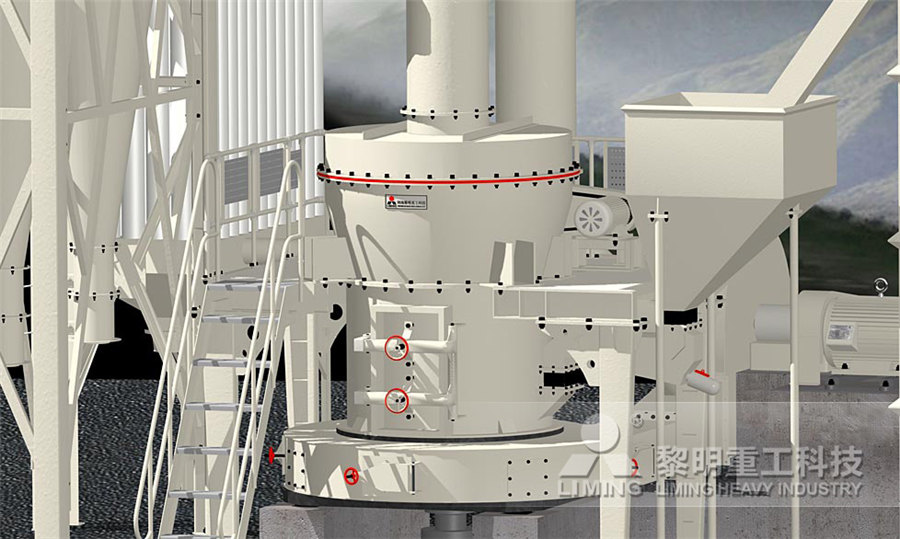

sk vertical lithium ore crushing process

.jpg)

ReviewProcessing of lithium ores: Industrial technologies and case

2021年5月1日 Some specific techniques of lithium extraction from ores and minerals are systematized Autoclave methods seem the most promising for poor alkaline Li Impurity removal from the salar brine is a critical step in the process flowsheet for production of batterygrade lithium Our MaxRTM technology provides the most advanced method in the Lithium processing technology Complete solutions that FLSmidth2021年5月1日 The pros and cons of industrial technologies of lithium ores processing have been analyzed Some specific techniques of lithium extraction from ores and minerals are Processing of lithium ores: Industrial technologies and case studies 2023年1月1日 The process flow is to convert lithium in ore into lithium sulfate by mixing roasting lithium mineral and excessive potassium sulfate (or calcium sulfate or a mixture of both), leach Lithium extraction from hard rock lithium ores (spodumene,

.jpg)

LESSONS LEARNED FROM NEW HARDROCK LITHIUM PROJECTS

The lithium hardrock mining process at Mount Marion starts with primary crushing followed by secondary and tertiary crushing The crushed ores will be sent to gravity separation and dense three or four stages of crushing are used, with only the runofmine (ROM) jaw crusher operating in open circuit The fines generated during crushing are either sent to tails, combined with Lithium Ore Processing – an Overview of the Current and New 2021年2月1日 In modern Russian realities, roasting and hydrometallurgical processing of ores and concentrates using sulfuric acid and limesoda methods seem to be practically Processing of lithium ores: Industrial technologies and case studies ivia) Brines are processed through evaporation or ionexchangedriven processes Lithium Pegmatites (including Spodume) are processed through a more conventional mining approach Lithium Shakeup: An alternative crushing and grinding circuit for

.jpg)

Hard Rock Lithium Processing SGS

SGS supports the minerals and chemical industries in the design and operation of efficient crushing and grinding circuits using both power and modelbased methods We can design 1 天前 Electrochemical technologies add a unique dimension for ore refinement, representing tunable methods that can integrate with renewable energy sources and existing downstream Electrochemical lithium extraction from hectorite ore2023年5月27日 The role of ball milling in lithium ore processing is to break down the lithiumcontaining minerals and release the lithium ions into the solution This is achieved through the mechanical grinding of the ore, which helps to increase the surface area of the material, making it easier for the leaching solution to penetrate and dissolve the lithium ionsBall Milling in Lithium Ore Processing: A Comprehensive Guide6 天之前 Additionally, the ball mill’s versatility allows parameters such as speed, feed rate and material composition to be adjusted, making it adaptable to different types of lithium ore This flexibility is essential to optimize the grinding process Ball Mill Is The Key To Grinding Lithium Ore JXSC

