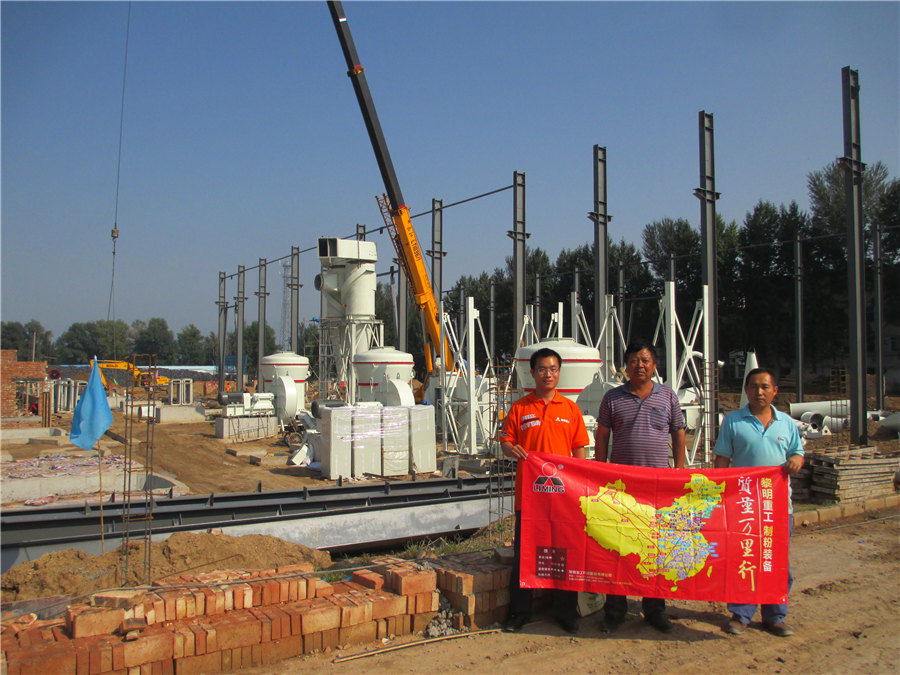

Hubei Huangshi water slag fine powder hot air furnace

Waste heat recovery of blast furnace slag in moving bed:

2024年7月1日 Physical recovery of waste heat from blast furnace slag (BFS) by a moving bed is a promising solution The heat recovery of BFS is mainly achieved through gas–solid heat 2020年3月29日 The present research provides an understanding of the two different types of slags of water quenched granulated slag and aircooled slag that are generated from iron Utilisation perspective on water quenched and aircooled blast It has undertaken the construction of hot blast stoves and drying lines for a number of key projects at home and abroad; it has a number of patented and proprietary technologies Hubei Tianda Hot blast stove seriesAir furnace seriesHuangshi Tianda hermal 2020年7月20日 In this study, the concept of “fullvolume slag alkaliactivated mortars (FSAM)” is proposed using ground granulated watercooled blast furnace slag (GGBS) as aluminosilicate Utilisation perspective on water quenched and aircooled blast

Thermodynamic Study on Modification of Converter Slag by Using

2022年2月4日 In this article, FactSage software is used to study the conversion of CS by using the heat of BFS, and the research results provide a theoretical basis for improving the 2023年7月21日 The water quenching granulation process, also known as the wet treatment process, is a process that uses a highpressure water stream to quickly cool the blast furnace Comprehensive utilisation of blast furnace slag Taylor Francis surface appears remarkably when blast furnace slag fine powder is used The purpose of this study is to reduce the effect of the temperature difference between the inside and surface of Effect of SO Content in Blast Furnace Slag Fine Powder on Heat 2012年7月31日 To recover the sensible heat of BF slag, three key problems should be considered: (I) the dry granulation of BF slag without consuming water, (II) increasing the Waste Heat Recovery from Blast Furnace Slag by Chemical Reactions

.jpg)

(PDF) UTILIZATION OF AIRCOOLED BLAST FURNACE SLAG AS A

2022年11月1日 Slag that cools slowly to atmospheric temperature is called aircooled blast furnace slag (ACBFS), and slag that is instantaneously cooled under pressurized water jets is Centrifugal granulationassisted thermal energy recovery (CGATER) remains the leading technology for the iron and steel industry to enable the lowcarbon treatment of high steel research international Wiley Online Library2019年3月1日 A cupola furnace is the most frequently used furnace aggregate for cast iron production A byproduct of the production of cast iron in cupola furnaces is cupola slag Its amount is 40–80 kg per 1 tonne of the produced cast iron, and that is one of the reasons why this material is not as favoured as, for example, the blastfurnace slag The purpose of this article Cupola Furnace Slag: Its Origin, Properties and Utilization2022年2月2日 EVChandra Sekhar, KSpandana, KRaja Sekhar (2016), 'Strength Properties of Replacement of Air Cooled Blast Furnace Slag in Fine Aggregate', International Journal of Core Engineering USE OF AIR COOLED BLAST FURNACE SLAG AS A

