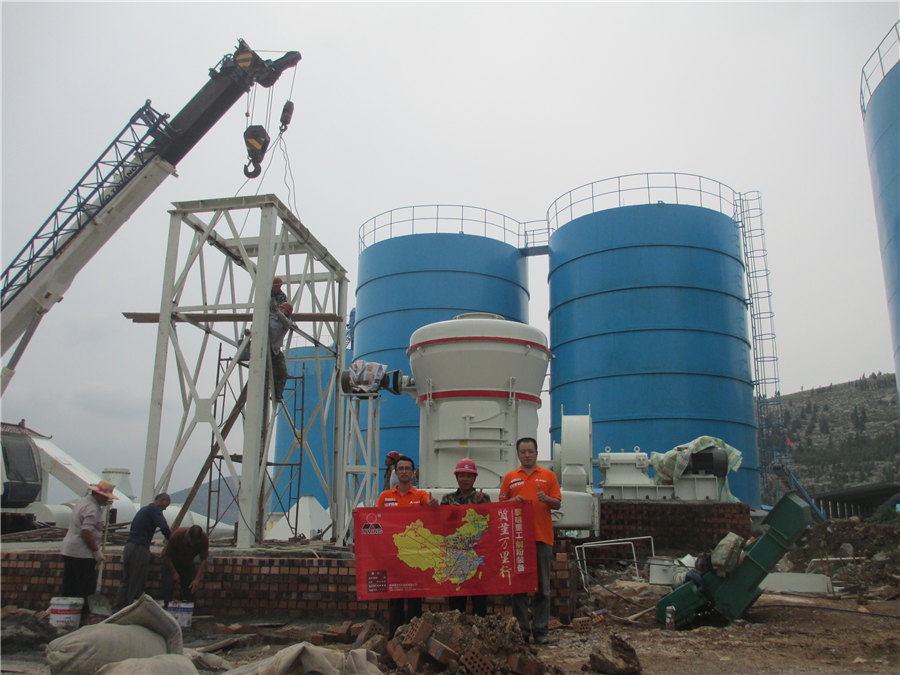

Slag mill before grinding

2 µm 5 µm Loesche

slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a Loesche mill, with a grinding track diameter of only 11 metres, was used as long ago as 1935 However, the breakthrough in grinding this type of material on the verticalefficient grinding plants for its customers Loesche plants are specifically planned for the required process steps and equipped with the associated techno logy This technology comprises: • PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTSneness levels of 2 mm as well as 5,000 Blaine or more to be adjusted The mills operating principle permits the utilisation of both the different levels of grindability and the different Loesche Mills for Metal Recovery and Filler Production from Steel 2024年6月1日 This study explored potential pretreatment methods to enhance slag's performance as a cement raw material and the research on utilizing steelmaking slag, Utilization of steelmaking slag in cement clinker production: A

制粉-10.25公众号.jpg)

The Effect of Removing HardtoGrind Minerals from Steel Slag on

2023年8月22日 It is found that the removal rate of hardtogrind minerals in steel slag is the highest when steel slag enters magnetic separation particle size of 1 mm and magnetic field 2022年3月7日 The preparation process of composite microslag used gradient grinding technology with a ball mill and a horizontal grinder so that to avoid the agglomeration Preparation of composite microslag based on the application of 2021年6月7日 In this study, steel slag was refined by wetgrinding technology to apply on cement The results showed that the initial setting time and final setting time were prolonged Effect of wetgrinding steel slag on the properties of Portland Dryinggrindingdrying processes are needed before the application for wet emission This paper aims at exploring the performances of concrete blended with GGBFS in form of slurry The Influences of Ultrafine Slag Slurry Prepared by Wet Ball Milling on

Improving the Carbonation of Steel Slags Through Concurrent

2024年8月12日 Besides permanently storing carbon dioxide (CO 2), carbonating the slags can improve their quality for use in beneficial applications and reduces the leaching of harmful 2024年1月31日 Slag grinding exhibits complex nonlinear dynamics that challenge control The proposed system monitors key operating parameters to assess machine health and automate Intelligent process control system for predicting operating A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are Mill (grinding) Wikipedia2021年6月17日 Due to its strong lifting capacity and excellent grinding performance, the trapezoidal liner is widely used in the SAG mill The structure of the trapezoidal liner is shown in Fig 1, the main dimensions are: dip angle \(\tau\), length of the top edge \(L\) and height \(h\)Dip angle \(\tau\) determines the trajectory of the mediums in the SAG mill, which directly affects PARAMETER OPTIMIZATION OF LARGE SAG MILL LINER BASED