Flow chart of lithium ore crushing, grinding and screening process

2022年12月27日 Loose lithium ore is divided into different particle grades through the sieve process, known as screening in lithium ore concentrator, screening is mostly combined with crushing operation Before lithium ore enters a certain section of the crusher, the preseparation of qualified products whose particle size has met the requirements is called prescreening2024年11月21日 The advantage of the grid type ball mill is that the ore discharge speed is fast, it can reduce the overcrushing of ore, and at the same time it can increase the output per unit volume 1 Large row of ore mouth design, stronger processing capacity for lithium ore, up to Ball Mill Is Indispensable For Lithium Ore ProcessingThis setup is for processing spodumene ore to recover lithium, it is a flotation separation plant and has a high recovery ratio for LiO2#hopper #vibratingfe500TPH Lithium Ore Crushing And Beneficiation ProcessLithium Ore Processing – an Overview of the Current and New Processes N J Welham1, A Nosrati2 and N Setoudeh3 1 FAusIMM, Principal, Welham Metallurgical Services, South Lake, WA 6164 : nicholaswelham@gmail 2 MAusIMM, Lecturer, Chemical Engineering, School of Engineering, Edith Cowan University, Joondalup, WA 6027Lithium Ore Processing – an Overview of the Current and New

.jpg)

Lithium Processing Plant JXSC Machine

2022年7月5日 Lithium is an element valuable for the production of glass, aluminum products, and batteriesWith the development of technology, electronic equipment, and new energy industries, the demand for lithium ore has increased rapidly Therefore, lithium ore is known as the “energy metal that drives the progress of the world”2024年6月13日 The processing and production technology of copper ore mainly includes three processes: crushing, grinding, and beneficiationThe modern copper ore crushing method adopts threestage closedcircuit crushing, which can not only complete the crushing and partial dissociation of the ore, but also improve the efficiency of subsequent grindingCopper Introduction And Ore Crushing JXSC Mineral2021年5月1日 Also, we have summarized and studied the conditions of lithium extraction from other raw materials, in particular, from mica, which is obtaining simultaneously in form of flotation tailings during the complex processing of fluorite‑beryllium ores of the Voznesenskoye deposit (Primorsky Territory) (Kupriyanova and Shpanov, 1997), and, also, from the petalite ores of Processing of lithium ores: Industrial technologies and case 2022年9月28日 For processing loose lithium ores, impact crushers (such as impact crushers and hammer crushers) are generally used for crushing #2 lithium Ore Screening Process The process of separating loose lithium ore into different particle sizes through a screen is called screening In lithium ore processing plants, screening is mostly combined with Lithium Ore Process Flow How is Lithium Ore Processed?

A Review of Characterization Techniques and

2022年8月2日 Process mineralogy plays a key role in defining the properties of ores, identifying key opportunities, and ascertaining potential challenges associated with the extraction of lithium2022年7月31日 In this regard, two specific devices, commonly used in ore processing operations, were utilized to apply energy in a material in order to reach abrasion by attrition, but with different kinetic approaches: stirring in a slurry media and using a light milling, in both cases reducing the grinding media in order to avoid material fractureAdvances in Ore Processing Technologies: Crushing, Milling and Lithium processing technologies A key issue for the spodumene miners is how to reduce production costs For brine miners, the question is how to produce more volumes more quickly, with the least environmental impact We have pioneered the global lithium processing industry for more than 20 years With an established record of product andLithium processing technology Complete solutions that3 Lithium Heavy Media Beneficiation Applicable minerals: Spodumene with relatively coarse crystal grain size The difference in specific gravity between lithium ore and gangue minerals is not greater than 0205g/m3 Main process: Mix the lithium ore after washing and desliming with heavy medium (heavy medium includes heavy liquid and heavy suspension, here mainly Lithium Ore Mining Process JXSC Mineral

