Xinyang slag micro powder

.jpg)

Experimental Study on the Mechanical Properties of

2023年5月20日 This study focused on improving Xinyang red clay using three methods: single lime, single fly ash, and compound lime–fly ash Various tests were conducted, including the limiting water content test, compaction test, 2020年11月1日 Optimal solution for slag powder production process is determined by proposed CTNSGAII algorithm Slag powder is a process with characters of multivariables, strongly Analysis and multiobjective optimization of slag powder process2023年12月11日 The composite micronized powder is prepared by using blast furnace slag (BFS), waterquenched manganese slag (WQMS), manganese tailing slag (MTS) and Preparation and Performance of UltraFine High Activity Xinyang Iron and Steel, a trustworthy steel! Xingang Company is an integrated iron and steel enterprise integrating steel rolling, steelmaking, ironmaking, sintering and pelletizing, coking, Xinyang Iron Steel Co,ltd of Angang Group China Steel Market

.jpg)

Development of slagbased filling cementitious materials and their

2024年11月2日 Not only reduces filling costs and carbon emissions, but also promotes the resourceful use of industrial solid waste This study addresses the issues of low strength and 2022年3月7日 To improve the application performance and utilization of tailings slag in building materials, a composite microslag composed of ultrafine tailings particles was prepared based Preparation of composite microslag based on the application of Xinyang Mingxiang Industrial Co, Ltd is a company engaged in sales: Perlite, vitrified micro beads, perlite filter aid, filter agent, bentonite, perlite slag remover, horticultural perlite, Perlite vitrified beads horticultural perliteXinyang MingXiang 2023年6月14日 Steel slag micro powder is an ultrafine powder processed from steel slag through magnetic separation and ball milling technology It contains various oxides and Experimental Study on Axial Stress–Strain Behaviour of Steel Fibre

.jpg)

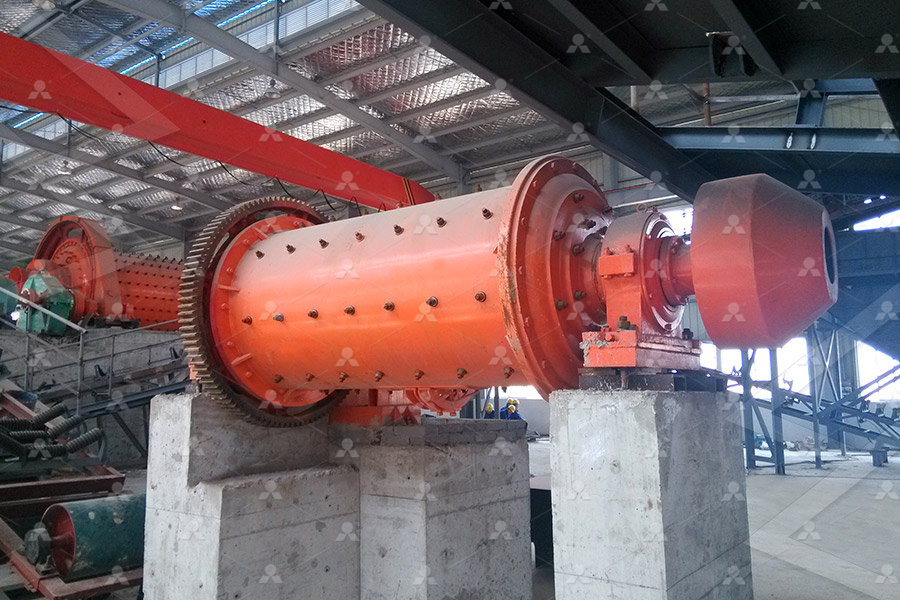

Optimization and improvement measures of slag micro

Optimization and improvement measures of slag micropowder metering system: LI Mingjie, et alAbstract: In this experiment, ultrafine iron phosphate micropowder was prepared by hydrothermal method which used phosphate slag as an iron source The effects of reaction temperature, Preparation of ultrafine iron phosphate micropowder from 2020年11月1日 Optimal solution for slag powder production process is determined by proposed CTNSGAII algorithm The vertical mill slag micropowders’ particle size distribution and microstructure analysis Applied Mechanics and Materials, Vol Analysis and multiobjective optimization of slag powder process2021年7月11日 Six different recycled micro powders were prepared by grinding the construction wastes that composed of concrete, tile, brick, and concrete Experimental researches on their physical and chemical properties, particle size distribution, chemical composition and strength activity index were investigated and compared with the characteristics of cement, slag powder Characteristics of Recycled Micro Powder Produced Using Construction

