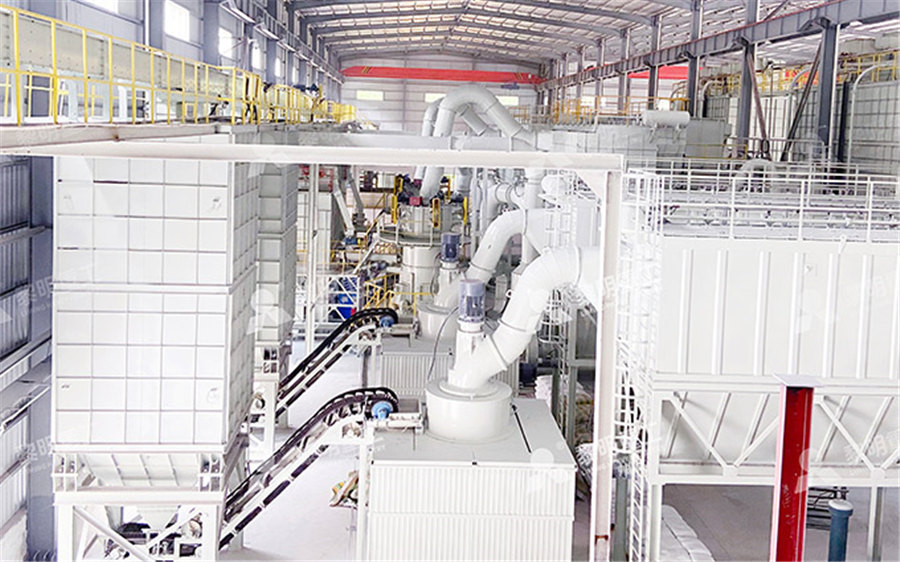

Material powder making system Material powder making system Material powder making system

.jpg)

Making Metal Powder MPIF

In this process, molten metal is separated into small droplets and frozen rapidly before the drops come into contact with each other or with a solid surface Typically, a thin stream of molten metal is disintegrated by subjecting it to the impact of highenergy jets of gas or liquid In principle, the technique is applicable to 展开Find innovative production technology for making metal powder and connect directly with worldleading specialists Forged metal objects appear seamless, simple items But as the use of metals changed over time and constructions Metal powder manufacturing equipment Making2023年6月29日 Additive manufacturing (AM) is a technology that rapidly converts digital computer files (CAD) into physical products It can layer metallic or nonmetallic materials according to a particular layer thickness and Powder‐Based Additive Manufacturing: A Critical 2024年9月4日 Powder Recycling Systems: Modern coating systems are equipped with advanced powder recycling systems that capture and reuse overspray, reducing waste and lowering material costs EnergyEfficient Curing Ovens: New designs in curing ovens focus on reducing energy consumption without compromising the quality of the finishAutomatic Coating System Powder Coating Equipment

.jpg)

Metal powder manufacturing equipment Making

To raise the purity rate, treat the material with a chemical agent React with a reducing agent to strip the metal of its electrons and form highlyadherent porous particles Grind the resulting material into a finer powder and anneal it to powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form The coating is typically applied electrostatically and is then cured under heat to allow it to flow and form a "skin" The powder may be a thermoplastic or a thermoset polymer It is usually used to create a hard finish that is tougher than conventional paint Powder coating is mainly Powder Coating MaterialsIron powder is a grayblack crystalline material with a density of 7694 and a melting point of 1837°C Produced via highpressure water atomization for powder metallurgy, it is sintered at 1121°C Due to its softness, iron is typically alloyed with carbon to create steelPowder Metallurgy: What Is It? Processes, Parts, Metals Used2024年8月19日 Composition and Characteristics of Powder Making Equipment Technology Composition The composition of powder making equipment technology includes several advanced machines and processes: Atomizers: Gas and water atomizers used for creating metal powders; Ball Mills: For mechanical alloying and grinding of metal powders; Reduction Powder Making Equipment Technology Additive Manufacturing Material

46.jpg)

Powdercoat System Powder Coating Equipment

2024年9月4日 Powder Recycling Systems: Modern coating systems are equipped with advanced powder recycling systems that capture and reuse overspray, reducing waste and lowering material costs EnergyEfficient Curing Ovens: New designs in curing ovens focus on reducing energy consumption without compromising the quality of the finish2019年9月1日 Utilization of the powder in composites development has attracted growing interest among researchers [14,16] possibly, due to the high CaO content as experienced in [17,18] for ceramics(PDF) Analysis of eggshell powder as a partial replacing material 2023年12月11日 Iron powder is a versatile ferrous material with diverse industrial and commercial applications owing to its magnetic properties, high strength, PBFSEBM 3D Printing Systems; Metal Powders; Metal Powder Making Equipment; Other Related Link; Contact Details Shanghai, China +8621Iron Powder Material Additive Manufacturing MaterialInjection Molding of Thermoplastics Vannessa Goodship, in Design and Manufacture of Plastic Components for Multifunctionality, 2016 4261 Material Appearance The majority of material for injection molding is received in the form of granules or peasized pellets; this makes for easy feeding down through the hopper system and onto the screw, powder material can also be Powder Material an overview ScienceDirect Topics

