How to distinguish the quality of fly ash

Fly ash properties, characterization, and applications: A review

2021年9月1日 Fly ash (FA) is the principal industrial waste byproduct from the burning of solid fuels FA is a powdery solid that is constituted mostly of unburned carbon (UC), metal oxides (Si, Fe, Ca, and Al), and other inorganic substances UC is an inexpensive source of activated 2019年12月1日 Fly ash is used as a supplementary cementitious material (SCM) to produce Portland cement concrete Fly ash when used as SCM contributes to properties of hardened Physical, chemical, and geotechnical properties of coal fly ash: A 2018年6月30日 Fly ash is applied widely in concrete Therefore, the quality of fly ash plays a critical role in altering the compressive strength of concrete As Methods to Characterize Fly Ash Quality in the Field2021年7月1日 Fly ash (FA) is the principal industrial waste byproduct from the burning of solid fuels FA is a powdery solid that is constituted mostly of unburned carbon (UC), metal oxides Fly Ash properties, characterization, and applications: a review

.jpg)

Methods to Characterize Fly Ash Quality in the Field

2018年6月8日 Fly ash is applied widely in concrete Therefore, the quality of fly ash plays a critical role in altering the compressive strength of concrete As the fact, it is necessary to 2017年11月2日 Fly ash is a byproduct of coal burning and is widely used as a substitute for cement material The advantages of using fly ash in concrete include the improvement of workability and(PDF) Consistency of fly ash quality for making high 2018年9月1日 To realize sustainable development and beneficial use of fly ash in the construction industry, this paper presents a comprehensive review of relevant literature to Characteristics and applications of fly ash as a sustainable Light color fly ash represents good quality ash as compared to black or dark color fly ash (EPA ) The color gives a broad idea about the quality and composition of the fly ash acts as a State of the art review on physiochemical and engineering

.jpg)

Fly ash quality, past, present and future, and the effect of ash on

2002年2月18日 In recent years, there has been increasing interest in the processing of boiler fly ashes to improve ash quality and consistency, and in the manufacture of high‐value secondary Coal fly ash (CFA) is a coal ignition buildup at thermal power plants, which has been viewed as a hazardous waste globally The major problems with CFA are the large volume of land needed for its disposal and poisonous weighty metal Full article: A comprehensive review on coal fly ash and 2019年12月1日 There has been an increasing attempt for fly ash utilization in different sectors Loya and Rawani [5] identified top areas for the quantity of fly ash utilization as 4419% in cement and concrete sectors, 1525% of ash in roads, embankments and ash dyke raising, followed by 1249% in reclamation of low lying areas and land filling, 884% in mine filling, 761% in bricks, Physical, chemical, and geotechnical properties of coal fly ash: 2021年9月1日 The dispersion of fly ash in water results in an alkaline pH from 10 to 13 At high pH, the fly ash becomes negatively charged allowing the removal of heavy metal ions by precipitation and electrostatic adsorption from water (Cho et al, 2005) Fly ash can be modified or transformed into new materials for heavy metal ions adsorptionFly ash properties, characterization, and applications: A review

.jpg)

(PDF) Exploring the Viability of Fly Ash Bricks as an

2023年3月1日 Fly ash, which is recovered from the gases produced when coal is burned to produce power, is essentially a fine glass powder Fly ash is a siliceous substance that has an amorphous or glassy bulk Coal fly ash (CFA) which is a waste obtained from the coal ignition buildup at thermal power plants which has been viewed as a very dangerous waste globally Though specific gravity does not influence the concrete quality, it is good to distinguish changes in other CFA propertiesFull article: A comprehensive review on coal fly ash and its Physical Properties of Fly Ash The physical properties of fly ash are, 1 Fineness of Fly Ash As per ASTM, the fineness of the fly ash is to be checked in both dry n wet sieving The fly ash sample is sieved in 45 micron sieve and the percentage of retained on Fly Ash – Properties, Types, Mechanism and Uses2016年11月1日 Fly ash is one of the most common waste materials created by burning of coal It is composed of smaller particles, consisting mainly of aluminosilicateglass, mullite and quartz, which are (PDF) Laboratory testing of fly ash ResearchGate

.jpg)

The Difference Between Fly Ash and Bottom Ash Powder Bulk

2023年5月24日 The two ash types are distinguished by their physical properties Fly ash is a fine powdery material, while bottom ash is a coarser, heavier material Composition of Fly Ash and Bottom Ash FLY ASH Fly ash is composed of tiny particles of ash carried up the smoke stack by the hot gasses created during coal burning2023年2月11日 Fly ash powder affects the environment, but it has a different direct impact on the human body Figure 5 summarizes the effects of fly ash powder on the environment and the human body The figure shows that due to rain in the landfill and ash ponds leads to the leaching of various toxic metals such as lead, cadmium, arsenic, mercury, etc, pollutes the A Review of Coal Fly Ash Utilization to Save the Environment2021年1月16日 Fly ash (FA) is burning coal product which is used as supplementary cementitious materials (SCM) as the conjunction with cement The use of FA is considered by its pozzolanic properties ie SiO 2 Effect of fly ash to watercement ratio on the characterization of 2015年2月6日 For instance, a 2009 study, “Fly Ash Properties and Mercury Sorbent Affect Mercury Release from Curing Concrete,” performed by chemists at Ohio State University, discovered that concrete made with a 55% fly ash replacement emitted basically the same trace amount of mercury vapor during curing as concrete made without fly ash, according to Alan The Truth About Fly Ash Green Builder Media