.jpg)

Waste Heat Recovery from Blast Furnace Slag by Chemical

2012年7月31日 Blast furnace (BF) slag, which is the main byproduct in the ironmaking process, contains large amounts of sensible heat To recover the heat, a new waste heatrecovery system—granulating molten BF slag by rotary multinozzles cup atomizer and pyrolyzing printed circuited board with obtained hot BF slag particle—was proposed in this study The feasibility The use of slags in recycled aggregate concrete Paul O Awoyera, Oluwatobi G Aluko, in The Structural Integrity of Recycled Aggregate Concrete Produced with Fillers and Pozzolans, 2022 723 Electric arc furnace slag EAF is a byproduct of oxidation of old steel during the production of steel in an EAFElectric Arc Furnace Slag an overview ScienceDirect Topics2017年12月15日 The chemical components of ferronickel slag primarily include SiO 2, MgO, CaO, Al 2 O 3, and Fe 2 O 3 [8], [11] and the crystalline minerals in ferronickel slag include enstatite, forsterite, and diopside [12]The content of amorphous minerals in ferronickel slag is usually greater than 50% [13]Ferronickel slag powder exhibits pozzolanic activity and hence is Characteristics and reactivity of ferronickel slag powder2021年2月5日 DOI: 101016/JJHAZMAT2020 Corpus ID: ; Experimental study on fullvolume slag alkaliactivated mortars: Aircooled blast furnace slag versus machinemade sand as fine aggregatesExperimental study on fullvolume slag alkaliactivated mortars: Air

Furnace Slag an overview ScienceDirect Topics

Cement additives Johannes Fink, in Petroleum Engineer's Guide to Oil Field Chemicals and Fluids (Third Edition), 2021 Furnace slag A furnace slag cement slurry can have a density of 15001600 kg m −3A combination of silica flour and furnace slag may be used to achieve service temperatures exceeding 200 °C [100]A gas may be suitable as a foaming agent [101]2020年3月29日 These products are termed as: granulated blast furnace (GBF) slag, aircooled blast furnace slag (ACBF), expanded or foamed slag, and pelletized slag In recent years, most of the plants use granulated method for cooling whereas a small number of plants still use aircooled methods ( Gan et al, 2012 ; Durinck et al, 2008 ; Geiseler, 1996 ; Das et al, 2007 ; WSA, Utilisation perspective on water quenched and aircooled blast furnace 2021年7月17日 The present study evaluates the effect of utilising granulated blast furnace slag as a partial substitution of the fine fraction of natural aggregates on various concrete parameters using the general factorial approach Two levels of the water/cement ratio (045 and 05) and four different percentages of granulated blast furnace slag (0, 20%, 40% and 60%) have been Effects of utilising granulated blast furnace slag as fine aggregate It is a kind of high efficiency and energy saving hot air Furnace Product Features: Both the hot air temperature and the wind speed can be Wuhan, Hubei, China +8627 / +86 hkfurnace@hotmail Contact Us Furnace Car Bottom Furnace Pit Furnace Box Furnace PreVacuum Furnace Melting Furnace Salt Bath Furnace Vertical Hot Air Furnace HKFurnace

Hydration superposition effect and mechanism of steel slag powder

2023年2月22日 Granulated blast furnace slag (GBFS) is a glassy calciumaluminum silicate coproduct with latent hydration activity produced during the blast furnace ironmaking process [21]When the GBFS is in contact with water, a layer of calciumdeficient aluminosilicate protective film would be formed rapidly on the surface, and only a small amount of calcium ions and 2020年1月21日 Blastfurnace slags are usually processed by either the wet or dry method The wet method is based on water quenching; however, this method wastes water resources, produces harmful gases, and cannot use sensible heat [1,2,3,4]The heat value of slag (1500 °C) is 1600 MJ/t: the annual production capacity of 210 million tons of slag in 2016 was therefore Crystallization behavior of blastfurnace slag by single hot Request PDF On Jan 1, 2018, Isa Yuksel published Blastfurnace slag Find, read and cite all the research you need on ResearchGateBlastfurnace slag Request PDF ResearchGate2016年11月30日 Request PDF Improving the mechanical properties of rapid air cooled ladle furnace slag powder by gypsum The aim of this research is supporting the recycling of ladle furnace slag from steel Improving the mechanical properties of rapid air cooled ladle furnace

