mill Is Indispensable For Lithium Ore ProcessingLithium carbonate grinding production line of a lithium industry company in Jiangxi City Raw Material:Lithium Carbonate Capacity:10000t/y Feeding Size:60100 mesh Product Size:D50:5μm our experts will contact you within 6 hours Lithium carbonate grinding production line of a lithium industry Download scientific diagram Overview of main processing options for production of lithium carbonate from rock minerals from publication: Minerometallurgical processes for lithium recovery from Overview of main processing options for production of lithium carbonate

.jpg)

Hard Rock Lithium Processing SGS

suitable for lithium carbonate production contains 67% Li 2 O (75% 87% spodumene) Higher grade concentrates with 76% Li 2 O and low iron content are grinding circuits, ball and rod mill circuits, and crushing circuits also facilitate testing and circuit design After production2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the mill Grinding: Use a bucket elevator to send the crushed small pieces of calcium carbonate to the silo, then use a vibrating feeder to send them Guide to Calcium Carbonate Grinding: Mills, Tips, and UsesGrinding / Milling Machine Get know to our grinding / milling machine such as Ball Mill for mineral – limestone / calcium carbonate / GCC / PCC / silica, Impact Mill – pin mill, beater or hammer for food – spices / herbs / chili, for chemical – wax / powder coating / paint, and for pharma, Pulverizer, Air Classifier Mill, Jet Mill grinder for recycling purpose – cable / plastic and Machines Hosokawa Micron MalaysiaIn the production of lithiumion batteries, it is used for grinding and micronizing both cathode and anode materials Applications Grinding of lithium carbonate ; Grinding of coke ; Micronizing of graphite Principle of operation The product is pneumatically fed into the Mikro ACM® Air Classifying MillLithium compounds for batteries Hosokawa Micron Group

How to Choose a Calcium Carbonate Grinding Mill

The grinding mill is the core of the entire production line The choice of grinding mill machine is related to the quality of the final ground calcium carbonate powder, so how to choose the right calcium carbonate grinding equipment has Cobalt based precursors include cobalt oxide, cobalt hydroxide, oxy cobalt hydroxide, cobalt carbonate, as well as lithium carbonate, lithium hydroxide, and manganese oxide Manganese based precursors include The machine is HOSOKAWAMICRON CORPORATION2023年10月9日 The processing of lithium ore involves several steps, from mining and extraction to refining and purification The machinery and equipment used in a lithium ore processing plant may vary depending Lithium ore processing plant machinery and equipment LinkedInLithium carbonate grinding production line of a lithium industry company in Jiangxi City The customer is a hightech company invested by a listed company in Guangdong in Jiangxi According to peer customers, ALPA's ultrafine milling technology is at the leading level in the industry and is excellent in all aspects, so he contacted and purchased two sets of equipmentLithium carbonate grinding production line of a lithium industry

Flotation Machine for Lithium Ore: Efficient Separation and

2023年5月14日 3 Advantages of Lithium Ore Flotation Machine 1) High Efficiency The lithium ore flotation machine is designed to separate lithium from other minerals in the ore It uses the principle of selective attachment of air bubbles to the surface of the lithium mineral particles, allowing them to float to the surface and be collected2023年1月6日 Causticization of Lithium Sulfate Hard rock consisting of spodumene is one of the potential sources for commercial lithium production Calcination of spodumene concentrate at ~1050 °C for ~30 min followed by sulfuric acid roasting at ~250 °C for 30 min, water leaching, and impurities removal by precipitation and ion exchange have become the main methods to Potential Processes for Producing HighPurity Lithium Hydroxide: 2022年5月10日 A thick liquid lithium carbonate and secondary products attached contains Na2SO4 and other impurities, then wash with clean water to about 90 ℃ for stirring, drove with alkali solution, the centrifuge is used after washing strike isolated wet pure lithium carbonate, then through far infrared drying machine to dry, dry magnetic separation to remove machine fall off Lithium carbonate production process Machine Knowledge2016年5月9日 They forecast the lithium demand to grow by 81% from the current 192kt lithium carbonate equivalent (LCE) to 347kt LCE by 2020, and by 259% to 687kt LCE by 2025 (Figure 88), representing a CAGR of 14% across all demand sectors, driven by demand for Liion batterybased electric vehicles accounting for 38% of all lithium demand by 2025 (from ~6% in 2015), Processing Spodumene by Froth Flotation for Lithium Extraction