.jpg)

How to Make Detergent Washing Powder – Process, Cost, Material

It was there; it is here and will remain so till the world continue to exist The compound annual growth rate of detergent powder has been valued at 95% within the machine wash category since 2005 and 88% within the hand wash category since 2005 Also the detergent powder making process is not a complex matter2022年2月2日 A Powder Transfer System is a dependable and effective way to move powdered and granular materials It is a huge improvement over any traditional, mechanical technology, and it allows for completely dustfree Powder Transfer System Kiron Food Processing Making Metal Powder The first step in the overall powder metallurgy (PM) process is making metal powders separated from all nonmetallic material, and sieved to produce powder Since no refining operation is involved, the purity of Making Metal Powder MPIF2024年8月16日 Welcome to the comprehensive guide on powder making equipment process! The powder making process involves converting solid materials into fine particles or powders PBFSEBM 3D Printing Systems; Metal Powders; Metal Powder Making Equipment; Other Related Link; Contact Details Shanghai, China +8621Powder Making Equipment Process Additive Manufacturing Material

Vacuum Powder Transfer System, Vacuum Conveying Systems

Senieer powder transfer system is also known as powder vacuum conveyor It uses the vacuum to transport or convey powder materials in the manufacturing process The system does not deadend to ensure a smooth transfer and delivery of the materials The vacuum powder transfer system has a wide range of applications in different industriesAdditionally, automated unpacking devices, dustfree feeding systems, and vacuum conveying systems streamline the handling of raw materials packed in 25kg bags For larger batches, FIBC systems for material transfer and positive pressure feeding bins for nontoxic materials in smaller quantities are utilized, maintaining safety and operational efficiencyFine chemical powder system Making2023年6月25日 PDF This Special Issue (SI) of Materials, “Powder Metallurgy Materials based on the NiAlCrMo system with zirconium oxide or aluminum In both Al–Fe66Cr10Nb5B19 and Al–Fe systems, Powder Metallurgy: Materials and Processing ResearchGate2024年9月9日 Gas Delivery System: Supplies and controls the gas used for atomizing the molten metal Material Compatibility: PBFSEBM 3D Printing Systems; Metal Powders; Metal Powder Making Equipment; Other Related Link; Contact The Ultimate Guide to Gas Atomizers for Metal Powder Production

Nanomaterials through Powder Metallurgy: Production,

2020年7月30日 This chapter reviews the fundamentals on nanoparticles, powder processing via mechanical alloying and powder metallurgy, powder characterization techniques, choice of nanopowders in making You can reach the PneuCon sales team by calling 1 (800) 6554481 from 7:00am 5:00pm, Monday through Friday Outside of regular business hours, you can send an online message to sales for delivery Our sales team will get back with you during regular business hoursPowder Conveying Systems PneuConHIGHPERFORMANCE MATERIAL PROCESSING SYSTEMS AND EQUIPMENT Leading Powder Handling Equipment Matcon designs and manufactures powder handling equipment that can be used to improve manufacturing processes across a range of applications At the heart of our Powder Handling System is an IBC fitted with our patented Cone Valve Technology, a Powder Handling Systems and Equipment Matcon IBCAishin Industrial Corporation, a pneumatic conveying system manufacturer, is well known for its expertise in material and powder transfer systems We specialize in vacuum conveying systems for powder and granules and have expertise in Vacuum Transfer System for Powder and Granule

.jpg)

What is Powder Metallurgy Process, Materials, and

Powder metallurgy continues to evolve, with ongoing advancements and emerging trends shaping the future of the field Some critical areas of development include: New materials and alloys Researchers and engineers 2022年3月1日 Recent research demonstrated the use of novel powder deposition systems on LPBF machines to achieve spatial material variations on demand Material switch between layers has been commonly applied between alloys that show metallurgical compatibility (Exner et al, 2003; Liu et al, 2014; Mei et al, 2019; Sing et al, 2015)For instance Liu et al (2014) showed Enabling multimaterial gradient structure in laser powder Forget wet paint Try a dry finish Powder coatings are excellent choices for that final film of color, texture or protection According to the Powder Coating Institute, powder coating is a more economical and environmentally friendly alternative to liquid paint, and it’s been around since the 1960s Compared to liquid paint, powder coat finishes are more durable, attractive and Powder Coating Types Materials Metaltech Products2023年9月5日 It can be said that there is no industrial sector that does not use powder metallurgy materials and products (2) Classification: Powder metallurgy porous material; Powder metallurgy antifriction material; Powder metallurgy friction material; Powder metallurgy structural parts; Powder metallurgy mold material; Powder metallurgy electromagnetic Powder Metallurgy: A Comprehensive Guide for Beginners