Autogenous and SAG SemiAutogenous Mill Design Calculations

2018年4月17日 Mill Sizing: After laboratory and pilot plant testing confirm the feasibility of autogenous or semiautogenous grinding, it can be used to establish the exact grinding circuit and mill sizeIn the pilot plant tests, the tare power of the pilot plant mills should be determined before and after each test run The tare power should be for the empty mill2020年10月9日 This method simulates the particles size, mill power, and qualified particles quality of crushed particle, which reveal the grinding strength and energy consumption of the SAG mill In this paper Operation Analysis of a SAG Mill under Different Conditions Based on 2017年8月5日 If the secondary mill is a pebble mill, grinding media for the pebble mill may be removed from the top deck of the screen with any excess returned to the primary mill In some circuits, the screen oversize is put through a shorthead cone crusher before it How to Control a SAG Grinding Mill Circuit 911Metallurgist2024年5月17日 A SAG (SemiAutogenous Grinding) mill is a giant rotating cylinder filled with grinding media and the ore being reduced As the mill rotates, the grinding media lifts and the impact crushes the feed material SAG mill control refers to the practice of managing the mill load, which is the amount of material inside the mill at any given timeA guide to SAG Mill management

.jpg)

Integrated advanced process control with a sag mill monitor

in southern Peru The plant employs a semiautogenous SABCA grinding circuit comprising of a primary SAG mill and pebble crushing followed by a secondary grinding circuit including two ball mills and classification cyclone clustersMetso Premier™ horizontal grinding mills are customized and optimized grinding solutions built on advanced simulation tools and unmatched expertise A Metso Premier™ horizontal grinding mill is able to meet any projects needs, even if it means creating something novel and unseen before Learn more about the Premier™ horizontal grinding Grinding mills for mining and minerals processing MetsoThe first example of using an agitated vessel and grinding media for comminution was in 1922 when Szegvari stirred a gallon can full of pebbles to rapidly disperse a sulphur suspension [19]This was developed into the first ‘stirred ball mill’ by Klein and Szegvari in 1928 [20]This prototype was refined into the Attritor mill, a low tip speed (3–5 m/s [21]) vertical pin mill which Semi Autogenous Grinding Mill ScienceDirect Topics2020年3月20日 Ball mill: When the particle size of the product is less than 05mm, the grinding effect of the ball mill is greater than that of a rod mill of the same specification SAG mill: The SAG mill has a wide range of feeding particle sizes and can process larger minerals, but at the same time, its output particle size is relatively largerWhat’s the Difference Between Ball Mill, Rod Mill and SAG Mill?

Dark Steel Grinding Ball Official Feed The Beast Wiki

The Dark Steel Grinding Ball (previously known as Dark Steel Ball) is an item added by Ender IO Its sole purpose is being a Grinding Ball for use in the SAG Mill Its stats are: Main Output 135% (= 35% chance to double all outputs, including bonus outputs) Bonus Output 200% (doubles bonus output chances) Power Use 70% (= 30% faster processing speed) Before Grinding The SAG Mill is a machine added by Ender IO It uses Micro Infinity (µI) to grind (or mill) items into their crushed variants, like Ores into Dusts The SAG Mill has four output slots; recipes can have 14 different outputs, with different chances of obtaining those outputs Uniquely, the SAG Mill can use Grinding Balls made from various materials to increase energy efficiency SAG Mill Official Feed The Beast Wiki2021年1月8日 A CRITICAL REVIEW OF GRINDING DESIGN PROCEDURES FOR THE 21st CENTURY J H Starkey (Starkey Associates Grinding Design and Process Engineering) Email for correspondence: johnstarkey@sagdesign Introduction There are four main aspects of SAG mill design that will be discussed in this paper The first and mostA CRITICAL REVIEW OF GRINDING DESIGN PROCEDURES FOR THE 2 GRINDING ICNTERNATIONAL CEMENT REVIEW SEPTEMBER 2022 energy requirements:1 • ball mill: 38kWh/t • HPGR plus ball mill: 3034kWh/t • VRM: 2832kWh/t Grinding is a very energy intensive process that accounts for a significant amount of production costs7 This is why advances in classifier technology have been vital in increasing productionGRINDING Grinding options for slag and pozzolan PEC

