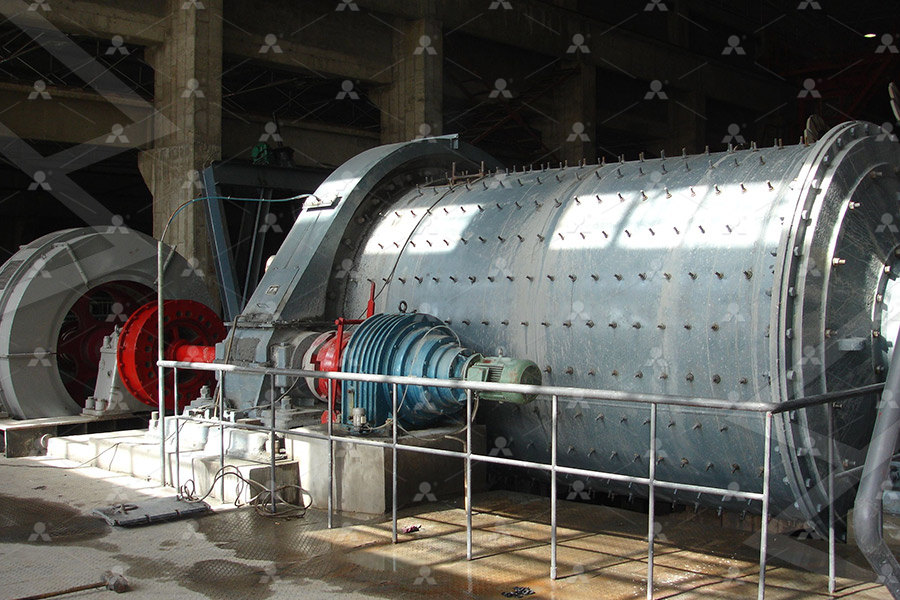

Ultrafine steel slag powder Equipment

.jpg)

Laboratory Preparation and Performance

2022年11月11日 In this paper, steel slag ultrafine powder (SSUP) was prepared in the laboratory through mechanical activation combined with grinding aids Furthermore, the grinding time was optimized The particle size, specific 2022年11月11日 In this paper, steel slag ultrafine powder (SSUP) was prepared in the laboratory through mechanical activation combined with grinding aids Furthermore, the grinding time was optimized TheLaboratory Preparation and Performance 2024年10月25日 Slag processing technology converts slag into high valueadded products such as slag powder and new slag silicate cement through highfine grinding This process not only Slag Ultrafine Powder Processing Technology Mining machinery 2013年6月22日 Mechanical grinding of steel slag is investigated and characterized using Xray diffraction and size analyzer The results indicate that the obtained ultrafine powders contain Mechanochemical processing of ultrafine steel slag powders

Applications of Steel Slag Powder and Steel Slag

2018年1月30日 The applications of steel slag powder and steel slag aggregate in ultrahigh performance concrete (UHPC) were investigated by determining the fluidity, nonevaporable water content, and pore structure of paste and the 2021年3月20日 The mechanical properties and hydration mechanism of ultrafine ground granulated blast furnace slag powder (UFS)cementsteel slag powder (SS) ternary Preparation of sustainable and green cementbased composite In this paper, steel slag ultrafine powder (SSUP) was prepared in the laboratory through mechanical activation combined with grinding aids Furthermore, the grinding time was Laboratory Preparation and Performance Characterization of Steel 2024年11月1日 Ultrafine slag powder cement paste (USPCP) is a promising green cementitious material with excellent mechanical properties and environmental benefitsDynamic mechanical properties and microstructure of ultrafine

Performance improvement to ashcement blocks by adding

2019年7月10日 The use of supersonic steam jet technology to smash steel slag can not only achieve ultrafine steel slag, but also optimize the composition characteristics of steel slag The 2021年3月20日 The mechanical properties and hydration mechanism of ultrafine ground granulated blast furnace slag powder (UFS)cementsteel slag powder (SS) ternary cementitious material systems were studied The chemical effects and contribution ratios of UFS and SS in ternary system at different hydration ages were also investigated The results show that by Preparation of sustainable and green cementbased composite binders 2023年10月19日 In accordance with the agreement requirements, the main evaluation indicators are as follows: Material composition: Steel slag powder 35%; slag powder 25%; fly ash 40%; Fineness control: 30μm What is a ultrafine slag grinding plant? ultrafine 2018年1月30日 The applications of steel slag powder and steel slag aggregate in ultrahigh performance concrete (UHPC) were investigated by determining the fluidity, nonevaporable water content, and pore structure of paste and the compressive strength of concrete and by observing the morphologies of hardened paste and the concrete fracture surface The results show that Applications of Steel Slag Powder and Steel Slag Aggregate in

