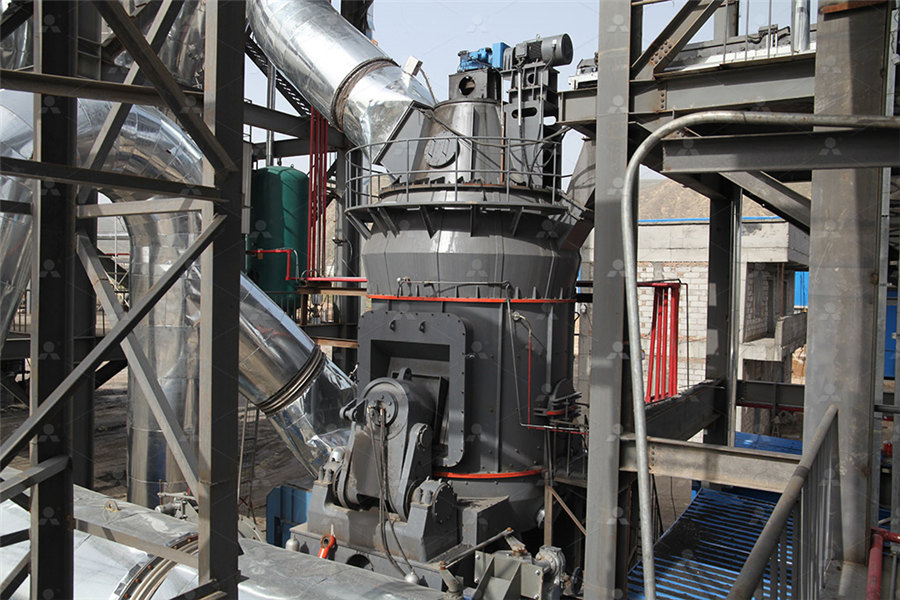

Operation video of Fucheng overhaul slag vertical mill

Vertical Mill Of Slag Grinding Plant YouTube

https://oreproskd/grindingmill/lmseriesverticalrollermillhtmlslag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a Loesche mill, with a grinding track diameter of only 11 metres, was used as 2 µm 5 µm Loeschea vertical roller mill (VRM) • Surpasses the classic methods if the controlled process demonstrates significant disturbances • A high degree of attention to the process states is required in order PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS2022年3月28日 The VXPmill is an established vertical ceramic media regrind mill used in energy efficient gold, copper, lead and zinc plants worldwide All slurrycontacting components of the FLSmidth VXPmill Operation

.jpg)

Operating experience with a vertical roller mill for grinding

2012年3月1日 Numerous optimization measures have ensured that the vertical roller mills installed in the Buzzi Unicem/Dyckerhoff Group have a high level of availability This article UBE Vertical Mill is used for grinding of cement raw materials, coal, cement clinker, blast furnace slag and other material Restoring your equipment to its original performance Maximizing your UBE Vertical Mill UBE Machinery Corporation, Ltd2007年11月1日 In the cement industry MPS vertical roller mills with installed powers of over 5000kW are currently in operation or on order These mills are used to grind cement raw MPS vertical roller mills for slag and slag cementsThe slag vertical mill is a grinding equipment for granulated blast furnace slag developed by Tongli Through integrated grinding and powder selection functions, the slag is converted into Slag Vertical Roller Mill CEMENTL

.jpg)

Atox Vertical Roller Mill, Maintenance and Repair

The document discusses maintenance and repair of an ATOX Vertical Mill It describes systematic and conditionbased maintenance approaches Systematic maintenance consists of regular 2023年6月1日 This study aims to improve the output and production efficiency of a large vertical mill by optimizing its operational parameters This paper takes a large vertical mill in LGM as the object, a numerical calculation method of particle–fluid coupling system in large vertical mill based on CFDDPM theory, and a multiobjective optimization method of operating parameters of Operation parameters multiobjective optimization method of Vertical mill is a equipment that grinds materials by relative rolling of a grinding roller on grinding disc There are several aspects to the normal operation of the vertical mill: ring is low, and the roller surface or the grinding disc wears Important Operation Tips For Cement Vertical MillVertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills Cement grinding Vertical roller mills VS ball mills

.jpg)

