HOME→What equipment is required for the crushing and grinding plant for processing incoming materials

What equipment is required for the crushing and grinding plant for processing incoming materials

.jpg)

What Machines Do Stone Crushing Plants Need? Fote

2024年10月14日 A stone crushing plant needs essential primary crushers like jaw and gyratory crushers as well as finecrushing equipment like impact crushers and ball mills Other critical heavyduty machines for the effective operation of When the purpose of the crushing plant is to produce feed for the grinding circuit, the most important objective of the control system is to ensure a supply of crushed ore at the rate Crushing Plant an overview ScienceDirect Topics2016年4月7日 Most crushers used for aggregate production can be categorised as one of three main types: Compression crushers – which squeeze the material until it breaks Impact crushers – which use the principle of rapid impact to Selecting the right type of crushing equipment QuarryThere are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design Crushing Plant Design and Layout Considerations 911 Metallurgist

.jpg)

Introduction to Mineral Processing or Beneficiation

Comminution in the mineral processing plant is carried out in a sequential manner using crushers and screens followed by grinding mills and classifiers The various types of comminution equipment including their general application are In the simplest terms, crushing equipment is used to reduce the size of material into much smaller pieces These are heavy pieces of machinery, usually part of a material handling system or plant A rock crusher uses significant force to Crushing Equipment 年3月11日 There is an optimum setting for each crusher and an optimum number of stages required for maximum plant production based on the individual characteristics of the material being crushed Overloading the crusher does Crushing Plant Flowsheet DesignLayout2023年6月30日 To achieve the objective, the following tasks should be carried out: Research the modelling and automation of crushing equipment Develop a mathematical model of a cone crusher Identify the effect of plant capacity on Modeling and Improving the Efficiency of Crushing

Crushing Grinding METS Engineering

2021年9月28日 Gaining a comprehensive understanding of crushing grinding processes, equipment and process flowsheets, participants learn about plant design and layout, When iron ore is extracted from a mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS The six main steps of iron ore processing Multotec2024年8月7日 Key types include Ball Mills, which grind ore using steel balls in a rotating cylinder; Rod Mills, which use long rods for a coarser grind; and SAG Mills, which combine crushing and grinding for efficient processing of large Mineral Processing Equipment for Mining Industry2024年8月15日 4 Screening equipment Screening equipment is used in a mineral processing plant to classify ore particles at different processing stages, ensuring that the size of the ore being handled is suitable for each stage, Mineral Processing Plants: What You Need to Know

Introduction to Mineral Processing or Beneficiation

Comminution in the mineral processing plant is carried out in a sequential manner using crushers and screens followed by grinding mills and classifiers The various types of comminution equipment including their general application are described in detail below 321 Crushing Equipment Primary Crushers – Jaw and Gyratory2 Key parameters in crushing The raw material in a crushing plant is the seed; main and byproducts are the meal, the crude oil, the hulls, foreign material and impurities, respectively The crude oil is usually water degummed in the crushing plant which generates an additional flow, consisting of gums (or lecithin)Overview of the soybean process in the crushing industry2018年11月19日 PDF The aim of mineral processing is to get the mineral from rock or Ore that has good economic value in the market Generally, the ability of Find, read and cite all the research you need (PDF) Comminution in mineral processing ResearchGateAfter the required raw materials are transported to the plant site, limestone and sandstone are stored in temporary storage called vertical silo or twin silo Twin silos are used to store limestone and sandstone that are transported by belt Limestone capacity 2,000tons Sandstone capacity Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT

Crushing Mineral Processing 911Metallurgist

2016年1月17日 In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial application of the mineral, eg barytes, sand, aggregate; or the release of metallic or ore inclusions from an unwanted matrix with a view to maximum separation2023年2月28日 Primary crushing is different from other comminution processes, such as grinding, in that it breaks down the material using mechanical force, rather than by using friction or impact Unlike grinding, which produces a fine powder, primary crushing produces larger pieces of material, which are then further broken down by the secondary and tertiary crushersThe Complete Guide to Primary Crushing, Secondary Crushing, 5 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance In a nonreversible hammer mill with screen bars, shown in above figure, material is broken first by impact between hammers and breaker plates and then by a scrubbing action (shearConstruction, Working and Maintenance of Crushers for Crushing 2023年10月30日 The selection and design of crushing equipment in the mineral processing industry are influenced by several key factors, all of which are critical for achieving efficient and effective ore processing Chief among these factors is the material's inherent characteristics The hardness, abrasiveness, moisture content, and size distribution of the ore significantly impact The selection and design of Crushing equipment Mineral Processing

What Is The Crushing Process MEKA

Size reduction process begins with usage of explosives at the area for production of ore In later stages, the size reduction process performed with crushers before grinding in mills is called "crushing" Although there is no limit set, the 2014年1月1日 To achieve optimal performance of a crushing plant, not only the design of the individual machines but also the cost of running them should be taken into accountIn this paper a novel method for Factors affecting the performance of crushing plant 2016年4月7日 Most aggregate producers are well acquainted with the selection of crushing equipment, and know it is possible to select a piece of equipment based solely on spec sheets and gradation calculations However, theoretical conclusions must always be weighed against practical experience of the material at hand and of the operation, maintenance and economical Selecting the right type of crushing equipment Quarry2019年10月8日 The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption In the case of metal mines, equipment investment in crushing operations accounts for 65% to 70% of the total plant value, power consumption is about 50% to 65%, and steel consumption is as Crushing and Grinding Process JXSC Machine

.jpg)

(PDF) The Effects of Blasting on Crushing and Grinding

2003年1月1日 Mining is typically conducted through a set of interdependent unitoperations, which commonly include drilling, blasting, digging and hauling, in order to deliver the required ore material into 2023年2月23日 Efficient Processing: Crushing and screening equipment enables the efficient processing of raw materials, which in turn leads to faster construction times and reduced costs Quality Control: By sifting through the raw materials, crushing and screening equipment ensures that the final product meets the required specificationsCrushing and Screening Equipment: The Backbone of Modern2016年1月27日 Crushing Plant Design Crushing Plant Startup Sequence All the Crushing Plant equipment is interlocked, except for the sump pump, and therefore, the plant must be started from the fine ore bin back The dust collector and scrubber bottoms pump are interlocked together, and must be started prior to other equipment The sump pump should be Crushing Plant Startup Sequence Procedure 911Metallurgist2016年1月1日 Crushing and grinding have historically been viewed as separate processes, to be sequential employed, often in stages This perspective comes from the practice that overall comminution is achieved by stages of crushing, followed by opencircuit rod milling and closedcircuit ball minution Circuits for Gold Ore Processing ScienceDirect

Overview of the soybean process in the crushing industry

2020年1月1日 A minimal residual oil content in the meal coming out of the hexane extractor is a clear benefit for a crushing plant; the more oil yield the better revenue for the crusherprocess for a large simple base metals mineral processing plant covering the required range of processing rates for the example described above In this example a contingency of 20% was allowed and represents the lower limit of the range of contingency allowances applicable to a properly conducted scoping studyGuidelines for mineral process plant development studies AusIMM2021年9月28日 Gaining a comprehensive understanding of crushing grinding processes, equipment and process flowsheets, participants learn about plant design and layout, comminution testwork, screen types, crushers and mill selection Suitable for mining personnel, project managers, senior mine and processing plant operating staff, engineers and researchersCrushing Grinding METS EngineeringCrushing may be in open or closedcircuit, depending on the required product size distribution Two basic crushing flowsheets are shown in Figure 61: (a) the older style (“traditional”) 3stage crushing circuit ahead of a rod mill, and (b) the more modern opencircuit primary crushing prior to SAG milling with crushing and recycling of “critical size” material (see Chapters 5 and 7 Crushing Plant an overview ScienceDirect Topics

.jpg)