.jpg)

A Comprehensive Guide on How to Make Fly Ash Bricks

2024年9月23日 The use of cement enhances the durability of fly ash bricks It makes them resistant to weathering and harsh chemicals Fly Ash Brick Manufacturing Process The manufacturing process of fly ash bricks involves a series of controlled steps It transforms industrial waste into highquality construction material Fly ash is collected and processedFigure 1 shows fly ash produced in a typical pulverizedcoalfired utility boiler and collected by an electrostatic precipitator There are two commonly used methods for removing the fine powdery fly ash from the fly ash hopper of the precipitator – a wet method or a dry method [12–15]In the wet method, water is used to flush the fly ash out of the hoppers and the ash slurry is pumped Fly Ash SpringerLink2017年11月2日 Several rapid tests on determining the quality of fly ash had been suggested [11], ie, lossonignition (LOI), pH, percent retained on sieve #325 (45 µm), and normal consistency(PDF) Consistency of fly ash quality for making high 2009年7月1日 The most important physical and chemical properties of the bottom ash and fly ash are given in Table 1The pH of the ashes was strongly alkaline According to Van Herck and Vandecasteele [9], an alkaline pH indicates that part of the dissolved metals in the ash occur as basic metal salts, oxides, hydroxides and/or carbonatesThe XRD patterns in Fig 1 show clear Comparison of the characteristics of bottom ash and fly ash from

.jpg)

Use of Flyash in Agriculture: A Way to Improve Soil Fertility and its

2010年1月14日 Flyash production depends on the quality of the coal, which contains a relatively high proportion of ash that leads to 1030% Flyash formation (Singh and Siddiqui, 2003)In India 75% of electricity is generated by coal based thermal power plants, according to the data revealed in Table 1, provided by Government of India 112 million tones of this kind of waste is Fly ash is a coal combustion productIt is part of a set of products that makes up the most abundant waste materials worldwide If not collected, this waste material is blown out with the flue gas in a coal fired power plantFly ash exists after combustion because ash adheres to coal, making up between 115% of its weight About 90% of the ash is fly ash, while 10% is bottom Fly ash Energy Education2002年1月1日 Tomato plants (Solanum lycopersicum L) were developed in soils with different fly ash (FA) amendments (25, 50, 75, 100% FA) to measure the effects of FA on metal accumulation , chlorophyll Impacts of flyash on soil and plant responses ResearchGate2022年8月11日 According to a survey by the American Coal Ash Association (ACAA), approximately 69 million tons of fly ash were produced in the US in 2020, impacted, of course, by the COVID19 pandemic Of this, nearly 40 million tons were used in concrete and other applications, with more than half kept out of landfillsFly Ash and Innovation in Concrete CarbonCure

.jpg)