2 µm 5 µm Loesche

for grinding clinker and granulated blast furnace slag, was used for the first time in an LM 462+2 for cement grinding in the Pu Shin mill works of Lucky Cement, Taiwan 1995 An LM 352+2 went into production in Fos sur Mer, Ciments Lafarge, France, as the first mill for grinding granulated blast furnace slag2016年6月6日 From a liner supplier standpoint, this method is certainly preferrable to grinding out The use of mill liner handlers has also reduced the need to grind out since they work close to the mill centerline and the leveled, dewatered charge at 30 to 35% mill volume becomes a convenient work platform for the maintenance crewSAG Mill Liner Design 911MetallurgistToday we will learn about difference between sag mill vs ball mill A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding, crushing or cutting This commutation is an essential part of many processes Various kinds of mills are there with which different material processing takes placeDifference Between Sag Mill vs Ball Mill Mech4studydirectly from a primary crusher, and the mill product is then classified through a hydrocyclone (or fine screen) and oversized material is returned to the mill for further grinding The product of the singlestage mill is finished material suitable for flotation or leaching, usually in the size range of 80% passing 200 µm to 100 µmPowerbased modelling of singlestage AG and SAG mill circuits

.jpg)

SAG Mill Testing Test Procedures to Characterize Ore

device Because grinding theories are imperfect and ore hardness can vary with size, grindability tests are designed to best represent the size reduction of the industrial equipment analysed For that reason, it is preferable to design a primary ball mill from a rod mill work index rather than a ball mill index, because the industrial mill will2019年8月14日 The last 90 years have generated a considerable volume of technical literature on the subject of grinding mill power and its prediction It is therefore surprising that in all this time there have Optimisation of secondary crushing stage before Single Stage SAG mill 2017年1月23日 PDF Successful control of SemiAutogenous Grinding (SAG) mill circuits has been the subject of many researches and main concern of plant operators for Find, read and cite all the research (PDF) Supervisory Fuzzy Expert Controller for SAG Mill Grinding 2024年6月1日 (grinding media and mill liners) standpoint, with mines able to achieve high equipment availability and productivity “Since their early application in the 1960s, SAG mills have provided the modern mining industry with workhorses used for most high throughput grinding applications,” Bianca Foggiatto, director of Comminution and ProcessingTHE FUTURE OF SAG MILLS Ausenco

SAG Mill Semi autogenous mill or sag mining as by

2022年9月5日 Semi autogenous mill or sag mining as they are often called, can perform grinding operations equivalent to two or three stages of crushing and screening SAG mills are characterized by their largepressure on mill sizing has resulted in nonflexibility in new SAG mill circuit designs In order to defend the mill size selected, the owner’s engineers need to be able to quantify the loss in productivity that will occur if the SAG mill is downsized Power based methods allow this calculation to be executed rapidly with good accuracyDesign SAG mill production when you need it most: In day 1 and 2021年1月11日 Choosing a SAG Mill To Achieve Design Performance John Starkey1, Principal Consulting Engineer Sami Hindstrom2, Manager, Grinding Travis Orser2, Project Manager, Grinding 1 Starkey Associates Grinding Design and Process Engineering 336 – 268 Lakeshore Rd E Oakville, Ontario L6J 7S4 PH: (905) 4657512 Fax (905) 8445297Choosing a SAG Mill to Achieve Design Performance2023年6月6日 Attrition mill is a type of grinding mill by kinds of media to crush lump to powderlike substances The impact can be rock on rock such as in an Autogenous Grinding (AG) mill, rock and a small ball charge (~10%), used in Semi Autogenous Grinding (SAG) mills, balls of various sizes in Ball Mills and less commonly these days, steel rods in Rod MillsWhat’s the difference of Ball mill, SAG mill, AG mill? Baichy

