Internal structure diagram of rotating drum mtw178G European version grinding mill

.jpg)

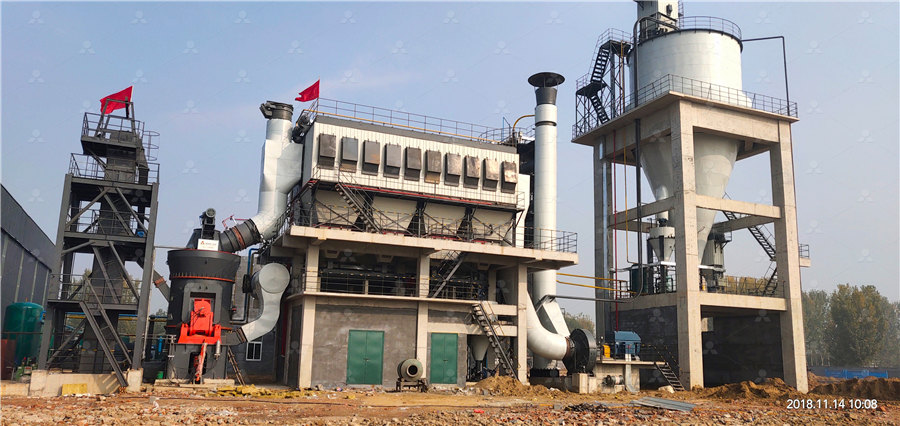

Raymond mill, raymond grinding mill, MTW European Type

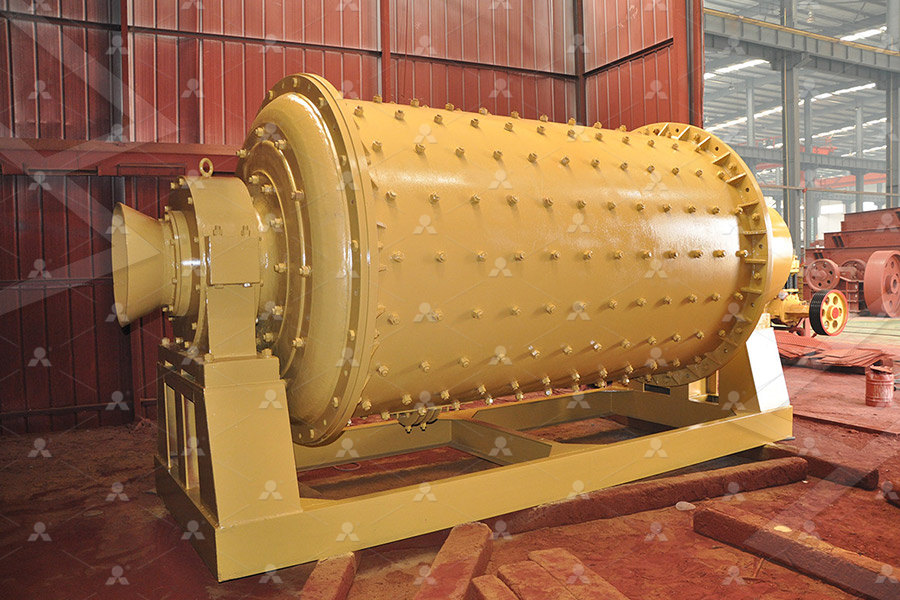

Raymond mill, widely used in minerals grinding process of metallurgy, building materials, chemicals, mining and other fields, is suitable for processing various nonflammable and non A large variety of flow regimes is observable in rotating drums, which are easiest to explain by considering different rotation speeds For low rotation speeds, individual avalanches are 7 Rotating Drum2015年10月1日 We conducted a verity of DEM simulations in rotating drums to investigate velocity profile and circulation time – as two important parameters in the design and scaleup Insights into the granular flow in rotating drums ScienceDirectThe drum mills are used for fine and ultrafine grinding of brittle materials Discontinuous operated drum mills make, in addition to size reduction, homogenization of the material to be ground For fine and ultrafine grinding SIEBTECHNIK TEMA

Rotating Drums an overview ScienceDirect Topics

Rotating drums are widely used in various industries for various purposes A comprehensive understanding of the flow of particles in a drum under different conditions is essential for According to the ways by which motion is imparted to the charge, grinding mills are generally classified into two types: tumbling mills and stirred mills In tumbling mills, the mill shell is Grinding Mill an overview ScienceDirect Topics2023年7月4日 Structure diagram of vertical roller mill Working principle: the motor drives the grinding table to rotate through the reducer, the material falls into the center of the grinding Roller Mill SpringerLink we will explore the effects of both the rice sieve and the rotating roller on the milling performance Figure 1 c represents a hexagonal sieve made of two identical sheet metal plates(a) Diagram of a rice mill machine (b) The crosssection profile of

