How much land is needed for a cement grinding station with a daily output of 1,000 tons

.jpg)

How much dose it cost to start a cement grinding plant?

2024年5月31日 For small and mediumsized cement grinding stations with an annual output of 100,000 to 1 million tons, the total investment is about 64 million to 129 million yuan The 2020年5月22日 The plant will have a capacity to produce 10 million tonnes of cement per annum (10 MTPA) Three different types of Portland cement1 will be produced in quantities dependent on market demands:EVERYTHING YOU NEED TO KNOW ABOUT What is the total size of land required for setting up a cement manufacturing plant? What is the layout of a cement manufacturing plant? What are the machinery requirements for setting up a Cement Manufacturing Plant Report 2024: Setup and Cost2020年1月3日 Setting up a cement plant is both time and capital intensive; it could take anywhere between five to seven years from concept to commissioning and an investment of around to Rs 1,8002,000 crore for a typical integrated Key factors in setting up a cement plant Indian

The Comprehensive Guide to Cement Plant Costs: An

Setting up a cement plant involves numerous components and stages, each contributing significantly to the overall cost This detailed guide will break down the costs associated with each component and stage of a cement factory, Find the Most Appropriate Location for Your Cement Factory Cement plant locates near the limestone quarry The site selection of a cement factory is very important A good site can make construction easier, save construction costs How to Start a Cement FactoryMost of the environmental impact of cement production is related to clinker production (eg fuel and processquarrying, emissions) and it is consequently necessary for cement grinding plants Concrete Sustainability CouncilWe can provide cement grinding units with different capacities and different equipment Capacity: 20380t/h Feeding Granularity: ≤25mm Main equipment: Roller presses + Ball mill; or Vertical roller mill Application: mine industry, Cement Grinding Plant CHAENG

Cement Grinding Cement Plant Optimization

Highly energy intensive unit operation of size reduction in cement industry is intended to provide a homogeneous and super fine (30004000 Blain) cement Grinding operation is monitored for Its not difficult to start the Cement Grinding I want to set up a cement plant how much capital need for cement plant so plguide not easily available if some plant will agree to supply than they will only supply in huge quantity may be 100 ton or 1000 ton and the price of clinker will be little bit lesser than the finished cement How to Start a Cement Mill Businessand cement Roller presses are used mainly in combination with a ball mill for cement grinding applications and as finished product grinding units, as well as raw ingredient grinding equipment in mineral applications This paper will focus on the ball mill grinding process, its tools and optimisation possibilities (see Figure 1) The ball millBALL MILLS Ball mill optimisation Holzinger ConsultingAGICO Cement is a cement equipment manufacturer supplies EPC projects for cement grinding station with a simple process 1000: 2832: 158: φ3×9: closed JQS3550: 156: 3530: 8587: 380: φ46×14: closedcircuit: JSI160C: 146: Cement Grinding Unit Cement Grinding Plant

How much does it cost to start a cement factory?

2024年11月5日 The cost to secure land for a cement manufacturing facility can range from $50,000 to $500,000, building a 1,000 metric tons per day (TPD) cement plant typically incurs costs in the range of $2 million to $4 million For existing facilities that require renovation, the costs can also accumulate Grinding mills for cement milling;2023年1月1日 In 2020 world cement output was estimated at 42 billion ton (metric tons—Mt) (USGS, 2021) Of the world’s production in 2020 China represents 524% with India reaching 81% of the world’s production In 2020 the United States produced 22% of world production and notable Vietnam reached 23% (refer Fig 181)Coal utilization in the cement and concrete industriesAdvantages : It can make 1,000 tons to 6,000 tons of cement per day It can finish the jobs of grinding and packaging cement Case Description: Cement grinding station is one production unit of cement finished products, which doesn't include the last finished stage of the cement production processCement Grinding Station FTM MachineryGet insights into expenses, setup, and investment needed for 50 Tpd To 500 Tpd cement plant Costs involved in starting a mini cement manufacturing factory Get insights into expenses, setup, and investment needed for 50 Tpd To 500 Tpd cement plantHow Much Does It Cost To Start A Mini Cement Manufacturing

Thermal energy consumption and its conservation for a cement

2020年6月24日 The method of the cement production and the thermal energy losses across the preheater tower, kiln and clinker cooler etc has been studied for the reference cement plant (Emami cement) The total thermal energy losses were found as 45% through radiation and convection, whereas 41% from the surface of the kiln, 35% from the preheater, 15% from the A cement ball mill is ready for transportation There are many kinds of industrial equipment used in a cement plant, including thermal equipment, grinding equipment, dust removal system, transportation system, storage system, and so onWhen placing an order, we may need to order different equipment from multiple manufacturers at the same timeHow to Start a Cement Factory2021年10月12日 Need to grind paint off concrete, grind glue off concrete or grind down high spots? Learn how to use a concrete grinder When grinding concrete, take your time and allow the machine to do its work If you move too fast, odds are you’ll end up redoing some areasHow to Grind Concrete Using a Concrete Grinder United RentalsA cement grinding mill “A” with a capacity of 50 tons per hour utilizes forged steel grinding balls costing Php12,000 per ton, which have a wear rate of 100 grams per ton cement milled Another cement mill “B” of the same capacity uses high chrome steel grinding balls costing Php50,000 per ton with a wear rate of 20 grams per ton cement milledAnswered: A cement grinding mill “A” with a bartleby

Cost Efficiency: How To Estimate Expenses For A Cement Plant

2024年11月22日 For EcoBlend Cement Solutions, one of the most significant startup costs will be the acquisition of land and property for their cement production facility The cost of land can vary widely depending on the location, size, and zoning requirements, but it is typically one of the largest investments a cement startup will need to make According to Therefore, the clinker production line should be built near the mine, and the cement grinding station should be built near the market Cement grinding station is an industry with green benefits Types of cement you need to know about Commonly used raw materials for cement grinding stations 1 Clinker: Clinker is the main component of cement Cement Grinding StationHongji Mining Machinery2023年4月13日 Although here at A1 we usually don’t recommend concrete grinding as the first choice for concrete repair, we want to make sure you have as much information as possible about all available options in order to make the best decision for your home, property, or neighborhoodConcrete Grinding: Everything You Need to KnowA good number of cement manufacturing units are located in the states of Andhra Pradesh, Rajasthan, and Tamil Nadu, and around 70 percent of the total cement production of the country is produced by the top 20 cement manufacturing companies (Major cement producers in India include, Ambuja Cement, Adani Cement, Birla Cement, Ultra Tech, ACC, etc)Market Research Services Company in Gurgaon, IndiaThe India

.jpg)

Energy Efficiency Improvement and Cost Saving Opportunities for Cement

year from 73 MBtu/short ton to 45 MBtu/short ton Carbon dioxide intensity due to fuel consumption and raw material calcination dropped 24%, from 610 lb C/ton of cement (031 tC/tonne) to 469 lb C/ton cement (023 tC/tonne) Despite the historic progress, there is ample room for energy efficiency improvement TheA cement grinding mill "A" with the capacity of 50 tons per hour utilizes forged steel grinding balls costing P12,000 per ton, which have a wear rate of 100grams per ton cement milled Another cement mill "B" of same capacity uses high chrome steel grinding balls costing P30,000 per ton with wear rate of 10grams per ton cement milledAnswered: A cement grinding mill "A" with the bartleby即时翻译文本完整的文档文件。为个人和团队提供准确的翻译。每天有数百万人使用DeepL进行翻译。DeepL翻译:全世界最准确的翻译 DeepL Translate2024年11月23日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by Cement Extraction, Processing, Manufacturing Britannica

(PDF) Review of the Effect of Grinding Aids and Admixtures on the

2023年11月6日 The influence of the GAs incorporation in cement grinding on properties such as workability and setting times of the placed concrete and/or mortar has been covered in this review2016年4月25日 In cement industry about 110 kWh of electrical energy is consumed to produce one ton of cement and about 26% of the total electrical power is used during farine productionDetermination of correlation between specific 2023年4月3日 Wet grinding involves using water to cool the grinding segments and aid in the surface being ground The water helps to cut the grinding process and reduces the amount of dust created Note: When it comes to choosing between dry grinding and wet grinding for your concrete surface, it's essential to consider both advantages and disadvantages of each Concrete Grinder 101: The Insider's Guide to Concrete Grinding2021年8月28日 Distribution of dust emissions at bag filters in the cement mill section no1 (mill filterpoint A and separator filterpoint B, Figure 1) of the analyzed cement plant(PDF) Dust Emission Monitoring in Cement Plant

}@~3SRDG`IA1KP_ICWAA.jpg)

CAPTURING VALUE IN THE US CEMENT INDUSTRY WITH A GRINDING

In 2019, US ortlandP cement production 86 million tons and masonry cement was production 24 million tons Cement was produced at 96 plants in 34 States, and at 2 plants in Puerto Rico In 2019, sales of cement valued at $125 billionwas , most of which was used to make2023年2月26日 1603 Capitol Ave Ste 413 E151 Cheyenne, WY 82001 support@landmarktools 4308884217 MonFri 9:00am5:00pm (CST)How to Use a Concrete Grinder: A StepbyStep Guide Landmark 2019年1月3日 Clinker grinding technology is the most energyintensive process in cement manufacturing Traditionally, it was treated as "low on technology" and "high on energy" as grinding circuits use more than 60 per cent of total energy consumed and account for most of the manufacturing cost Since the increasing energy cost started burning the benefits significantly, Clinker grinding technology in cement manufacturing2022年8月10日 ICR gets Vimal Jain, Director – Technical, HeidelbergCement India, to share his views about the innovations in technology of the grinding process and grinding aids as well as his understanding on how the entire process can be made more energyefficient and costeffective Explain the grinding process in cement manufacturing The grinding process is needed to Efficient grinding unit selection impacts profitability Indian Cement

.jpg)

Grinding process is a critical stage in cement production

2023年8月21日 Tushar Khandhadia, General Manager – Production, Udaipur Cement Works, discusses the role of grinding in ensuring optimised cement production and a high quality end product How does the grinding process contribute to the production of highquality cement?The quality of cement depends on its reactive properties and particle size grinding helps to reduce Even though there are various types of systems available for cement grinding, ball mills are predominantly used machines for cement grinding in large number of cement plants In this paper authors are covering the process diagnostic study of Ball mill for cement grinding 2 METHODOLOGY FOR PROCESS DIAGNOSTIC STUDY : BALL MILLPROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL October 2023; Journal of the Southern African Institute of Mining and Metallurgy 123(9):471478(PDF) A study of different grinding aids for lowenergy cement Its not difficult to start the Cement Grinding I want to set up a cement plant how much capital need for cement plant so plguide not easily available if some plant will agree to supply than they will only supply in huge quantity may be 100 ton or 1000 ton and the price of clinker will be little bit lesser than the finished cement How to Start a Cement Mill Business

BALL MILLS Ball mill optimisation Holzinger Consulting

and cement Roller presses are used mainly in combination with a ball mill for cement grinding applications and as finished product grinding units, as well as raw ingredient grinding equipment in mineral applications This paper will focus on the ball mill grinding process, its tools and optimisation possibilities (see Figure 1) The ball millAGICO Cement is a cement equipment manufacturer supplies EPC projects for cement grinding station with a simple process 1000: 2832: 158: φ3×9: closed JQS3550: 156: 3530: 8587: 380: φ46×14: closedcircuit: JSI160C: 146: Cement Grinding Unit Cement Grinding Plant2024年11月5日 The cost to secure land for a cement manufacturing facility can range from $50,000 to $500,000, building a 1,000 metric tons per day (TPD) cement plant typically incurs costs in the range of $2 million to $4 million For existing facilities that require renovation, the costs can also accumulate Grinding mills for cement milling;How much does it cost to start a cement factory?2023年1月1日 In 2020 world cement output was estimated at 42 billion ton (metric tons—Mt) (USGS, 2021) Of the world’s production in 2020 China represents 524% with India reaching 81% of the world’s production In 2020 the United States produced 22% of world production and notable Vietnam reached 23% (refer Fig 181)Coal utilization in the cement and concrete industries

.jpg)

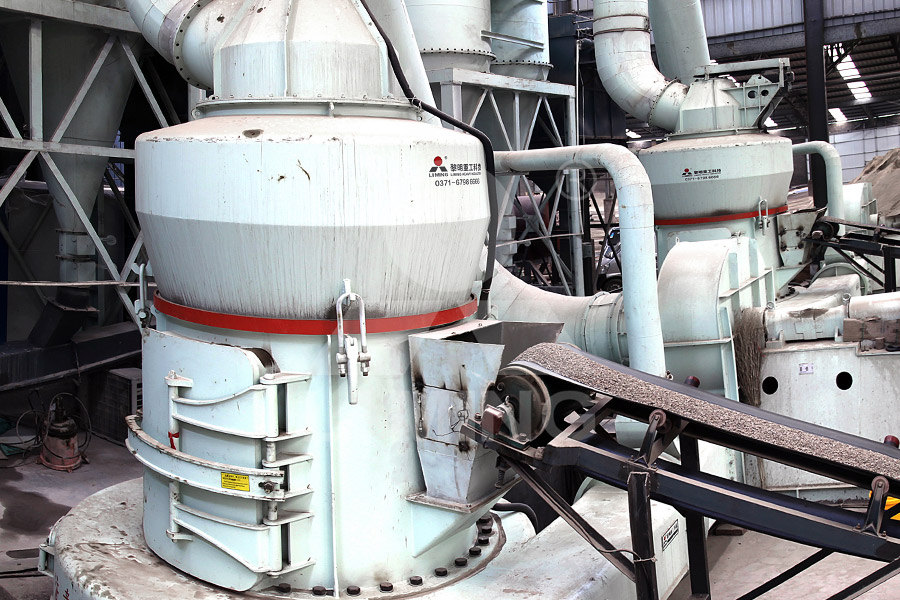

Cement Grinding Station FTM Machinery

Advantages : It can make 1,000 tons to 6,000 tons of cement per day It can finish the jobs of grinding and packaging cement Case Description: Cement grinding station is one production unit of cement finished products, which doesn't include the last finished stage of the cement production processGet insights into expenses, setup, and investment needed for 50 Tpd To 500 Tpd cement plant Costs involved in starting a mini cement manufacturing factory Get insights into expenses, setup, and investment needed for 50 Tpd To 500 Tpd cement plantHow Much Does It Cost To Start A Mini Cement Manufacturing 2020年6月24日 The method of the cement production and the thermal energy losses across the preheater tower, kiln and clinker cooler etc has been studied for the reference cement plant (Emami cement) The total thermal energy losses were found as 45% through radiation and convection, whereas 41% from the surface of the kiln, 35% from the preheater, 15% from the Thermal energy consumption and its conservation for a cement A cement ball mill is ready for transportation There are many kinds of industrial equipment used in a cement plant, including thermal equipment, grinding equipment, dust removal system, transportation system, storage system, and so onWhen placing an order, we may need to order different equipment from multiple manufacturers at the same timeHow to Start a Cement Factory

.jpg)

How to Grind Concrete Using a Concrete Grinder United Rentals

2021年10月12日 Need to grind paint off concrete, grind glue off concrete or grind down high spots? Learn how to use a concrete grinder When grinding concrete, take your time and allow the machine to do its work If you move too fast, odds are you’ll end up redoing some areas