Simple diagram of movement of calcite grinding mechanism

Analysis of grinding aid performance effects on dry fine milling of

2022年3月1日 The influence of grinding aids on the dry fine grinding of calcite using several analysis methods was revealed in the present study Within the context, the results were 2023年8月1日 The usage of grinding aids prevents particle pelleting and leads to reduced energy consumption The work aims to research the impacts of three pure grinding aids from Effective role of grinding aids in the dry grinding performance of Download scientific diagram Examples of movement of the media inside a ball mill simulated using DEM: centrifuge (left), cataract (middle) and cascade (right) from publication: Effect of Examples of movement of the media inside a ball mill simulated In nature, aragonite and calcite form through biogenic and geogenic processes that lead to different degrees of atomic order The latter is aAragonite and calcite grinding curve plots and location of

The Influence of Stirred Mill Orientation on Calcite Grinding

2021年4月21日 In the vertical orientation, the grinding mechanism can be described as follows: powder rapidly moved down through the mill as a result of gravity In the mill, balls (and 2002年11月1日 This paper is a de tailed analysis of the grinding kinet ics o f calcite and barite minerals in terms of the specific rates of breakage, the primary breakage distribution function Kinetics of dry grinding of industrial minerals: Calcite and barite2014年3月1日 The structure and granularity of calcite were measured during dry grinding in a ball mill by Xray diffraction, Fourier transform infrared spectroscopy and laser diffraction, and Effects of dry grinding on the structure and granularity of calcite Mechanical grinding is one of the most effective and simple means to comminute and acti vate mineral powders: grinding can lead to extended solubility, phase transformations, mech ano XRD line profile analysis of calcite powders produced by high

Effect of Grinding Method on Particle Morphology and Flotation

2020年4月25日 Based on the grinding test, the single mineral flotation test, the wettability test and the scanning electron microscope test, the effects of ceramic rod grinding and ceramic 2020年9月23日 With respect to flotation, the adsorption mechanism of the reagent on the calcite mineral was studied by using different techniques such as FTIR (Fourier transform infrared), An Overview of Calcite Recovery by Flotation Materials SpringerDownload scientific diagram XRay diffraction patterns of calcite (In agreement with JCPDS, cardN°050586) from publication: Studies of The Mechanism of Polyvinyl Alcohol Adsorption on The XRay diffraction patterns of calcite (In agreement When muscle cells are viewed under the microscope, one can see that they contain a striped pattern (striations) This pattern is formed by a series of basic units called sarcomeres that are The Sliding Filament Theory of Muscle Contraction

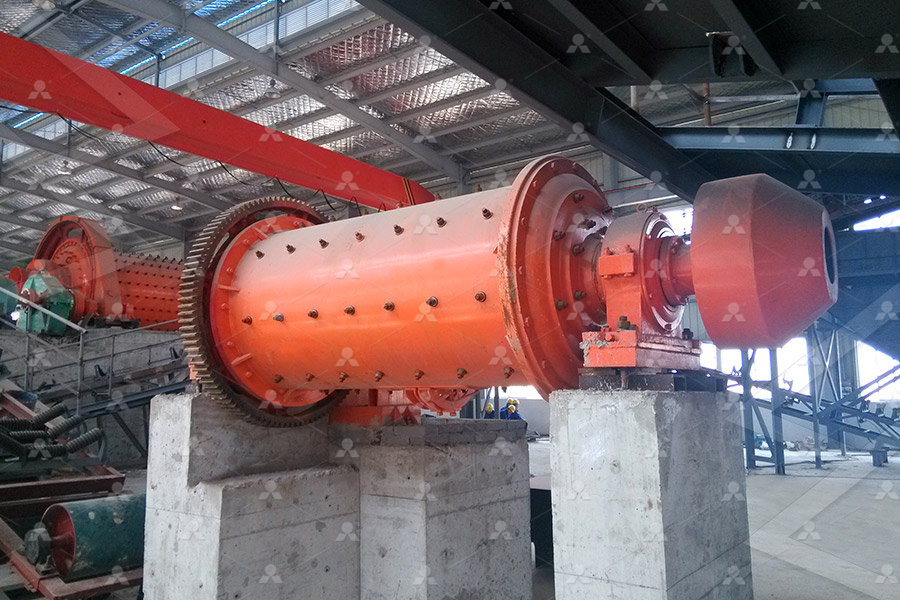

14 Types of Grinding Machines [Working, Diagram

2021年11月23日 These grinders are used for grinding round and hollow jobs whether the internal surface of this job is completely round, ditched round, or is in taper Small grinding wheels of 3 cm to 5 cm, are used in such grinders 2021年3月3日 Cement is produced by a hightemperature (about 1500 °C) reaction in a rotary kiln of carefully proportioned and blended ratios of lime (CaO), silica (SiO 2), alumina (Al 2 O 3), and iron oxide (Fe 2 O 3)The production of cement is a chemical process requiring an accurate blend of the previously cited four key organic oxides and the limitation of several undesirable Cement SpringerLink2024年6月1日 Agarwal et al [10] studied the grinding characteristics, material removal, and damage formation mechanisms in high removal rate grinding of SiC The study indicated that the primary material removal processes in SiC grinding include intergranular microfracturing and grain dislodgement, with the material removal mechanism influenced by its mechanical Grinding mechanism and surface quality evaluation strategy of 2021年3月11日 Industrial Machinery: Linkage mechanisms drive the motion of conveyor belts, robotic arms, and packaging machines Aerospace Engineering: Linkages control the movement of flaps, landing gear, and other critical components in aircraft Everyday Devices: Linkage mechanisms are found in everyday objects such as bicycles, can openers, and scissorsLinkage Mechanisms: An Informative Guide for Engineering