.jpg)

Recycling aircooled blast furnace slag in fiber reinforced alkali

2022年7月1日 Blast furnace slag (BFS) is a major nonmetallic industrial byproduct from blast furnace during the melting of iron ore which is associated with an energyintensive and wasteintensive industry According to the cooling method, BFS can be classified as granulated blast furnace slag (GBFS) and aircooled blast furnace slag (ACBF) [13]2020年7月20日 Efficient utilisation and recycling of industrial waste along with minimum exploitation of natural resources are major challenge towards the circular economy and sustainability of the planet Blast furnace slag is a byproduct of the ironmaking process while producing pig iron The present research provides an understanding of the two different types Utilisation perspective on water quenched and aircooled blast furnace 2017年8月6日 Durability of concrete structures is degraded due to variety of mechanical and environmental action during the service life One of such environmental actions is freezethaw action pronounced in cold regions facing subzero temperatures, which results in surface scaling and internal microcracking of concrete leading to deterioration of structural performance Mechanical Properties of Concrete with Blast Furnace Slag Fine PDF On Aug 24, 2018, Shabarish V Patil and others published Granulated BlastFurnace Slag (GGBS) based Geopolymer concrete Review Concrete Review Find, read and cite all the research you (PDF) Granulated BlastFurnace Slag (GGBS) based ResearchGate

Effect of high MgO content on the performance of alkaliactivated fine

2018年10月20日 1 Introduction Portland cement is a key component in construction materials due to its excellent performance and quality Around 1500 million tons of Portland cement are produced annually worldwide [1]However, the cementmanufacturing process is a major contributor to global industrial CO 2 emissions, with Portland cement production generating an Slag processing George C Wang, in The Utilization of Slag in Civil Infrastructure Construction, 2016 53 Blast furnace slag processing Iron blast furnace slag results from the fusion of iron ore, fluxing materials, and coke; the reduction reactions; and the separation of iron from the ore As indicated in Chapter 2, the term blast furnace slag is used often to refer to iron blast furnace Blast Furnace Slag an overview ScienceDirect Topics2017年12月15日 In this study, the hydration properties of a blended cement containing 30% ferronickel slag powder are investigated The activities of electric arc furnace ferronickel slag (EFS) powder and blast Characteristics and reactivity of ferronickel slag powder2020年8月28日 Based on the fundamental principles of preparing reactive powder concrete (RPC), a new type of RPC was composed by replacing cement with the active powder component ultrafine ground granulated blastfurnace slag (GGBS) GGBS is proposed as a potential alternative to silica fume (SF), which is currently the most commonly used RPC mineral The hydration properties of ultrafine ground granulated blastfurnace

Hydration and Microstructure of Steel Slag as

2020年9月28日 Due to the low hydration activity and poor volume stability, extensive steel slag utilization is restricted In this paper, the hydration process and microstructure of alkaliactivated materials with steel slag as a 2018年1月1日 Blast furnace slag (BFS) which is defined “as the nonmetallic product consisting essentially of silicates and alumina silicates of calcium and other bases, that is developed in a molten condition simultaneously with iron in a blast furnace” by ASTM C 12516 (2016) has been widely used in construction industry for more than 80 years When the mixture of ironore, Blastfurnace slag ScienceDirect2006年5月1日 Request PDF Use of Granulated BlastFurnace Slag in Concrete as Fine Aggregate This paper reports the results of some experimental studies on the use of nongroundgranulated blastfurnace Use of Granulated BlastFurnace Slag in Concrete as Fine 2021年2月5日 For aircooled blast furnace slag (ACBFS), it forms when iron ore is melted and reduced into molten pig iron in blast furnaces, which is classified as hazardous material in some countries ([Ríos et al, 2019], [Tripathy et al, 2020], [Grubb and Berggren, 2018], Zulhan, 2014)The crystallinity of slag mainly depends on the cooling method of meltExperimental study on fullvolume slag alkaliactivated mortars: Air