.jpg)

Applications of Steel Slag Powder and Steel Slag

2018年1月30日 1 Introduction Steel slag is a byproduct of steel manufacturing []Approximately 160 kg of steel slag is generated per ton of steel produced []The common chemical compounds in steel slag are SiO 2, CaO, Fe 2 O 3, Al 2 O 2023年8月30日 The analysis of Table 9 shows that when the strength of the UHPC filled with steelslag micro powder increased from 120 MPa to 130 MPa, 140 MPa, 150 MPa, and 160 MPa, respectively, the ultimate flexural bearing capacity of the member increased by 16%, 32%, 49%, and 66%, respectively, and the rate of the increase in the flexural bearing Research on the Flexural Performance of Steel Pipe Steel Slag Powder 2020年2月26日 The present investigation is mainly focused on the effect of copper slag (CS) on micro, macro, and flexural characteristics of geopolymer concrete (GPC)(PDF) Effect of Copper Slag on Micro, Macro, and Flexural 2020年4月20日 Effectiveness of waste steel slag powder on the strength development and associated micromechanisms of cementstabilized dredged sludge Author links open overlay panel Lei Lang a b, Chunyu Song b, However, the microcrack and pores were also clearly found in Fig 16 (c), Effectiveness of waste steel slag powder on the strength

.jpg)

Preparation of ultrafine iron phosphate micropowder from phosphate slag

a Corresponding author: Preparation of ultrafine iron phosphate micropowder from phosphate slag Fangjing Sun1,2, Yi Zhang1, Jiawei Zhang1, Xixi Yan1, Xiaoyu Liu1,2, Lijun Wang1,2,a 1School of Environmental and Materials Engineering, Shanghai Polytechnic University, Shanghai , P R China; 2Research Center of Resource 2023年5月20日 There is limited research on the utilization of lime and fly ash for improving the mechanical properties of red clay soils This study investigates the physical and mechanical properties of modified red clay with single fly ash, single lime, and mixed cases using various experimental tests, such as direct shear tests, unconfined compression tests, etc Scanning Experimental Study on the Mechanical Properties of Xinyang Red As experts in small particle additives for 50 years, we continue to design specialty waxes and other fine powders that help solve formulation problems and enhance performance in industrial coatings, inks, agricultural, and personal care productsMicro Powders Inc Small Particles, Big Ideas2018年1月1日 In this experiment, ultrafine iron phosphate micropowder was prepared by hydrothermal method which used phosphate slag as an iron source The effects of reaction temperature, surfactants type and Preparation of ultrafine iron phosphate micropowder from phosphate slag

Effect of Iron Tailings and Slag Powders on Workability

2021年7月25日 When the ratio of iron tailings powder to mineral admixtures (slag powder and iron tailings powder) is less than 50%, the compressive strength of concrete with different ages has little difference from that with single slag 2023年2月1日 The broad hump at 20°–35°(2θ) of the XRD pattern of blast furnace slag indicates a typical amorphous structure (Fig 2), and the crystalline form is mainly a small amount of calcite, dolomite and quartz, which indicates that blast furnace slag is mainly an amorphous glass body, which depolymerizes under the condition of alkali activator, which is also the reason for the Solidification of uranium tailings using alkaliactivated slag mixed Steel slag is one of the main solid wastes in steel plants, with considerable discharge The recycling of steel slag has become the focus of social attention The micropowder processing scheme using steel slag vertical roller mill can Introduction To The Way Of Steel Slag Recycling The Request PDF On Apr 1, 2020, Lei Lang and others published Effectiveness of waste steel slag powder on the strength development and associated micromechanisms of cementstabilized dredged sludge Effectiveness of waste steel slag powder on the strength

