Bentonite suspension roller mill is energysaving and durable

.jpg)

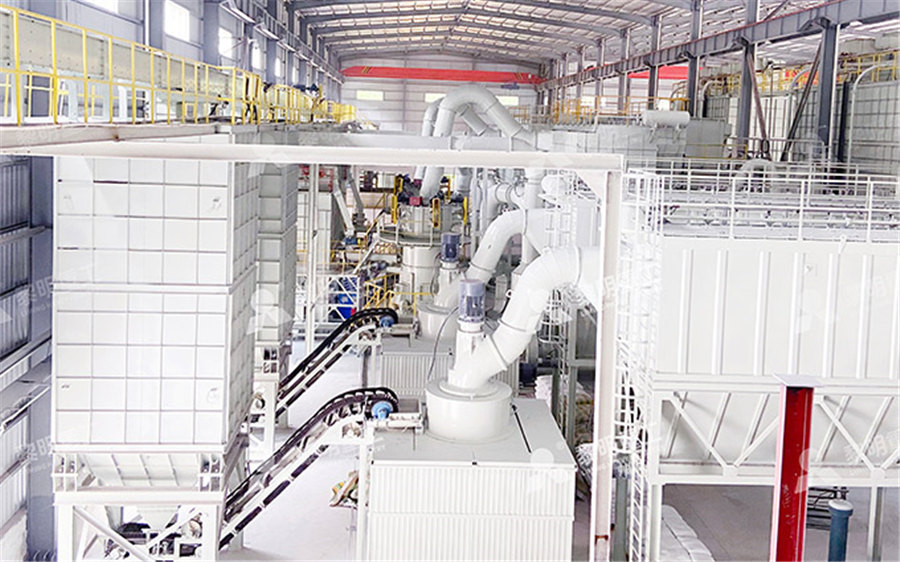

News Bentonite HighPressure Suspension Roller Mill

The highpressure suspension roller mill is suitable for grinding nonflammable and nonexplosive granular and brittle materials It has the characteristics of low preloading, laborsaving, and no wear at the contact between the spring and 2024年11月15日 Highpressure roller mill is an indispensable and important equipment in mining production, with low energy consumption per unit of crushing, strong processing capacity, Optimization of working parameters of highpressure roller mill Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Vertical roller mill for raw Application p rocess materialsThe Pendulum Mill PM by NEUMAN ESSER is a roller mill used for fine grinding and drying minerals such as bentonite, clay, limestone, and others It combines grinding, de Grinding and drying of bentonite Making

.jpg)

High Speed Dispersion of Bentonite US Silverson

It is more energy efficient and economical The shorter processing time required to form a stable suspension reduces wear and therefore maintenance and spare part costs The batch size, 2024年1月1日 It has the advantages of simple structure, stable operation, high efficiency, energy saving, and convenient maintenance It is widely applied in the crushing and grinding of metal Roller Mill SpringerLink2022年4月5日 In this study, the influence of a hybrid coagulation/flocculation process on the electrokinetic of highly stable bentonite suspension has been examined Choline chloride Enhancing the flocculation of stable bentonite suspension using The roller mill’s ability to reduce materials to a uniform particle size provides more control of product characteristics and minimizes waste, as shown in Figure 1 The mill’s controlled Roller mills: Precisely reducing particle size with greater efficiency

.jpg)

Application of bentonite in cementbased composites: A review of

3 天之前 Bentonite (BT), an environmentally friendly alternative, has been widely used as a substitute for cement due to its advantageous properties, including cost reduction, lessened Widely used for processing materials, such as barite, bentonite, kaolin, cement, gypsum, and many other minerals and ores, roller mills from laxmi ensure maximum production, flexibility Roller Mills laxmi engineeringHefei Hengcheng Industrial Equipment Technology Co, Ltd hcverticalrollermill@outlook 86 HomeVertical Roller Grinding Mill Energy Saving And Efficient Bentonite 2024年1月1日 'Roller Mill' published in 'The ECPH Encyclopedia of Mining and Metallurgy' Skip to main causticburned magnesia powder, kaolin, wollastonite, gypsum, lime, bentonite, etc), stable operation, high efficiency, energy saving, and convenient maintenance It is widely applied in the crushing and grinding of metal and non Roller Mill SpringerLink

.jpg)

What are the types of industrial grinding mills?

