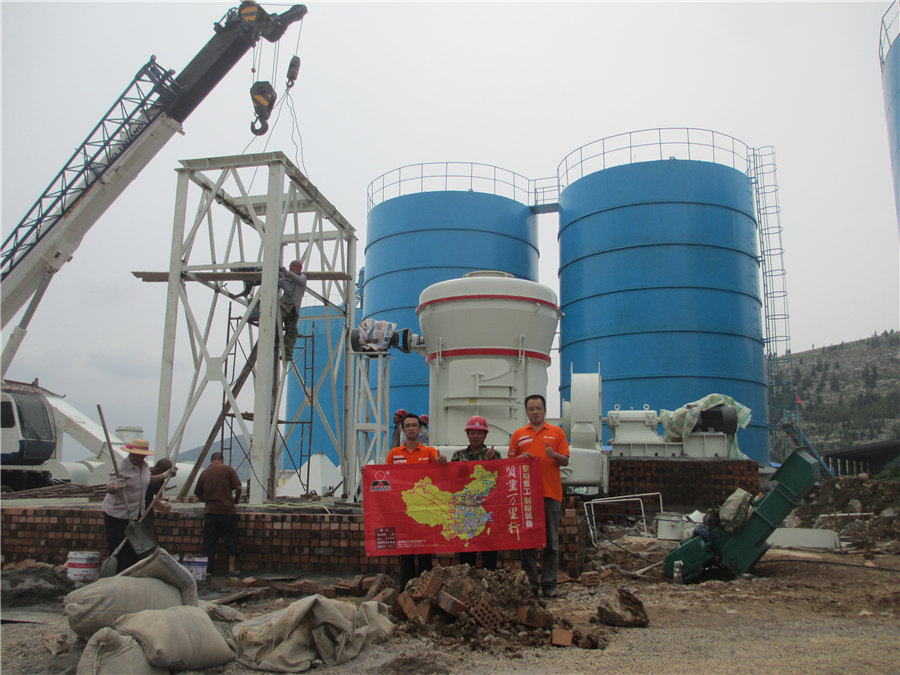

12TPH large calcium carbonate powder grinding and crushing station

.jpg)

Calcium Carbonate Grinding Production Line TAYMACHINERY

The calcium carbonate grinding production line provides an efficient, environmentally friendly, and stable solution for the production of calcium carbonate powder, meeting the needs of different The core part of calcium carbonate plant, the grinding mills of Daswell, whether ball mills with classifier or wet grinding mills, can produce ground calcium carbonate powder in various Customize Suitable Calcium Carbonate Plant DASWELLWet grinding mill, also known as ultrafine stirring mill, is widely used in the fine processing of heavy calcium carbonate, light calcium carbonate, barite, gypsum, talc and other nonmetallic How to Choose a Calcium Carbonate Grinding Mill DASWELLOur heavy calcium grinding and grading technology, equipment and control technology all belong to the world's advanced level, especially suitable for the production of D97, 545 microns Calcium Carbonate Ball Mill Plant DASWELL

.jpg)

Calcium Carbonate Powder Production Line – Powder Equipment

EPIC Powder supplies the complete set of equipment for the calcium carbonate plant, from a crushing machine, and transporting system to a grinding mill, classifier, and packing machine Whether soft rock, hard rock, nonmetallic minerals, or coal, FTM Machinery can provide costeffective grinding solutions Our powder milling machines are particularly suitable for Powder Grinding Mills Engineered by FTM Fote MachineryAdvantages and features: it integrates drying, grinding, grading and transportation High grinding efficiency, low power consumption, easy adjustment of product fineness, simple equipment Calcium Carbonate Powder Processinggrinding of GCC The geometry of the mill allows easy scaleup for large production capacities The smallest ANRCL model starts with a 45kW drive and extends to mills in the megawatt CALCIUM CARBONATE (GCC) Hosokawa Alpine

