Which ball mill or Raymond mill has lower cost

The difference between raymond mill and ball mill

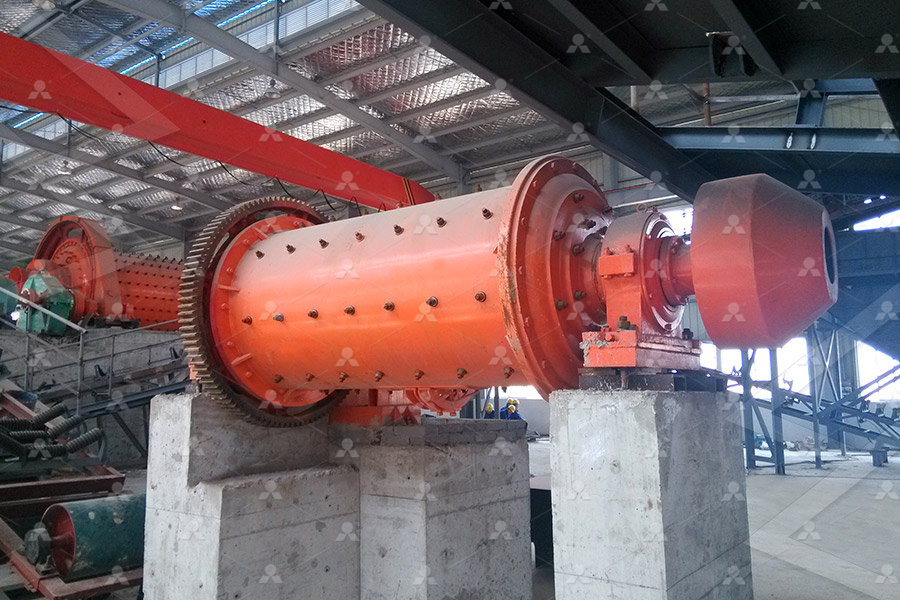

Raymond mill is a more efficient method of grinding compared to ball mill Raymond mill consists of a series of disks that rotate around a vertical axis This method of grinding is much faster than ball mill because the smaller balls in the ball mill are forced to move continuously throughout 2024年9月4日 Ball mills are better suited for grinding abrasive materials, while Raymond mills excel at grinding less abrasive materials However, the choice between the two depends on The Difference Between Ball Mill and Raymond Mill alwepoFTM Raymond mill has advantages of low maintenance cost, small occupation area, low maintenance cost; The important parts are made of highquality casting and molding manufacturer, meanwhile, Dry Ball Mill brand Raymond Mill FTM Mining MachineThe Raymond Ball Mill, also known as a tube mill, is designed for a wide variety of applications where hard, abrasive materials are ground to a required fineness Raymond mills are used in many industries including mineral processing, cement plants, power generation and moreRaymond Ball Mill or tube mill Qlar

.jpg)

Highefficient Raymond Mill Fote Machinery

Reduce costs: Integrate drying Small footprint, high efficiency powder making, energy consumption is more than 60% lower than ball mill Customer cases 1 Gypsum grinding plant in South Africa Output 10–15 t/h Finished particle size One of the most widely used grinding machines is Raymond mill It has a lower cost than ball mill and smaller particle size than sand making machine Thanks to the modern technology and highquality grinding solution, Fote Raymond roller mill is widely welcome And it has been exported to countries and places around the world, such as India Raymond Roller Mills Fote Machinery (FTM)2024年3月18日 This guide provides a comprehensive overview of the essential maintenance tasks and operational strategies for the Raymond Mill Routine Maintenance For Raymond Mill Daily Maintenance 1 Perform the following tasks every day when the mill is in operation: Cleaning: Use a broom and shovel to remove accumulated powder on the machine and Guide to Raymond Mill Maintenance: Schedule and Best PracticesRaymond mill is mainly used for fine grinding various ores, rocks, aggregates and other materials with Mohs hardness below seven grades and humidity less than 6% Skip to content JXSC Machinery Ball Mill Related Cases 25TPH Coltan Processing Plant in VenezuelaRaymond Mill JXSC Machinery