Applications of Steel Slag Powder and Steel Slag Aggregate in

2018年1月30日 The applications of steel slag powder and steel slag aggregate in ultrahigh performance concrete (UHPC) were investigated by determining the fluidity, nonevaporable water content, and pore 2024年11月1日 The cementitious materials in this study were prepared by dry mixing ultrafine slag powder (USP) and cement in varying molar ratios The USP was provided by Tongling Nonferrous Metals Group New Material Technology Co, Ltd, comprising a blend of 52 % industrial tailings powder and 48 % grade I fly ashDynamic mechanical properties and microstructure of ultrafine slag 2023年7月3日 Also, Fan et al [27] designed a green UHPC with steel slag using DOD model, which achieved high usage of steel slag (200 kg/m 3) and multiobjective optimization (ie, maximized steel slag powder content, maximized workability, minimized voids ratio and maximized compressive strength)Intelligent design and manufacturing of ultrahigh performance 2011年5月1日 Request PDF Durability and Microstructure of UltraHigh Performance Concrete Having High Volume of Steel Slag Powder and UltraFine Fly Ash The durability, such as chloride ion permeability Durability and Microstructure of UltraHigh Performance

Development of slagbased filling cementitious materials and their

2024年11月2日 The quality variation of slag micropowder is also a significant factor; the incorporation of untested admixtures and activators into the slag micropowder can lead to significant strength fluctuations, particularly a reduction in strength at later stages accompanied by cracking, posing a significant risk to the safety and durability of the structureULTRAFINE GROUND GRANULATED BLAST FURNACE SLAG No of Amendments : 1 2 Sampling Guidelines: a) Raw material : b) Grouping guidelines : NA c) Sample Size : For Physical test – 9 kg For Chemical test – 1 kg 3 List of Test Equipment: Please refer ANNEX – A 4 Scheme of Inspection and Testing : Please refer ANNEX – B 5PRODUCT MANUAL FOR ULTRAFINE GROUND GRANULATED BLAST FURNACE SLAG This invention relates to a process and system for treating ultra fine powder steel slag, which comprises: collecting the steel slag into a tank and carrying the tank onto a tipping device by a hoisting equipment; operating the tipping device to transport the steel slag to a granulating device and granulating the steel slag in the granulating device to form granulated slag; transporting A process and system for treating ultra fine powder of steel slag3 the preparation process and equipment of steel slag micropowder vertical grinding have been popularized and applied If you have ultrafine steel slag grinding project needs, welcome to leave a message:hcmkt@hcmilling Post time: Feb052024 understand NEED A Application prospect of ultrafine steel slag grinding

Influence of Ultrafine Fly Ash and Slag Powder on

2024年5月25日 This study investigated the influences of ultrafine fly ash (UFA) and ultrafine slag powder (USL) on the compressive strengths, autogenous shrinkage, phase assemblage, and microstructure of magnesium potassium HLM Steel Slag powder Vertical Grinding Mill, as a highly intelligent largescale grinding equipment, be mixed with water slag powder, fly ash, tailings powder, etc to form composite mineral powder for use In addition, ultrafine steel slag powder can also be used for the production of anticorrosion coatings, rubber, fertilizers, etcCan steel slag Raymond mill be used to processed steel slag powder steel slag ultrafine powder (SSUP) wi th a specific surface area of 786 m 2/kg by mechanical grinding They found that SSUP exhibits a higher activity at an early and middle ageLaboratory Preparation and Performance Characterization of Steel Slag 2023年4月10日 Effect of Steel Slag Powder Content and Curing Condition on the Performance of Alkali Activated Materials Based UltraHigh Performance Concrete (UHPC) MatrixEffect of Steel Slag Powder Content and Curing Condition on the

