Technical regulations for maintenance of C110 heavy calcium grinding machine Raymond mill

.jpg)

Guide to Raymond Mill Maintenance: Schedule and Best Practices

2024年3月18日 This guide provides a comprehensive overview of the essential maintenance tasks and operational strategies for the Raymond Mill Routine Maintenance For Raymond Mill 1970年1月1日 Raymond mill should be maintenance after been used for a period of time, to repair and replacement for grinding roller, ring, blade and other wearing parts, to examine Raymond mill maintenance guidelineBy following these maintenance practices, operators can minimize downtime, reduce maintenance costs, and maintain high productivity levels Always refer to the manufacturer’s Maintenance of Raymond Mills: Ensuring Optimal Performance The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a Raymond Mill TAYMACHINERY

.jpg)

What is Raymond Mill? How Does It Work? alwepo

2024年9月4日 AfterSales Service: Ensure that the manufacturer or distributor of the grinding machine provides adequate aftersales service, including warranties and maintenance How to Maintain Raymond Mill? Proper maintenance of June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process: 2024年3月18日 Routine Maintenance For Raymond Mill Daily Maintenance 1 Perform the following tasks every day when the mill is in operation: Cleaning: Use a broom and shovel to remove accumulated powder on the machine and surrounding areas Inspect the grinding system and remove any blockages 2Guide to Raymond Mill Maintenance: Schedule and Best Practices2021年8月17日 Maxing Feeding Size: 40 mm Ouput Size: 06130033 micron (40400 mesh) Capacity: 125 t/h D97 325 mesh 2μm 10% Raymond Roller Grinding Mill Machine also named Raymond Mill, Raymond Roller Mill, 3R/4R/5R/6R Roller Mill and Raymond Mill Machine It is widely applied in ore materials grinding Raymond mill is the key equipment of powder Raymond Roller Grinding Mill Machine

How to Choose a Calcium Carbonate Grinding Mill DASWELL

Methods Equipment Finished product(D97/ μ m) Features Dry grinding process Raymond roller mill 25150 1Applicable materials: medium and low hardness; 2Product features: medium and lowend products, suitable for the production of coarse powder;2009年7月1日 Because of the array of precision functions grinding machines perform, it’s vital to properly maintain them to keep them operating at their peak in terms of accuracy and reliability You can start by devising a maintenance program and sticking with it This article provides tips on how to set up key parts of that programPracticing routine grinding machine maintenance produces Overview of specifications of Rail grinding Machine, infrastructural requirements and cost –benefit analysis Sanjeev Agarwal, CE/TM/SCR BRam Mohan Reddy, Dy CE/TM/Line/Vijayawada 10 Introduction: This overview offer insights into working of Rail grinding Machine used for maintenance of heavyhaul trak by rail profiling Section 20 covers theMaintenance of heavyhaul track by rail profiling Overview of The bulk material of calcium carbonate is crushed by the crusher to the feed fineness (15mm50mm) that can enter the mill The crushed calcium carbonate small pieces of material are sent to the silo through the elevator, and then sent to the grinding chamber of the mill by the vibrating feeder for quantitative grindingCalcium carbonate millGrinding mill machine, mineral mill, raymond

