Loesche vertical mill hydraulic composition

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest • Lowvibration mill running, even in partial load ranges down to 20% of the mill load, thanks to individuallyguided grinding rollers • The speciallydeveloped hydraulic roller relief system LOESCHEMILLSslag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a Loesche mill, with a grinding track diameter of only 11 metres, was used as 2 µm 5 µm LoescheStudies for applications of LOESCHE mills for the dry comminution of ores and minerais have proven that in particular cases the recovery and the grade ofU Schaefer LOESCHE VERTICAL ROLLER MILLS FOR MINERAL

Loesche vertical roller mills for the comminution of ores and

2001年10月1日 The hydropneumatic spring system is a very versatile feature on the LOESCHE mill because it allows easy adjustment of the grinding process responding to changing Vertical Spindle Roller Mill Hydraulic loaded rollers crush and shear the input material upon a rotating table With over 100 years’ experience, the Loesche Group has made its name in the development of the vertical spindle roller mill Dynamic Classifier Vertical Spindle Roller Mill Solutions2012年9月1日 Mills (VRM) installations and summarises the main benefits of the dry compressive Loesche grinding technologies in Airflow and OverflowMode Some of these Latest Installations And Developments Of Loesche Vertical Roller 2001年10月1日 LOESCHE vertical roller mills are widely used for the comminution of raw materials in the cement industry, for the comminution of clinker and blast furnace slag and for Loesche vertical roller mills for the comminution of ores and

.jpg)

Loesche vertical roller mills for the comminution of ores and

2001年10月1日 This paper presents an experimental approach to measure and model the residence time distribution of vertical roller mill in cement clinker grinding circuit The 2001年10月1日 LOESCHE vertical roller mills are widely used for the comminution of raw materials in the cement industry, for the comminution of clinker and blast furnace slag and for LOESCHE vertical roller mills for the comminution ofFor the greenfield project in Thanh Thang LOESCHE will supply two vertical roller mills type LM 533+3 CSVertical Roller Mill Loescheitems Amongst others these involve the mill drive and the roller/hydraulic system Figure 1: Loesche Mill type LM 696 with 6 rollers for cement raw material grinding Grinding track outer diameter Number of rollers Mean roller diameter Roller width Mill motor capacity kW m – m m 9600 70 4 S + 4 M ˜ 27 ˜ 075 Mill radial bearing Mill LATEST TECHNOLOGICAL INNOVATIONS IN GRINDING WITH THE VERTICAL ROLLER MILL

Loesche PDF Gases Mill (Grinding)

Loesche Free download as PDF File (pdf), Text File (txt) or view presentation slides online The document provides an overview of training on troubleshooting a Loesche vertical roller mill (VRM) for a cement plant in India It discusses Since 1906 worldwide market leader in designing, manufacturing and servicing vertical roller mills for the cement, power and industrial minerals industries Plant engineering solutions for any mission LoeschePlant engineering solutions for any mission LoescheNew or refurbished plant, Loesche have the mill to meet your needs Loesche vertical roller mills for solid fuels are offered with 2, 3 or 4 rollers with a capacity range of 8 to 240 t/h (16,000 to 640,000 lb/h) giving us the flexibility to match the process requirements for your plant Our mills offer a large range of benefits for both purchaserLoesche Grinding Technology for the Power IndustryFig2 Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimationVertical roller mill for raw Application p rocess materials

.jpg)