(PDF) Lithium extraction from hard rock lithium ores: technology

2022年1月1日 Lithium extraction from hard rock lithium ores (Spodumene, Lepidolite, Zinnwaldite, Petalite): Technology, resources, environment and cost Tianming Gao, Na Fan, Wu Chen, Tao Dai2023年4月23日 Lithium (Li) ore is a type of rock or mineral that contains significant concentrations of lithium, a soft, silverwhite alkali metal with the atomic number 3 and symbol Li on the periodic table Lithium is known for its unique properties, such as being the lightest metal, having the highest electrochemical potential, and being highly reactive with waterLithium (Li) Ore Minerals, Formation, Deposits Geology Science2021年10月7日 These generally low grades re quire a concentratio n step prior to metallurgical ore processing and lithium leaching In general, lithium occurs in more tha n 145 different minerals, with (PDF) Lithium Mining, from Resource Exploration to Battery Grade 2016年3月11日 It was felt by some that crushing to this fine size is only possible if the ore is friable and is relatively soft in comparison to the harder ores Our results show that some of the copper ores are as hard as taconite and are crushed to ball mill feed all passing 13MM (½”)Crushing Plant Flowsheet DesignLayout 911Metallurgist

.jpg)

Lithium Ore Flotation Plant Pineer Mining Machinery

The Pineer froth flotation process enables sustainable and costeffective spodumene/lithium ore recovery Comes from one supplier, responsible for the whole package Provides mechanical and performance guarantees for the entire plant machinery, with clear battery limits for engineering and implementation2024年4月26日 Crushing is the initial stage in the iron ore processing journey, where large chunks of ore are broken down into smaller fragments The primary objective of crushing is to reduce the ore size for subsequent processing and improve the liberation of valuable minerals from the gangue a Jaw Crushers: Jaw crushers are commonly used for primary Iron Ore Processing: From Extraction to Manufacturing2022年8月3日 Iron ore crushing process: In the iron ore crushing process, the feeder, first crushing, secondary crushing, screening, Clum ultrafine vertical mill Fineness: 1503000mesh Yield: 120t/h see More >> GET IN TOUCH Iron ore crushing and screening process SBM When iron ore is extracted from a mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS The six main steps of iron ore processing Multotec

Sustainable Lithium Extraction: How is Lithium Mined

2023年10月6日 The process of extracting lithium from mines primarily revolves around extracting lithiumbearing minerals, notably spodumene, through an intricate interplay of mining and processing methodologies Initially, ore 2023年10月9日 The processing of lithium ore involves several steps, from mining and extraction to refining and purification The machinery and equipment used in a lithium ore processing plant may vary depending Lithium ore processing plant machinery and equipment LinkedInThe lithium ore processing line includes six systems: crushing system, screening system, grinding system, classification system, flotation system, and dryingWhat does a lithium ore processing plant consist of? YouTube2023年6月8日 Lepidolite is the most common lithium mineral and an important mineral for extracting lithium Due to the low grade of lepidolite ore, the content of lithium oxide is usually 123% to 590% It is a basic aluminosilicate of potassium and lithium, which is Three Common Beneficiation Process For Lithium Ore

.jpg)