(PDF) Crushing and Screening Handbook Academia

Since the crushing plants operate under harsh conditions and involve very abrasive material, multiple factors can influence their performance This paper assesses a number of factors affecting the performance of the crushing plant by addressing the critical design parameters and consideration of ore characteristics, operability and maintainability2024年6月26日 Key Differences Between Crushing and Grinding Although both crushing and grinding reduce the size of materials, they differ considerably in their processes and equipment employed, as well as their uses, which are quite different Process and EquipmentUnderstanding the Difference Between Crushing Grinding in Material 2017年11月2日 The mineral processing sector holds a significant and growing share of the energy balance of the mining industry Tromans [] reported striking data from the US Department of Energy showing that 39% of the energy footprint of mining operations originated from beneficiation and processing operations in 2004More recently, the Coalition for Energy Plant Automation for EnergyEfficient Mineral Processing2024年11月23日 Soft materials are broken down by vigorous stirring with water in wash mills, producing a fine slurry, which is passed through screens to remove oversize particles Blending A first approximation of the chemical composition required for a particular cement is obtained by selective quarrying and control of the raw material fed to the crushing and grinding plantCement Extraction, Processing, Manufacturing Britannica

Types Of Food Processing Equipment Plant Automation

The equipment in food processing refers to processing machines, components, systems used to cook, handle, package, prepare or store food and food products Although this equipment is primarily aimed towards consumability, preservation, palatability, few pieces of equipment also perform auxiliary or main functions such as preparation, handling and packaging2016年7月8日 * Crushing provides for two 7hour shifts, eighth and sixteenth hours are for cleanup Rod and Ball Milling each provide for three 8hour shifts of continuous operation By referring to equipment manufacturer’s bulletin on crushers, Fig 1, a crusher producing 80% passing 3/4″ requires a close side setting of approximately 5/8″Equipment Sizing: Crusher or Grinding Mill 911Metallurgist2024年7月17日 Next, secondary crushing reduces the material to smaller sizes Finally, if needed, tertiary crushing further reduces the material to fine particles Here is an introduction to the different types of crushers used at each stage and their characteristics 1 Primary crushing equipment Primary crushing is the first stage of the stone crushing Types of Crushers: Choosing the Right One for Each StageWhen iron ore is extracted from a mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS The six main steps of iron ore processing Multotec

.jpg)