2021年7月7日 Compared with other mills, the output is increased by 1020% under the same isokinetic conditions The grinding pressure of the grinding roller on the material is increased under the action of the highpressure spring The VRM operation and optimizationppt Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online The document discusses vertical mills used for grinding clinker, raw materials, coal, and cement Vertical mills can be used for both pregrinding and finish grinding They comprise rollers that are hydraulically pressed onto a VRM Operation and Optimization PDF Mill (Grinding)Limestone Powder Ultrafine Vertical Roller Mill Modle : CLUM Series Finished Size: 4003000 mesh Processing Ability: 3 – 45t/h Max Feeding Size: 10 mm M 1 Set Price: $ Range Of Application: Limestone, Calcium Carbonate, Talc, Limestone Powder Ultrafine Vertical Roller MillVerticalrollermill Free download as PDF File (pdf), Text File (txt) or read online for free The document discusses vertical roller mills, which integrate crushing and grading into a single machine They provide efficient powder grinding with no overgrinding Models range in capacity from 762 tons per hour and can grind materials like coal, limestone, and mineralsVertical Roller Mill PDF Mill (Grinding) Industrial Processes

Concentration dependence of yield stress of bentonite suspension

2023年5月1日 These indicate that the bentonite suspension becomes more viscous as the concentration of bentonite particles increases We may therefore suspect that the gel structure in suspensions at high concentrations may be different from that of low concentrations: the gels formed by bentonite particles are more solidlike at low concentrations, while they become Model Number:HVM800 HVM1250 HVM1300 HVM1500 HVM1700 HVM1750 HVM1900 HVM2400 HVM2400 HVM2500,Certification:ISO Patent Certificate HighTech Product Certificate,Place of Origin:CHINA,Price:Negotiable,Payment Terms:L/C, D/A, D/P, T/T, Western Union, MoneyGram,Supply Ability:5 sets/month,Delivery Time:90 daysVertical Roller Grinding Mill Energy Saving And Efficient Bentonite 2019年3月8日 233 LowPressure Drop Cyclones for Suspension Preheaters mills or in vertical roller mills In a ball mill, Besides the energysaving effect, IMPROVING THERMAL AND ELECTRIC ENERGY EFFICIENCY AT Cellular Concrete Mixes with Bentonite Suspension K A Suleymanov(B),VSLesovik, and I A Pogorelova Belgorod State Technological University Named After VG Shukhov, Belgorod, Russia used for energy saving in buildings due to fire resistance, low cost, safety and aesthetic appearance, heat insulation and moisture control abilitiesCellular Concrete Mixes with Bentonite Suspension Springer

.jpg)

New Bentonite Grinding Mill Equipment Used In Iron ore Pellet

2021年1月29日 The selection of bentonite grinding mill equipment is an important equipment for grinding bentonite powder Based on the market demand, HCM recommends new Raymond mill machine and vertical roller mill equipment, which are beneficial to grinding iron ore pellets in steel plants Bentonite grinding machine for grinding bentonite powder2021年9月1日 HGM Ultrafine grinding mill Fineness: 1503000mesh Output: 0245t/h Application scope: This ultrafine grinding mill can grind nonmetallic minerals with Mohs hardness less than 6, such as limestone, calcium carbonate, kaolin, bentonite, vermiculite, etcBentonite Ultrafine Powder Grinding Mill2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and 2022年4月5日 The stability of the bentonite particles in dispersion can be explained through the DLVO (DerjaguinLanduaVerweyOverbeek) theory [18], [19], [20]It states that in dispersion the colloidal particles are under the influence of two independent forces represented in the van der Waals attractive forces and the electrostatic repulsive forces arising from the formation of the Enhancing the flocculation of stable bentonite suspension using