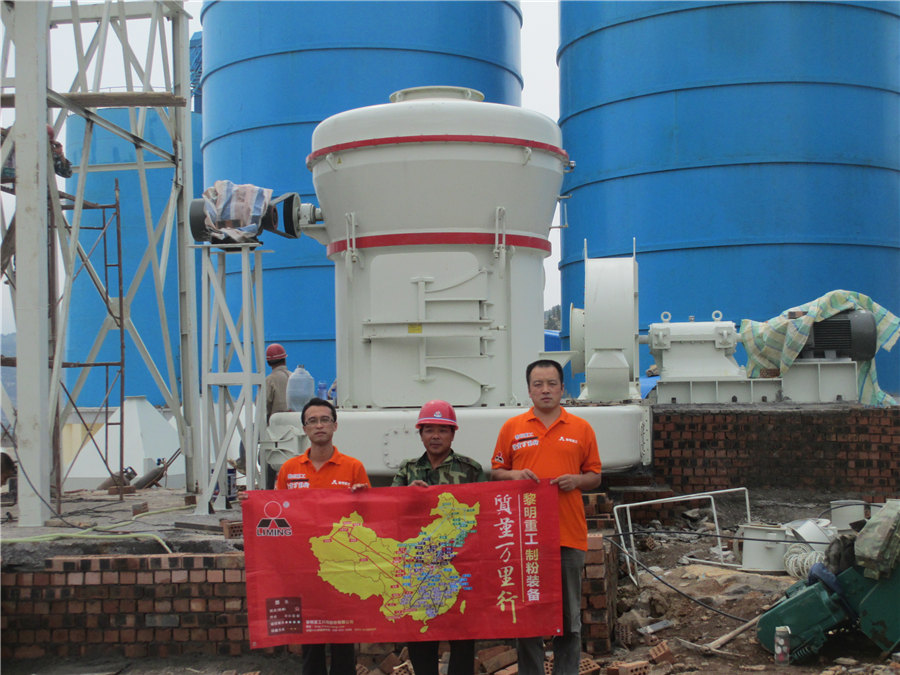

News Apply The Heavy Calcium Grinding Mill Machine To The

At present, the production methods of heavy calcium carbonate mainly include dry method and wet method The dry method generally produces heavy calcium with less than 2500 mesh If the heavy calcium with more than 2500 mesh is produced, wet grinding is mainly used, and dry grinding is the first step of wet grinding Wet grinding heavy calcium has the characteristics of 2022年5月11日 What’s more, a perfectly functioning machine is always more pleasant to operate and makes a better impression on customers Here’s how to take advantage of all the benefits of preventive maintenance: Ask Customer Service for annual maintenance contracts Ask Customer Service to perform a machine assessment Maintain a regular servicing Six Tips for Optimizing the Performance of Your Grinding Machine2022年5月5日 The YGM Raymond grinding mill can be used to produce calcium carbonate powder between 50500 mesh This equipment is an improvement on the traditional Raymond grinding mill, which is more efficient, more Calcium Carbonate Grinding Mill Powder ModifyThere are many kinds of grinding and processing equipment for heavy calcium in China Generally, they can achieve the effect of ultrafine production by combining with ultrafine classifier to form an ultrafine processing system How To Select The Dry Process Production Line For

.jpg)

What Preventative Maintenance of Grinding Machines Can

2020年11月3日 Take Advantage of the Opportunity to Perform Preventative Maintenance While manufacturing companies have broadly experienced a decline in demand as a result of the COVID19 pandemic, many are nevertheless expecting orders to increase according to a recent survey by Gardner Business Media There may not be a better time window for maintenance The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system Raymond Mill TAYMACHINERYBall mill grinding machines are valuable tools in various industries, offering efficient and reliable grinding and mixing capabilities Understanding their working principle, different types, parts, applications, advantages, and recent developments helps to appreciate their significance and wideranging applications in industries such as cement, mining, pharmaceuticals, chemicals, Ball Mill Grinding Machines: Working Principle, Types, Parts 2023年11月13日 Ultrafine grinding mill production line process flow The loader transports the crushed ore with a particle size of less than 500 mm to the firstlevel vibrating feeder, and intelligently adjusts the feeding speed through the variable frequency motor to ensure that large pieces of ore are transported smoothly and evenly to the secondlevel vibrating feederChina Hubei heavy calcium carbonate HGM100P ultrafine grinding mill

Safe maintenance of equipment (including machinery)

How can injuries happen during maintenance? People carrying out maintenance can be injured by electric shock and burns, and also by inadvertent startup of equipment Accidents at machinery often occur when access is required to dangerous parts while work is being carried out, such as: cleaning or clearing blockages inspection and maintenance2020年6月26日 The Value of Preventive Maintenance for Grinding Machines • Technical Information • White Papers • Case Studies Receive updates! Contact Us UNITED GRINDING North America 2100 UNITED GRINDING Blvd Miamisburg, OH 45342 Tel +19378591975The Value of Preventive Maintenance for Grinding MachinesThe ultrafine grinding mill for processing heavy calcium carbonate and calcite In the modern industrial landscape, the demand for ultrafine powders of minerals such as heavy calcium carbonate Reliability: Constructed with robust materials, the mill ensures a reliable and longlasting operation with minimal maintenance requirementsThe ultrafine grinding mill for processing heavy calcium 5 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance In a nonreversible hammer mill with screen bars, shown in above figure, material is broken first by impact between hammers and breaker plates and then by a scrubbing action (shear and attrition) of material against screen barsConstruction, Working and Maintenance of Crushers for Crushing

Roller Mill Calcium Carbonate Production Line

2024年6月7日 At the same fineness, compared with ball mill, impact mill, jet mill and stirring mill, ring roller mill has higher production efficiency, lower energy consumption and lower production cost At the same production capacity, 2024年7月10日 At present, heavy calcium carbonate with d97≥5μm is mainly produced by dry method, and the equipment includes improved Raymond mill (suspension roller mill or pendulum mill), roller mill (including pressure roller mill/vertical mill, ring roller mill, etc) and ball mill, etc Ultrafine heavy calcium carbonate with d97<5μm generally Heavy calcium carbonate grinding, surface modification 2015年1月1日 As grinding machines belong to the class of machines for the material removal with geometrically nondefined cutting edges, those machines can be classified in correlation to the classification of the different process technologies with geometrically nondefined cutting edges as it is given in DIN 8589, parts 11, 12, and 13 (DIN 858911 2003; DIN 858912 2003; Grinding Machines SpringerLink2023年9月28日 The material is fed into the grinding chamber between the grinding roller and the grinding ring, and the grinding roller applies pressure to the material, resulting in grinding and pulverizing of the calcium carbonate particlesThey are commonly used in the production of calcium carbonate powders with a fineness ranging from 80 mesh to 600 meshExploring Different Grinding Mills for Calcium Carbonate Processing