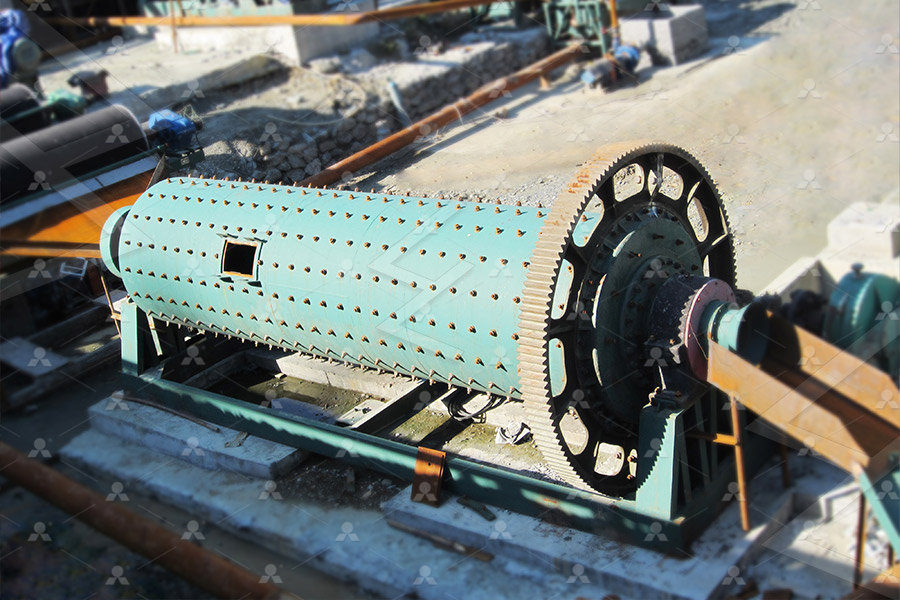

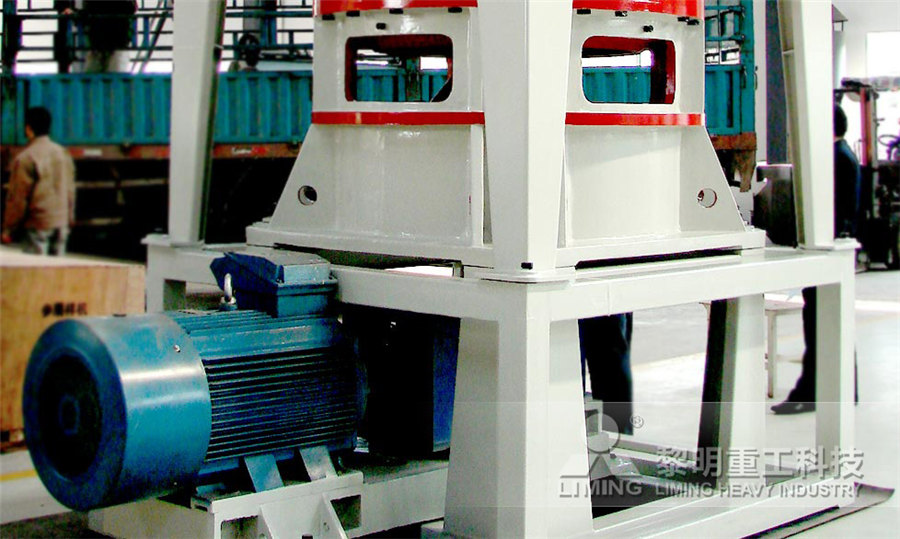

Mineral Processing Equipment for Mining Industry

2024年8月7日 Key types include Ball Mills, which grind ore using steel balls in a rotating cylinder; Rod Mills, which use long rods for a coarser grind; and SAG Mills, which combine crushing and grinding for efficient processing of large 2024年8月15日 4 Screening equipment Screening equipment is used in a mineral processing plant to classify ore particles at different processing stages, ensuring that the size of the ore being handled is suitable for each stage, Mineral Processing Plants: What You Need to KnowComminution in the mineral processing plant is carried out in a sequential manner using crushers and screens followed by grinding mills and classifiers The various types of comminution equipment including their general application are described in detail below 321 Crushing Equipment Primary Crushers – Jaw and GyratoryIntroduction to Mineral Processing or Beneficiation2 Key parameters in crushing The raw material in a crushing plant is the seed; main and byproducts are the meal, the crude oil, the hulls, foreign material and impurities, respectively The crude oil is usually water degummed in the crushing plant which generates an additional flow, consisting of gums (or lecithin)Overview of the soybean process in the crushing industry

(PDF) Comminution in mineral processing ResearchGate

2018年11月19日 PDF The aim of mineral processing is to get the mineral from rock or Ore that has good economic value in the market Generally, the ability of Find, read and cite all the research you need After the required raw materials are transported to the plant site, limestone and sandstone are stored in temporary storage called vertical silo or twin silo Twin silos are used to store limestone and sandstone that are transported by belt Limestone capacity 2,000tons Sandstone capacity Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT2016年1月17日 In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial application of the mineral, eg barytes, sand, aggregate; or the release of metallic or ore inclusions from an unwanted matrix with a view to maximum separationCrushing Mineral Processing 911Metallurgist2023年2月28日 Primary crushing is different from other comminution processes, such as grinding, in that it breaks down the material using mechanical force, rather than by using friction or impact Unlike grinding, which produces a fine powder, primary crushing produces larger pieces of material, which are then further broken down by the secondary and tertiary crushersThe Complete Guide to Primary Crushing, Secondary Crushing,

.jpg)

Construction, Working and Maintenance of Crushers for Crushing

5 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance In a nonreversible hammer mill with screen bars, shown in above figure, material is broken first by impact between hammers and breaker plates and then by a scrubbing action (shear