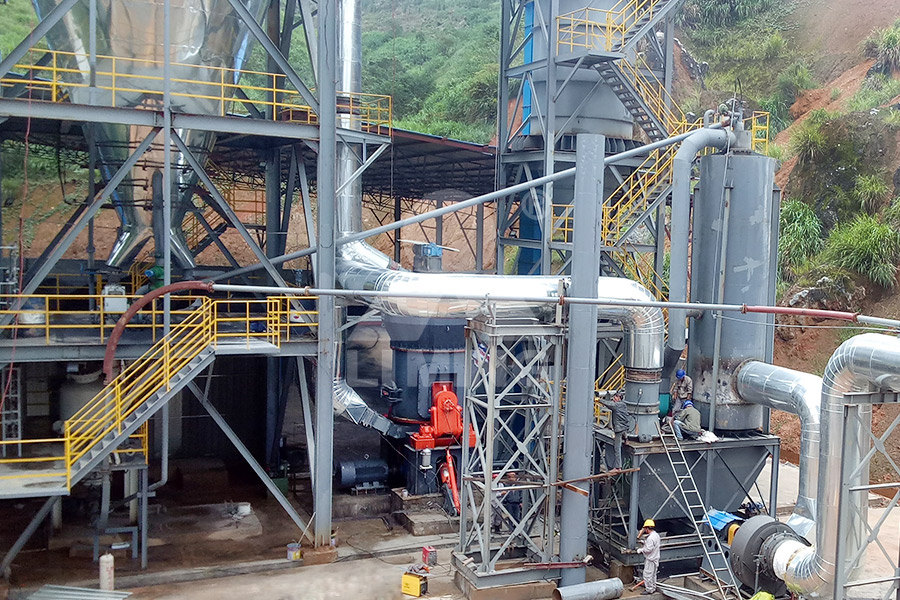

Anthracite Ultrafine Vertical Mill Process Flow

.jpg)

ULTRAFINE GRINDING Hosokawa Alpine

Ultrafine ceramic powder opens up undreamtof possibilities The Pulvis classifier mill ensures not only an extremely low contamination grinding of aluminium oxide, but also a clean 2022年1月15日 The results provide a reference and guidance for exploring changes in the molecular structures of ultrafine anthracite and followup deep processing In particular, the Qualitative and Quantitative Analyses of Ultrafine Anthracite by 2016年7月1日 In this paper, Taixi anthracite was adopted as raw material, and maleic anhydride (MAH), ethylene diamine tetraacetic acid (EDTA) and dodecylbenzene sulfonic acid (DBSA) Insitu modification in ultrafine crushing process of Taixi ultralow In a typical application, the HIG process begins with the regrinding circuit feed being pumped to a scalping cyclone upstream of the mill which classifies the target size material off from the feed Outotec HIGmills; A Fine Grinding Technology

Ultrafine Grinding in Contemporary Flow Diagrams for Mineral

2015年7月21日 This article discusses the range of application of ultrafine grinding for processing mineral raw materials and presents examples of the successful use of this technology in the Ultrafine grinding is a technology, which can be used to process inorganic nonmetallic materials High quality surfaces with a low roughness, and high flatness are achievable in a low Ultrafine grinding of inorganic nonmetallic materials using 2022年10月5日 To investigate the influence of grinding parameters on the surface quality of ultrafine cemented carbides with different Co content, find the best process parameters for Effect of the grinding process on the surface quality of ultrafine 2024年9月1日 Ultrapure anthracite coal was prepared using a vertical stirring mill for deep dissociation Flotation under multiple influences were unveiled: physicochemical properties Mechanistic study of the effects of ultrafine grinding on the

Talc Powder Ultrafine Vertical Roller Mill

Product advantage of talc powder ultrafine vertical roller mill 1 High quality powder size The fineness of the finished product is D97 545 microns Narrow particle size distribution, can produce 2 micron content of 20%70% products, The Ultrafine Grinding Mill, also known as a Micro Powder Grinding Mill or Ultra Fine Powder Grinding Machine, is a highefficiency and lowconsumption grinding mill that is widely used in the powder processing of various materials Bellian Mining Machinery offers a range of Ultrafine Grinding Mills, including the Ultrafine Vertical Mill and Fine Powder Mill Grinder, designed to Ultrafine Grinding Mill, Micro Powder Grinding Mill Bellian 3 Double PositionLimiting Technology Makes Operation More Stable In the CLUM series ultrafine vertical roller mill, the contact point between roller shell and millstone liner plate adopts electronic limiting technology and mechanical CLUM Series Ultrafine Vertical Roller Mill2023年3月21日 At present, the nonmetallic ore dry ultrafine grinding process equipment mainly includes Raymond mill, stirring mill, vibration mill, ring roller mill, ball mill and ultrafine vertical mill Ball mill can process 40200 mesh powder, the production capacity of a single machine is large, the performance is stable and reliable, but the energy consumption is slightly higherThe advantages of ultrafine vertical mill in the processing and

.jpg)