Analysis of noise and vibration during the operation of the ball mill

Analysis of noise and vibration during the operation of the ball mill The ball mill is used for grinding materials after crushing, and CHAENG is a professional manufacturer of ball mill accessories, such as girth gear of ball mill, ball mill trunnion, ball mill end cover, etc, which are used by customers in various industrial fields Ball mills are widely used in industries such as cement 2016年9月1日 The vertical roller mill (VRM) is a comminution device in which crushing, grinding and classification processes are combine together into a single unit operationOperational parameters affecting the vertical roller mill 2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from Find, read and cite all the research (PDF) Performance Evaluation of Vertical Roller Mill in Cement 2021年1月29日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing consumes around Increase productivity of vertical roller mill using seven QC tools

VRM Operation and Optimization PDF Mill (Grinding)

VRM operation and optimizationppt Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online The document discusses vertical mills used for grinding clinker, raw materials, coal, and cement Vertical mills can be used for both pregrinding and finish grinding They comprise rollers that are hydraulically pressed onto a 2023年6月6日 Slag vertical mill selection requires rigorous numerical analysis, equipment price, scale of slag vertical mill manufacturer and aftersales capabilities are all factors that need to be considered As a slag vertical mill manufacturer with nearly 30 years of production experience, Guilin Hongcheng has rich experience in slag vertical mill parison and Analysis of Slag Vertical Mill SelectionFor slag vertical mills, targeted and planned maintenance should not omit hidden dangers in key wearresistant parts of the vertical mill, so as to achieve advance prediction and control, and eliminate hidden dangers in advance, which can prevent major accidents and improve the operation of the equipment efficiency and unithour output, providing guarantee for efficient How to properly maintain cement and slag vertical mills?The GRMSS steel slag vertical mill of CHAENG is a kind of special equipment for grinding industrial waste such as steel slag and water slag into powder +79Steel Slag Vertical Mill CHAENG

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, Energysaving and Efficient Vertical Roller Mill Fote vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS2020年10月9日 In order to obtain the optimal operation parameters of a SAG mill, in this paper, the discrete element method (DEM) is used to simulate the breakage process of the particles by controlling three Operation Analysis of a SAG Mill under Different Conditions Based on

.jpg)

Performance Evaluation of Vertical Roller Mill in Cement

operation in vertical roller mill In Figure 12 (and 13, presents the particle size distributions of total table feed and products for two surveys in Figure 14 and Figure 15HLM series slag vertical roller mill produced by HCMilling(Guilin Hongcheng) can be widely used in slag grinding treatment The whole set of slag grinding treatment process includes crushing, drying, grinding, grading, transportation, collection, storage and other steps, which can realize the complete production and processing of slag from large particles to finished fine powderNews Application Of Slag Grinding Mill Introduction To Vertical roller mill for raw materials Application p rocess Raw material process Background Grinding raw materials needs lots of energy By this production increasing, it is expected that operation in the daytime can be shortened and then power cost can be reduced Cost estimation About 73 million US$ (depending on the scale) [1US$=¥110]Vertical roller mill for raw Application p rocess materialsAlmost 30 years ago LOESCHE introduced the first vertical roller mill to grind both, cement clinker and granulated blast furnace slag, in one process The concept of M and Srollers was established in 1992, which is one of the most cost effective and Cement Blast Furnace Slag Loesche

Schematic operation principle of a verticalrollermill

Download scientific diagram Schematic operation principle of a verticalrollermill from publication: Modeling and simulation of vertical roller mill using population balance model There are For cement, composite cement and blast furnace slag grinding many modular vertical roller mills are in operation, starting with first industrial experience in 2008Grinding Process Optimization Featuring Case Studies and The document discusses optimization and operation of vertical roller mills (VRMs) Key points include: 1) Continuously monitor and adjust process parameters to find the optimum operating conditions of highest capacity and Optimization of Vertical Raw Mill Operation PDF1 Suitable material layer thickness The vertical mill works on the principle of material bed crushing A stable material bed is the prerequisite for the continuous and stable operation of the vertical mill If the material layer is too thick, the grinding efficiency will be low; if the materialWhat are the operating techniques for vertical mills?