.jpg)

Raymond Mill, Raymond Mill Technical Innovation

Raymond Mill Raymond mill is suitable for preparation of various mineral powder and pulverized coal, also called high pressure roller mill After longterm research and development, Zenith has developed the upgrading products of Raymond mill MTM series medium speed trapezium mill and MTW series trapezium mill Feed Size: 035mm2023年9月18日 Want to know more about Raymond grinding mill? Check this ultimate guide If you want to buy Raymond roller mills, contact us Skip to content +63 997 allowing for efficient operation with a minimal amount of maintenance This type of grinding machine has a variety of applications in the industry They are including the Raymond Grinding Mill: The Ultimate Guide From SMAT MachineryThe machine is used for grinding the barite rare earth ore, hematitie, talcum, feldspar, slag and so on Compared with traditional Raymond mill, it has advantages of fine product, low energy consumption, is the ideal equipment of dry type calcium crabonate super fine powder grinding Technical Parameter Model: 4525: 4119: Feeding Size(mm Highstrength raymond mill, grinding machine Hongxing Maintenance allows these faults to be diagnosed early to manage any risks However, maintenance needs to be correctly planned and carried out Unsafe maintenance has caused many fatalities and serious injuries, either during the maintenance or to those using the badly maintained or wrongly maintained/repaired equipmentMaintenance of work equipment HSE

.jpg)

How to choose a suitable calcium carbonate grinding mill?

2024年9月14日 Raymond mill Raymond mill is mainly used for coarse powder grinding The feed particle size is 2530mm The discharge size is 45180μm The pass rate can reach 99% Other grinders find this hard to matchThe Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a Raymond Mill TAYMACHINERY2024年9月4日 AfterSales Service: Ensure that the manufacturer or distributor of the grinding machine provides adequate aftersales service, including warranties and maintenance How to Maintain Raymond Mill? Proper maintenance of What is Raymond Mill? How Does It Work? alwepoJune 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process:

.jpg)

Guide to Raymond Mill Maintenance: Schedule and Best Practices

2024年3月18日 Routine Maintenance For Raymond Mill Daily Maintenance 1 Perform the following tasks every day when the mill is in operation: Cleaning: Use a broom and shovel to remove accumulated powder on the machine and surrounding areas Inspect the grinding system and remove any blockages 22021年8月17日 Maxing Feeding Size: 40 mm Ouput Size: 06130033 micron (40400 mesh) Capacity: 125 t/h D97 325 mesh 2μm 10% Raymond Roller Grinding Mill Machine also named Raymond Mill, Raymond Roller Mill, 3R/4R/5R/6R Roller Mill and Raymond Mill Machine It is widely applied in ore materials grinding Raymond mill is the key equipment of powder Raymond Roller Grinding Mill MachineMethods Equipment Finished product(D97/ μ m) Features Dry grinding process Raymond roller mill 25150 1Applicable materials: medium and low hardness; 2Product features: medium and lowend products, suitable for the production of coarse powder;How to Choose a Calcium Carbonate Grinding Mill DASWELL2009年7月1日 Because of the array of precision functions grinding machines perform, it’s vital to properly maintain them to keep them operating at their peak in terms of accuracy and reliability You can start by devising a maintenance program and sticking with it This article provides tips on how to set up key parts of that programPracticing routine grinding machine maintenance produces

Maintenance of heavyhaul track by rail profiling Overview of

Overview of specifications of Rail grinding Machine, infrastructural requirements and cost –benefit analysis Sanjeev Agarwal, CE/TM/SCR BRam Mohan Reddy, Dy CE/TM/Line/Vijayawada 10 Introduction: This overview offer insights into working of Rail grinding Machine used for maintenance of heavyhaul trak by rail profiling Section 20 covers theThe bulk material of calcium carbonate is crushed by the crusher to the feed fineness (15mm50mm) that can enter the mill The crushed calcium carbonate small pieces of material are sent to the silo through the elevator, and then sent to the grinding chamber of the mill by the vibrating feeder for quantitative grindingCalcium carbonate millGrinding mill machine, mineral mill, raymond At present, the production methods of heavy calcium carbonate mainly include dry method and wet method The dry method generally produces heavy calcium with less than 2500 mesh If the heavy calcium with more than 2500 mesh is produced, wet grinding is mainly used, and dry grinding is the first step of wet grinding Wet grinding heavy calcium has the characteristics of News Apply The Heavy Calcium Grinding Mill Machine To The