Powder Coating Guide Nordson Powder Coating Systems

2023年3月30日 Fully selfpurging, capable of color change in less than 30 seconds without disassembly, reporting also powder savings in excess of 15% compared to ejector pump systems Get your powder coating finishes done faster and better with Nordson’s Encore powder coating system! Powder Coating System Automatic2016年9月1日 Given a coating time of 7 s for monomaterial processes in midsize PBFLB systems [39,40], effective layer heights of 75110 µm [41], and powder densities of 40% [42] to 56% [43], the system MultiMaterial Processing: Next step in laserbased powder Which metal powders can be produced by PREP System? PREP plasma rotary electrode atomization metal powder making equipment is mainly used to produce nickelbased hightemperature alloy powder, titanium alloy powder, stainless steel powder, and refractory metal powder, etcThe powder produced is of high quality and is widely used in electron beam Best Plasma Rotating Electrode Process (PREP) System supplier2020年10月26日 Powder metallurgy is a production method applied by using powder metal in today's developing industry, which has undergone many processes Powder metallurgy, which is an advanced production method Powder Metallurgy Processes and Making Metal Powder

Hongjia New Material Technologypowdermetal powder

2024年2月28日 Assigned as the of Guangdong Powder Material Application Engineering Technology Research Center in 2018 Recognized as a national hightech enterprise in 2017 Assigned as Jiangmen Technical Engineering Center for Metal Powder in 2015 has passed ISO9001:2018 quality management system certification2024年9月4日 Powder Recycling Systems: Modern coating systems are equipped with advanced powder recycling systems that capture and reuse overspray, reducing waste and lowering material costs EnergyEfficient Curing Ovens: New designs in curing ovens focus on reducing energy consumption without compromising the quality of the finishAutomatic Coating System Powder Coating EquipmentTo raise the purity rate, treat the material with a chemical agent React with a reducing agent to strip the metal of its electrons and form highlyadherent porous particles Grind the resulting material into a finer powder and anneal it to Metal powder manufacturing equipment Makingpowder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form The coating is typically applied electrostatically and is then cured under heat to allow it to flow and form a "skin" The powder may be a thermoplastic or a thermoset polymer It is usually used to create a hard finish that is tougher than conventional paint Powder coating is mainly Powder Coating Materials

Powder Metallurgy: What Is It? Processes, Parts, Metals Used

Iron powder is a grayblack crystalline material with a density of 7694 and a melting point of 1837°C Produced via highpressure water atomization for powder metallurgy, it is sintered at 1121°C Due to its softness, iron is typically alloyed with carbon to create steel2024年8月19日 Composition and Characteristics of Powder Making Equipment Technology Composition The composition of powder making equipment technology includes several advanced machines and processes: Atomizers: Gas and water atomizers used for creating metal powders; Ball Mills: For mechanical alloying and grinding of metal powders; Reduction Powder Making Equipment Technology Additive Manufacturing Material2024年9月4日 Powder Recycling Systems: Modern coating systems are equipped with advanced powder recycling systems that capture and reuse overspray, reducing waste and lowering material costs EnergyEfficient Curing Ovens: New designs in curing ovens focus on reducing energy consumption without compromising the quality of the finishPowdercoat System Powder Coating Equipment2019年9月1日 Utilization of the powder in composites development has attracted growing interest among researchers [14,16] possibly, due to the high CaO content as experienced in [17,18] for ceramics(PDF) Analysis of eggshell powder as a partial replacing material

.jpg)

Iron Powder Material Additive Manufacturing Material

2023年12月11日 Iron powder is a versatile ferrous material with diverse industrial and commercial applications owing to its magnetic properties, high strength, PBFSEBM 3D Printing Systems; Metal Powders; Metal Powder Making Equipment; Other Related Link; Contact Details Shanghai, China +8621Injection Molding of Thermoplastics Vannessa Goodship, in Design and Manufacture of Plastic Components for Multifunctionality, 2016 4261 Material Appearance The majority of material for injection molding is received in the form of granules or peasized pellets; this makes for easy feeding down through the hopper system and onto the screw, powder material can also be Powder Material an overview ScienceDirect TopicsIt was there; it is here and will remain so till the world continue to exist The compound annual growth rate of detergent powder has been valued at 95% within the machine wash category since 2005 and 88% within the hand wash category since 2005 Also the detergent powder making process is not a complex matterHow to Make Detergent Washing Powder – Process, Cost, Material