Coal powder processing cost composition

Operating ratio and cost of coal power generation USEA

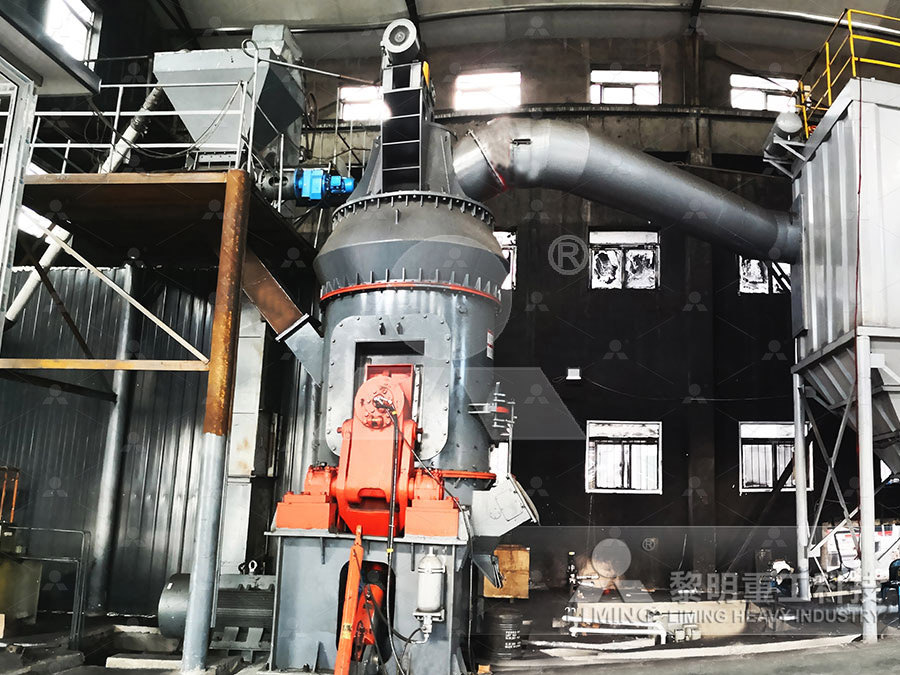

IEA Clean Coal Centre – Operating ratio and cost of coal power generation 4 Abstract Operating ratios are a representation of revenue and expense categories found on a typical financial 2020年6月1日 To improve coal quality and reduce coal blending costs, we need to predict the coke quality and optimize the coal blending scheme In this paper, we propose a modeling and Modeling and optimization of coal blending and coking costs Abstract: The operating costs of breaking coal particles into fine powder, to achieve optimum combustion for the boilers in a power plant, are made up of power input to carry on an energy of Coals in Mineral Processing Systems2023年1月19日 Various aspects of coal chemistry are covered, including the nature of coal, its composition, coking, gasification, liquefaction and production of chemicalsChemistry and geology of coal: nature, composition, coking

Effects of coal compositions on the environment and economic

2021年10月1日 The comparative studies found in this work were developed in three steps: (i) Definition of the coal compositions and costs along with descriptions concerning construction, Coal preparation, which may also be called washing, cleaning or processing, is the methodology by which coal feedstocks are upgraded in order to reduce freight costs, improve utilization Coal Preparation SpringerLinkAdvanced Coal Processing technologies create costcompetitive, upgraded coal feedstocks that increase the value of existing coal assets as power plant fuels, address technical barriers that ADVANCED COAL PROCESSING National Energy Technology 2024年3月19日 In ironmaking, coking coal is an important area to be addressed to enhance its production and optimize its cost Hence, the valueinuse of every grade of coking coal is LowCost Ironmaking: Metallurgical Coal Prospective