Rotating drum SpringerLink

2007年1月1日 Rotating drum In: Pattern Formation in Granular Materials Springer Tracts in Modern Physics, vol 164 Springer, Berlin, Heidelberg https://doi/101007/BFb 2021年5月5日 Today we will study the Definition, Parts, Working Principle, Operation, Advantages, Application of the Grinding machine in detail Lets start with the definition first,Grinding Machine: Definition, Parts, Working Principle, Operation Download scientific diagram Internal view of a twochamber ball mill from publication: Radiotracer Investigation of Clinker Grinding Mills for Cement Production at Ghacem Radiotracer Internal view of a twochamber ball mill ResearchGateDrum mills have a horizontal grinding drum rotating around a fixed center of rotation Located in this cylindrical working space is a grindingmedia filling, which is tumbled by the rotating grinding drum The material fed is pulverized by the Drum mills by SIEBTECHNIK TEMA Comminution

Grinding Machine: Definition, Parts, Working

2021年5月5日 Internal and External Grinding: In an internal grinding, a small wheel is used to grind the inside diameter of the part, such as bushings and bearing races The workpiece is held in a Rotating Chuck The headstock of 2019年1月1日 A grain size reduction hammer mill for crushing corn (Zea mays L) was designed depending on variety characteristics and by using computer aided design “ANSYS” softwareDesign and Evaluation of Crushing Hammer mill ResearchGateFind your rotary drum mill easily amongst the 99 products High operational reliability, stable performance, simple structure and easy maintenance Model system that has achieved truly interesting results The "Magellano" series laboratory mill, uses a planetary type rotating system where up to 4 grinding containers (jars Rotary drum mill, Rotary drum grinding mill All industrial June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process:

Grinding Mills and Their Types – IspatGuru

2015年4月9日 Some mills are compartmentalized with each subsequent section having a smaller ball size The material can pass through to the proceeding section, but the balls cannot This ensures that the smaller particles are attacked by the smaller grinding media Ball mill is a versatile grinding mill and has a wide range of applicationsLayered LiNi04Mn04Co018Ti002O2 cathode powders were ballmilled for various lengths of time The structural properties of the pristine and milled powders, which have different particle sizes Schematic diagram of the planetary ball mill2013年12月23日 The drum is rotating with low speed (ie 1637 RPM) inside the mill Spout and motor is entered with the help of horizontal and inclined rail Drive is given to spout feeder with the help of motorDesign of a typical Autogenous Mill: PartII ResearchGateDownload scientific diagram Schematic diagram of the cylindrical grinding process from publication: Measuring strain during a cylindrical grinding process using embedded sensors in a workpiece Schematic diagram of the cylindrical grinding process

Raymond mill, raymond grinding mill, MTW

Raymond mill, widely used in minerals grinding process of metallurgy, building materials, MTW European Type Trapezium Mill this model adopts a number of new patented technologies such as bevel gear integral transmission, Download scientific diagram Schematic diagram of a drum with Lshaped lifters Parameters including rotating speed (n), lifter number (LN), lifter height (LH) and lifter width (LW) is considered Schematic diagram of a drum with Lshaped liftersDownload scientific diagram Drawing of the basic structure of a roller mill with two rotating/counterrotating rollers (crosssection) from publication: A study of operating parameters of a Drawing of the basic structure of a roller mill with two placed Furthermore, the internal surface of the drum can be equipped with lifters to raise the grinding media to higher heights The aim of the lifters is to promote the breakage of the mineral by impact of the collisions with these bodies (Rezaeizadeh et al 2010) The rotating drums may present dierent ow regimesExperimental study of clinker grinding in a ball mill and the

Schematic illustration of a tumbling mill Download Scientific Diagram

He shows that Kick's law is reasonably accurate in the crushing range above about 1 cm in diameter; Bond's theory applies reasonably in the range of conventional rodmill and ballmill grinding Download scientific diagram Snapshots of a rotating drum simulation for different numbers of rotations n for ω = 524 rad/s The color is proportional to the damage, defined by the number of Snapshots of a rotating drum simulation for different numbers of 2018年4月18日 These studies have been important in a coordinated optimization program for mill heads, shells and trunnion bearings Mill Shells require a similar but more complicated program for stress and deflection analysis Often, depending on the load concentration and mill length, special shell designs are required An example is shown on Figure 5SAG Mill Components 911MetallurgistThe focus of the current investigation is to study the influence of particles’ shape on segregation of bidisperse mixture of particles in a rotating drumSchematic diagram of active and passive regions in a rotating drum

.jpg)

Grinding Mill an overview ScienceDirect Topics

A crushing plant delivered ore to a wet grinding mill for further size reduction The size of crushed ore (F 80) was 40 mm and the SG 28 t/m 3 The work index of the ore was determined as 122 kWh/t A wet ball mill 1 m × 1 m was chosen to grind the ore down to 200 micronsUsing F AE−T and F I rms , the performance is reduced to 95 to 97% Consequently, a reliable classification of grinding burn is possible using only features from one of the three sensor Table 6 Schematic diagram of the grinding machine and instrumentation2022年4月16日 The vital structure, concerned with the excellence of machining for this grinding machine, is of the internal grinding tool because of the length of more than 900 mm and the complicated design of the structure with a restricted outer dimension The tool structure is constructed and also carried out through a separate stiffness analysisModeling and Design Analysis of a Deep Hole Internal Grinding 2022年1月1日 Sasahara et al [20] developed a cuptype vitrified bonded grinding wheel, as is Fig 2 (a) showed, which can provide coolant from the inside of the grinding wheel and carried out the experiment of grinding CFRPResults found that the grinding temperature and surface roughness were reduced Peng et al [23] prepared two pressurized internal cooling grinding Design and evaluation of an internalcooling grooved grinding