Loesche Mills for industrial minerals

Loesche hot gas generators The mill is driven by an electric motor via a flexible coupling and the mill gearbox via a vertical output flange A segmental thrust bearing at the top of the gearbox absorbs the grinding forces Before the mill motor is started, the grinding rollers are lifted hydraulically from the grinding track The millThermal conversion of fossil fuels is the main contributor to the anthropogenic carbon emissions Also, the hot gas generators for the provision of heat for the grinding drying in a VRM are operated almost exclusively with fossil fuels (see Figure 6) This gives a high CO 2 reduction potential to Loesche’s core product: the vertical roller millGreenkey Solutions: Loesche’s contribution to a sustainable ZKGLOESCHE America, Inc 20170 Pines Boulevard, Suite 302 Pembroke Pines, Florida 33029, USA Phone: +1 954 602 14 24 Toll Free: +1 800 989 91 55 Fax: +1 954 602 14 23LOESCHE America, IncLOESCHE South Africa Pty (Ltd) Old Trafford 1 1st Floor, Office 106 36 boundary Road Isle of Houghton, Houghton Estate 2198, South Africa Phone: +27 (0) 11 032 9360 Mobile: +27 082 908 6866 Fax: +27 (0) 11 482 2940 : Web: loesche WHERE WE ARELOESCHE South Africa

.jpg)

Molinos Verticales PDF Mill (Grinding) Valve

MOLINOS VERTICALES Free ebook download as PDF File (pdf), Text File (txt) or read book online for free This document provides a technical agenda for optimizing the performance of vertical raw mills It aims to help plant teams The accumulator assembly of the present invention can be connected to either or both the piston side or the rod side of the vertical roller mill's hydraulic cylinder The accumulator assembly may be used by itself or in conjunction with a standard accumulator, as is depicted in FIG 4Vertical roller mill with improved hydropneumatic loading systemLOESCHE is a wcll rcputated supplicr of vertical roller mills Manufacturcrs in the United States and in Japan have becn liccnsccs for many ycars ln the beginning of thc history of LOESCHE thc mills were mainly used for pulverization of coai for power plants Nowadays thc U Schaefer LOESCHE VERTICAL ROLLER MILLS FOR MINERAL Loesche GmbH 38619 Follower:innen auf LinkedIn Global market leader in vertical roller mill technology for the cement industry since 1906 Loesche is an ownermanaged, exportoriented company, which was founded in Berlin in 1906 Today, the company operates from its head office in Düsseldorf and has subsidiaries, representatives and agencies around the world It was in Loesche GmbH LinkedIn

ZWEI PRODUKTE AUS EINER MAHLANLAGE Loesche

other minerals A Loesche mill LM 152 (Lead picture), has been used for this purpose since 2010 The feed materials processed, which are obtained from the company‘s own quarry, are used in the construction industry, the agricultural industry and also in horticulture, inter alia 3 The functioning of Loesche vertical roller millsLOESCHE is a wcll rcputated supplicr of vertical roller mills Manufacturcrs in the United States and in Japan have becn liccnsccs for many ycars ln the beginning of thc history of LOESCHE thc mills were mainly used for pulverization of coai for power plants Nowadays thc U Schaefer LOESCHE VERTICAL ROLLER MILLS FOR MINERAL production line with vertical roller mills made by Loesche, Germany, which were supplied via the company’s American subsidiary, Loesche America in Pembroke Pines, Florida 2 Cement raw material grinding The grinding of the entire cement raw material for the new line is carried out by a Loesche mill LM 606, which 1 Einleitung Am 5Trials on high quality cement with a Loesche vertical roller mill Nowadays, Loesche vertical mills form the core of many plants used to drygrind coal, cement raw materials, granulated slag, industrial minerals and ores Thanks to its grinding plants with throughputs of 2 to 1000 t/h for the cement industry and selfinert, central coalgrinding plants for hard and brown coal power stations, Loesche is the global market leader for vertical mills and About Us Loesche

.jpg)