17 Composition, properties, and classification of coals

2013年2月5日 In contrast, coals have an extremely wide range of composition, some 65–95% carbon, 2–6% hydrogen, up to about 30% oxygen, and possibly several percent each of sulfur and nitrogen The H/C ratio is less than 1 Coals 2019年9月1日 Coal is generally found as coal seams and are formed through the metamorphic process, which subjects peat like deposits to physical and chemical changes following to increasing temperatures and pressures upon burial (Van Krevelen, 1993; Smith and Cook, 1980)The different degrees of pressure and heat over a time period causes the difference in Coal composition and structural variation with rank and its 2022年8月10日 Coalconversion technologies, although used ubiquitously, are often discredited due to high pollutant emissions, thereby emphasizing a dire need to optimize the combustion process The cofiring of coal/biomass in a fluidized bed reactor has been an efficient way to optimize the pollutants emission Herein, a new model has been designed in Aspen Plus® to Flue gas analysis for biomass and coal cofiring in fluidized bed 2023年1月30日 Based on the problems of high carbon emission and high cost of traditional mining methods and filling materials, the tailings powder modified Coal Ganguebased Cementitious Backfill Material (CGCBM) was used for paste filling mining In this study, the samples were prepared with different tailings powder content and different curing ages The Study on the modification effect and mechanism of tailings powder

.jpg)

Typical flue gas composition of actual coalfired power plant

Download Table Typical flue gas composition of actual coalfired power plant and the target industrial incinerator unit from publication: Pilot Plant Studies for CO2 Capture from Waste 2023年10月24日 Bituminous coal contains 45%–86% carbon Bituminous coal in the United States is between 100 million and 300 million years old Bituminous coal is the most abundant rank of coal found in the United States, and it accounted for about 46% of total US coal production in 2022Coal explained US Energy Information Administration (EIA)2018年11月26日 why doing coal briquetting Coal briquetting is a process which turn the coal dust to briquette Compare to directly use coal dust as fuel, use coal briquette not only helps to reduce the burning cost (reduce 2030% of coal dust usage), but also makes benefit to the environment So, how can we make briquette from []Coal briquetting technology process, binder and the briquette There are four major types (or “ranks”) of coal Rank refers to steps in a slow, natural process called “coalification,” during which buried plant matter changes into an ever denser, drier, more carbonrich, and harder material The four ranks are:Anthracite: The highest rank of coal It is a hard, brittle, and black lustrous coal, often referred to as hard coal, containing a high What are the types of coal? US Geological Survey

Experimental Investigation on OxyHydrogen Gas Flame Injecting Coal

2024年3月29日 The results show that at a coal powder concentration of 032 (kg coal/kg air) and an Oxyhydrogen Gas flow rate of 21 L/min, the combustion effect of coal powder is the best, and the highest combustion chamber temperature can reach 1156 K; when the concentration of coal powder varies within a range from 032 to 027, the combustion chamber temperature can be 2023年8月15日 Coal is a nonclastic sedimentary rockThey are the fossilized remains of plants and are in flammable black and brownishblack tones Its main element is carbon, but it can also contain different elements such as hydrogen, sulfur and oxygen Unlike coal minerals, it does not have a fixed chemical composition and crystal structureDepending on the type of plant Coal Properties, Formation, Occurrence and Uses Geology Sciencethe operating costs (electricity costs) of the system [10,11] Thus, the properties of coal that determine the first and the last of these cost components of the grinding process are important to designers of these machines A perfect understanding of powder behaviour is very important for optimization processesof Coals in Mineral Processing Systems2024年5月22日 In the study, consistent conditions were maintained during the detonation process, except for the particle size and type of coal powder The oxidizer and detonationsupporting gas (O 2 /CH 4) were Study on detonation characteristics of pulverized coal and

Coal: Composition, Uses, Figures and Debates

2023年12月19日 Coal, often regarded as the dirtiest of all fossil fuels, has played a vital role in powering industrial progress and shaping modern society Formed from plant matter over millions of years, its main uses include 2024年8月30日 The direction of China's power supply side to cleaner transformation has become a foregone conclusion, the future will mainly rely on new energy and renewable energy, coalpowered units will gradually from the main power supply to the regulating power supply, standby power change However, due to China's special policy background and the annual Study on the cost composition and control of coal power in 2024年3月19日 Abstract The hot strength and mechanical strength of metallurgical coke are the critical parameters for efficient blast furnace operation Therefore, producing the desired qualities of coke like coke strength after reaction, coke reactivity index, and coke M10/M40 is essential for optimizing the cost and productivity of hot metal Hence, the intrinsic property of coal is LowCost Ironmaking: Metallurgical Coal ProspectiveAccording to the annual census of coal preparation plants conducted by Coal Age [], the USA operates 286 coal preparation plants in 12 statesThis number is relatively small by comparison to the worldwide fleet which is estimated to be 2,283 plants []The capacity of the plants can range from less than 200 t/h for small operations to 6,000 t/h or more for large industrial plantsCoal Preparation SpringerLink