.jpg)

Roller Mill SpringerLink

2023年7月4日 The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, and the device for easy replacement It can be divided into vertical roller mill, horizontal cylinder roller mill, high pressure roller mill, Raymond mill, and column mill2021年1月29日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing consumes around Increase productivity of vertical roller mill using seven QC toolsQuality Vertical Roller Grinding Mill Energy Saving And Efficient Bentonite Vertical Mill for sale from Hefei Hengcheng Industrial Equipment Technology Co, Ltd it is a professional Vertical Roller Grinding Mill Energy Saving And Efficient Bentonite Vertical Mill manufacturer providing high quality Vertical Roller Grinding Mill Energy Saving Vertical Roller Grinding Mill Energy Saving And Efficient Bentonite The Omas roller mill is designed with their patented system which allows the machine to recover energy from the fast cylinder through the slow cylinder, saving up to 70% on energy usage This machine is built with 48 rolls for extremely accurate grinding of cereals at high capacitiesRoller Mill Equipment Bratney

The Effect of Carboxymethylcellulose and Xanthan on the

In this case, the cohesive energy of the aggregates decreases for an increase of pH 4 Results and Discussion After the installation of the sample (bentonite suspension or bentoniteadditive interlayers Bentonite B is an activated calcium bentonite, which means the Ca2+ ions in the interlayers were replaced by Na+ ions The suspensions were made by dispersing bentonite powder in desalted water Different bentonite concentrations were considered, namely 60 and 70 kg of bentonite A per m3 suspension and 35 and 40 kg/m3 of bentonite BRheological Properties of Bentonite Suspensions Modified with PDF On Dec 20, 2015, Abdelhakim Benslimane and others published Laminar and turbulent pipe flow of bentonite suspensions Find, read and cite all the research you need on ResearchGateLaminar and turbulent pipe flow of bentonite suspensions2016年6月1日 1 Development of Vertical Roller Grinding Mill in Cement Industry Throughout development process of the cement industry raw material grinding technology and equipment, Vertical Roller Grinding Mill has an age of Vertical roller grinding mill0601 PDF Free Download

.jpg)

Table Roller Mill Vertical Mill

The ultrafine vertical mill is currently the superlarge ultrafine grinding equipment in Asia, which has been successfully applied in the market and has mature technology It can replace imported equipment and is an ideal equipment for As the vertical roller mill works, larger feeding size, ease of fineness adjustment, lower operating cost, space saving, low noise, wearresisting, environmental protection, and etc This vertical mill machine is maximal feeding moisture is up to 15% A separate drying machine and energy for the mill system can be both Best HLM Vertical Roller Mill Manufacturer and Factoryconcentration of prepared bentonite suspension, the results of this procedure are presented on Figure 1 Then a single suspension dose was determined to achieve the desired turbidity in order to conduct critical concentration tests Measurements were verified several times to avoid errors of measuring the volume of the bentonite suspension Fig 1Bentonite clay suspension coagulation process and 2021年10月20日 In terms of feed particle size, the difference between the two is generally between 1535 mm; the particle size of the finished product is between 00440165 mm for Raymond mill, and between 00330613 mm for highpressure suspension roller mill; for output, suspension roller mill It has more spring pressure than Raymond mill, so the output What is the difference between highpressure suspension roller mill

