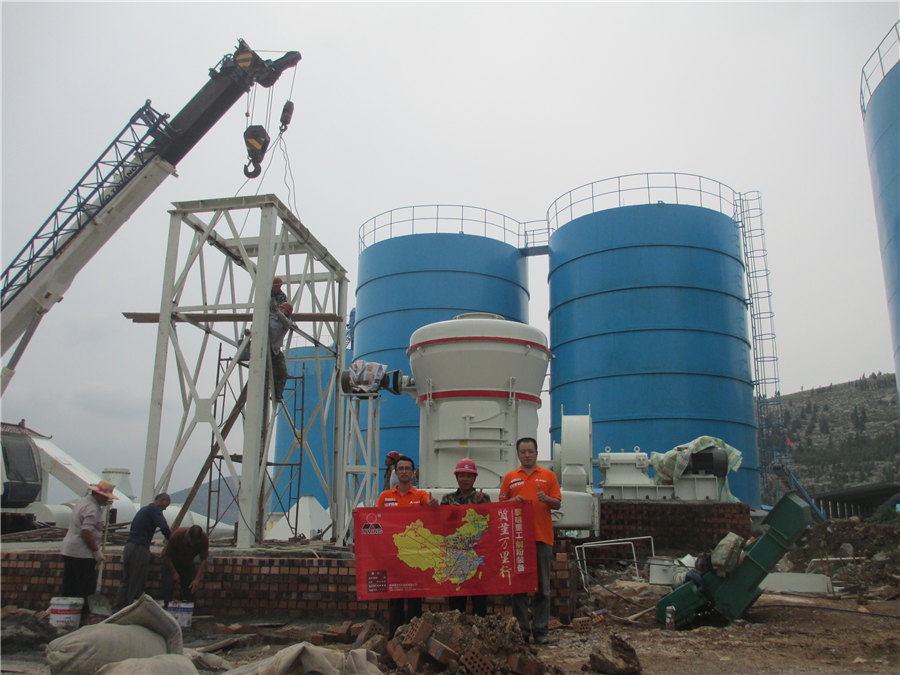

Highefficiency and energysaving ore powder making equipment

.jpg)

Advancements in ore powder production process equipment:

Automation: Modern ore powder production equipment is equipped with advanced automation systems, which improve operational efficiency and reduce labor costs Energy Efficiency: Innovations in mill design and technology have led to more energyefficient equipment, 2021年11月1日 Ceramic grinding, which in this paper is defined as a method of using ceramic materials as grinding media, is favored by many processing plants as an emerging high Highefficiency and energyconservation grinding technology 2024年11月5日 The results demonstrate significant improvements: energy utilization efficiency increased by 067%, energy consumption decreased by 173 MJ/t, production costs were Intelligent Optimization and Impact Analysis of Energy Efficiency 2022年1月1日 The results suggested that the highefficiency liberation of ore was obtained using the ceramicmedium stirred mill grinding technology, thus the efficient separation of iron and Highefficiency and energyconservation grinding technology

ENERGYEFFICIENT TECHNOLOGY OPTIONS FOR DIRECT

energyefficient and innovative lowcarbon technologies will be essential The Sponge Iron Manufacturers Association (SIMA) acts as an apex body to promote and protect the growing 2022年7月25日 The high precision, strong antiinterference capability, and high speed of these factors guarantee the separation efficiency of intelligent ore sorting equipment Color ore A review of intelligent ore sorting technology and equipment HGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and SBM Ore Ultrafine Grinding Mill2023年10月9日 Fluidized bed technology has become a crucial method used to process iron ore powder in nonblast furnace ironmaking, such as smelting reduction and direct reduction This Development and Problems of Fluidized Bed Ironmaking Process:

.jpg)

Comprehensive Technologies for Iron Ore Sintering with a Bed

highefficiency and stable thickbed sintering In actual production, either the equipment cost or the complexity of operation was significantly increased Through the cooperation with PDF On Aug 1, 2013, Ernst Worrell and others published Energy Efficiency Improvement and Cost Saving Opportunities for Cement Making An ENERGY STAR® Guide for Energy and Plant Managers Find (PDF) Energy Efficiency Improvement and Cost 2003年1月1日 Energy consumption is equal to 38 percent of the production costs of beer, making energy efficiency improvement an important way to reduce costs, especially in times of high energy price volatilityEnergy Efficiency Improvement and Cost Saving By reducing these losses through energy efficiency upgrades, you can save money and be more comfortable in your home or business Start with an Energy Evaluation Completing a home or building energy evaluation, also known as Why Energy Efficiency Matters Department of Energy

