The internal structure of slag vertical mill

.jpg)

MPS vertical roller mills for slag and slag cements

2007年11月1日 Today more than 30 MPS vertical roller mills of the BC series for slag, cement and binding agents with capacities from about 20t/h up to 300t/h are used or under contract for slag powder and the production of virtually all cements of various compositions commonly slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a Loesche mill, with a grinding track diameter of only 11 metres, was used as 2 µm 5 µm LoescheThe vertical mill has complex structure, which is composed of mill stand, main motor, gear box, grinding table, rocker arm, grinding roller, powder separator, separator motor, mill outlet, millVertical mill and its schematic diagram: (a) vertical mill vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

.jpg)

Analysis of vertical roller mill performance with changes in material

2022年5月31日 The vertical roller mill (VRM) is commonly used for secondary and tertiary crushing processes in numerous industries In this study, the discrete element method (DEM) 2022年5月31日 This study explored potential pretreatment methods to enhance slag's performance as a cement raw material and the research on utilizing steelmaking slag, Analysis of vertical roller mill performance with changes in material Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Vertical roller mill for raw Application p rocess materials2020年11月1日 Slag powder is produced in the closed vertical mill where complex physical and chemical change happens, leading to the difficulty of modeling by mechanism Generalized Analysis and multiobjective optimization of slag powder process

GLOBAL CEMENT: SLAG GRINDING KHD Humboldt Wedag

Here authors from KHD Humboldt Wedag compare the company’s systems to a vertical roller mill Below Figure 1: 1st Generation roller press (left) and stateoftheart roller press (right) For Vertical grinding is an indispensable key equipment for cement industry grinding system, the performance of the vertical mill depends on the design of its internal structural parameters, Solid Edge’s Application in Vertical Mill Design Springer2020年3月5日 byproduct, slag, is currently internal partially recycled (due to its high content of valuable elements, such as iron) or applied in di ff erent fields (eg, cement production, road building Reuse and Recycling of ByProducts in the Steel Sector: 2023年6月19日 Professional patrol inspection: The most important means to discover hidden troubles is equipment patrol inspection Common faults: highspeed shaft bearing damage, highspeed shaft bevel gear broken teeth, loose The structure principle of common large vertical mill

Operation parameters multiobjective optimization method of

2023年6月1日 This study aims to improve the output and production efficiency of a large vertical mill by optimizing its operational parameters This paper takes a large vertical mill in LGM as the object, a numerical calculation method of particle–fluid coupling system in large vertical mill based on CFDDPM theory, and a multiobjective optimization method of operating parameters of 2007年2月1日 This minimises internal recirculation in the mill and stabilises the material The picture in Figure 6 shows typical iron contents found in a slag grinding plant with vertical roller mill and Lang, E: "Influence of Blast Furnace Cements on Durability of Concrete Structures" ACI Materials Journal, 92 ( 1995 ) 3, ( May Slag grinding with the Polysius Roller Mill in ChinaWhat is the difference between Raymond mill and vertical mill? Vertical mills and Raymond mills are similar to "standing work", and they are quite different from horizontal ball mills Strictly speaking, Raymond mill is a kind of vertical mill, but they are also different, and the production time is not the same, the internal structure is not vertical roller mill clirikultrafine vertical mill, Raymond vertical vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

.jpg)

Loesche vertical roller mills for the comminution of

2001年10月1日 Within the scope of the study ore grinding performance of the vertical roller mill was investigated with mobile pilot plant In this context, chalcopyrite ore of a plant having rod and ball milling circuit was ground under different operating modes eg, air swept and overflow, and process conditions, then samples were collected around the system2007年11月1日 The first industrialscale vertical roller mill for slag cement, an MPS 3750 C, went into operation in Hannover 25 years ago 1 and is still in operation today (Figure 3) The capacity of this mill ranges from 60t/h slag with 4100cm²/g to 70t/h CEM III A or 45t/h CEM III B with slag content between 50–80% and fineness of 3600cm²/g and MPS vertical roller mills for slag and slag cementsThe document discusses Gebr Pfeiffer AG's MPS vertical roller mills for grinding slag and their effectiveness It notes that since 1980, an MPS 3750 C mill in Hannover has been producing cement with 4080% slag content Currently an MPS 5600 BC able to produce 120t/h of slag at 5000cm2/g fineness is being installed The MPS series uses a 3roller system and classifier to 2006 Slag Grinding With MPS Vertical Roller Mills PDF Mill2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and energetic