Crystal structure of calcite optimized by CASTEP

Download scientific diagram Crystal structure of calcite optimized by CASTEP from publication: Calcite crystallization in the cement system: Morphological diversity, growth mechanism and shape Owing to the complexity of the movement and contact relationships between grinding wheel and face gear, the previous surface prediction models for cylindrical, flat, and internal grinding are not Principle of face gear grinding by disk wheelBroadly there are three different types of internal grinding machine as follows: 1 Chucking type internal grinder 2 Planetary internal grinder 3 Centreless internal grinder Read more : Types of Grinding Machines – LearnMech; Types Of Surface Grinding machine with Diagram Explained Types of Cylindrical grinding machine with Diagram ExplainedTypes of Internal grinding machine with Diagram Explained2024年9月1日 In the exploration of grinding mechanisms, the grinding force produced during material removal is a critical role that must be examined, as it has a direct correlation with material removal behavior, subsequently influencing machining quality, grinding temperature and vibration, and service lifespan of the grinding wheel [101, 102]Towards understanding the machining process in grinding of

.jpg)

Planer Machine Parts, Types, Working principle with

2023年8月1日 I appreciate the information provided about types of planer, but you have not provided the table drive mechanism of the divided table planer Kindly provide the table drive mechanism of divided table planer It will help grinding machine with the help of a mechanism that is driven with the help of belt drive The efficiency of this mechanism is very low it is very less used these days 7 Magnetic Wheel The component to be fed is stuck on the magnetic wheel that rotates feeds the component to the grinding machine The mechanism is pretty simple Design Manufacturing of Feeding Mechanism for Horizontal Grinding Ultrasonic vibrationassisted grinding (UAG) has been proven to be a promising grinding ability improvement technique due to the grinding force reduction However, the reduction mechanism is still unclear due to the lack of knowledge on material softening and grain—workpiece contact conditions in UAG In this paper, we present a numerical and experimental study on ultrasonic Study on force reduction mechanism in ultrasonicassisted grinding Download scientific diagram Aragonite and calcite grinding curve plots and location of experimental and archaeological Effects of the Acid Composition on the Neutralization Mechanism ArticleAragonite and calcite grinding curve plots and location of

Comprehensive understanding of grinding aids ResearchGate

2014年6月1日 Grinding aids are materials that are added to cement mixtures to improve the characteristics of the cement or increase the efficiency of the milling systems or both in the clinker grinding (finish 2024年3月1日 Analysis of the changing law of residual stress and material micromechanisms under high efficiency deep grinding: (a) Residual stress with (a) strong grinding (Huang, 2009); (b) change in coarse grinding area angle (Yin et al, 2018), (b) Mechanism of efficient deep grinding removal of microscopic morphology (Zhang et al, 2021), (c) Relationship between grinding Residual stress generation in grinding: Mechanism and modeling2020年12月1日 Oleate adsorption isotherms determined for calcite at 20 °C and 60 °C and at pH 92 by in situ FTNIR/IRS with overtone and combination bands of the aliphatic stretch from Young and Miller (2007 An Overview of Calcite Recovery by Flotation ResearchGate2008年7月2日 A simulation of the threedimensional motion of grinding media in the stirred media mill for the research of grinding mechanism has been carried out by 3dimensional discrete element method (DEM) The movement of ball assemblies was graphically displayed with some snapshots from start of the milling to 020 s From these simulation results, the grinding zone Analysis of ball movement for research of grinding mechanism

.jpg)

Effects of impact and attrition mechanisms on size distribution

2021年10月1日 For the cases with the mixture grinding including calcite (phase1), the size by calcite contents were determined via the procedure prescribed in TSE CEN/TR 196–4 [20] In brief, initially, the residue of the mixture is weighed after the sample was heat treatedDownload scientific diagram Schematic diagram of face gear generating grinding a Face gear meshing contact line b Decomposition of wheel movement from publication: Prediction model for surface Schematic diagram of face gear generating grinding a Face gear Simple Indexing in Milling Machine: The indexing mechanism involves the use of an index plate, which is a circular plate consisting of a series of six or more circles of evenly spaced holes; the index pin on the crank can be inserted into any Simple Indexing in Milling Machine Mechanical Realm2019年4月8日 Cutting tools and machine tools are the two main factors to achieve removal Based on the needs of processing technology in the movement requirement of the tool, the machine tool can achieve the tool’s trajectory and then achieve removal, and the cutting tools in contact with the workpiece can remove the workpiece material directly (Altintas 2012)Design of Tools, Grinding Wheels, and Precision Spindles