Ecocem Dunkirk A modern slag grinding plant Global Cement

2020年4月8日 Ecocem opened its Dunkirk slag grinding plant in 2018 Global Cement visited before the coronavirus shutdown to see the plant and speak with its manager Anne Most had never seen a vertical roller mill before Once training was completed we could start up parts of the plant This involved people from Ecocem in Ireland, from AM Highpressure grinding rolls (HPGR) technology was first utilized in the grinding of clinker and raw material in the mid1980s and quickly proved be an economical choice in the comminution process 10 The HPGR compresses the material into a “cake” that includes both fines and coarse material, which later needs to be deagglomerated by a hammer mill, ball mill or a Vseparator Options for Grinding Slag and Pozzolan for Use as Construction 2016年3月16日 Request PDF Optimisation of secondary crushing stage before SAG mill at Freda Rebecca Freda Rebecca Gold Mine (FRGM) is situated near the town of Bindura, approximately 90km northeast of Optimisation of secondary crushing stage before SAG mill at 2018年8月17日 Extreme temperatures, impact velocity, mill load, grinding media, ore types, and applications are some of the factors to be considered while installing new linersGrinding Mills — Types, Working Principle Applications

.jpg)

Mill (grinding) Wikipedia

A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are 2021年6月17日 Due to its strong lifting capacity and excellent grinding performance, the trapezoidal liner is widely used in the SAG mill The structure of the trapezoidal liner is shown in Fig 1, the main dimensions are: dip angle \(\tau\), length of the top edge \(L\) and height \(h\)Dip angle \(\tau\) determines the trajectory of the mediums in the SAG mill, which directly affects PARAMETER OPTIMIZATION OF LARGE SAG MILL LINER BASED 2018年4月17日 Mill Sizing: After laboratory and pilot plant testing confirm the feasibility of autogenous or semiautogenous grinding, it can be used to establish the exact grinding circuit and mill sizeIn the pilot plant tests, the tare power of the pilot plant mills should be determined before and after each test run The tare power should be for the empty millAutogenous and SAG SemiAutogenous Mill Design Calculations2020年10月9日 This method simulates the particles size, mill power, and qualified particles quality of crushed particle, which reveal the grinding strength and energy consumption of the SAG mill In this paper Operation Analysis of a SAG Mill under Different Conditions Based on

How to Control a SAG Grinding Mill Circuit 911Metallurgist

2017年8月5日 If the secondary mill is a pebble mill, grinding media for the pebble mill may be removed from the top deck of the screen with any excess returned to the primary mill In some circuits, the screen oversize is put through a shorthead cone crusher before it 2024年5月17日 A SAG (SemiAutogenous Grinding) mill is a giant rotating cylinder filled with grinding media and the ore being reduced As the mill rotates, the grinding media lifts and the impact crushes the feed material SAG mill control refers to the practice of managing the mill load, which is the amount of material inside the mill at any given timeA guide to SAG Mill managementin southern Peru The plant employs a semiautogenous SABCA grinding circuit comprising of a primary SAG mill and pebble crushing followed by a secondary grinding circuit including two ball mills and classification cyclone clustersIntegrated advanced process control with a sag mill monitorMetso Premier™ horizontal grinding mills are customized and optimized grinding solutions built on advanced simulation tools and unmatched expertise A Metso Premier™ horizontal grinding mill is able to meet any projects needs, even if it means creating something novel and unseen before Learn more about the Premier™ horizontal grinding Grinding mills for mining and minerals processing Metso

.jpg)

Semi Autogenous Grinding Mill ScienceDirect Topics

The first example of using an agitated vessel and grinding media for comminution was in 1922 when Szegvari stirred a gallon can full of pebbles to rapidly disperse a sulphur suspension [19]This was developed into the first ‘stirred ball mill’ by Klein and Szegvari in 1928 [20]This prototype was refined into the Attritor mill, a low tip speed (3–5 m/s [21]) vertical pin mill which 2020年3月20日 Ball mill: When the particle size of the product is less than 05mm, the grinding effect of the ball mill is greater than that of a rod mill of the same specification SAG mill: The SAG mill has a wide range of feeding particle sizes and can process larger minerals, but at the same time, its output particle size is relatively largerWhat’s the Difference Between Ball Mill, Rod Mill and SAG Mill?