TECHNICAL PAPER UTILIZATION OF AIRCOOLED BLAST FURNACE SLAG

TECHNICAL PAPER THE INDIAN CONCRETE JOURNAL JULY 2022 7 the ore and coke ash to form a nonmetallic product called blast furnace slag [13,14]Based on the period of cooling and hardening2024年2月3日 Fine slag (FS) is an unavoidable byproduct of coal gasification FS, which is a simple heap of solid waste left in the open air, easily causes environmental pollution and has a low resource utilization rate, thereby restricting the development of energysaving coal gasification technologies The multiscale analysis of FS performed in this study indicates typical grain size Multiscale analysis of fine slag from pulverized coal gasification in 2012年7月31日 Blast furnace (BF) slag, which is the main byproduct in the ironmaking process, contains large amounts of sensible heat To recover the heat, a new waste heatrecovery system—granulating molten Waste Heat Recovery from Blast Furnace Slag by Chemical 2018年12月1日 As far as we know, China was the only world region that developed blast furnace technology before the 2 nd millennium AD The earliest cast iron fragment found so far in China is dated to the 8 th century BC (Zou, 2000) whereas large quantities of excavated material show that cast iron production became the prevailing technique for iron metallurgy in the Bloomery iron smelting in the Daye County (Hubei): Technological

Cupola Furnace Slag: Its Origin, Properties and Utilization

2019年3月1日 A cupola furnace is the most frequently used furnace aggregate for cast iron production A byproduct of the production of cast iron in cupola furnaces is cupola slag Its amount is 40–80 kg per 1 tonne of the produced cast iron, and that is one of the reasons why this material is not as favoured as, for example, the blastfurnace slag The purpose of this article 2022年2月2日 EVChandra Sekhar, KSpandana, KRaja Sekhar (2016), 'Strength Properties of Replacement of Air Cooled Blast Furnace Slag in Fine Aggregate', International Journal of Core Engineering USE OF AIR COOLED BLAST FURNACE SLAG AS A 2012年7月31日 Blast furnace (BF) slag, which is the main byproduct in the ironmaking process, contains large amounts of sensible heat To recover the heat, a new waste heatrecovery system—granulating molten BF slag by rotary multinozzles cup atomizer and pyrolyzing printed circuited board with obtained hot BF slag particle—was proposed in this study The feasibility Waste Heat Recovery from Blast Furnace Slag by Chemical The use of slags in recycled aggregate concrete Paul O Awoyera, Oluwatobi G Aluko, in The Structural Integrity of Recycled Aggregate Concrete Produced with Fillers and Pozzolans, 2022 723 Electric arc furnace slag EAF is a byproduct of oxidation of old steel during the production of steel in an EAFElectric Arc Furnace Slag an overview ScienceDirect Topics

.jpg)

Characteristics and reactivity of ferronickel slag powder

2017年12月15日 The chemical components of ferronickel slag primarily include SiO 2, MgO, CaO, Al 2 O 3, and Fe 2 O 3 [8], [11] and the crystalline minerals in ferronickel slag include enstatite, forsterite, and diopside [12]The content of amorphous minerals in ferronickel slag is usually greater than 50% [13]Ferronickel slag powder exhibits pozzolanic activity and hence is 2021年2月5日 DOI: 101016/JJHAZMAT2020 Corpus ID: ; Experimental study on fullvolume slag alkaliactivated mortars: Aircooled blast furnace slag versus machinemade sand as fine aggregatesExperimental study on fullvolume slag alkaliactivated mortars: Air Cement additives Johannes Fink, in Petroleum Engineer's Guide to Oil Field Chemicals and Fluids (Third Edition), 2021 Furnace slag A furnace slag cement slurry can have a density of 15001600 kg m −3A combination of silica flour and furnace slag may be used to achieve service temperatures exceeding 200 °C [100]A gas may be suitable as a foaming agent [101]Furnace Slag an overview ScienceDirect Topics2020年3月29日 These products are termed as: granulated blast furnace (GBF) slag, aircooled blast furnace slag (ACBF), expanded or foamed slag, and pelletized slag In recent years, most of the plants use granulated method for cooling whereas a small number of plants still use aircooled methods ( Gan et al, 2012 ; Durinck et al, 2008 ; Geiseler, 1996 ; Das et al, 2007 ; WSA, Utilisation perspective on water quenched and aircooled blast furnace

Effects of utilising granulated blast furnace slag as fine aggregate

2021年7月17日 The present study evaluates the effect of utilising granulated blast furnace slag as a partial substitution of the fine fraction of natural aggregates on various concrete parameters using the general factorial approach Two levels of the water/cement ratio (045 and 05) and four different percentages of granulated blast furnace slag (0, 20%, 40% and 60%) have been It is a kind of high efficiency and energy saving hot air Furnace Product Features: Both the hot air temperature and the wind speed can be Wuhan, Hubei, China +8627 / +86 hkfurnace@hotmail Contact Us Furnace Car Bottom Furnace Pit Furnace Box Furnace PreVacuum Furnace Melting Furnace Salt Bath Furnace Vertical Hot Air Furnace HKFurnace