What is the output of a ball mill with a diameter of 1.5 meters per hour

Ball Mill Design/Power Calculation 911Metallurgist

2015年6月19日 Ball Mill Power Calculation Example #1 A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns) The required product size distribution is to be 80% passing 100 mesh The balls are usually made of flint or steel and occupy between 30 and 50 per cent of the volume of the mill The diameter of ball used will vary between 12 mm and 125 mm and the optimum Ball Mill an overview ScienceDirect TopicsIn a ball mill circuit, the "output" can be defined as the production rate of fines of the circuit As for any output, ball mill circuit output is a function of both its inputs and efficiencies There are two MODULE #5: FUNCTIONAL PERFOMANCE OF BALL MILLING2016年2月14日 Do you need a quick estimation of a ball mill’s capacity or a simple method to estimate how much can a ball mill of a given size (diameter/lenght) grind for tonnage a product Small Ball Mill Capacity Sizing Table 911Metallurgist

.jpg)

Technical specifications and selection guide for ball mills

Some of the key technical specifications include: Diameter and Length: Ball mills are typically available in diameters ranging from 06 meters to 4 meters and lengths ranging from 15 Autogenous mills range up to 12 meters in diameter The lengthtodiameter ratios in the previous table are for normal applications For primary grinding, the ratio could vary between 1:1and AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Operator How to calculate the grinding efficiency of ball mills? Ball mill grinding efficiency can be calculated using the following equation: Efficiency = (100% Productivity) * 100 Efficiency = Ball mill Grinding efficiency of ball mill calculating equationBall mills give a controlled final grind and produce flotation feed of a uniform size Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear Ball Mill an overview ScienceDirect Topics

.jpg)

Ball mill Wikipedia

A ball mill is a type of grinder filled with grinding balls, used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It 2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process ControlThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mill an overview ScienceDirect TopicsOutput: 1200 T/H Applicable materials: various ores, goldsilvercopperiron various metal beneficiation, The composition of the ball mill The ball mill is composed of main parts such as feeding part, discharging and the Ball Mill SBM Ultrafine Powder Technology

Ball Mill Success: A StepbyStep Guide to Choosing the Right

2024年8月8日 In the intricate dance of ball milling, where raw materials are transformed into finely milled particles, the choice of grinding media emerges as a pivotal performance lever This seemingly minor selection can dramatically influence the efficiency of the milling process, the quality of the output, and, ultimately, the bottom line2019年8月14日 D—the inner diameter of the ball mill, M; N0 critical speed of revolutions, r /min When the nonsmooth ball mill liner is used, the grinding ball filling ratio is 4050%, and the grinding concentration is relatively large, the calculation result The Ultimate Guide to Ball Mills Miningpedia2023年5月29日 The cost of a ball mill with an output of 30 tons per hour can vary based on several factors The size and design of the mill, material of construction, motor power, and auxiliary equipment all How much does a ball mill with an output of 30 tons per hour2016年3月21日 Pulp Densities Pulp densities indicate by means of a tabulation the percentages of solids (or liquidtosolid ratio) in a sample of pulp This figure is valuable in two ways—directly, because for each unit process and operation in milling the optimum pulp density must be established and maintained, and indirectly, because certain important tonnage calculations are Common Basic Formulas for Mineral Processing Calculations

Ball mill characteristics and test conditions Mill Diameter, D

Download Table Ball mill characteristics and test conditions Mill Diameter, D (cm) 204 Length, L (cm) 166 Volume, V (cm 3 ) 5,423 Operational speed, Ν (rpm) 66 from publication 2020年3月10日 It’s called a “ball mill” because it’s literally filled with balls Materials are added to the ball mill, at which point the balls knock around inside the mill How a Ball Mill Works Ball mills work by using balls to grind materials Materials such as iron ore, pain and ceramics are added to the ball mill Next, the ball mill is What Is a Ball Mill? Blog Posts OneMonroeProductivity = Ball mill output per hour % Productivity = Ball mill output as a percentage of input What are the grinders used in a ball mill? Grinders are used in ball mills to reduce the size of the crushed material They rotate at high speed and follow a specific pattern, which helps to achieve a consistent particle sizeGrinding efficiency of ball mill calculating equationThe size reduction in the ball mill is a result of fragmentation mechanisms At a low speed, Fig1(a), the mass of the ball slides or rolls over each other with inefficient output Usually, the grinding media ball's weight is kept constant Ball Mill Principle, Construction, Working, and More

.jpg)