(PDF) Effect of Polyvinyl FiberSteel Slag Powder on Mechanical

2021年8月1日 Steel slag micro powder is steel slag after special process grinding, is a byproduct in the process of steel production This paper studied the basic mechanical properties and crack control The blast furnace slag selected for the experiments was S95 slag micro powder, which was produced by a building materials enterprise, with a density of 286 g/cm3 and a specific surface area of 431 m2/kg According to the chemical composition of the blast furnace slag, its chemical modulus was K ¼ 191, its alkali modulusNuclear Engineering and Technology Korea Science2023年6月14日 To investigate the toughening effect and stress–strain relationship of steel fibrereinforced steel slag micropowder ultrahighperformance concrete (UHPC), nine sets of specimens with coarse aggregate and steel fibre contents were prepared for axial compression and elastic modulus tests This study examines the variations in compressive strength and Experimental Study on Axial Stress–Strain Behaviour of Steel Fibre 2022年3月7日 The main components of the three tailings slag are CaO, SiO 2, and Al 2 O 3 (Table 2), which are consistent with the main chemical components of limestone powder and red clay, it can be used as a mineralizer, especially the content of Fe 2 O 3And Fe 2 O 3 in lead–zinc tailings accounts for 1392% Nickel tailings contain relatively high MgO When they are Preparation of composite microslag based on the application of

.jpg)

(PDF) Effect of Iron Tailings and Slag Powders on Workability and

2021年7月1日 The addition of tailings powder improves the working performance of concrete and slightly improves the strength Due to the large amount of cement used in ultrahighperformance concrete, physical 2024年11月2日 The quality variation of slag micropowder is also a significant factor; the incorporation of untested admixtures and activators into the slag micropowder can lead to significant strength fluctuations, particularly a reduction in strength at later stages accompanied by cracking, posing a significant risk to the safety and durability of the structureDevelopment of slagbased filling cementitious materials and their 2024年7月28日 The cement industry is known for being highly energyintensive and a significant contributor to global CO2 emissions To address this environmental challenge, this study explores the potential of using the waste Optimizing AlkaliActivated Mortars with Steel Slag 2024年2月3日 Slag micro powder is a kind of ultrafine powder material with a particle size of less than 45μm It is made by grinding slag, a byproduct of steelmaking, into a fine powder Slag micro powder has a wide range of Slag Micro Powder Processing Grinding Equipment

Effectiveness of waste steel slag powder on the strength

2020年4月20日 DOI: 101016/jconbuildmat2019 Corpus ID: ; Effectiveness of waste steel slag powder on the strength development and associated micromechanisms of cementstabilized dredged sludge2023年3月1日 Steel slag powder and steel slag mud were moulded, carbonationcured and seawatercured Various testing methods were used to characterize the macro and micro properties of the prehensive utilization of steel slag: A review Request PDF2022年11月11日 Steel slag powder and steel slag mud were moulded, carbonationcured and seawatercured Various testing methods were used to characterize the macro and micro properties of the materialsLaboratory Preparation and Performance Characterization of Steel Slag 2024年3月28日 Steel slag micronized powder, granulated blast furnace slag, and cement were used as cementitious materials to prepare a foamed lightweight soil for roadbed filling to reduce the settlement and additional stress of the foundation and to solve the environmental problems caused by the storage of large amounts of steel slag However, the instability of steel slag and Features of Processes for Preparation and Performance of Foamed

.jpg)