HighQuality Melting Furnaces and Equipment SuperbMelt

Our highquality melting furnaces and equipment provide exceptional performance, Gold Powder Making Machine Menu Toggle Menu ltem; Gold Leaf Making The machinery is lightweight and of a small size, and it provides high efficiency and energysaving advantages Low Ambient Temperature, Minimal Smoke, Favourable Workplace: The furnace 2009年1月1日 PDF Energy is an important cost factor in the US iron and steel industry Energy efficiency improvement is an important way to reduce these costs and Find, read and cite all the research (PDF) Energy Efficiency Improvement and Cost Saving Opportunities 2024年10月1日 Energy ratings for home appliances are there to help you understand the energy efficiency, running costs and CO 2 emissions of products Energy ratings in the UK come in a few different forms, letting you choose between different types of Home appliances and energy efficiency ratings Energy Saving Some products, such as your HVAC system and water heater, are major energyusers and can experience large energy and cost savings through improvements in energy efficiency Additionally, other products don’t use energy directly, but they improve the overall efficiency and comfort of a house or a building (such as thermal insulation or windows)Energy Efficiency ENERGY STAR

EnergySaving and Efficient Equipment Selection for Machining

2022年9月13日 In order to achieve energysaving and high efficiency in the production Equipment selection is an important part of product production decisionmaking and is of great significance to product production "EnergySaving and Efficient Equipment Selection for Machining Process Based on Business Compass Model" Processes 10, no 9:2019年6月15日 Figure 4: Simplified flow of steel powder and energy where the proportions of mass of material are similar to Figure 2 Table 4: Energy efficiency of the powder metallurgy processes studied in this work References: a[36], b[37], c[6], d[27], e[29], f[23]Energy and material efficiency of steel powder metallurgyCLUM vertical mills are suitable for largescale and highvolume nonmetallic ore grinding production lines The equipment is controlled intelligently, the work efficiency is high, and the ground powder has high whiteness and good shape CLUM vertical roller mills are very popular in the production of highend nonmetallic mineral powders SBM Ore Ultrafine Grinding Mill2021年10月20日 In the drying process, in order to obtain a sufficiently high energy efficiency, it is necessary to properly mix the air flow so that there are no gradients in the temperature distribution in the grain drying chamber Essential is the even temperature distribution to prevent overdrying of the grain close to the air channelsImprovements in drying technologies ScienceDirect

Bamboo Powder Making Machine

The bamboo powder making machine is an industrial ultrafine grinding mill independently developed stable operation, simple operation, convenient maintenance, high efficiency, and environmental protection, etc 86 Stone powder making machine is an ultrafine saving unnecessary equipment investment and reducing the total equipment investment ② 24hour The HGM micro powder grinding mill is a popular choice for grinding montmorillonite and Stone Powder Making Machine2019年4月18日 Figure 2 Energy efficiency is improved by eliminating losses and getting more energy to add value The energy intensity of a manufacturing process is the amount of energy that is required to produce one logical unit of product (eg, kWh/ton of metal melted at a foundry, MMBtu/bbl of oil refined at a refinery, MMBtu/lb of polymer produced at a chemical plant)Powder Coating Energy Efficiency: Ten Steps for Process Energy High energy utilization rate, low operating cost, grinding particle size range D50: 0510μm The revolution of dry milling technology, the milled particle size can reach submicron or nanometer level, which greatly improves the energy utilization efficiency and realizes low carbon, energy saving, environmental protection and resource recycling by supersonic steam jet millSupersonic Steam Jet Mill ALPA Powder Equipment

Energy Efficiency and Renewable Energy Technologies

Energysaving equipment, like dehumidifiers with efficient parts, highcapacity washers, and clothes dryers with moisture sensors, can lower energy usage without sacrificing functionality Reduced energy costs and lessening of the environmental impact are made possible by refrigerators with increased insulation and compressors, dishwashers with dirt sensors, 2023年5月29日 In December 2019, a novel coronavirus broke out in Wuhan City, Hubei Province, and, as the center of the coronavirus disease 2019 (COVID19) epidemic, the economy and production throughout Hubei Province suffered huge temporary impacts Based on the input–output and industrial pollution emissions data of 33 industrial industries in Hubei from Research on the Optimal Energy Saving and Emission Reduction 2022年9月13日 Traditional equipment selection is only through qualitative analysis comparing the process characteristics of using different equipment or optimizing parameters for a single piece of equipment(PDF) EnergySaving and Efficient Equipment Selection for 2023年7月31日 The sustainable development and intelligent transformation of the manufacturing industry have become inevitable trends As a typical example of the intelligent transformation, the networked manufacturing mode has been widely applied through sharing and utilizing manufacturing resources all over the world Existing research on energysaving use of A framework for energysaving selection and scheduling of equipment

.jpg)

Copper Ore Processing And Equipment JXSC Mineral

2023年5月26日 Generally speaking, when adopting energysaving, environmentally friendly, and highefficiency new equipment, once crushing and grinding operations are required, it is necessary to improve the equipment according to the actual situation of the mineral, plant the crushing time and grinding particle size in detail, and at the same time Adjust the crushing and 2024年1月12日 Energy efficiency and energy conservation are related and often complimentary or overlapping ways to avoid or reduce energy consumption Energy efficiency generally pertains to the technical performance of energy conversion and energyconsuming devices and to building materials Energy conservation generally includes actions to reduce the Energy efficiency and conservation US Energy Information 2019年7月19日 Normally, coal drying during coke making is an high energyconsuming operation High and variable moisture contents affect both the coke rate and the balances within the blast furnace The coil moisture control system dries the coal from around 12% up to 5% reducing the energy consumption in the coke oven by 150 MJ/tCoke Making: Most Efficient Technologies for Greenhouse Emissions What is EnergySaving Equipment? Energysaving equipment are devices, which help reduce fuel consumption in addition to the used stove These include hotbags, in which food can continue to simmer and be kept warm, pressure Improved Cookstoves and Energy Saving Cooking