Loesche Mills for industrial minerals Ammermann

Loesche hot gas generators The mill is driven by an electric motor via a flexible coupling and the mill gearbox via a vertical output flange A segmental thrust bearing at the top of the gearbox absorbs the grinding forces Before the mill motor is started, the grinding rollers are lifted hydraulically from the grinding track The millUp to date, the LOESCHE Mill type LM 352+2 is the sole vertical roller mill in this plant for cement grinding LOESCHE America to hold its 4th Annual Technical Seminar in South Florida LOESCHE America Inc has opened registrations for its fourth Technical Seminar, to take place in Downtown Miami, from 19 September through to 22 September, 2016Loesche Mining TechnologyLOESCHE's special series of industrial mineral mills LOESCHE has developed a special series of industrial mineral mills for the specific needs of grinding minerals The smallest mills in this series – LM 12200 and LM 15200 – are Industrial Minerals Loesche2001年10月1日 PRINCIPLE OF THE LOESCHE MILL LOESCHE has been manufacturing vertical roller mills for cement raw materials, clinker and slag, indus trial minerais, and for coal for cement kilns, for power plants and for blast fumaces for more than 90 years In the last three decades the cement industry demanded significantly higher mill capacitiesLoesche vertical roller mills for the comminution of ores and minerals

.jpg)

50 years of Loesche mills in Turkey – let’s try again!

ments ground in the vertical roller mill fulfil or even exceed the quality requirements of the market” He compared a ball mill with the vertical roller mill from Loesche Possibilities to influence the cement quality in the VRM are, for example, grindLOESCHE SEMINAR, ISTANBUL/TURKEY 50 years of Loesche mills in Turkey – let’s try again!2021年1月29日 In recent years vertical roller mill Mill Inlet Outlet Temp, Hydraulic Pressure, Loesche GmbH : Vertical Roller Mill LM 533 Manual Presen tation Increase productivity of vertical roller mill using seven QC tools2001年10月1日 Fig 1 illustrates the grinding parts of a Loesche vertical roller mill The grinding force is provided by rollers that are attached to the hydraulic Phase composition analyses of raw LOESCHE vertical roller mills for the comminution ofLoesche Roller Grinding Mill Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free The report summarizes visits and information gathered by Hamza Younas during initial training on process understanding and line tracing of Line 1 at Lucky Cement's PEZU plant in KPK, Pakistan The training included supervision from various Loesche Roller Grinding Mill

