Cone Crushing Equment Design And O Ration of limestone

.jpg)

New developments in cone crusher performance optimization

2009年6月1日 This physics based virtual comminution model will enable engineers to optimize the design development of future crushers by allowing a wider range of values for the crusher variables to be investigated in a rapid, yet more detailed manner, without the need for the 2021年8月15日 We review the state of the art developments in process modeling and cone crusher control from 1972 to 2020 The steadystate model of Whiten (1972) is still used today A review of modeling and control strategies for cone crushers in DEM simulation of a Svedala H6000 cone crusher studied in the thesis Compressive crushing has been proven to be the most energy efficient way of mechanically reducing the size of rock CONE CRUSHER MODELLING AND SIMULATION Chalmers2020年7月15日 The crushing simulation of the softer material (limestone) reached steadystate conditions in about three seconds of crusher operation, whereas nearly six seconds were Simulating a laboratoryscale cone crusher in DEM using

.jpg)

(PDF) Cone Crusher Performance ResearchGate

2015年5月13日 In this thesis a method for prediction of cone crusher performance is presented The model is based on the laws of mechanics and 2023年6月30日 This article presents a systematic review of the task of improving the energy efficiency of crushing units This is achieved by studying modelling methods and results, the automation ofModeling and Improving the Efficiency of Crushing 2019年3月21日 In research on the design and performance of cone crushers, it is generally assumed that crushing occurs as a result of the compression of the piece by mobile and Forces in a Cone Crusher Steel in Translation Springer2021年3月15日 Results show that considering the amount of ore uplift in the blockage layer, the revised mathematical model of crusher productivity can better characterize the actual Chamber Optimization for Comprehensive Improvement of Cone

.jpg)

A review of modeling and control strategies for cone crushers in

2021年6月27日 Based on the particle crushing pressure model, the particle crushing pressure distribution of the mantle and concave can be obtained according to the compression ratio and Crushing Principles of Mechanical Crushing Objective Explain the interaction between rock material and crusher Take home messages Agenda • Crusher Application • Cone Crushing Principles of Mechanical Crushing 911 Metallurgist1 Firststage Crushing The Limestone raw material is transported to the jaw crusher by the vibrating feeder for coarse crushing 2 Secondstage Crushing Screening After coarse crushing, the Limestone enters the impact crusher for Limestone Aggregate Crushing JXSC Machine– The greater reduction ratio the worse particle shape – Inter particle breakage improves shape When crushing a bed of material weaker particles will break first Flaky or elongated particles are weaker then round – Breaking round particles gives flaky material F l a k i n e s s i n d e x [%] Particle size [mm] Increasing average feed Crushing Principles of Mechanical Crushing 911 Metallurgist

.jpg)

(PDF) Design and Construction of Rock Crushing

2018年8月7日 Chermileusky EV, Romanor VA (1994) Cone crusher performance Ph D thesis department of machine and vehicle design, Chalmers University Of Technology, Sweden Mechanical engineers hand book 15701572Limestone Crushing Production Line The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control, and other equipment To meet the different processing needs of customers, it can be equipped with a cone crusher, dust collector Equipment, etcLimestone Crushing Equipment and Production Line2019年11月4日 The limestone crusher machine has jaw crusher, impact crusher, cone crusher, etc JXSC custom makes limestone crushing plant for different requirements to meet high efficiency, energysaving performance Limestone stone crusher plant equipped with mature rock crushers, which is very suitable for crushing limestone, malmstone and other materialsLimestone Rock Crushing Flow Price JXSC Machine2024年1月11日 The hammer crusher is a crushing processing equipment for limestone This equipment can replace the rough crushing process of the stone crusher, directly crushing limestone into particles below 25mm The hammer crusher adopts a dual motor operation, consisting of a plate hammer and a rotor to form a crushing powerLimestone Crushing And SandMaking Plant Eastman Rock