17 Signs of Problems with Ball Mills: Quickly

2023年2月15日 High temperature of the ball mill will affact the efficiency 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% 10% 4 when the moisture is greater than 5%, the ball mill will be unable to 2015年10月15日 A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside Calculate Ball Mill Grinding Capacity 911MetallurgistIn a ball mill circuit, the "output" can be defined as the production rate of fines of the circuit As for any output, ball mill circuit output is a function of both its inputs and efficiencies There are two "inputs" to a ball mill circuit: the ore fed to the circuit and the power delivered by the grinding millMODULE #5: FUNCTIONAL PERFOMANCE OF BALL MILLING2020年5月1日 Cement industry consumes a huge amount of electrical energy that is about 100 kWh/t (kWh per ton (10 3 kg) of cement) [16]In a cement plant, about twothirds of the total electrical energy is used for particle size reduction of raw materials and clinker [17]There is a diverse range of options to decrease the production expenses as well as CO 2 emissions that Energy and exergy analyses for a cement ball mill of a new

BALL MILLS Ball mill optimisation Holzinger Consulting

process Together with ball charge composition, both tools – liners and media – can be optimally adjusted for the application They can then fulfil the Figure 2: ball mill tools and comminution process Figure 1: ball mill communition process chain Ball charge management grinding Ventilation and cooling Operation and control2024年10月3日 The cylinder is the container that holds the ball mill grinding process together We size cylinders by their total volume when empty When selecting a cylinder, it’s important to pick a size that could potentially hold all of your grinding media, raw materials, and 25% of your total volume for processing space—what we consider the "working" area of the ball millUnderstanding the Parts of a Ball Mill Economy Ball MillMill performance is based on mill diameter and length only increases or decreases capacity The Slice Mill is simply a mill of the same diameter as the production mill but much shorter A Slice Mill of 72” diameter by 12” wide would replicate the result of Variables in Ball Mill Operation Paul O AbbeThe ball impact energy on grain is proportional to the ball diameter to the third power: 3 E K 1 d b (3) The coefficient of proportionality K 1 directly depends on the mill diameter, ball mill loading, milling rate and the type of grinding (wet/dry) None of the characteristics of the material being ground have any influence on K 1THE OPTIMAL BALL DIAMETER IN A MILL 911 Metallurgist

.jpg)

What is a Ball Mill Explained: InDepth Guide JXSC

2024年4月28日 Critical Speed: Critical speed is the hypothetical speed at which the centrifugal force is equal to the gravitational force, and the grinding media starts sticking to the inner shell of the equipment instead of falling freelyGrinding at or close to critical speed of the mill yields a poorer grinding efficiency The ball mills are mostly operated at 6575% of the critical speed to 2017年7月26日 The finer you crush, the higher your ball mill tonnage and capacity will be 911 Metallurgist is a trusted If we consider the crushing plant runs at an average of 100,000 kilowatt hours per 20hour day, the mill output will increase with this reduced size to approximately 77,000 tons per day The gain in production How Ball Mill Ore Feed Size Affects Tonnage Capacity2024年6月21日 There are multiple units of angular velocity, and the ones that we use in our angular velocity calculator are mentioned below: rad/s or radians per second — The definition comes straight out of the first angular velocity Angular Velocity CalculatorModeling And Simulation Of A Closed Loop Ball Mill Grinding Circuit Proceedings of IRF International Conference, Chennai, India, 20th April 2014, ISBN: 978938 10 II DYNAMICS OF THE BALL MILL GRINDING CIRCUIT product Blaine measured in cm²/g and the rejects Fig1 In a continuous ball mill grinding circuit, the ball millMODELING AND SIMULATION OF A CLOSED LOOP BALL MILL

.jpg)

Effect of ball and feed particle size distribution on the milling

Dry batchmillingtestswere performedin alaboratoryscale ball mill measuring 302 by 282cm The mill specifications are given in Table 1 A constant ball load of 20% was maintained in all the tests with a ratio of 05 for binary and 033 for trinary ball mix 21 Feed material preparation A quartz ore samplewas used in the experimental test 2020年11月16日 D = inside diameter of the mill in feet, In the following analysis capacity, T, is expressed in short tons per hour, tph, and power consumption, P, in kilowatts, kw Accordingly power consumption per unit of capacity, Po will be expressed in Ball Mill Capacity and Power Consumption Relationship to Mill Wave Ball Mill Shell Liners Wave liners are made with lifters and liner sections manufactured as one piece and are bolted in The mill's length is typically the same as its diameter Ball mills are extensively used in fields The maximum rod length typically reaches around 61 meters (20 feet), which limits the length, diameter, and Mills: What are they? How are Mills used? Advantages IQS O serviço do Google, oferecido sem custo financeiro, traduz instantaneamente palavras, frases e páginas da Web do português para mais de cem outros idiomasGoogle Tradutor