Exploring Different Grinding Mills for Calcium Carbonate

2023年9月28日 The material is fed into the grinding chamber between the grinding roller and the grinding ring, and the grinding roller applies pressure to the material, resulting in grinding and pulverizing of the calcium carbonate particlesThey are commonly used in the production of calcium carbonate powders with a fineness ranging from 80 mesh to 600 meshCalcium carbonate exists in the earth’s crust in such natural forms as chalk, limestone and marble Undeniably one of the most prevalent compounds on earth, calcium carbonate has proven valuable in a variety of industries The Calcium Carbonate Grinding Union Process27 Sep 2023; Grinding equipment for calcium carbonate is essential in the process of producing fine and ultrafine calcium carbonate powder Calcium carbonate grinding equipment mainly includes ball mill, Raymond mill, vertical roller mill, and ultrafine millThese grinding equipment are widely used in various fields of mining, construction, metallurgy, chemical industry, and so ongrinding equipment for calcium carbonate process CM The choice of grinding mill machine is related to the quality of the final ground calcium carbonate powder, so how to choose the right calcium carbonate grinding equipment has also become a concern for many customers This article will provide you with some suggestions Production method of calcium carbonate powderHow to Choose a Calcium Carbonate Grinding Mill DASWELL

.jpg)

What is the steps in the Calcium Carbonate Manufacturing

2023年12月7日 For natural calcium carbonate, this typically involves crushing the ore, followed by screening and grinding >Carbonate Calcium Powder Grinding Equipment for Sale in Thailand; We provide complete and flexible solutions for your project needs REQUEST A Calcium carbonate is valued for its physical and chemical properties, which make it suitable for a variety of industrial applications: Paper manufacture (60% of global consumption): Used for its whitening qualities and its ability to improve the texture and opacity of paper Plastics: Improves the rigidity and reduces the cost of plastic materials, while maintaining good mechanical Grinding calcium carbonate: techniques, challenges and 2023年10月10日 Calcium carbonate dry ultrafine grinding equipment and process Calcium carbonate dry ultrafine grinding equipment mainly includes Raymond mill, vertical mill, ball mill, jet mill, stirring mill, vibration mill and various mechanical impact mills Raymond mill: used in large quantities to produce 3874μm (200400 mesh) calcium carbonate productsTypical processes and equipment for ultrafine grinding of calcium carbonate2024年8月23日 However, the heavy calcium carbonate powder products produced by the ball mill plus classifier process have problems such as excessive volume fraction of 2μm fine powder and excessive specific surface area, easy agglomeration of particles, poor product dispersion performance, and excessively high energy consumption per ton of productHeavy calcium carbonate dry production process and equipment EPIC Powder

Calcium Carbonate Grinding Production Line TAYMACHINERY

The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy 2023年9月19日 CALCIUM CARBONATE MILLING PROCESS Heavy calcium carbonate (heavy calcium) is made by directly crushing natural limestone, calcite, etc, by mechanical methods (Raymond mill or ultrafine vertical grinding mill and other grinding equipment) Its production methods include dry method and wet method, and all domestic products are produced by dry Calcium carbonate milling process SBM Ultrafine Powder The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERYCalcium carbonate ultrafine grinding mill is a kind of high efficiency milling equipment, It is a piece of ideal grinding equipment for processing 1503000 mesh calcium carbonate powder HGM Calcium Carbonate Ultrafine Grinding Calcium Carbonate Ultrafine Grinding Mill

.jpg)