Limestone Crusher for Efficient Limestone Crushing Plant

The limestone crushing process is a complex operation that requires a variety of limestone crusher and additional equipment to produce the desired material for its various uses Understanding the characteristics of different limestone crushers and how they operate is crucial for designing an efficient limestone processing operationP¢ÂЊJ ¤jÄjtÐV µ‰Rl;vâ(£ÄÄÄ쎚„i Éà´¥>fJ (±bD£u£â‹©£"VÑ¡M\ á ¸=ç~»û=ö[È›v2Ó= ìÝ{îýν¿{Ï9÷^€€ $ H@ € $ H@¾÷ j6™¢ýø>v”I! ] Å‹ ²¡hl§ áñîºy€÷A¨« bRŽ²ÞQk?S”î9þ“)åu ¹TØv¼’¤“t QxßÕVk( þ@½[ } ‚lþÒU¯»ž( dxI½hÿÚ 9Hè Crushing2020年2月18日 Limestone is a fundamental raw material in various industrial sectors It is formed due to biochemical precipitation of calcium carbonate, and further compaction over long periods of time(PDF) Environmental Hazards of Limestone Mining and2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] crusher [4] The tie rod and compression spring ensure that the SIZE REDUCTION BY CRUSHING METHODS ResearchGate

.jpg)

Evaluation of size reduction process for rock aggregates in cone

2020年6月4日 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratoryscale cone crusher Based on several mineralogical, physico 2023年12月8日 After being processed by the coarse crushing equipment, the secondary crushing equipment is used for secondary crushing to break the stones into stones between 20100mm The particle size of the discharged stones Limestone crushing technology and equipment2020年11月8日 Crusher; Crushing; and Classification Equipment 1 Mineral Processing: Crusher and Crushing by Hassan Z Harraz hharraz2006@yahoo Ancient and Modern Local Quality and High quality Crusher; Crushing; and Classification Equipment PPT3 Size reduction of ores is normally done in order to liberate the value minerals from the host rock This means that we must reach the liberation size, normally in the interval 100 – 10 micron SIZE REDUCTION BY CRUSHING METHODS By ResearchGate

.jpg)

AusIMM – Leading the way for people in resources

Dm›lŒ#B¡hýüôØ) V7ó䫱÷6ÃyæßæÑ;ô¶Öìå”# ë7U X ¤€;Å ˆG “÷Cõ—A Êï–?rùAq} Æ:Øœ47 Jò*ÙŒ¤f‘HÓibå sä!ÔÉ Öö½G%$‚B:È»mÿ»‰D„wwf¾Œ–j´½ ˜>$‡ û a=›Ê n† +ß /# É`©¿ œ y}š xÔþÎÃzÖSÖٹνY±ü7Òæ[æË#L?®”š]¼™Ê %‹bÄ£koÁðÃ+9xöµ€ZMÆ®±”û™:=]T2 ÚÔ¡w:t÷ÛÈsW 2019年7月9日 In sand crushing machinery, friction occurs betwe en the limestone particles in the rotor and between the particles and the wall of the rotor, which is made of steel Therefore, our experiment wasStudy on Physical and Contact Parameters of Limestone by 2019年5月10日 Reduction ratios become an important consideration in secondary crushing Knowing just how fine you need a final output to be, along with the feed requirements of your tertiary crushing station, will help to determine how much reduction needs to Simplifying the crushing process Pit Quarry2018年6月1日 When considering that the crushing process takes place in the crushing chamber, cone crushers can be generally classified into two basic types: (1) large eccentric throw, flat, shortchambered crushers normally with a cantilevered shaft supporting a mantle such as the Symons (Rexnord) standard and shorthead designs shown in Figs 47 and 48 (the Telsmith Cone Crushers: Types, Benefits, and Applications in Mining

.jpg)