Evaluation of the use of steel slag in micro surfacing ResearchGate

2020年5月15日 Therefore, the main objective of the present research is to verify the technical, financial and environmental viability of using steel slag aggregate (SSA) in micro surfacing applicationsDownload Citation The Vertical Mill Slag MicroPowders' Particle Size Distribution and Microstructure Analysis During the pro 10 duction process of slag powder, The Vertical Mill Slag MicroPowders' Particle Size Distribution 2022年6月27日 After thermal braising and magnetic separation, steel slag is often ground into steel slag powder (SSP), which contains active silica (SiO 2) and can be used as a cementitious material to replace part of the cement and applied in concreteHowever, there have been relatively few studies on the influence of SSP on the performance of pavement cement concrete (PCC)Characteristics of Pavement Cement Concrete Incorporating Steel Slag PowderSilica fume and slag powder are both supplementary cementitious materials (SCMs) used in the construction industry to improve the properties and performance of concrete While they may share some similarities, they have unique characteristics and different applications Here, we will discuss the key differences between silica fume and slag powder Composition and Origin Silica Fume vs Slag Powder Henan Superior Abrasives

.jpg)

Analysis and multiobjective optimization of slag powder process

2020年11月1日 Optimal solution for slag powder production process is determined by proposed CTNSGAII algorithm The vertical mill slag micropowders’ particle size distribution and microstructure analysis Applied Mechanics and Materials, Vol 2021年7月11日 Six different recycled micro powders were prepared by grinding the construction wastes that composed of concrete, tile, brick, and concrete Experimental researches on their physical and chemical properties, particle size distribution, chemical composition and strength activity index were investigated and compared with the characteristics of cement, slag powder Characteristics of Recycled Micro Powder Produced Using Construction 2018年1月30日 1 Introduction Steel slag is a byproduct of steel manufacturing []Approximately 160 kg of steel slag is generated per ton of steel produced []The common chemical compounds in steel slag are SiO 2, CaO, Fe 2 O 3, Al 2 O Applications of Steel Slag Powder and Steel Slag 2023年8月30日 The analysis of Table 9 shows that when the strength of the UHPC filled with steelslag micro powder increased from 120 MPa to 130 MPa, 140 MPa, 150 MPa, and 160 MPa, respectively, the ultimate flexural bearing capacity of the member increased by 16%, 32%, 49%, and 66%, respectively, and the rate of the increase in the flexural bearing Research on the Flexural Performance of Steel Pipe Steel Slag Powder

(PDF) Effect of Copper Slag on Micro, Macro, and Flexural

2020年2月26日 The present investigation is mainly focused on the effect of copper slag (CS) on micro, macro, and flexural characteristics of geopolymer concrete (GPC)2020年4月20日 Effectiveness of waste steel slag powder on the strength development and associated micromechanisms of cementstabilized dredged sludge Author links open overlay panel Lei Lang a b, Chunyu Song b, However, the microcrack and pores were also clearly found in Fig 16 (c), Effectiveness of waste steel slag powder on the strength a Corresponding author: Preparation of ultrafine iron phosphate micropowder from phosphate slag Fangjing Sun1,2, Yi Zhang1, Jiawei Zhang1, Xixi Yan1, Xiaoyu Liu1,2, Lijun Wang1,2,a 1School of Environmental and Materials Engineering, Shanghai Polytechnic University, Shanghai , P R China; 2Research Center of Resource Preparation of ultrafine iron phosphate micropowder from phosphate slag2023年5月20日 There is limited research on the utilization of lime and fly ash for improving the mechanical properties of red clay soils This study investigates the physical and mechanical properties of modified red clay with single fly ash, single lime, and mixed cases using various experimental tests, such as direct shear tests, unconfined compression tests, etc Scanning Experimental Study on the Mechanical Properties of Xinyang Red

.jpg)

Micro Powders Inc Small Particles, Big Ideas

As experts in small particle additives for 50 years, we continue to design specialty waxes and other fine powders that help solve formulation problems and enhance performance in industrial coatings, inks, agricultural, and personal care products2018年1月1日 In this experiment, ultrafine iron phosphate micropowder was prepared by hydrothermal method which used phosphate slag as an iron source The effects of reaction temperature, surfactants type and Preparation of ultrafine iron phosphate micropowder from phosphate slag