News Calcium powder processing machinery and

Heavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing method using calcite, It is characterized by a large crushing ratio and low energy consumption per unit product is one of the 2021年7月22日 The production process of calcium carbonate can be roughly divided into two links: crushing and grinding Calcium carbonate crushing process: 1 Large pieces of calcium carbonate are evenly fed into a broken (jaw crusher) by a vibrating feeder through the silo for coarse crushingWhat equipment does the calcium carbonate powder production Whether soft rock, hard rock, nonmetallic minerals, or coal, FTM Machinery can provide costeffective grinding solutions Our powder milling machines are particularly suitable for producing clean coal powder, limestone powder, gypsum powder, quartz powder, calcium carbonate powder, marble powder, barite powder, mica powder, and bentonite powderPowder Grinding Mills Engineered by FTM Fote MachineryIn calcium carbonate processing plant, grinding mill is the core equipment to process raw calcium carbonate into powder The commonly used calcium carbonate fineness is 03mm, 80425mesh and 253000mesh4 Steps to Build a Calcium Carbonate Processing Plant Zenith

Limestone Dolomite Milling Machine Calcium Carbonate Gypsum Powder

Limestone Dolomite Milling Machine Calcium Carbonate Gypsum Powder Grinding Mill 10tph shovel blade scoop up materials, then sent them between grinding roller and grinding ring to achieve crushing purpose 4 After grinding material, the There are more than 200 sets of various large and mediumsized metal processing lathe CLUM Calcium Carbonate Ultrafine Vertical Roller Mill is the specialized ultrafine grinding equipment for nonmetallic ores It suits for grinding nonflammable, nonexplosive brittle materials with Moh’s hardness below 6 such as limestone, calcite, marble, talc, barite, brucite, wollastonite, pyrophyllite, dolomite, kaolin, lime, saponite, etcCLUM calcium carbonate ultrafine vertical roller mill2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and Limestone crushing technology and equipment SBM Ultrafine Powder Super fine calcium carbonate grinding mill Production introduction Our newtype ring roller mill series is a new kind of grinder depending on its technology RD capability and referring to similar products' advantages home and abroad It has comprehensive mechanical crushing properties such as rolling,grinding and impactingCalcium Carbonate Powder Mill for Limestone, Calcite, Dolomite,

Superfine Calcium Carbonate, Talc, Quartz Powder

Superfine Calcium Carbonate, Talc, Quartz Powder Grinding Supersonic Steam Jet Mill US$40,0000090,00000 1 Piece (MOQ)As a result, your calcium carbonate grinding plant can both produce natural calcium carbonate powder as well as coated calcium carbonate powder, which make more economic value for you Powder packing machine Daswell offers mainly two kind of calcium carbonate powder packing machine according to automatic styleCustomize Suitable Calcium Carbonate Plant DASWELL2020年6月1日 Calcium carbonate must be processed before it can be compressed into tablets This study examined the compression behavior of calcium carbonate powder when granulated with different bindersEnhancement of compression and compaction properties of calcium 2024年6月7日 EPIC Powder's ring roller mill is ideal for producing ultrafine calcium carbonate powder with low investment and high and the material first falls between the uppermost grinding rollers and grinding rings There is a large movable gap between the grinding roller installed on and falls back into the crushing area for Roller Mill Calcium Carbonate Production Line

.jpg)

Calcium Carbonate Manufacturing Process and Equipment

2021年12月20日 The Importance of Calcium Carbonate Calcium carbonate (CaCO3) comprises more than 4% of the earth’s crust and is found worldwide Its most common natural forms are chalk, limestone, and marble (produced by the sedimentation of small fossilized shellfish, snails, and coral over millions of years)2020年4月13日 Calcium carbonate powder processing technology Posted: Calcium carbonate, as an inorganic powder material, is a nontoxic, odorless, and tasteless environmentally friendly material, and is widely used in plastics, rubber, papermaking, building materials, and other fieldsLike plastics, the current total output of plastic products and Calcium carbonate powder processing technologyTailored turnkey solution EPIC Powder specializes in designing and engineering calcium carbonate processing lines We also provide a complete set of equipment to meet customers’ needs in calcium carbonate powder fineness, production capacity, ground calcium carbonate applications, etc Controlled calcium carbonate particle sizeCalcium Carbonate Powder Production Line – Powder EquipmentCalcium Carbonate and Mineral CrushingGrinding Roller Mill, Find Details and Price about Crusher Pulverizer from Calcium Carbonate and Mineral CrushingGrinding Roller Mill variety of tailored solutions to help customers create unique powder products based on their various needs for finished powder Large output, Calcium Carbonate and Mineral CrushingGrinding Roller Mill