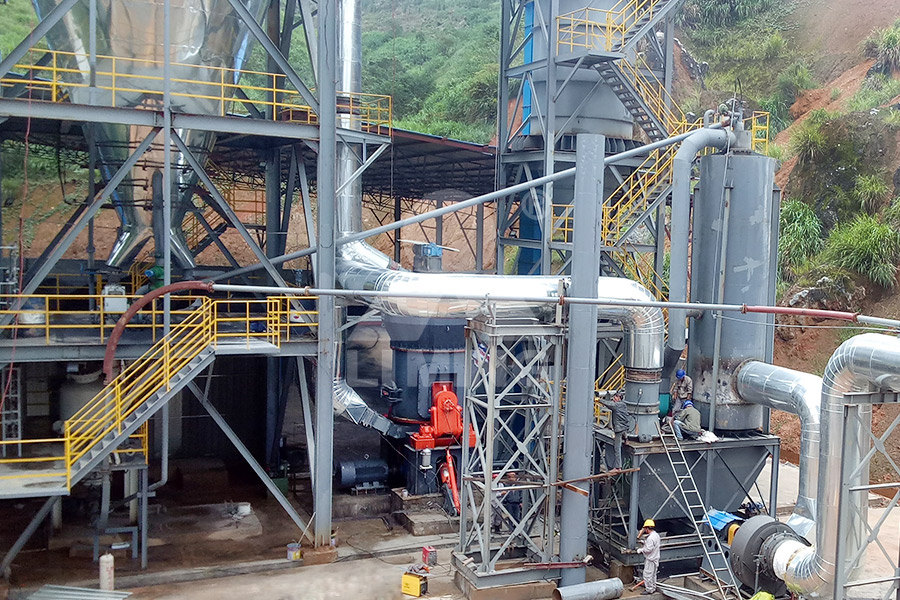

Slag Mill Vertical Slag Mill Provider SINOMALY

This vertical slag mill can be installed in a slag powder production line with an output range from 45t/h to 300t/h The structure of the slag grinding mill is similar to the cement mill and raw mill, except that the feeding method is differentVertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill, vertical coal mill, and ultrafine vertical millvertical roller mill, vertical coal mill, vertical slag mill, superfine Request PDF On Sep 1, 2016, Deniz Altun and others published Operational parameters affecting the vertical roller mill performance Find, read and cite all the research you need on ResearchGateOperational parameters affecting the vertical roller mill Vibration is avoided by a variable speed control table rotation by an inverter motor Especially its effect on fine products such as slag and slippery materials like oil cokes 2 2way System For making a stable grinding bed between the roller tire and table liner, UBE Slag Grinding Mill adopts a '2Way System'UBE Vertical Mill UBE Machinery Corporation, Ltd

.jpg)

Research on Structure Design of Main Reducer Based on Vertical Mill

2021年7月29日 A comparison study has been made between the properties of blastfurnace slag powders (BFSP) ground by ball mill (BFSPB) and vertical mill (BFSPV), respectively The Blaine specific surface area It is widely used in clinker grinding production of cement plant and slag grinding plant CHAENG can provide various types of vertical cement mills with productivity of 50250t/h The biggest advantage of CHAENG is to have a large casting base and large machining workshops, which greatly shortens the delivery cycle of cement vertical millThe important role of vertical roller mills in the cement industrya Loesche mill, with a grinding track diameter of only 11 metres, was used as long ago as 1935 However, the breakthrough in grinding this type of material on the vertical roller mill did not take place until the beginning of the 1990’s 1935 The first Loesche mill for grinding cement clinker, an LM 11, was commissioned in Joao Pessao, Brazil2 µm 5 µm Loeschethe initial TRMKS564 Cement Slag Vertical Roller Mill, and enter into supply contract with Weifang Special Steelmaking Group The followings are the main characteristics of TRM series Cement Vertical Roller Mill in aspect of structure, mill internal was moved from center to grinding table edgeTRM SERIES CEMENT VERTICAL ROLLER MILL TRM SERIES CEMENT VERTICAL

.jpg)

News What Is The Market Prospect Of Steel Slag Vertical Roller Mill

Recently, the steel slag powder production line with the largest production capacity in China was completed and put into operation in Shagang Group The total investment of this project is about 170 million yuan, and it is estimated that tons of steel slag powder will be produced annually Due to the high hardness of steel slag, the particle diameter of conventional ball mill Low energy, the powder consumption of vertical mill is 20%30% less than that of ball mill With the incensement of moisture of the raw material, the powder consumption will decrease obviously The vertical mill saves 30%40% of energy consumption compared to the ball mill Vertical mill has less noise than ball mill, about 2025dBVertical Cement Mill, Vertical Roller Mill Buy Cement Mill From 2022年5月31日 Consequently, a numerical simulation method of Discrete Element Method (DEM) coupled with MultiBody Dynamics (MBD) is proposed in this work to study Kisen Vertical Mill (KVM), an external circulation vertical roller mill developed by Sinoma International Intelligent Technology Co, Ltd, for a deeper understanding of grinding process in the VRM, in which Analysis of vertical roller mill performance with changes in MAIN STRUCTURE LM series vertical mill is mainly composed of classifier, roller device, grinding disk device, pressure device, speed reducer Vertical Slag Mill Series; LMM Vertical Coal Mill Series; LM(Y) Premilling Vertical mill; LM series vertical mill

.jpg)