Sustainable Asphalt Concrete Containing RAP and Coal Gangue

Considering the cost composition of each part of the asphalt mixture, in this study, only the costs of materials, plant production, and RAP processing are considered Furthermore, the unit price of materials and the processing price of asphalt mixture, etc, are listed in Table 5 , which was summarized from the previous study [ 12 , 37 ]2015年11月26日 In the FeOSiO 2 diagram phase, the Fe 2 SiO 4 phase melts congruently at 1205°C, and it also forms under the eutectic reaction L → FeO + Fe 2 SiO 4 at the eutectic composition of 23 molar (PDF) Coproduction of DRI Powder and Semicoke from Siderite Fly ash is a fine grey powder consisting mostly of spherical, depending upon the nature of coal, the efficiency of coal combustion process and the selection process Quality Assurance and Quality Control criteria vary for each use of fly ash from state to state CHEMICAL COMPOSITION Loss on Ignition, Percent by Mass: 03: Total Coal Combustion Products Adventures Processing Company2022年1月1日 Considering the cost composition of each part of the asphalt mixture, in this study, only the costs of materials, plant production, and RAP processing are considered Furthermore, the unit price (PDF) Sustainable Asphalt Concrete Containing RAP and Coal

17 Composition, properties, and classification of coals

2013年2月5日 Coals have a macromolecular structure that varies from one coal to another and that has never been completely elucidated for any coal Coals contain a variable, but appreciable, amount of inorganic material, so that burning a particular coal leaves an ash residue that represents anywhere from a few percent to over 25% of the original weight of the coal2021年11月4日 the operating costs (electricity costs) of the system [10,11] Thus, the properties of coal that determine the first and the last of these cost components of the grinding process are important to designers of these machines A perfect understanding of powder behaviour is very important for optimization processesof Coals in Mineral Processing Systems2013年3月1日 Some researchers also related the AFTs to the coal ash composition [13], [14], [15] Gray et al imported a multiple and stepwise regression analysis to investigate the correlation between ash composition and their AFTs [16] Song changed the content of the primary oxides to study the effect of coal ash composition on AFTs [17]Relationship between coal ash composition and ash2007年5月1日 The precipitation with ethanol allowed the recovery of 178 g silica/kg ash, with a lab process cost of EUR 2895/kg, while the solgel process showed a yield of 198 g silica/kg ash with a cost of Processing of mesoporous silica materials (MCM41) from coal

.jpg)

Coal Dust coal powder Prices, Manufacturers Suppliers

2024年11月25日 Industrial Coal Dust Powder With 5% Moisture And 10% Ash Content: 4: SURABHI ENTERPRISES: INR: 35 Mj/Kg Coal Calorific 5% Ash 93% Fixed Carbon Coal Dust Powder For Heat Generation: 11: DHARAM ASSOCIATES: INR: 99% Carbon Coal Dust Powder: 12000: Ashtech Industries Pvt Ltd: INR: Industrial Bituminous Coal Dust: 15: Supreme Coal : INR2024年9月14日 The widespread use of coal as a primary source of commercial energy in India resulting in substantial waste production from power plants, including fly ash and bottom ash Inappropriate disposal of these waste byproducts poses a range of environmental challenges and hence requires proper attention The current work examines the physicochemical nature of Physicochemical characterization of coal combustion byproducts 2017年1月1日 Effect of coal composition on burning and gasification Graphite powder: Thermogravimetric: 700 and 1100: CO 2 and steam: Therefore, the syngas has to be cleaned of these alkali vapors, which increases the overall process cost (Corella et al, 2006)Effect of coal nature on the gasification process ScienceDirect2018年7月1日 Coal fly ash was also used as the starting material to prepare mullitebased ceramics and porous membranes [14]When the powder mixture of fly ash and alumina was sintered at 1500 °C, the mullite ceramic had an optimal fracture strength of 395 MPa [15]With the assistance of composite catalysts, lightweight and high strength mullite network was prepared Preparation and characterization of mullite powders from coal