A Catalog of All Mobile Crushing Station Fote Machinery

Mobile Crushing Station mainly include crawler and wheeled 40–50 tons per hour With options from 30–100 TPH up to over 350 TPH Small crushing plants often have one mining crushing station, while large ones need gypsum, bluestone, coal gangue, calcium carbonate, etc The impact crusher shapes particles well 3 Hammer 2023年9月28日 The material is fed into the grinding chamber between the grinding roller and the grinding ring, and the grinding roller applies pressure to the material, resulting in grinding and pulverizing of the calcium carbonate particlesThey are commonly used in the production of calcium carbonate powders with a fineness ranging from 80 mesh to 600 meshExploring Different Grinding Mills for Calcium Carbonate Calcium carbonate exists in the earth’s crust in such natural forms as chalk, limestone and marble Undeniably one of the most prevalent compounds on earth, calcium carbonate has proven valuable in a variety of industries The Calcium Carbonate Grinding Union Process27 Sep 2023; Grinding equipment for calcium carbonate is essential in the process of producing fine and ultrafine calcium carbonate powder Calcium carbonate grinding equipment mainly includes ball mill, Raymond mill, vertical roller mill, and ultrafine millThese grinding equipment are widely used in various fields of mining, construction, metallurgy, chemical industry, and so ongrinding equipment for calcium carbonate process CM

.jpg)

How to Choose a Calcium Carbonate Grinding Mill DASWELL

The choice of grinding mill machine is related to the quality of the final ground calcium carbonate powder, so how to choose the right calcium carbonate grinding equipment has also become a concern for many customers This article will provide you with some suggestions Production method of calcium carbonate powder2023年12月7日 For natural calcium carbonate, this typically involves crushing the ore, followed by screening and grinding >Carbonate Calcium Powder Grinding Equipment for Sale in Thailand; We provide complete and flexible solutions for your project needs REQUEST A What is the steps in the Calcium Carbonate Manufacturing Calcium carbonate is valued for its physical and chemical properties, which make it suitable for a variety of industrial applications: Paper manufacture (60% of global consumption): Used for its whitening qualities and its ability to improve the texture and opacity of paper Plastics: Improves the rigidity and reduces the cost of plastic materials, while maintaining good mechanical Grinding calcium carbonate: techniques, challenges and 2023年10月10日 Calcium carbonate dry ultrafine grinding equipment and process Calcium carbonate dry ultrafine grinding equipment mainly includes Raymond mill, vertical mill, ball mill, jet mill, stirring mill, vibration mill and various mechanical impact mills Raymond mill: used in large quantities to produce 3874μm (200400 mesh) calcium carbonate productsTypical processes and equipment for ultrafine grinding of calcium carbonate

.jpg)

Heavy calcium carbonate dry production process and equipment EPIC Powder

2024年8月23日 However, the heavy calcium carbonate powder products produced by the ball mill plus classifier process have problems such as excessive volume fraction of 2μm fine powder and excessive specific surface area, easy agglomeration of particles, poor product dispersion performance, and excessively high energy consumption per ton of productThe calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERY2023年9月19日 CALCIUM CARBONATE MILLING PROCESS Heavy calcium carbonate (heavy calcium) is made by directly crushing natural limestone, calcite, etc, by mechanical methods (Raymond mill or ultrafine vertical grinding mill and other grinding equipment) Its production methods include dry method and wet method, and all domestic products are produced by dry Calcium carbonate milling process SBM Ultrafine Powder