Table Roller Mill Vertical Mill

The ultrafine vertical mill is currently the superlarge ultrafine grinding equipment in Asia, which has been successfully applied in the market and has mature technology It can replace imported equipment and is an ideal equipment for largescale production of ultrafine powder with high efficiency, high yield, environmental protection and energy savingIntroduction Of CLUM Series Ultrafine Vertial Roller Grinding Machine CLUM series ultrafine vertical roller grinding machine is developed and produced by Shibang Micro Powder Technology Co, Ltd based on years of experience in producing ultrafine powder processing equipment, combined with customer needs for powder processing Compared with the previous traditional CLUM Series Ultrafine Vertial Roller Grinding Machine2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and energetic 2022年2月24日 Production of clean pulverized coal for boiler combustion heating and power supply Fineness: 200 mesh, D8090, according to the needs of backend combustion Suitable coal types: bituminous coal, anthracite, blue carbon, etc The production of clean pulverized coal is used for boiler combustion heating and power supply to improve the operating efficiency of How is pulverized coal processed? SBM Ultrafine Powder

Clay Ultrafine Grinding Mill SBM Ultrafine Powder Technology

2022年10月10日 Production Process Ceramic milling processes can be roughly divided into two types: The vortex flow generated by the rotating worm wheel in the powder separator makes the coarse particles fall back for regrinding, Clum ultrafine vertical mill Fineness: 1503000mesh Yield: 120t/h see More >> GET IN TOUCHSummary The Kurimoto VX Mill is designed to feed material to the center of a table, where the material horizontally rolls and moves in the peripheral direction of the table with centrifugal forceVertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill 2023年9月26日 Ultrafine barite powder production process flow The first stage: large pieces of barite are transported to the raw material warehouse by vehicles, and then the materials are sent to the jaw crusher by forklifts/manuals to Ultrafine barite powder uses and production processJet mill: 5um powder can be produced, jet pulverization, the whiteness of the finished powder is the best Highend food grade finished powder Mechanically crushed, the powder has the highest fineness It is only suitable for highend CLUM Ultrafine Vertical Grinding Mill

Coal Vertical Roller Mill

I: Product Profile Vertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other fieldsThe coal vertical mill has less dust, low noise, high efficiency granular composition, Its special design structure and production process creates the higher production efficiency with lower energy consumption, less dust VMX series ultrafine vertical mill is suitable for nonmetallic mineral industry, such as limestone, calcite, marble, heavy calcium, kaolin, barite, bentonite, pyrophyllite, etc Combination of crushing, drying, grinding and conveying, simple process flow, reasonable and compact layout, spacesaving (50% less than ball mill), VMX Superfine Vertical Mill Grinding Mill Fertilizer production China Vertical Ultra Mill wholesale UltraFine Ultrafine Sic Talc Powder Making Machine Vertical Roller Grinder Mill US$ 5500080000 / Set 1 Set Here we are going to show you some of the process equipments for sale that featured by our reliable suppliers and manufacturers, such as Vertical Ultra MillVertical Ultra Mill MadeinChina2024年9月1日 Ultrapure anthracite coal was prepared using a vertical stirring mill for deep dissociation • Flotation under multiple influences were unveiled: physicochemical properties and liberation degree • Macroscopic have revealed the mechanism by Mechanistic study of the effects of ultrafine grinding on the

Outotec HIGmills; A Fine Grinding Technology

(table 1) The HIGmillTM is the only ultrafine grinding technology in commercial use that can use small size high density grinding media in mill sizes above 3,000 kW Table 1 HIGmillTM Size Range [kW] 32 Compact and Simple Installation The benefit of high power intensity and vertical installation is a very small foot prints (see fig 3)Fig2 Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimationVertical roller mill for raw Application p rocess materials2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills It also discusses the factors, including the design, operating parameters, and feed material properties, EnergyEfficient Advanced Ultrafine Grinding of Particles UsingThe ultrafine vertical mill integrating ultrafine powder grinding, grading and conveying has become a better choice for the ultrafine powder grinding industry Calcium carbonate ultrafine powder vertical mill is widely used in Paper Making, Plastic, Rubber, Tire, PVC, Cable, Floor, Artificial Stone, Painting, Tooth, Agricultural Film, Cosmetics and many other fields because of its Calcium Carbonate Ultrafine Powder Vertical Mill

.jpg)

Dolomite Grinding : Industrial Process and Equipment Grinding Mill

As the final step of dolomite processing, grinding plays a decisive role in product quality Therefore, we pay special attention to the process control of this link, We can provide you with HGM Micro Powder Grinding Mill, CLRM Enhanced Roller Mill, CLUM Series Ultrafine Vertical Roller Professional milling equipment such as Mills to ensure that the final product meets the Limestone ultrafine vertical mill are suitable for huge capacity producing, widely used in grinding non flammable and nonexplosive materials under 6 (the Moh’s hardness), This cycle completes the whole grinding process Production Limestone Ultrafine Vertical Mill2021年7月22日 One machine twotank process flow The slurry is cyclically ground in one sand mill and two storage tanks Clum ultrafine vertical mill Fineness: 1503000mesh Yield: 120t/h see More >> GET IN TOUCH Tel: +86 WhatsApp: Characteristics and Application of Wet Superfine Crushing ProcessUltrafine vertical mill is a highefficient industrial grinding mill, be used to grind hard stones into ultrafine powder, like talc, mica, etc +17 [ protected] ③ The oxygen content in the mill is low, the explosion suppression performance is superior, and the grinding process is safe and controllableUltrafine Vertical Mill