Energy efficiency of manufacturing systems: A review of energy

2019年12月10日 Energy efficiency represents an important measure for mitigating the environmental impacts of manufacturing processes, and it is the first step towards the implementation of sustainable production (IPCC, 2018)Additionally, from the companies’ points of view, energy efficiency is becoming an important theme in production management due to Shanghai Zenith Abundant hot sales with multiple models Gold Ore MTW215G European Trapezium Mill Spare Parts Rock Grinding Plant Cement Ball Mill Price Ball Mill 2400X4000 Hot selling 10 ton per hour stone grinding ball mill equipment 4R Raymond Mill Dewo Lime Stone Processing Machine South Africa Powdered Coal Mill Small feldspar quartz dry grinding EnergySaving Mining Gold Copper Ore Grinding Ball Mill Gypsum Powder Making Machine is also called Gypsum Powder Production Line Equipment ,Natural gypsum powder is dihydrate gypsum (CaSO42H2O) after crushing, grinding, calcination, cooling homogenization, aging, packaging and made; gypsum powder production is the core technology of calcination (dehydration) system, the two gypsum crystal Structure, various Gypsum Powder Making Machine,Gypsum Powder Production Line Equipment 2023年6月30日 The necessity to develop energyefficient technologies for the mineral industry will increase in the future, considering the exhaustion of highquality resources and severe environmental limitationsModeling and Improving the Efficiency of Crushing Equipment

Energy efficiency improvement and cost saving opportunities

2011年1月1日 Request PDF Energy efficiency improvement and cost saving opportunities for the pulp and paper industry The US pulp and paper industrydefined in this Energy Guide as facilities engaged in 2016年10月5日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study performed on a EnergyEfficient Technologies in Cement Grinding IntechOpen2010年1月1日 Comparative high pressure grinding rolls (HPGR) and cone crusher pilotscale tests were conducted using Upper Group 2 (UG2) platinumbearing ore in order to determine the impact of microcracks in Efficiency, economics, energy and emissionsemerging criteria for PDF On Aug 1, 2013, Ernst Worrell and others published Energy Efficiency Improvement and Cost Saving Opportunities for Cement Making An ENERGY STAR® Guide for Energy and Plant Managers Find (PDF) Energy Efficiency Improvement and Cost

Energy Efficiency Improvement and Cost Saving

2003年1月1日 Energy consumption is equal to 38 percent of the production costs of beer, making energy efficiency improvement an important way to reduce costs, especially in times of high energy price volatilityBy reducing these losses through energy efficiency upgrades, you can save money and be more comfortable in your home or business Start with an Energy Evaluation Completing a home or building energy evaluation, also known as Why Energy Efficiency Matters Department of EnergyOur highquality melting furnaces and equipment provide exceptional performance, Gold Powder Making Machine Menu Toggle Menu ltem; Gold Leaf Making The machinery is lightweight and of a small size, and it provides high efficiency and energysaving advantages Low Ambient Temperature, Minimal Smoke, Favourable Workplace: The furnace HighQuality Melting Furnaces and Equipment SuperbMelt2009年1月1日 PDF Energy is an important cost factor in the US iron and steel industry Energy efficiency improvement is an important way to reduce these costs and Find, read and cite all the research (PDF) Energy Efficiency Improvement and Cost Saving Opportunities

Home appliances and energy efficiency ratings Energy Saving

2024年10月1日 Energy ratings for home appliances are there to help you understand the energy efficiency, running costs and CO 2 emissions of products Energy ratings in the UK come in a few different forms, letting you choose between different types of Some products, such as your HVAC system and water heater, are major energyusers and can experience large energy and cost savings through improvements in energy efficiency Additionally, other products don’t use energy directly, but they improve the overall efficiency and comfort of a house or a building (such as thermal insulation or windows)Energy Efficiency ENERGY STAR2022年9月13日 In order to achieve energysaving and high efficiency in the production Equipment selection is an important part of product production decisionmaking and is of great significance to product production "EnergySaving and Efficient Equipment Selection for Machining Process Based on Business Compass Model" Processes 10, no 9:EnergySaving and Efficient Equipment Selection for Machining 2019年6月15日 Figure 4: Simplified flow of steel powder and energy where the proportions of mass of material are similar to Figure 2 Table 4: Energy efficiency of the powder metallurgy processes studied in this work References: a[36], b[37], c[6], d[27], e[29], f[23]Energy and material efficiency of steel powder metallurgy

.jpg)

SBM Ore Ultrafine Grinding Mill

CLUM vertical mills are suitable for largescale and highvolume nonmetallic ore grinding production lines The equipment is controlled intelligently, the work efficiency is high, and the ground powder has high whiteness and good shape CLUM vertical roller mills are very popular in the production of highend nonmetallic mineral powders