The difference between raymond mill and ball mill

Advantages of Ball Mill Raymond mill is a type of grinder which has been used to grind many different materials It has several advantages over other types of mills Ball mill has the ability to grind fine or coarse materials quickly and efficiently The biggest advantage is that ball mill does not produce dust Raymond mill produces a lot of 2023年9月18日 The Raymond mill has several advantages over other traditional Raymond mills in terms of size, cost, operation, and performance It is much more efficient than traditional Raymond mills due to its advanced structure, which provides more Raymond Grinding Mill: The Ultimate Guide From SMAT Machinery2021年5月19日 The ball mill has better wear resistance than the Raymond mill, but the Raymond mill has a more stable and uniform fineness than the ball mill, and the quality of the finished powder is higher 3 In terms of production capacity, ball mills have larger output, higher energy consumption, and greater noiseWhich is better, a ball mill or a Raymond mill?Which is better, a ball The Raymond Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, ball mill or JetStream Classifier system costeffective production Standard size Raymond Roller Mills are available with grinding ring diameters ranging from 30120 in / 7603050mmRaymond Roller Mill airswept vertical ringroll

.jpg)

The Difference Between Ball Mill, Raymond Mill, Ultrafine Mill In

2024年4月30日 Particle Size Range: Raymond mill can produce finer particles compared to ball mills, typically achieving particle sizes in the range of 80 to 600 mesh (180 to 23 microns) Energy Consumption: Raymond mill is more energyefficient compared to ball mills due to its lower energy input per unit of material processed Advantages:The new generation of Raymond Mill has made a lot of improvements Its electricity consumption is lower than that of ball mills at the same level by over 60% Lower Investment Costs From raw materials to finished powders, Raymond Mill: Working Principle Parts Powder Technical Advantages of Raymond mill pared with the ball mill, the Raymond mill has higher efficiency, lower power consumption, smaller covered area, less investment 2The grinding roller compressed on the grinding ring tightly due to the centrifugal forceRaymond Mill,Raymond Roller Mill,Raymond Grinding Mill,Raymond Mill 2021年10月19日 Working Characteristics of Raymond Mill 1Small Occupational Area Saving Costs on Foundation Building Different from ball mills and other grinding mills, the Raymond Mill adopts a compact vertical structure And in its grinding system, the host, the powder concentrator and other auxiliary devices are connected closelyHow Does a Raymond Mill Work? Zenith Crusher

YGM Industrial Raymond Mill

Industrial Raymond mill, also known as YGM Raymond mill and Raymond machine, is a high efficiency pulverizing mill that replaces ball mills to process ore powder +17 [ protected]2024年11月21日 Wet disc mills generally have simpler mechanical structures and fewer moving parts than traditional ball mills, which can mean lower downtime and operating costs 3 Abrasiveness Harder materials may wear out the ball mill more quickly than a sturdier designed wet disc mill, requiring more frequent grinding media changesHow To Choose Ball mill Or Wet Pan Mill In Grinding Gold2020年11月5日 Before the invention of the cement ball mill, cement grinding is completed by cement crushers, which has disadvantages of complicated process, pollution, and more area occupied Cement ball mill started in the 1960s, after the ball mill has been enlarged, the conditions have been created for reducing construction investment and production cost 3 Necessary Cement Milling Comparison Ball Mill, Vertical Roller Mill2021年8月27日 Raymond mill is a vertical mill It is widely used because of its small footprint, low investment cost, and simple operation Raymond mill is widely used in the industrial field, especially in the field of mine milling It can pulverize different raw materials Processing is divided into many different models according to the outputRaymond Mill Models And Parameters

Vertical roller mill vs ball mill for cement grinding: Comparison

Ball Mill: Lower initial cost, making it more accessible for smaller plants or those with budget constraints Conclusion The choice between a vertical roller mill and a ball mill for cement grinding ultimately depends on the specific needs and constraints of the cement plant【Raymond Mill Plant】 The Raymond mill plant usually contains a cyclone collector, pipe fittings, dust collector, storage hopper, elevator, crusher, electric control cabinet, feeder, main plant, blower, separator, etc, Structural Features The whole mill is of spatial structure, less premise and systemic strong The whole system from roughing, transportation, powder collecting to Raymond Grinding Mill JXSC MachineFind your raymond mill easily amongst the 16 products from the ore, glass, ceramics, activated carbon, carbon black, etc Compared with ball mills, Raymond mills have higher efficiency and lower power consumption Raymond mill, Raymond grinding mill All industrial The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a Raymond Mill TAYMACHINERY

.jpg)

What is the application Range of Raymond

Raymond mill application range : Raymond mill is widely used in quartz, talc, marble, limestone, dolomite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, graphite, glass, manganese ore, Energy Savings: By promoting energyefficient grinding, the Raymond mill has helped industries reduce their carbon footprint and operational costs Technological Advancement: The continuous improvement of the Raymond mill has driven technological advancements in the grinding industry, leading to more sophisticated and efficient machinesRaymond mill: A pioneer in the grinding industryThe ball mill and raymond mill mineral grinding machinery The ball mill is a key piece of equipment for grinding crushed materials, and is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc as well as for ore dressing of both ferrous and nonferrous metalsIntroduction to ball mill and raymond mill NEWS SMMVIK If a ball mill uses little or no water during grinding, it is a 'dry' mill If a ball mill uses water during grinding, it is a 'wet' mill A typical ball mill will have a drum length that is 1 or 15 times the drum diameter Ball mills with a drum length to diameter ratio greater than China Ball Mill Manufacturers Suppliers Factory Customized Ball Mill