A Detailed Overview of Cone Crushers and What You Need to

2020年6月3日 In this Cone Crusher article we want to educate you about what to consider when purchasing a cone crusher It also will inform and educate you if you are a current owner or operator of a Cone Crusher If you have a good base of knowledge about cone crushers you can skip through the article by choosing the topics belowWe will be exploring in more detail the If your limestone crushing operation is down you are losing money Without easy to operate equipment you’re wasting man hours on repairing equipment, you are overwhelmed by the complexity, you are eating away at profit margin with outdated processes, and the growth of your company is being held backCrushing Limestone Impact Jaw Crushers RUBBLE MASTER2015年8月31日 Features Equipped with efficient cone crusher, it has excellent crushing performance Optimized crushing cavity can significantly increase crushing ratio and output It features great production capacity, high reliability, Aggregate Crushing Equipment PPT Free Download 2024年6月11日 Primary Crushing: Primary crushing is the first stage of the crushing process and is used to reduce large pieces of limestone down to a size that can be handled by the secondary crushers Jaw crusher and gyratory Limestone Processing Crushing Operations and

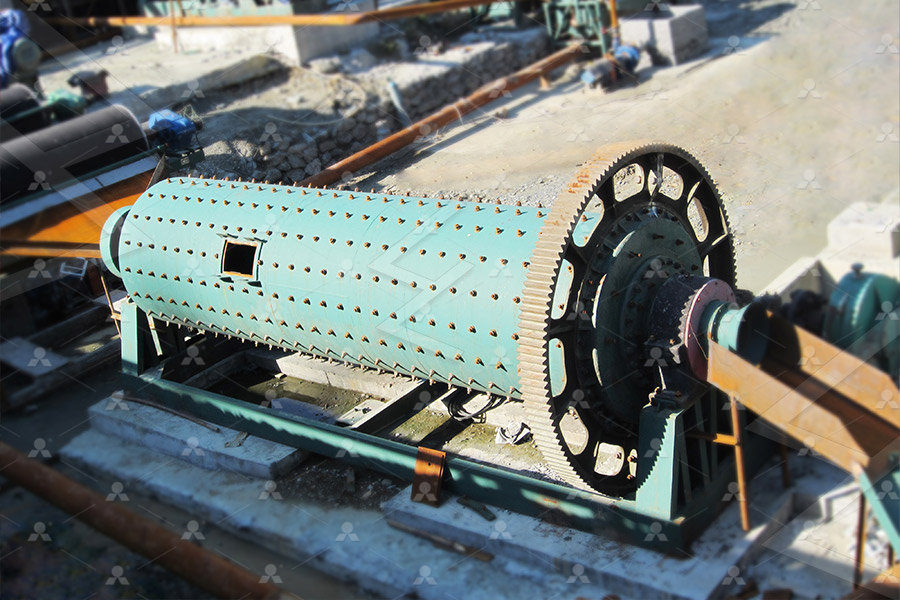

Crushing PlantHydraulic Cone Crusher

and ordinary Hydraulic Cone Crusher: 1 High crushing ratio and production efficiency >> Connection of higher turning speed and stroke makes rated power and passing capacity improved greatly and crushing ratio and capacity increased 2 About Limestone Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3) in the form of the mineral calcite or aragonite It is a kind of stone widely found in nature Limestone can be directly processed into stone using crushing equipment and fired into quicklime Quicklime absorbs moisture or adds water to become hydrated limeLimestone Crushing Process JXSC MineralLimestone property, limestone crushing circuit layout, The impact crusher has a larger crushing ratio and can more fully utilize the highspeed impact energy of the entire rotor 【Related equipment】cone crusher, B1000X23m conveyor, HVI1250 sand making machine, Limestone Crushing Plant Layout and Price JXSC Machine2021年10月7日 Crushers are one of the main equipment used for reducing size in metallurgical, mechanical, and other similar industries They exist in various sizes and capacities which range from 30 tons/hr to Design and Performance Evaluation of a Stone Crusher

.jpg)