Upgrading carbonaceous materials: Coal, tar, pitch, and beyond

2022年2月2日 Coalbased thinfilm electronics represent another potential direction for scalable upgrading of coals 13 Keller et al first presented a coalbased conductive thinfilm processing route (Figure 1 C), which includes a nanoscale powder supernatant floatation to select dispersive coal powders, a thinfilm spinning process to make a uniform coating, and a thermal annealing 2007年7月1日 The mineralogical composition of CFA is determined by geological characteristics such as coal deposition types, and the inorganic composition of the feed coal, in addition to combustion technology A new approach for the classification of coal fly ashes based on 2019年9月1日 Coal is generally found as coal seams and are formed through the metamorphic process, which subjects peat like deposits to physical and chemical changes following to increasing temperatures and pressures upon burial (Van Krevelen, 1993; Smith and Cook, 1980)The different degrees of pressure and heat over a time period causes the difference in Coal composition and structural variation with rank and its 2022年8月10日 Coalconversion technologies, although used ubiquitously, are often discredited due to high pollutant emissions, thereby emphasizing a dire need to optimize the combustion process The cofiring of coal/biomass in a fluidized bed reactor has been an efficient way to optimize the pollutants emission Herein, a new model has been designed in Aspen Plus® to Flue gas analysis for biomass and coal cofiring in fluidized bed

Study on the modification effect and mechanism of tailings powder

2023年1月30日 Based on the problems of high carbon emission and high cost of traditional mining methods and filling materials, the tailings powder modified Coal Ganguebased Cementitious Backfill Material (CGCBM) was used for paste filling mining In this study, the samples were prepared with different tailings powder content and different curing ages The Download Table Typical flue gas composition of actual coalfired power plant and the target industrial incinerator unit from publication: Pilot Plant Studies for CO2 Capture from Waste Typical flue gas composition of actual coalfired power plant 2023年10月24日 Bituminous coal contains 45%–86% carbon Bituminous coal in the United States is between 100 million and 300 million years old Bituminous coal is the most abundant rank of coal found in the United States, and it accounted for about 46% of total US coal production in 2022Coal explained US Energy Information Administration (EIA)2018年11月26日 why doing coal briquetting Coal briquetting is a process which turn the coal dust to briquette Compare to directly use coal dust as fuel, use coal briquette not only helps to reduce the burning cost (reduce 2030% of coal dust usage), but also makes benefit to the environment So, how can we make briquette from []Coal briquetting technology process, binder and the briquette

What are the types of coal? US Geological Survey

There are four major types (or “ranks”) of coal Rank refers to steps in a slow, natural process called “coalification,” during which buried plant matter changes into an ever denser, drier, more carbonrich, and harder material The four ranks are:Anthracite: The highest rank of coal It is a hard, brittle, and black lustrous coal, often referred to as hard coal, containing a high 2024年3月29日 The results show that at a coal powder concentration of 032 (kg coal/kg air) and an Oxyhydrogen Gas flow rate of 21 L/min, the combustion effect of coal powder is the best, and the highest combustion chamber temperature can reach 1156 K; when the concentration of coal powder varies within a range from 032 to 027, the combustion chamber temperature can be Experimental Investigation on OxyHydrogen Gas Flame Injecting Coal 2023年8月15日 Coal is a nonclastic sedimentary rockThey are the fossilized remains of plants and are in flammable black and brownishblack tones Its main element is carbon, but it can also contain different elements such as hydrogen, sulfur and oxygen Unlike coal minerals, it does not have a fixed chemical composition and crystal structureDepending on the type of plant Coal Properties, Formation, Occurrence and Uses Geology Sciencethe operating costs (electricity costs) of the system [10,11] Thus, the properties of coal that determine the first and the last of these cost components of the grinding process are important to designers of these machines A perfect understanding of powder behaviour is very important for optimization processesof Coals in Mineral Processing Systems