Hydraulic system vertical roller mill operation PDF SlideShare

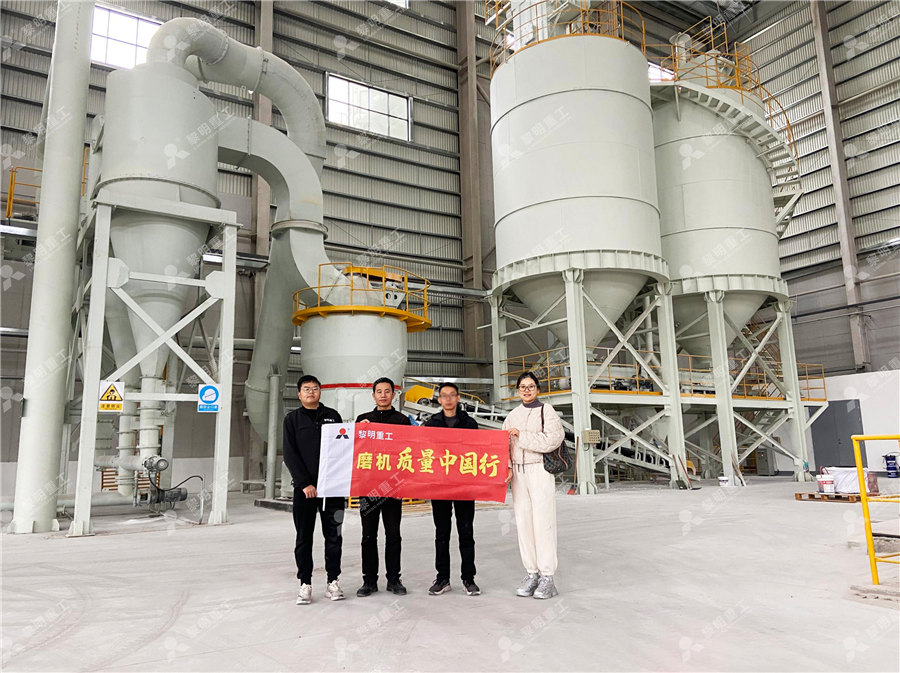

2015年3月25日 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts or repairThis type vertical roller 金鸡送喜,捷报频传,莱歇喜迎新订单 “莱歇磨,中国造”得到更多客户认可。春回大地,万物复苏!在这个春意盎然的季节里,莱歇公司,全球立式辊磨领域的佼佼者,也迎来了越来越多的客户的信任和订单。莱歇中国 Loesche2014年11月6日 5 4 Quality and reliability right from the start are the globally recognised benefits to be derived from Loesche grinding plants As early as 1928, when the first Loesche mill came onto the market, the grinding principle of the vertical roller grinding mill, with a driven grinding track and springloaded rollers was shown to be particularly energyefficient and reduced the Loesche Technology Always a Step Ahead: Loesche MillsThe Loesche vertical mill is characterised by the fact that several processes – comminution, drying and classifying – can be implemented in a single machine Since the birth of the Loesche mill back in 1927 we have devoted ourselves just as much to classifying as we have to the grinding process This is because only highly efficientOVER VIEW Loesche

Vertical Roller Mill Loesche

For the greenfield project in Thanh Thang LOESCHE will supply two vertical roller mills type LM 533+3 CSitems Amongst others these involve the mill drive and the roller/hydraulic system Figure 1: Loesche Mill type LM 696 with 6 rollers for cement raw material grinding Grinding track outer diameter Number of rollers Mean roller diameter Roller width Mill motor capacity kW m – m m 9600 70 4 S + 4 M ˜ 27 ˜ 075 Mill radial bearing Mill LATEST TECHNOLOGICAL INNOVATIONS IN GRINDING WITH THE VERTICAL ROLLER MILLLoesche Free download as PDF File (pdf), Text File (txt) or view presentation slides online The document provides an overview of training on troubleshooting a Loesche vertical roller mill (VRM) for a cement plant in India It discusses Loesche PDF Gases Mill (Grinding)Since 1906 worldwide market leader in designing, manufacturing and servicing vertical roller mills for the cement, power and industrial minerals industries Plant engineering solutions for any mission LoeschePlant engineering solutions for any mission Loesche

.jpg)

Loesche Grinding Technology for the Power Industry

New or refurbished plant, Loesche have the mill to meet your needs Loesche vertical roller mills for solid fuels are offered with 2, 3 or 4 rollers with a capacity range of 8 to 240 t/h (16,000 to 640,000 lb/h) giving us the flexibility to match the process requirements for your plant Our mills offer a large range of benefits for both purchaserFig2 Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimationVertical roller mill for raw Application p rocess materialsLoesche hot gas generators The mill is driven by an electric motor via a flexible coupling and the mill gearbox via a vertical output flange A segmental thrust bearing at the top of the gearbox absorbs the grinding forces Before the mill motor is started, the grinding rollers are lifted hydraulically from the grinding track The millLoesche Mills for industrial mineralsThermal conversion of fossil fuels is the main contributor to the anthropogenic carbon emissions Also, the hot gas generators for the provision of heat for the grinding drying in a VRM are operated almost exclusively with fossil fuels (see Figure 6) This gives a high CO 2 reduction potential to Loesche’s core product: the vertical roller millGreenkey Solutions: Loesche’s contribution to a sustainable ZKG

.jpg)

LOESCHE America, Inc

LOESCHE America, Inc 20170 Pines Boulevard, Suite 302 Pembroke Pines, Florida 33029, USA Phone: +1 954 602 14 24 Toll Free: +1 800 989 91 55 Fax: +1 954 602 14 23LOESCHE South Africa Pty (Ltd) Old Trafford 1 1st Floor, Office 106 36 boundary Road Isle of Houghton, Houghton Estate 2198, South Africa Phone: +27 (0) 11 032 9360 Mobile: +27 082 908 6866 Fax: +27 (0) 11 482 2940 : Web: loesche WHERE WE ARELOESCHE South Africa