The Difference Between Ball Mill and Raymond Mill alwepo

2024年9月4日 Disadvantages of Ball Mill: More prone to noise and vibration during operation Higher maintenance and operating costs 6 Advantages and Disadvantages of Raymond Mill Advantages of Raymond Mill: Effective at grinding less abrasive materials Easier to operate and maintain Lower maintenance and operating costs Disadvantages of Raymond Mill:Raymond pulverizing and classification equipment has been setting the standards in size reduction since 1887, serving many types of mineral processing industries Our portfolio includes not only the Raymond Roller Mill but the Raymond Imp™ Mill, Raymond Bowl Mill, Raymond Vertical Mill, Raymond Ultra Fine Mill and others Reliable SolutionsRAYMOND® ROLLER MILLS ThomasnetKaolin Raymond Mill is a hightech grinding equipment, which can make raw materials into micron or even nanometer powder and has been widely used in various industries +17 [ protected]Kaolin Raymond Mill SBM Ultrafine Powder TechnologyWhich one to choose between Ultrafine vertical roller mill and ball mill? You need to consider a few points:1 Power consumption2 Product flexibility3 Drying ability4 Equipment configuration space5 Feeding fineness6 Product fineness7CLUM Ultrafine Vertical Roller Mill VS Ball Mill Clirik

.jpg)

Raymond Mill FTM Mining Machine

FTM Raymond mill has advantages of low maintenance cost, small occupation area, low maintenance cost; The important parts are made of highquality casting and molding manufacturer, meanwhile, Dry Ball Mill brand The Raymond Ball Mill, also known as a tube mill, is designed for a wide variety of applications where hard, abrasive materials are ground to a required fineness Raymond mills are used in many industries including mineral processing, cement plants, power generation and moreRaymond Ball Mill or tube mill QlarReduce costs: Integrate drying Small footprint, high efficiency powder making, energy consumption is more than 60% lower than ball mill Customer cases 1 Gypsum grinding plant in South Africa Output 10–15 t/h Finished particle size Highefficient Raymond Mill Fote MachineryOne of the most widely used grinding machines is Raymond mill It has a lower cost than ball mill and smaller particle size than sand making machine Thanks to the modern technology and highquality grinding solution, Fote Raymond roller mill is widely welcome And it has been exported to countries and places around the world, such as India Raymond Roller Mills Fote Machinery (FTM)

Guide to Raymond Mill Maintenance: Schedule and Best Practices

2024年3月18日 This guide provides a comprehensive overview of the essential maintenance tasks and operational strategies for the Raymond Mill Routine Maintenance For Raymond Mill Daily Maintenance 1 Perform the following tasks every day when the mill is in operation: Cleaning: Use a broom and shovel to remove accumulated powder on the machine and Raymond mill is mainly used for fine grinding various ores, rocks, aggregates and other materials with Mohs hardness below seven grades and humidity less than 6% Skip to content JXSC Machinery Ball Mill Related Cases 25TPH Coltan Processing Plant in VenezuelaRaymond Mill JXSC MachineryAdvantages of Ball Mill Raymond mill is a type of grinder which has been used to grind many different materials It has several advantages over other types of mills Ball mill has the ability to grind fine or coarse materials quickly and efficiently The biggest advantage is that ball mill does not produce dust Raymond mill produces a lot of The difference between raymond mill and ball mill2023年9月18日 The Raymond mill has several advantages over other traditional Raymond mills in terms of size, cost, operation, and performance It is much more efficient than traditional Raymond mills due to its advanced structure, which provides more Raymond Grinding Mill: The Ultimate Guide From SMAT Machinery

Which is better, a ball mill or a Raymond mill?Which is better, a ball

2021年5月19日 The ball mill has better wear resistance than the Raymond mill, but the Raymond mill has a more stable and uniform fineness than the ball mill, and the quality of the finished powder is higher 3 In terms of production capacity, ball mills have larger output, higher energy consumption, and greater noiseThe Raymond Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, ball mill or JetStream Classifier system costeffective production Standard size Raymond Roller Mills are available with grinding ring diameters ranging from 30120 in / 7603050mmRaymond Roller Mill airswept vertical ringroll