LOESCHE METHOD FOR MANUFACTURING ULTRAFINE BLAST FURNACE SLAG

furnace slag Ultrafi ne blast furnace slag could reduce one of the main weaknesses of cements containing blast furnace slag, that being too little early strength for many applications (Diagram 1) As is already apparent today, the ultrafi ne blast furnace slag could be used for many different specialised products2023年4月6日 The effect of the addition of ultrafine slag powder (USL) on the rheology, strength, and porosity of UltraHigh Performance Concrete (UHPC) was investigated, whose microstructure was analysed by XRD, NMR, XPS, and SEM The results show that whether the USL was incorporated or not, the paste keeps its original shear thickening behaviour However, the yield EFFECT OF ULTRAFINE SLAG POWDER ON THE RHEOLOGICAL 2020年11月13日 DOI: 101016/jjclepro2020 Corpus ID: ; Preparation of sustainable and green cementbased composite binders with highvolume steel slag powder and ultrafine blast furnace slag powderPreparation of sustainable and green cementbased composite 2022年2月21日 A binder with 50% granulated blast furnace slag, 35% steel slag and 15% desulfurisation gypsum, a binder to tailing ratio of 1:4, and a slurry concentration of 78% resulted in strength values of 669 MPa, 1205 MPa, 1636 MPa and 1837 MPa after 3, 7, 28 and 180 days, respectivelyPreparation of mine backfilling from steel slagbased non

.jpg)

Preparation of sustainable and green cementbased composite binders

2020年11月1日 The mechanical properties and hydration mechanism of ultrafine ground granulated blast furnace slag powder (UFS)cementsteel slag powder (SS) ternary cementitious material systems were studied2019年7月30日 Steel slag is a byproduct of steel making and is produced when the molten steel is separated from impurities in the furnaces [14]The conversion rate of steel slag is approximately 10–15% per ton of steel produced [15]As the largest steel producer in the world, China yields 100 million tons of steel slag in 2016, the disposal of which mainly consists of open dumping and Utilization of steel slag in ultrahigh performance concrete with 2020年8月28日 Based on the fundamental principles of preparing reactive powder concrete (RPC), a new type of RPC was composed by replacing cement with the active powder component ultrafine ground granulated blastfurnace slag (GGBS) GGBS is proposed as a potential alternative to silica fume (SF), which is currently the most commonly used RPC mineral The hydration properties of ultrafine ground granulated blast Steel slag is a byproduct of steel manufacturing Approximately 160 kg of steel slag is generated per ton of steel produced The common chemical compounds in steel slag are SiO2, CaO, Fe2O3, Al2O3, and MnO The major mineral Applications of Steel Slag Powder and Steel Slag

Enhancement in compressive strength of foamed concrete by ultrafine slag

2023年4月1日 Studies showed that ultrafine slag (UFS) could improve the microstructure of cementitious materials in concrete [27] S Teng et al [28] added the ultrafine ground granulated blastfurnace slag to improve the workability and mechanical properties It was found that ultrafine slag changed microstructure and increased concrete strength [14]2018年1月1日 Free Online Library: Applications of Steel Slag Powder and Steel Slag Aggregate in UltraHigh Performance Concrete(Research Article, Report) by "Advances in Civil Engineering"; Engineering and manufacturing Compressive strength Analysis Mechanical properties Technology application Concretes Powders Powders (Particulate matter) SlagsApplications of Steel Slag Powder and Steel Slag Aggregate in 2021年11月23日 Steel slag (SS) is a byproduct in the process of steel production The world’s annual output of steel slag exceeds 16 billion tons every year Steel slag mainly consists of CaO, SiO 2, MgO, and Fe 2 O 3 [15 – 18] The main mineral compositions of steel slag are C 2 S, C 3 S, C 2 F, C 4 AF, and RO phase and fCaO [15 – 17]Influence of Steel Slag‐Superfine Blast Furnace Slag Composite 2020年7月1日 To improve the properties of cemented ultrafine tailings backfill (CUTB), the authors intend to outline the framework of the effect of steel slag (SS) on the properties of CUTBExperimental study on the utilization of steel slag for cemented