.jpg)

14 Types of Grinding Machines [Working, Diagram

2021年11月23日 This is a small grinder operated with electric power It can be easily carried anywhere Grinding can be done by holding it in hand It is used for cleaning heavy welding jobs On one end of the motor shaft, a grinding wheel Download scientific diagram (a) Schematic diagram of the rotating drum; (b) rolling mode of particles' motion in a transverse plane of the rotating drum; and (c) mesh of the transverse plane (a) Schematic diagram of the rotating drum; (b) rolling mode of Nanofibers provide a lot of opportunities for changing things physically and chemically during or after the production process to give them new features [1; 2]Various types of collectors (a: rotating drum, b: rotating wire drum 2017年3月4日 These are grinding and pulverizing machines consisti ng of a shell or drum rotating on a horizon tal axis The material to be reduced in size is fed into one end of the mill SIZE REDUCTION BY GRINDING METHODS ResearchGate

.jpg)

Grinding Mills — Types, Working Principle Applications

2018年8月17日 Further, the grinding mills can be categorized into three major types — rod mills, ball mills, and SAG mills So, which one is for you? Well, the answer essentially lies in the feed size and the Find your rotary drum mill easily amongst the 99 products from the construction material, ceramics Working Principle The ball mill is a horizontal rotating device transmitted by the outer gear The materials are Compare this A compact benchtop grinding mill with powerful and shear crushing capabilities IQ MILL2070 makes the Rotary drum mill, Rotary drum grinding mill All2020年3月1日 A deep understanding of the granular behavior is of fundamental importance towards the design and optimization of any industrial processes, such as drying, granulation, mixing, and milling [1,2]Experimental study and DEM analysis of granular segregation in a 2021年6月17日 Due to its strong lifting capacity and excellent grinding performance, the trapezoidal liner is widely used in the SAG mill The structure of the trapezoidal liner is shown in Fig 1, the main dimensions are: dip angle \(\tau\), length of the top edge \(L\) and height \(h\)Dip angle \(\tau\) determines the trajectory of the mediums in the SAG mill, which directly affects PARAMETER OPTIMIZATION OF LARGE SAG MILL LINER BASED

.jpg)

Internal view of a twochamber ball mill ResearchGate

Download scientific diagram Internal view of a twochamber ball mill from publication: Radiotracer Investigation of Clinker Grinding Mills for Cement Production at Ghacem Radiotracer Drum mills have a horizontal grinding drum rotating around a fixed center of rotation Located in this cylindrical working space is a grindingmedia filling, which is tumbled by the rotating grinding drum The material fed is pulverized by the Drum mills by SIEBTECHNIK TEMA Comminution 2021年5月5日 Internal and External Grinding: In an internal grinding, a small wheel is used to grind the inside diameter of the part, such as bushings and bearing races The workpiece is held in a Rotating Chuck The headstock of Grinding Machine: Definition, Parts, Working 2019年1月1日 A grain size reduction hammer mill for crushing corn (Zea mays L) was designed depending on variety characteristics and by using computer aided design “ANSYS” softwareDesign and Evaluation of Crushing Hammer mill ResearchGate

Rotary drum mill, Rotary drum grinding mill All industrial

Find your rotary drum mill easily amongst the 99 products High operational reliability, stable performance, simple structure and easy maintenance Model system that has achieved truly interesting results The "Magellano" series laboratory mill, uses a planetary type rotating system where up to 4 grinding containers (jars June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process: 2015年4月9日 Some mills are compartmentalized with each subsequent section having a smaller ball size The material can pass through to the proceeding section, but the balls cannot This ensures that the smaller particles are attacked by the smaller grinding media Ball mill is a versatile grinding mill and has a wide range of applicationsGrinding Mills and Their Types – IspatGuruLayered LiNi04Mn04Co018Ti002O2 cathode powders were ballmilled for various lengths of time The structural properties of the pristine and milled powders, which have different particle sizes Schematic diagram of the planetary ball mill

Design of a typical Autogenous Mill: PartII ResearchGate

2013年12月23日 The drum is rotating with low speed (ie 1637 RPM) inside the mill Spout and motor is entered with the help of horizontal and inclined rail Drive is given to spout feeder with the help of motorDownload scientific diagram Schematic diagram of the cylindrical grinding process from publication: Measuring strain during a cylindrical grinding process using embedded sensors in a workpiece Schematic diagram of the cylindrical grinding process