Comparison of XRD diffraction pattern of (a) pure

Download scientific diagram Comparison of XRD diffraction pattern of (a) pure calcite from the reservoir rock with (b) calcite sample from Ward from publication: Use of Xray powder diffraction 2020年7月1日 Grinding aid additives are established in various industrial dry fine grinding processes, primarily to achieve either a) an increase of the production capacity, b) a decrease of the specific Grinding aids for dry fine grinding processes – Part I: Mechanism Grinding Media: The grinding media are the balls used for grinding and come in various materials such as steel, ceramic, or natural pebbles Different sizes and types of media are used for different applications Mill Liners: Liners protect the mill shell from wear and facilitate the movement of grinding mediaBall Mill Grinding Machines: Working Principle, Types, Parts 1987年1月1日 LTTaylor calculations for simple shear document that the displacement angle of the [0001] maximum, ~o, does not change with increasing deformation and is therefore independent of the shear angle (Fig 11) The total shear is expressed in peak densities If simple shear is combined with pure shear (Fig 12), the displacement angle ~o is smallerPure shear and simple shear calcite textures Comparison of

Hexagonal representation of the rhombohedral structure of calcite

Download scientific diagram Hexagonal representation of the rhombohedral structure of calcite showing the alternating layering of calcium ions and carbonate groups along the caxis of the unit 2009年7月1日 Batch grinding tests were carried out for five spans of 6, 12,18,24 and 30min with zirconia or alumina, absence of grinding aids; According to the former paper [17], the addition of grinding aids Effect of grinding aids on the kinetics of fine grinding energy 2023年9月4日 In the formula, v s is the wheel speed, v w is the feed rate, a p is the grinding depth, d eq is the diameter of the grinding wheel, and λ s is the perimeter of the grinding wheel 22 Plastic mechanism of subsurface During the grinding process, the workpiece is subject to the tangential force exerted by the abrasive particles, often resulting in subsurface crystal slips Plastic deformation mechanism of grinding subsurface of nickel Download scientific diagram Grinding curves of aragonite, showing location of archeological samples, modified after Toffolo et al [51] (nau: normalized absorbance units) Data points from Grinding curves of aragonite, showing location of archeological

.jpg)

XRay diffraction patterns of calcite (In agreement

Download scientific diagram XRay diffraction patterns of calcite (In agreement with JCPDS, cardN°050586) from publication: Studies of The Mechanism of Polyvinyl Alcohol Adsorption on The When muscle cells are viewed under the microscope, one can see that they contain a striped pattern (striations) This pattern is formed by a series of basic units called sarcomeres that are The Sliding Filament Theory of Muscle Contraction2021年11月23日 These grinders are used for grinding round and hollow jobs whether the internal surface of this job is completely round, ditched round, or is in taper Small grinding wheels of 3 cm to 5 cm, are used in such grinders 14 Types of Grinding Machines [Working, Diagram 2021年3月3日 Cement is produced by a hightemperature (about 1500 °C) reaction in a rotary kiln of carefully proportioned and blended ratios of lime (CaO), silica (SiO 2), alumina (Al 2 O 3), and iron oxide (Fe 2 O 3)The production of cement is a chemical process requiring an accurate blend of the previously cited four key organic oxides and the limitation of several undesirable Cement SpringerLink

.jpg)

Grinding mechanism and surface quality evaluation strategy of

2024年6月1日 Agarwal et al [10] studied the grinding characteristics, material removal, and damage formation mechanisms in high removal rate grinding of SiC The study indicated that the primary material removal processes in SiC grinding include intergranular microfracturing and grain dislodgement, with the material removal mechanism influenced by its mechanical 2021年3月11日 Industrial Machinery: Linkage mechanisms drive the motion of conveyor belts, robotic arms, and packaging machines Aerospace Engineering: Linkages control the movement of flaps, landing gear, and other critical components in aircraft Everyday Devices: Linkage mechanisms are found in everyday objects such as bicycles, can openers, and scissorsLinkage Mechanisms: An Informative Guide for Engineering Download scientific diagram Crystal structure of calcite optimized by CASTEP from publication: Calcite crystallization in the cement system: Morphological diversity, growth mechanism and shape Crystal structure of calcite optimized by CASTEPOwing to the complexity of the movement and contact relationships between grinding wheel and face gear, the previous surface prediction models for cylindrical, flat, and internal grinding are not Principle of face gear grinding by disk wheel

Types of Internal grinding machine with Diagram Explained

Broadly there are three different types of internal grinding machine as follows: 1 Chucking type internal grinder 2 Planetary internal grinder 3 Centreless internal grinder Read more : Types of Grinding Machines – LearnMech; Types Of Surface Grinding machine with Diagram Explained Types of Cylindrical grinding machine with Diagram Explained2024年9月1日 In the exploration of grinding mechanisms, the grinding force produced during material removal is a critical role that must be examined, as it has a direct correlation with material removal behavior, subsequently influencing machining quality, grinding temperature and vibration, and service lifespan of the grinding wheel [101, 102]Towards understanding the machining process in grinding of