A Comprehensive Guide to Lithium Processing Equipment

According to the processing principle of "more crushing and less grinding", a threestageoneclosedcircuit crushing and screening process or a twostageoneclosedcircuit crushing and screening process can be used in the crushing and screening stage of lithium ore Which process to use specifically needs to refer to the particle size of the 2021年10月1日 A closedloop process for the extraction of lithium from βspodumene (βLiAlSi2O6) by leaching with Na2SO4, the byproduct of the lithium precipitation process, was proposedLithium extraction from claytype lithium resource using ferric sulfate 2022年10月24日 The Lithium Ore Process Fatty acid or soap flotation of spodumene is one well established recovery method, but pulverized or ground particle surface conditions generally necessitate preflotation Processing Spodumene by Froth Flotation for Lithium Extraction803% Due to its high lithium content, spodumene is considered the most important lithium ore mineral A typical run of mine ore can contain 12% Li 2 O, while a typical spodumene concentrate suitable for lithium carbonate production contains 67% Li 2 O (75% 87% spodumene) Higher grade concentrates with 76% Li 2 O and low iron content areHard Rock Lithium Processing SGS

Ball Milling in Lithium Ore Processing: A Comprehensive Guide

2023年5月27日 The role of ball milling in lithium ore processing is to break down the lithiumcontaining minerals and release the lithium ions into the solution This is achieved through the mechanical grinding of the ore, which helps to increase the surface area of the material, making it easier for the leaching solution to penetrate and dissolve the lithium ions6 天之前 Additionally, the ball mill’s versatility allows parameters such as speed, feed rate and material composition to be adjusted, making it adaptable to different types of lithium ore This flexibility is essential to optimize the grinding process Ball Mill Is The Key To Grinding Lithium Ore JXSC 2022年12月27日 Loose lithium ore is divided into different particle grades through the sieve process, known as screening in lithium ore concentrator, screening is mostly combined with crushing operation Before lithium ore enters a certain section of the crusher, the preseparation of qualified products whose particle size has met the requirements is called prescreeningFlow chart of lithium ore crushing, grinding and screening process2024年11月21日 The advantage of the grid type ball mill is that the ore discharge speed is fast, it can reduce the overcrushing of ore, and at the same time it can increase the output per unit volume 1 Large row of ore mouth design, stronger processing capacity for lithium ore, up to Ball Mill Is Indispensable For Lithium Ore Processing

.jpg)

500TPH Lithium Ore Crushing And Beneficiation Process

This setup is for processing spodumene ore to recover lithium, it is a flotation separation plant and has a high recovery ratio for LiO2#hopper #vibratingfeLithium Ore Processing – an Overview of the Current and New Processes N J Welham1, A Nosrati2 and N Setoudeh3 1 FAusIMM, Principal, Welham Metallurgical Services, South Lake, WA 6164 : nicholaswelham@gmail 2 MAusIMM, Lecturer, Chemical Engineering, School of Engineering, Edith Cowan University, Joondalup, WA 6027Lithium Ore Processing – an Overview of the Current and New 2022年7月5日 Lithium is an element valuable for the production of glass, aluminum products, and batteriesWith the development of technology, electronic equipment, and new energy industries, the demand for lithium ore has increased rapidly Therefore, lithium ore is known as the “energy metal that drives the progress of the world”Lithium Processing Plant JXSC Machine2024年6月13日 The processing and production technology of copper ore mainly includes three processes: crushing, grinding, and beneficiationThe modern copper ore crushing method adopts threestage closedcircuit crushing, which can not only complete the crushing and partial dissociation of the ore, but also improve the efficiency of subsequent grindingCopper Introduction And Ore Crushing JXSC Mineral

.jpg)

Processing of lithium ores: Industrial technologies and case

2021年5月1日 Also, we have summarized and studied the conditions of lithium extraction from other raw materials, in particular, from mica, which is obtaining simultaneously in form of flotation tailings during the complex processing of fluorite‑beryllium ores of the Voznesenskoye deposit (Primorsky Territory) (Kupriyanova and Shpanov, 1997), and, also, from the petalite ores of 2022年9月28日 For processing loose lithium ores, impact crushers (such as impact crushers and hammer crushers) are generally used for crushing #2 lithium Ore Screening Process The process of separating loose lithium ore into different particle sizes through a screen is called screening In lithium ore processing plants, screening is mostly combined with Lithium Ore Process Flow How is Lithium Ore Processed?