METHODS FOR LITHIUMBEARING RAW MATERIALS

precipitate by filtration, lithium carbonate is precipitated from the solution with a saturated soda solution The precipitate contains 96 97 % Li 2 CO 3 The extraction of lithium into carbonate from spodumene concentrate is 85 90 % [1] This technology is a traditional process and dominates the production of lithium compounds fromLithium salts crystallization: • Lithium Chloride (LiCl) • Lithium Carbonate (Li 2 CO 3) • Lithium Hydroxide anhydrous and monohydrate (LiOH) • Lithium Sulfate anhydrous and monohydrate (Li 2 SO 4) • Lithium Bromide (LiBr) • Lithium Phosphate (Li 3 PO 4), Byproduct recovery from lithium processing: • Potassium Chloride (KCl Lithium Processing Capabilities Veolia Water TechCornish Lithium has worked with Grinding Solutions Ltd and Wardell Armstrong International, both based in Cornwall, together with Strategic Metallurgy, based in Perth Australia to complete concentrator test work on different samples of ore Processing Technology Cornish Lithium PlcThe primary crude lithium carbonate and the second crude product adhesion liquid contain impurities such as Na2SO4, and then are stirred with purified water at about 90 ° C, and the washing liquid is sent to the alkali, and after washing, Rotary Kiln used for Lithium carbonate to lithium

Industrial Powder Grinding Machine Manufacturers,

Calcium Carbonate Modified Line Highspeed rotor pulverizer is used as the modified main machine to heat the air intake to keep the modified main machine at a suitable modification temperature, and the superfine heavy calcium (D97 2022年12月13日 The following is the process flow of lithium ore processing to obtain lithium carbonate: After the mining of lithium ore, the bulk material is first crushed by electromagnetic dressing equipment; Then under the action of belt conveyor, it is evenly sent to the grinding machine for deep grinding treatment; After grinding, lithium ore powder How to mine lithium ore, mineral processing, crushing, grinding2019年8月29日 As for the supply of lithium carbonate, there will be a gap in the supply and demand of global lithium carbonate by 2019 3 Lithium mining equipment Lithium ore beneficiation equipment includes crushers, ball mills, jigs, flotation machines, etc, as well as some auxiliary equipment to form a complete production lineThe 5 Most Useful Methods Of Lithium Mining BeneficiationLithium carbonate has a very wide range of applications in the production of secondary lithium salts and metal lithium products, and is the most critical product in the lithium industry In the current actual production process of lithium carbonate, its main production raw materials come from salt lake brine and ore extracts At present, in the production process of lithium carbonate News Process Flow Of Lithium Carbonate Vertical Roller Mill

.jpg)

Lithium carbonate Drugs BNF NICE

View lithium carbonate information, including dose, uses, sideeffects, renal impairment, pregnancy, breast feeding, May impair performance of skilled tasks (eg driving, operating machinery) Medicinal forms There can be variation in the licensing of different medicines containing the same drug2024年9月30日 Lithium (Li), a leading cathode material in rechargeable Liion batteries, is vital to modern energy storage technology, establishing it as one of the most impactful and strategical elements Given the surge in the electric car market, it is crucial to improve lithium recovery from its rich mineral deposits using the most effective extraction technique In recent years, both Aspects of Spodumene Lithium Extraction Techniques MDPI2022年7月5日 The three minerals, spodumene, petalite, and lepidolite, can be used for various purposes after beneficiation and concentrationThe cutoff grade and industrial grade of lithium deposits are divided into manual beneficiation and machine beneficiation, and the grade indicators are determined respectivelyThe division between manual and machine Lithium Processing Plant JXSC MachineLithiumIonenBatterien Maschinen Anlagen für die Produktion von LithiumIonenAkkus Kathode Anode Infos hier! Calcium Carbonate (GCC) Technical ceramic Hard Minerals Talc Graphite rounding for lithiumion batteries Grinding and classifying in one machine; Cool and contaminationfree grinding;Lithiumion batteries Hosokawa Alpine