(PDF) Effects of Ball Size Distribution and Mill Speed and Their

2020年7月2日 A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls segregation in a 2023年7月10日 Ballend Mill: Ballend mills have a hemispherical bottom face The purpose of ballend mills in a vertical milling machine is to create rounded grooves Grooves for metal bearings in machines are commonly made with a ballend mill Chamfer Mill: Chamfer milling cutter is used for the edge treatment of the workpieceWhat is Milling: Definition, Process Operations2024年7月26日 9 kWh per day as the actual output A 500 W wind turbine has 12 kWh rated output (the total energy capacity) Since wind turbines are highly dependent on other factors such as wind strength, weather conditions, and many more, they can only produce up to 80% of their original rated output Wind Turbine Calculator2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process Control

.jpg)

Ball Mill an overview ScienceDirect Topics

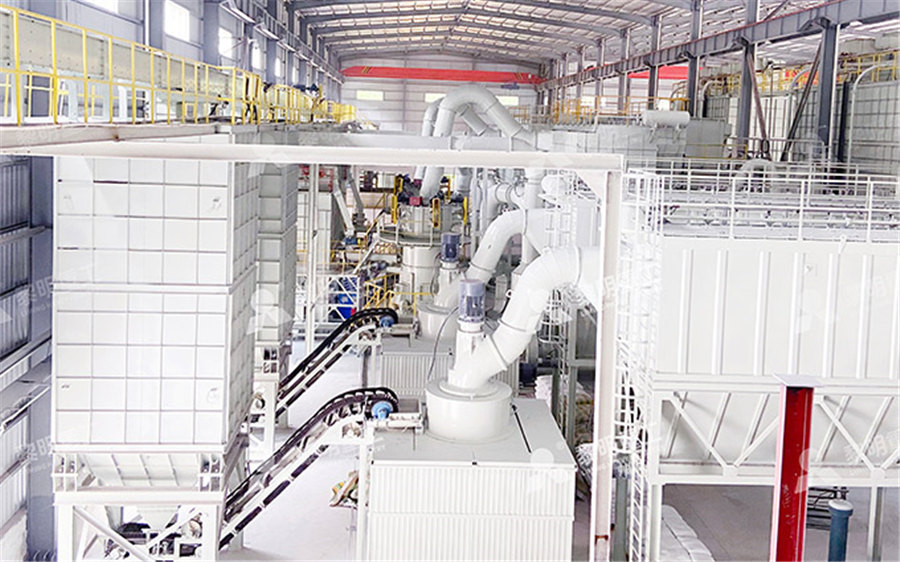

The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightOutput: 1200 T/H Applicable materials: various ores, goldsilvercopperiron various metal beneficiation, The composition of the ball mill The ball mill is composed of main parts such as feeding part, discharging and the Ball Mill SBM Ultrafine Powder Technology2024年8月8日 In the intricate dance of ball milling, where raw materials are transformed into finely milled particles, the choice of grinding media emerges as a pivotal performance lever This seemingly minor selection can dramatically influence the efficiency of the milling process, the quality of the output, and, ultimately, the bottom lineBall Mill Success: A StepbyStep Guide to Choosing the Right 2019年8月14日 D—the inner diameter of the ball mill, M; N0 critical speed of revolutions, r /min When the nonsmooth ball mill liner is used, the grinding ball filling ratio is 4050%, and the grinding concentration is relatively large, the calculation result The Ultimate Guide to Ball Mills Miningpedia

.jpg)

How much does a ball mill with an output of 30 tons per hour

2023年5月29日 The cost of a ball mill with an output of 30 tons per hour can vary based on several factors The size and design of the mill, material of construction, motor power, and auxiliary equipment all 2016年3月21日 Pulp Densities Pulp densities indicate by means of a tabulation the percentages of solids (or liquidtosolid ratio) in a sample of pulp This figure is valuable in two ways—directly, because for each unit process and operation in milling the optimum pulp density must be established and maintained, and indirectly, because certain important tonnage calculations are Common Basic Formulas for Mineral Processing CalculationsDownload Table Ball mill characteristics and test conditions Mill Diameter, D (cm) 204 Length, L (cm) 166 Volume, V (cm 3 ) 5,423 Operational speed, Ν (rpm) 66 from publication Ball mill characteristics and test conditions Mill Diameter, D 2020年3月10日 It’s called a “ball mill” because it’s literally filled with balls Materials are added to the ball mill, at which point the balls knock around inside the mill How a Ball Mill Works Ball mills work by using balls to grind materials Materials such as iron ore, pain and ceramics are added to the ball mill Next, the ball mill is What Is a Ball Mill? Blog Posts OneMonroe

Grinding efficiency of ball mill calculating equation

Productivity = Ball mill output per hour % Productivity = Ball mill output as a percentage of input What are the grinders used in a ball mill? Grinders are used in ball mills to reduce the size of the crushed material They rotate at high speed and follow a specific pattern, which helps to achieve a consistent particle size