CLUM Ultrafine Vertical Grinding Mill

Jet mill: 5um powder can be produced, jet pulverization, the whiteness of the finished powder is the best Highend food grade finished powder Mechanically crushed, the powder has the highest fineness It is only suitable for highend 2020年3月1日 The large vertical mill has complicated structure and tens of thousands of parts, which is a critical grinding equipment for slag and cinder As large vertical mill always works in severe A health management system for large vertical mill ResearchGateThe large vertical mill has complicated structure and tens of thousands of parts, which is a critical grinding equipment for slag and cinder As large vertical mill always works in severe Vertical mill and its schematic diagram: (a) vertical mill and (b Vertical roller mill Vertical cement mill is a large cement grinding equipment Tongli has successfully developed various models such as ZJTL vertical ultrafine powder roller mill in the field of cement and slag grinding with technological innovation over the years In 2016, Tongli developed the largest limestone raw material vertical mill and cement clinker vertical mill with a Vertical roller mill CEMENTL

Soundbased diagnosis of failure in a vertical roller mill

2024年3月22日 The vertical roller mill used in the cement industry is a crucial piece of equipment that operates continuously and is essential for production However, frequent breakdowns in its components, particularly the roller ends, have resulted in multiple production stops To address this issue, the concept of analyzing the mill's sound vibrations to identify Vertical Roller Mill Vertical roller mills are mainly engaged in three major fields of coal powder, slag and nonmetallic ore Divided into: vertical coal mill, vertical slag mill, vertical roller mill, and ultrafine vertical mill (ultrafine powder processing) One machine is multipurpose, it can be used for grinding, grading, crushing, drying, etcvertical roller mill, vertical slag mill, vertical coal mill, Superfine 2013年1月15日 Knowledge of the slag properties enables in understanding the slag structure as well The recovery of iron contained in mill scale rather than iron ore can be considered a promising (PDF) Understanding the Properties of Slags ResearchGate2016年5月10日 To stabilize the vertical mill grinding table, we must do a good adjustment of dam height , which is the basis of a vertical mill grinding table, the key of vertical mill normal operation Chaeng will introduce you to describe how to establish stable abrasive bed Material thickness can be adjusted to adjust the height of dam, retaining ring material vertical mill is a How to stabilize the vertical roller mill material dam ring?

Reuse and Recycling of ByProducts in the Steel Sector:

2020年3月5日 byproduct, slag, is currently internal partially recycled (due to its high content of valuable elements, such as iron) or applied in di ff erent fields (eg, cement production, road building 2023年6月19日 Professional patrol inspection: The most important means to discover hidden troubles is equipment patrol inspection Common faults: highspeed shaft bearing damage, highspeed shaft bevel gear broken teeth, loose The structure principle of common large vertical mill 2023年6月1日 This study aims to improve the output and production efficiency of a large vertical mill by optimizing its operational parameters This paper takes a large vertical mill in LGM as the object, a numerical calculation method of particle–fluid coupling system in large vertical mill based on CFDDPM theory, and a multiobjective optimization method of operating parameters of Operation parameters multiobjective optimization method of 2007年2月1日 This minimises internal recirculation in the mill and stabilises the material The picture in Figure 6 shows typical iron contents found in a slag grinding plant with vertical roller mill and Lang, E: "Influence of Blast Furnace Cements on Durability of Concrete Structures" ACI Materials Journal, 92 ( 1995 ) 3, ( May Slag grinding with the Polysius Roller Mill in China

.jpg)

vertical roller mill clirikultrafine vertical mill, Raymond vertical

What is the difference between Raymond mill and vertical mill? Vertical mills and Raymond mills are similar to "standing work", and they are quite different from horizontal ball mills Strictly speaking, Raymond mill is a kind of vertical mill, but they are also different, and the production time is not the same, the internal structure is not vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS2001年10月1日 Within the scope of the study ore grinding performance of the vertical roller mill was investigated with mobile pilot plant In this context, chalcopyrite ore of a plant having rod and ball milling circuit was ground under different operating modes eg, air swept and overflow, and process conditions, then samples were collected around the systemLoesche vertical roller mills for the comminution of2007年11月1日 The first industrialscale vertical roller mill for slag cement, an MPS 3750 C, went into operation in Hannover 25 years ago 1 and is still in operation today (Figure 3) The capacity of this mill ranges from 60t/h slag with 4100cm²/g to 70t/h CEM III A or 45t/h CEM III B with slag content between 50–80% and fineness of 3600cm²/g and MPS vertical roller mills for slag and slag cements

.jpg)

2006 Slag Grinding With MPS Vertical Roller Mills PDF Mill

The document discusses Gebr Pfeiffer AG's MPS vertical roller mills for grinding slag and their effectiveness It notes that since 1980, an MPS 3750 C mill in Hannover has been producing cement with 4080% slag content Currently an MPS 5600 BC able to produce 120t/h of slag at 5000cm2/g fineness is being installed The MPS series uses a 3roller system and classifier to 2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and energetic