Clirik Energy Saving Bentonite Raymond Roller Mill for Bentonite

Clirik Energy Saving Bentonite Raymond Roller Mill for Bentonite Powder Production Line, Find Details and Price about Mining Machine Grinder from Clirik Energy Saving Bentonite Raymond Roller Mill for Bentonite Powder Production Line Shanghai Clirik Machinery Co, Ltd2024年5月29日 In the case of this elegant roller mill, this dedication is mirrored in the refined design and durable construction of ROMIL – crafted for both the present and the next generation Swisca AG was founded in 2018 as a startup company in AppenzellRevolutionising roller mills Swisca’s next frontier in milling 2021年8月1日 Bentonite suspension is one of the candidate viscous fluids since it is widely used as drilling fluid for removing cuttings Thus, this study focused on ore lifting Experimental study of ore lifting efficiency with mixture of bentonite 6 天之前 Dry beneficiation is generally used to process bentonite with better raw ore quality, or bentoniterich ore with montmorillonite content of more than 80%This method is to dry the raw ore in the sun, air dry it naturally or dry it in the oven It is first crushed manually or with a jaw crusher, and then crushed with a Raymond mill and other roll mills into 100 mesh, 150 mesh, Bentonite Processing Methods And Required Equipment

.jpg)

Vertical Roller Grinding Mill Energy Saving And Efficient Bentonite

Hefei Hengcheng Industrial Equipment Technology Co, Ltd hcverticalrollermill@outlook 86 Home2024年1月1日 'Roller Mill' published in 'The ECPH Encyclopedia of Mining and Metallurgy' Skip to main causticburned magnesia powder, kaolin, wollastonite, gypsum, lime, bentonite, etc), stable operation, high efficiency, energy saving, and convenient maintenance It is widely applied in the crushing and grinding of metal and non Roller Mill SpringerLink2021年7月7日 Compared with other mills, the output is increased by 1020% under the same isokinetic conditions The grinding pressure of the grinding roller on the material is increased under the action of the highpressure spring The What are the types of industrial grinding mills?VRM operation and optimizationppt Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online The document discusses vertical mills used for grinding clinker, raw materials, coal, and cement Vertical mills can be used for both pregrinding and finish grinding They comprise rollers that are hydraulically pressed onto a VRM Operation and Optimization PDF Mill (Grinding)

Limestone Powder Ultrafine Vertical Roller Mill

Limestone Powder Ultrafine Vertical Roller Mill Modle : CLUM Series Finished Size: 4003000 mesh Processing Ability: 3 – 45t/h Max Feeding Size: 10 mm M 1 Set Price: $ Range Of Application: Limestone, Calcium Carbonate, Talc, Verticalrollermill Free download as PDF File (pdf), Text File (txt) or read online for free The document discusses vertical roller mills, which integrate crushing and grading into a single machine They provide efficient powder grinding with no overgrinding Models range in capacity from 762 tons per hour and can grind materials like coal, limestone, and mineralsVertical Roller Mill PDF Mill (Grinding) Industrial Processes2023年5月1日 These indicate that the bentonite suspension becomes more viscous as the concentration of bentonite particles increases We may therefore suspect that the gel structure in suspensions at high concentrations may be different from that of low concentrations: the gels formed by bentonite particles are more solidlike at low concentrations, while they become Concentration dependence of yield stress of bentonite suspension Model Number:HVM800 HVM1250 HVM1300 HVM1500 HVM1700 HVM1750 HVM1900 HVM2400 HVM2400 HVM2500,Certification:ISO Patent Certificate HighTech Product Certificate,Place of Origin:CHINA,Price:Negotiable,Payment Terms:L/C, D/A, D/P, T/T, Western Union, MoneyGram,Supply Ability:5 sets/month,Delivery Time:90 daysVertical Roller Grinding Mill Energy Saving And Efficient Bentonite

IMPROVING THERMAL AND ELECTRIC ENERGY EFFICIENCY AT

2019年3月8日 233 LowPressure Drop Cyclones for Suspension Preheaters mills or in vertical roller mills In a ball mill, Besides the energysaving effect, Cellular Concrete Mixes with Bentonite Suspension K A Suleymanov(B),VSLesovik, and I A Pogorelova Belgorod State Technological University Named After VG Shukhov, Belgorod, Russia used for energy saving in buildings due to fire resistance, low cost, safety and aesthetic appearance, heat insulation and moisture control abilitiesCellular Concrete Mixes with Bentonite Suspension Springer