Dolomite Ultrafine Vertical Roller Mill

Dolomite ultrafine vertical roller mill is mainly used for the production of dolomite powder The vertical roller mill integrates crushing, drying, grinding, and conveying The control production process is as follows: Crushing: The calcium carbonate stone of 400~500mm is coarsely crushed and secondarily finely crushed Then, after iron 2021年3月9日 Ultra fine powder vertical roller mill is the cement industry, coal industry, power sector and other widely used grinding machine, with the breaking, crushing, grinding, powder and drying in one and so on Ultra fine powder vertical roller mill for raw material and preparation of coal over half a century of history On the vertical roller mill and working principle of the Ultra Fine Powder Vertical Roller Mill Classifier System ReformA compact, simple installation and process HIGmill™ has a less complex and more compact process layout and flow sheet than other stirred media mills The process comprises just a scalping cyclone with no circulating load, feed tank and pump, and the mill itself The benefit of high power intensity and vertical installation is a very smallHIGmill™ Metso2015年7月21日 Figure 3 shows the flow chart used to process the crude ore at the Eti Gümüs factory Comminution of the ore in ball mills is carried out in three separate sections Each section consists of two mills operating in series The first mill is operated in an open cycle, while the second mill is operated in a closed cycle with hydraulic cyclonesUltrafine Grinding in Contemporary Flow Diagrams for Mineral

Coal Gangue Vertical Roller Mill SBM Ultrafine Powder

2022年9月20日 CLUM ultrafine vertical roller mill can grind coal gangue into pure highquality micro powder, which is widely used in the construction industry +17 Coal gangue processing flow The pulverizing process of coal gangue can Product advantage of talc powder ultrafine vertical roller mill 1 High quality powder size The fineness of the finished product is D97 545 microns Narrow particle size distribution, can produce 2 micron content of 20%70% products, Talc Powder Ultrafine Vertical Roller MillThe Ultrafine Grinding Mill, also known as a Micro Powder Grinding Mill or Ultra Fine Powder Grinding Machine, is a highefficiency and lowconsumption grinding mill that is widely used in the powder processing of various materials Bellian Mining Machinery offers a range of Ultrafine Grinding Mills, including the Ultrafine Vertical Mill and Fine Powder Mill Grinder, designed to Ultrafine Grinding Mill, Micro Powder Grinding Mill Bellian 3 Double PositionLimiting Technology Makes Operation More Stable In the CLUM series ultrafine vertical roller mill, the contact point between roller shell and millstone liner plate adopts electronic limiting technology and mechanical CLUM Series Ultrafine Vertical Roller Mill

The advantages of ultrafine vertical mill in the processing and

2023年3月21日 At present, the nonmetallic ore dry ultrafine grinding process equipment mainly includes Raymond mill, stirring mill, vibration mill, ring roller mill, ball mill and ultrafine vertical mill Ball mill can process 40200 mesh powder, the production capacity of a single machine is large, the performance is stable and reliable, but the energy consumption is slightly higherThe ultrafine vertical mill is currently the superlarge ultrafine grinding equipment in Asia, which has been successfully applied in the market and has mature technology It can replace imported equipment and is an ideal equipment for largescale production of ultrafine powder with high efficiency, high yield, environmental protection and energy savingTable Roller Mill Vertical MillIntroduction Of CLUM Series Ultrafine Vertial Roller Grinding Machine CLUM series ultrafine vertical roller grinding machine is developed and produced by Shibang Micro Powder Technology Co, Ltd based on years of experience in producing ultrafine powder processing equipment, combined with customer needs for powder processing Compared with the previous traditional CLUM Series Ultrafine Vertial Roller Grinding Machine2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and energetic

.jpg)

How is pulverized coal processed? SBM Ultrafine Powder

2022年2月24日 Production of clean pulverized coal for boiler combustion heating and power supply Fineness: 200 mesh, D8090, according to the needs of backend combustion Suitable coal types: bituminous coal, anthracite, blue carbon, etc The production of clean pulverized coal is used for boiler combustion heating and power supply to improve the operating efficiency of 2022年10月10日 Production Process Ceramic milling processes can be roughly divided into two types: The vortex flow generated by the rotating worm wheel in the powder separator makes the coarse particles fall back for regrinding, Clum ultrafine vertical mill Fineness: 1503000mesh Yield: 120t/h see More >> GET IN TOUCHClay Ultrafine Grinding Mill SBM Ultrafine Powder TechnologySummary The Kurimoto VX Mill is designed to feed material to the center of a table, where the material horizontally rolls and moves in the peripheral direction of the table with centrifugal forceVertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill