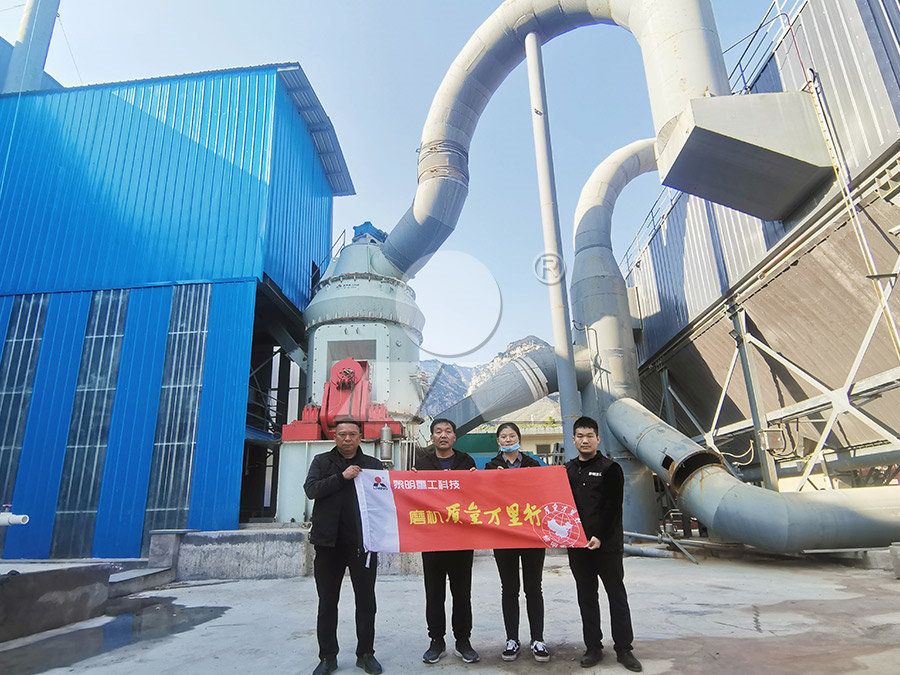

magnesium oxide steelmaking plant steel slag mill vertical mill

.jpg)

Basic Oxygen Steelmaking Slag: Formation, Reaction, and Energy

This article reviews the recent progress on the four important topics of BOS slags: 1) slag formation, ie, dissolution of lime in the BOS slag; 2) hightemperature phase transformation Wiley Online LibraryDownload PDF2023年5月15日 The main components of steel slag include calcium oxide, silicon dioxide, iron oxide, alumina, and magnesium oxide The raw materials of traditional ceramics are generally Comprehensive utilization of steel slag: A review ScienceDirect2024年4月1日 Steel and ironmaking slag contain 30–60 wt% of calcium oxide (CaO) and 3–15 wt% of magnesium oxide (MgO), suggesting high CO2 storage capacities [19]Carbon mineralization of steel and ironmaking slag: Paving the

Basic oxygen furnace slag: Review of current and potential uses

2020年4月1日 Steel slag, in particular, basic oxygen furnace slag (BOFS) – a byproduct in the steelmaking industry – is an environmental challenge due both to the large volume of the 2024年5月8日 The principal phases in steelmaking slag, namely α′Ca2SiO4 (C2S), RO (MgO–FeO solid solution), Ca2Fe2O5 (C2F) and Ca3SiO5 (C3S), were identified using XRD Effect of MgO on Phase Structure and Evolution of Steelmaking 2019年5月23日 Steel slag is the waste generated in the steelmaking process and includes ferric oxide and the impurities of some infusible matters It is the byproduct when slagforming Comprehensive Utilization Technology of Steel Slag2011年5月14日 Fluxes serve two important purposes First they combine with SiO2 which is oxidized from the hot metal to form a “basic” slag that is fluid at steelmaking temperatures This slag absorbs and retains sulfur and phosphorus from the hot metal Lime (95+% CaO) and dolomite (58%CaO, 39% MgO) are the two primary fluxesThe Basic Oxygen Steelmaking (BOS) Process – Consortium Steel

.jpg)

Properties of magnesium phosphate cement containing steel slag

2019年1月20日 The magnesium phosphate cement (MPC) mortars specimens were prepared by mixing the magnesium oxide (MgO, M), ammonium dihydrogen phosphate (NH 4 H 2 PO 4, P), borax (Na 2 B 4 O 7 10H 2 O), sodium triphosphate cement (STP), manufactured sand and steel slag powder (SSP) in different proportions1 Introduction The basic oxygen steelmaking (BOS) process produced over 70% of the global crude steel in 2018, [] generating 100 to 150 kg of slag (“BOS slag”) for every tonne of crude steel produced BOS slag, a product of hot metal Basic Oxygen Steelmaking Slag: Formation, Reaction, The steel industry is a pillar industry related to a country’s national economy and people’s livelihood, and is also one of the industries that emits the largest amount of solid waste Steel slag is one of the solid wastes discharged during the steelmaking process It is the oxide genAdvantages of HCM Machinery HLM Vertical Mill Steel Slag 2024年4月1日 Steel and ironmaking slag contain 30–60 wt% of calcium oxide (CaO) and 3–15 wt% of magnesium oxide (MgO), suggesting high CO 2 storage capacities [19] It has been reported that the potential CO 2 sequestration capacity if using alkaline industrial waste is 310 Mt CO 2 , and steel and ironmaking slag sources can contribute to a 435% reduction in CO 2 [20] Carbon mineralization of steel and ironmaking slag: Paving the

Use of steel slag as sustainable construction materials: A review of

2021年6月8日 Steel slag is a byproduct discharged from the steelmaking process, which is characterized by abundant free calcium/magnesium oxide, low cementitious properties, and high contents of heavy metalsThe steel slag is ground by vertical grinding powder, and the material is ground in a humid environment at high temperature (100℃ ~ 300℃) Most of the free calcium oxide and free magnesium oxide in the steel slag micropowder are hydrated into highly active calcium hydroxide and magnesium hydroxideNews Application prospect of ultrafine steel slag grinding2019年1月1日 In an integrated steel plant, wastes (including solid, liquid and gas) are generated for every ton of steel produced In India, almost 100 million tonnes of steel is produced every year, and along Recent trends in slag management utilization in the steel The steel slag ball mill is one of the main equipment for grinding and processing It has stable operation, good grinding effect and obvious economic benefit The emergence of steel slag ball mill meets the needs of steel slag plant for processing steel slag grinding, and also enables the rational use of steel slag and avoids waste of resourcesSteel Slag Ball Mill Quality Ball Bill Supplier Provide Best Price

.jpg)

Chemical, Mineralogical, and Morphological Properties of Steel Slag

2011年10月26日 Steel slag is a byproduct of the steelmaking and steel refining processes Multiserv Ltd, Harsco Corporation, which performs slag processing operations at the Mittal Steel Plant, Indiana, was the source for the EAF ladle (L) slag The Edward C Levy Co, which operates at the Whitesville Steel Mill, supplied The EAF(L) slagThe Company is also providing steel mill services for handling BOF Slag, etc During the year 201617, BSP reported production of Granulated Slag at 1,531,579 tonnes Tata Steel Plant produced 3,783,844 tonnes of BF Slag During the year 201516, RSP reported production of BF slag, Granulated slag and Steel slag at 1,141,810 tonnes, 868,395 SlagIron and Steel 2017 (2) IBMVertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plantVertical raw mill is an ideal grinding mill that crushing, drying, grinding, Vertical raw mill Cement Plant2018年2月5日 Piles of steel slag, a solid waste generated from the iron and steel industry, could be seen due to no utility found for the past century Steel slag has now gained much attention because of its new applications The properties of slag greatly influence its use and thus had got varied applications The chemical composition of steel slag varies as the mineral composition Review on the innovative uses of steel slag for waste minimization

.jpg)

(PDF) Iron and Steel Slags ResearchGate

2017年3月5日 Normalized CaO (MgO)SiO 2 (Na 2 O,K 2 O)Al 2 O 3 (Fe 2 O 3 ) phase diagram for various types of iron and steel slags Acronyms: blast furnace slag (BFS); basic oxygen furnace slag (BOFS 2023年5月15日 The primary minerals that make up steel slag include dicalcium silicate (C 2 S), tricalcium silicate (C 3 S), calcium‑magnesium olivine (CaMg[SiO 4]), tetracalcium iron aluminate (C 4 AF), dicalcium ferrate (C 2 F), RO (oxide solid solution of Mg 2+, Fe 2+, Mn 2+), free calcium oxide (fCaO)The mineral composition of steel slag is comparable to that of silicate cement, Comprehensive utilization of steel slag: A review ScienceDirectSteel slag is milled by steel slag vertical roller mill The materials are ground in a high temperature (100 ℃~300 ℃) and humid environment Most of the free calcium oxide and free magnesium oxide in the steel slag powder are hydrated into highly active calcium hydroxide and How to make paper with steel slag? Comprehensive utilization of 2020年3月5日 of strength than the steel slag; on the other hand, steel slag, due to its content of iron oxide, has shown to be much stronger than granite In addition, lower silica content in steel slag and bottomReuse and Recycling of ByProducts in the Steel Sector: Recent

Slag Vertical Roller Mill

2023年1月10日 Equipment configuration: LM vertical roller mill Treatment process: dry method Raw material source: selfgenerated solid waste from the Group's thermal power plant Finished product use: new marble material Process of Slag Grinding Plant Slag grinding is an important part of slag powder production2021年4月30日 Magnesium slag that is piled in the open air is basically in the form of fine powder after the magnesium slag decomposes naturally The particle size of the slag is measured with a laser particle size tester (Microtrac X100), and the particle size distribution diagram is shown in Fig 32Table 32 shows the corresponding composition of the slagMagnesium Slag Generated by Reduction Smelting Using Pidgeon ProcessSince 2007, SINOMALY has begun to develop and manufacture vertical slag mill, which has been successfully applied in the market, with a output range from 45t/h to 300t/h that can satisfy the slag powder production lineSlag Mill Vertical Slag Mill Provider SINOMALYRelease time 18/12/2014 Clirik Newest super fine HGM100 vertical powder grinding mill See detailsvertical roller mill clirikultrafine vertical mill, Raymond vertical

Sulphur removal in ironmaking and oxygen

2017年3月22日 An alternative for desulphurisation with lime is the use of magnesium oxide MgO in the slag and dissolved sulphur react via the following reaction (based on reaction (1)) MgO, however, is a less effective 2024年3月12日 If a powdered steel slag product is required, a combination of rod mill and vertical roller mill or vertical roller mill and ball mill can be selected This step can be equipped with a dust collector for dust removal operations, Steel Slag Recycling: The Definitive Processing Solutionand , ,Recent trends in slag management utilization in the steel industry2009年11月1日 A steelmaking slag (basic oxygen furnace) obtained from the Kardemir Steelworks was modified to be used as a clinker additive in the cement industryConcrete Produced by Steel‐Making Slag (Basic Oxygen Furnace

Glossary American Iron and Steel Institute

U¡b EYíí! ÕÅ æ” •³Z €FÊÂùûO Á¸û ´lÇåöx}~ÿŸ¦Ö ,%Ñ5ûÈ Æ ¹›ê‘(©y’¥ Ùí™iûø\ €² UèZH¢5:Ç ²eíù[¶ Ñ æü 2023年6月10日 Crude steel production in China exceeds 1 billion tons per year, and steel slag production accounts for 10%–15% of the crude steel mass Although slag presents certain hydration activity, it is still difficult to be used as a building material because the particles contain a large amount of active calcium oxide and magnesium oxide, which are easy to hydrate and Coupling Mineralization and Product Characteristics of Steel Slag We can provide different types of vertical roller mills in different industries such as cement, steel, and mining The production capacity is 30250 t/h More>>cement plant,ball mill,vertical mill,rotary kiln,slag grinding mill 2023年11月20日 In the twentyfirst century, steel has become one of the most utilized engineering materials, from house utensils to the automotive sector According to the World Steel Organization, the world produced a total of 1951 million tons of crude steel in 2021, in which China is the top producer of crude steel with 10328 million tonnes, followed by India and A Review on Environmental Concerns and Technological

.jpg)

2 µm 5 µm Loesche

a Loesche mill, with a grinding track diameter of only 11 metres, was used as long ago as 1935 However, the breakthrough in grinding this type of material on the vertical roller mill did not take place until the beginning of the 1990’s 1935 The first Loesche mill for grinding cement clinker, an LM 11, was commissioned in Joao Pessao, Brazil2011年5月14日 Fluxes serve two important purposes First they combine with SiO2 which is oxidized from the hot metal to form a “basic” slag that is fluid at steelmaking temperatures This slag absorbs and retains sulfur and phosphorus from the hot metal Lime (95+% CaO) and dolomite (58%CaO, 39% MgO) are the two primary fluxesThe Basic Oxygen Steelmaking (BOS) Process – Consortium Steel 2019年1月20日 The magnesium phosphate cement (MPC) mortars specimens were prepared by mixing the magnesium oxide (MgO, M), ammonium dihydrogen phosphate (NH 4 H 2 PO 4, P), borax (Na 2 B 4 O 7 10H 2 O), sodium triphosphate cement (STP), manufactured sand and steel slag powder (SSP) in different proportionsProperties of magnesium phosphate cement containing steel slag 1 Introduction The basic oxygen steelmaking (BOS) process produced over 70% of the global crude steel in 2018, [] generating 100 to 150 kg of slag (“BOS slag”) for every tonne of crude steel produced BOS slag, a product of hot metal Basic Oxygen Steelmaking Slag: Formation, Reaction,

43.jpg)

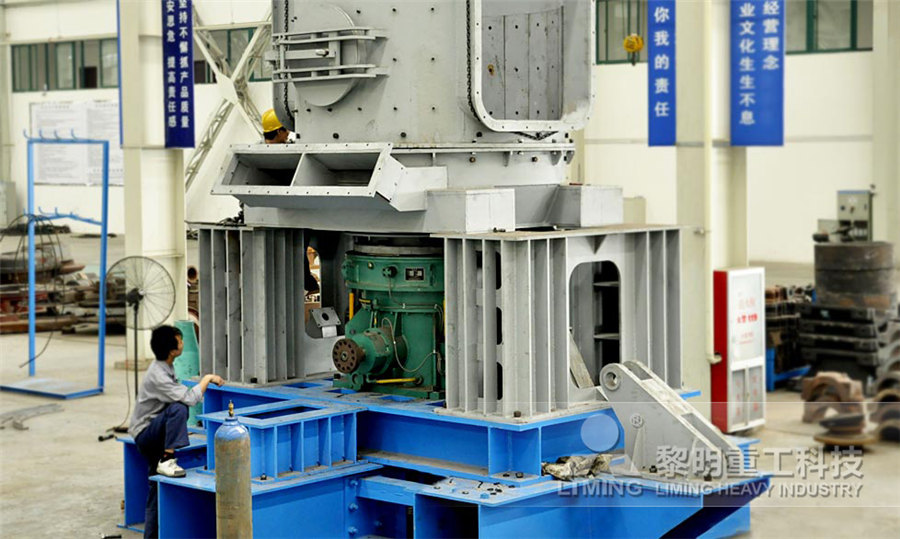

Advantages of HCM Machinery HLM Vertical Mill Steel Slag

The steel industry is a pillar industry related to a country’s national economy and people’s livelihood, and is also one of the industries that emits the largest amount of solid waste Steel slag is one of the solid wastes discharged during the steelmaking process It is the oxide gen2024年4月1日 Steel and ironmaking slag contain 30–60 wt% of calcium oxide (CaO) and 3–15 wt% of magnesium oxide (MgO), suggesting high CO 2 storage capacities [19] It has been reported that the potential CO 2 sequestration capacity if using alkaline industrial waste is 310 Mt CO 2 , and steel and ironmaking slag sources can contribute to a 435% reduction in CO 2 [20] Carbon mineralization of steel and ironmaking slag: Paving the 2021年6月8日 Steel slag is a byproduct discharged from the steelmaking process, which is characterized by abundant free calcium/magnesium oxide, low cementitious properties, and high contents of heavy metalsUse of steel slag as sustainable construction materials: A review of The steel slag is ground by vertical grinding powder, and the material is ground in a humid environment at high temperature (100℃ ~ 300℃) Most of the free calcium oxide and free magnesium oxide in the steel slag micropowder are hydrated into highly active calcium hydroxide and magnesium hydroxideNews Application prospect of ultrafine steel slag grinding

Recent trends in slag management utilization in the steel

2019年1月1日 In an integrated steel plant, wastes (including solid, liquid and gas) are generated for every ton of steel produced In India, almost 100 million tonnes of steel is produced every year, and along The steel slag ball mill is one of the main equipment for grinding and processing It has stable operation, good grinding effect and obvious economic benefit The emergence of steel slag ball mill meets the needs of steel slag plant for processing steel slag grinding, and also enables the rational use of steel slag and avoids waste of resourcesSteel Slag Ball Mill Quality Ball Bill Supplier Provide Best Price2011年10月26日 Steel slag is a byproduct of the steelmaking and steel refining processes Multiserv Ltd, Harsco Corporation, which performs slag processing operations at the Mittal Steel Plant, Indiana, was the source for the EAF ladle (L) slag The Edward C Levy Co, which operates at the Whitesville Steel Mill, supplied The EAF(L) slagChemical, Mineralogical, and Morphological Properties of Steel Slag