Performance improvement to ashcement blocks by adding ultrafine steel

2019年7月10日 Steel slag was first broken below 5 mm with a jaw crusher (PEF 100 × 60) Then, it was ultrafine smashed with a supersonic steamjet crusher (SFW 200), as shown in Fig 1This was a continuous process: the steel slag was first transferred to the silo with a hooper; it was then loaded into the smashing chamber; finally, it was entrained with the highspeed The slag vertical mill produced by HCM Machinery is an ideal equipment for grinding lithium slag and steel slag composite powder How to produce lithium slag steel slag composite powder? The process flow of vertical mill to produce lithium slag and steel slag composite powder is as follows: 1How to produce lithium slag steel slag composite powderSteel slag, desulphurised ash, desulphurised gypsum and ultrafine iron tailing sand are common industrial solid wastes with low utilisation rates Herein, industrial solid wastes (steel slag, desulphurised gypsum and desulphurised ash) were used as the main raw materials to prepare a gelling material and ultrafine tailing was used as an aggregate to prepare a new type of The Preparation Process and Hydration Mechanism of Steel Slag 2021年3月20日 The mechanical properties and hydration mechanism of ultrafine ground granulated blast furnace slag powder (UFS)cementsteel slag powder (SS) ternary cementitious material systems were studied The chemical effects and contribution ratios of UFS and SS in ternary system at different hydration ages were also investigated The results show that by Preparation of sustainable and green cementbased composite binders

What is a ultrafine slag grinding plant? ultrafine

2023年10月19日 In accordance with the agreement requirements, the main evaluation indicators are as follows: Material composition: Steel slag powder 35%; slag powder 25%; fly ash 40%; Fineness control: 30μm 2018年1月30日 The applications of steel slag powder and steel slag aggregate in ultrahigh performance concrete (UHPC) were investigated by determining the fluidity, nonevaporable water content, and pore structure of paste and the compressive strength of concrete and by observing the morphologies of hardened paste and the concrete fracture surface The results show that Applications of Steel Slag Powder and Steel Slag Aggregate in 2018年1月30日 The applications of steel slag powder and steel slag aggregate in ultrahigh performance concrete (UHPC) were investigated by determining the fluidity, nonevaporable water content, and pore Applications of Steel Slag Powder and Steel Slag Aggregate in 2024年11月1日 The cementitious materials in this study were prepared by dry mixing ultrafine slag powder (USP) and cement in varying molar ratios The USP was provided by Tongling Nonferrous Metals Group New Material Technology Co, Ltd, comprising a blend of 52 % industrial tailings powder and 48 % grade I fly ashDynamic mechanical properties and microstructure of ultrafine slag

Intelligent design and manufacturing of ultrahigh performance

2023年7月3日 Also, Fan et al [27] designed a green UHPC with steel slag using DOD model, which achieved high usage of steel slag (200 kg/m 3) and multiobjective optimization (ie, maximized steel slag powder content, maximized workability, minimized voids ratio and maximized compressive strength)2011年5月1日 Request PDF Durability and Microstructure of UltraHigh Performance Concrete Having High Volume of Steel Slag Powder and UltraFine Fly Ash The durability, such as chloride ion permeability Durability and Microstructure of UltraHigh Performance2024年11月2日 The quality variation of slag micropowder is also a significant factor; the incorporation of untested admixtures and activators into the slag micropowder can lead to significant strength fluctuations, particularly a reduction in strength at later stages accompanied by cracking, posing a significant risk to the safety and durability of the structureDevelopment of slagbased filling cementitious materials and their ULTRAFINE GROUND GRANULATED BLAST FURNACE SLAG No of Amendments : 1 2 Sampling Guidelines: a) Raw material : b) Grouping guidelines : NA c) Sample Size : For Physical test – 9 kg For Chemical test – 1 kg 3 List of Test Equipment: Please refer ANNEX – A 4 Scheme of Inspection and Testing : Please refer ANNEX – B 5PRODUCT MANUAL FOR ULTRAFINE GROUND GRANULATED BLAST FURNACE SLAG

A process and system for treating ultra fine powder of steel slag

This invention relates to a process and system for treating ultra fine powder steel slag, which comprises: collecting the steel slag into a tank and carrying the tank onto a tipping device by a hoisting equipment; operating the tipping device to transport the steel slag to a granulating device and granulating the steel slag in the granulating device to form granulated slag; transporting