.jpg)

Operating experience with a vertical roller mill for grinding

2012年3月1日 the distributions of the ball mill and the vertical roller mill Fig 6a shows an example of the circularity of a ground granulated blastfurnace slag, produced with the LM 352+22022年6月16日 Operation Precautions of Slag Superfine Vertical Mill 1 Material layer of vertical slag mill The selection of suitable mill material layer is the basis to ensure the stable operation of the vertical mill Too thick will reduce the grinding efficiency; If it is too thin, the driving force of the mill will increase, which will damage the Operation details of slag superfine vertical roller millPDF On May 1, 2017, Caroline Woywadt published Grinding process optimization — Featuring case studies and operating results of the modular vertical roller mill Find, read and cite all the (PDF) Grinding process optimization — Featuring case studies and 2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parametersAnalysis and Optimization of Grinding Performance of Vertical

.jpg)

quadropol® Vertical Roller Mill myPolysiusService

Cementos Cibao SA, cement producer in the Dominican Republic, continues the modernization process and ordered a cement mill type QMC² 40/20 for grinding different cement types Compact plant arrangement with service tower, quadropol® vertical roller mill and main filter are part of 2023年12月19日 Vertical milling machines win the prize for versatility Machinists use them as boring mills, but they can quickly transform into a variablespeed drill press, which is an awkward operation on a horizontal mill Both machines can face and slot, but the vertical mill is more adept at prototyping, custom work, and engraving 5 Cost of the MachineVertical Milling Machines vs Horizontal: Differences Explaineda Loesche mill, with a grinding track diameter of only 11 metres, was used as long ago as 1935 However, the breakthrough in grinding this type of material on the vertical roller mill did not take place until the beginning of the 1990’s 1935 The first Loesche mill for grinding cement clinker, an LM 11, was commissioned in Joao Pessao, Brazil2 µm 5 µm Loesche2023年6月1日 This study aims to improve the output and production efficiency of a large vertical mill by optimizing its operational parameters This paper takes a large vertical mill in LGM as the object, a numerical calculation method of particle–fluid coupling system in large vertical mill based on CFDDPM theory, and a multiobjective optimization method of operating parameters of Operation parameters multiobjective optimization method of

Important Operation Tips For Cement Vertical Mill

Vertical mill is a equipment that grinds materials by relative rolling of a grinding roller on grinding disc There are several aspects to the normal operation of the vertical mill: ring is low, and the roller surface or the grinding disc wears Vertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills Cement grinding Vertical roller mills VS ball millsAnalysis of noise and vibration during the operation of the ball mill The ball mill is used for grinding materials after crushing, and CHAENG is a professional manufacturer of ball mill accessories, such as girth gear of ball mill, ball mill trunnion, ball mill end cover, etc, which are used by customers in various industrial fields Ball mills are widely used in industries such as cement Analysis of noise and vibration during the operation of the ball mill 2016年9月1日 The vertical roller mill (VRM) is a comminution device in which crushing, grinding and classification processes are combine together into a single unit operationOperational parameters affecting the vertical roller mill

.jpg)

(PDF) Performance Evaluation of Vertical Roller Mill in Cement

2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from Find, read and cite all the research 2021年1月29日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing consumes around Increase productivity of vertical roller mill using seven QC toolsVRM operation and optimizationppt Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online The document discusses vertical mills used for grinding clinker, raw materials, coal, and cement Vertical mills can be used for both pregrinding and finish grinding They comprise rollers that are hydraulically pressed onto a VRM Operation and Optimization PDF Mill (Grinding)2023年6月6日 Slag vertical mill selection requires rigorous numerical analysis, equipment price, scale of slag vertical mill manufacturer and aftersales capabilities are all factors that need to be considered As a slag vertical mill manufacturer with nearly 30 years of production experience, Guilin Hongcheng has rich experience in slag vertical mill parison and Analysis of Slag Vertical Mill Selection

How to properly maintain cement and slag vertical mills?

For slag vertical mills, targeted and planned maintenance should not omit hidden dangers in key wearresistant parts of the vertical mill, so as to achieve advance prediction and control, and eliminate hidden dangers in advance, which can prevent major accidents and improve the operation of the equipment efficiency and unithour output, providing guarantee for efficient