4 Types of Cone Crushers: What Are They and How to Select

2024年10月14日 It perfectly combines crushing stroke, crushing speed, and the crushing cavity, so it has a higher output than other cone crushers The finished product has a more uniform particle size, higher strength, and fewer needles (below 8%), which is more in line with the requirements of highquality aggregateWelcome to Mechtech Inframine! Since 1987, we’ve been at the forefront of crushing and screening equipment innovation Founded in 1987 by a team of highly qualified and experienced engineers, our mission has always been to design we specialize in providing solutions for the crushing of coal, iron ore, limestone, and stone Mechtech Inframine Home of Superior Crushing and Screening Equipment2014年1月16日 This paper discusses the design calculations and considerations of belt conveyor system for limestone using 3 rolls idlers, in terms of size, length, capacity and speed, roller diameter, power and Design of a Material Handling Equipment: Belt Conveyor System 2023年2月13日 The maintenance and repair requirements for limestone crushing equipment also depend on several factors, including the type of equipment, the capacity, and the material properties In general, cone crushers and impact crushers require less maintenance and repair than jaw crushers and roller crushers, but the actual maintenance and repair requirements will What Is The Best Limestone Crusher Limestone Crushing AGICO

.jpg)

Limestone Aggregate Crushing JXSC Machine

1 Firststage Crushing The Limestone raw material is transported to the jaw crusher by the vibrating feeder for coarse crushing 2 Secondstage Crushing Screening After coarse crushing, the Limestone enters the impact crusher for – The greater reduction ratio the worse particle shape – Inter particle breakage improves shape When crushing a bed of material weaker particles will break first Flaky or elongated particles are weaker then round – Breaking round particles gives flaky material F l a k i n e s s i n d e x [%] Particle size [mm] Increasing average feed Crushing Principles of Mechanical Crushing 911 Metallurgist2018年8月7日 Chermileusky EV, Romanor VA (1994) Cone crusher performance Ph D thesis department of machine and vehicle design, Chalmers University Of Technology, Sweden Mechanical engineers hand book 15701572(PDF) Design and Construction of Rock Crushing Limestone Crushing Production Line The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control, and other equipment To meet the different processing needs of customers, it can be equipped with a cone crusher, dust collector Equipment, etcLimestone Crushing Equipment and Production Line

Limestone Rock Crushing Flow Price JXSC Machine

2019年11月4日 The limestone crusher machine has jaw crusher, impact crusher, cone crusher, etc JXSC custom makes limestone crushing plant for different requirements to meet high efficiency, energysaving performance Limestone stone crusher plant equipped with mature rock crushers, which is very suitable for crushing limestone, malmstone and other materials2024年1月11日 The hammer crusher is a crushing processing equipment for limestone This equipment can replace the rough crushing process of the stone crusher, directly crushing limestone into particles below 25mm The hammer crusher adopts a dual motor operation, consisting of a plate hammer and a rotor to form a crushing powerLimestone Crushing And SandMaking Plant Eastman Rock The limestone crushing process is a complex operation that requires a variety of limestone crusher and additional equipment to produce the desired material for its various uses Understanding the characteristics of different limestone crushers and how they operate is crucial for designing an efficient limestone processing operationLimestone Crusher for Efficient Limestone Crushing PlantP¢ÂЊJ ¤jÄjtÐV µ‰Rl;vâ(£ÄÄÄ쎚„i Éà´¥>fJ (±bD£u£â‹©£"VÑ¡M\ á ¸=ç~»û=ö[È›v2Ó= ìÝ{îýν¿{Ï9÷^€€ $ H@ € $ H@¾÷ j6™¢ýø>v”I! ] Å‹ ²¡hl§ áñîºy€÷A¨« bRŽ²ÞQk?S”î9þ“)åu ¹TØv¼’¤“t QxßÕVk( þ@½[ } ‚lþÒU¯»ž( dxI½hÿÚ 9Hè Crushing

.jpg)

(PDF) Environmental Hazards of Limestone Mining and

2020年2月18日 Limestone is a fundamental raw material in various industrial sectors It is formed due to biochemical precipitation of calcium carbonate, and further compaction over long periods of time2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] crusher [4] The tie rod and compression spring ensure that the SIZE REDUCTION BY CRUSHING METHODS ResearchGate