Fly Ash Bricks Mixing Proportion – 3 Important Formulas

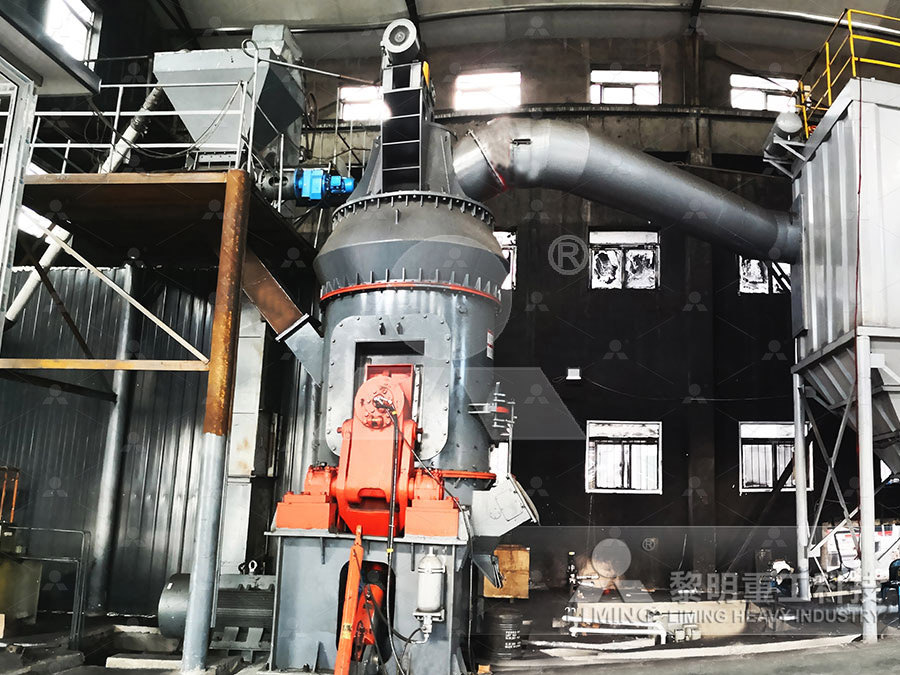

2013年8月15日 Sludge lime is normally wet and has lumps, However it can be used to make quality fly ash bricks 2 Mix Proportion For Fly Ash Bricks manufacturing – (Here Hydrated Lime is used instead of Sludge Lime) Fly ash – 57 to 65% River Sand or Stone dust – 18 to 27%2018年9月1日 The main purpose of this work is to provide a comprehensive review of fly ash as a construction material To achieve this goal, this literature review uses the following five steps: (1) Selecting review topics as follows: characterization, compositional understanding, activation approaches, nanotechnology applications, durability and sustainability evaluations of fly ash or Characteristics and applications of fly ash as a sustainable Operating system: Windows; Pricing: Free; Developer: hit00; ChipGenius is designed to help users extract information about their USB devices It helps find out the actual capacity of a USB device and is particularly useful when a flash Fake Flash Test: 7 Free Tools to Check Real Capacity2023年5月27日 The wet fly ash has to be dried to have economic value The wet fly ash is fed into a rotary dryer with burners After passing through the dryer, the dried material is discharged onto a conveyor belt for further sorting, How to Process Fly Ash and What Is It Used for? Fote

.jpg)

(PDF) The maximum percentage of fly ash to replace

2017年11月14日 In the current global trend of sustainable construction, the utilization of industrial byproduct such as fly ash (FA) for concrete to reduce the production of ordinary Portland cement (OPC) has 2022年9月5日 Class N natural pozzolan and class F fly ash were utilized in this investigation The properties of portland cement and SCMs are presented in Table 1, Table 2The cumulative grain size distribution curve of Natural pozzolan and fly ash are presented in Fig 1The utilized natural pozzolan, was obtained from a vitrified rhyolite deposit near Dayton, NevadaA comparative study of natural pozzolan and fly ash: Investigation 2022年1月1日 PDF Fly ash is a byproduct derived from coalfired thermal power plants and is being produced abundantly The scarcity of quality construction materials and the ever increasing waste produc(PDF) Fly ash in road construction ResearchGate2017年6月27日 Figure 13: Typical ash colors Quality of Fly Ash Quality requirements for fly ash vary depending on the intended use Fly ash quality is affected by fuel characteristics (coal), cofiring of fuels (bituminous and subbituminous coals), and various aspects of the combustion and flue gas cleaning/collection processesChapter 1 Fly Ash An Engineering Material Fly Ash Facts for

Impact of Fly Ash Placement in an Abandoned Opencast Mine on

2019年1月5日 We investigated potential contamination of surface and ground water due to placement of fly ash in an abandoned area of an active opencast mine Leachates from the fly ash and pond ash did not exceed the effluent discharge limits for inland surface water Even though iron was one of the major components of the ash, it did not exceed 03 mg/L in the leachates 2022年3月1日 To resolve the limited largescale methods of disposal of low calcium fly ash with poor activity, based on the double excitation principle, clinker and desulfurized gypsum are used as alkali/salt activators to activate fly ash and slag, avoiding the inconvenience of strong alkali activating fly ash in industry Firstly, the strength test of a filling body with multiple ratio The Ratio Optimization and Strength Mechanism of CompositeDownload scientific diagram Chemical Composition of Fly Ash 117 from publication: Suitability of Sarawak and Gladstone fly ash to produce geopolymers: A physical, chemical, mechanical Chemical Composition of Fly Ash 117 ResearchGateHelp in the recruiting of workers, employee motivation, quality of workalike, employee coaching, etc Personality domain Conduct research focused on identifying personality traits, measuring these traits, and determining how these traits interact in a particular context to determine how a person will behave in any given situation1E Distinguish the different domains of psychology

Physical, chemical, and geotechnical properties of coal fly ash:

2019年12月1日 There has been an increasing attempt for fly ash utilization in different sectors Loya and Rawani [5] identified top areas for the quantity of fly ash utilization as 4419% in cement and concrete sectors, 1525% of ash in roads, embankments and ash dyke raising, followed by 1249% in reclamation of low lying areas and land filling, 884% in mine filling, 761% in bricks, 2021年9月1日 The dispersion of fly ash in water results in an alkaline pH from 10 to 13 At high pH, the fly ash becomes negatively charged allowing the removal of heavy metal ions by precipitation and electrostatic adsorption from water (Cho et al, 2005) Fly ash can be modified or transformed into new materials for heavy metal ions adsorptionFly ash properties, characterization, and applications: A review2023年3月1日 Fly ash, which is recovered from the gases produced when coal is burned to produce power, is essentially a fine glass powder Fly ash is a siliceous substance that has an amorphous or glassy bulk (PDF) Exploring the Viability of Fly Ash Bricks as an Coal fly ash (CFA) which is a waste obtained from the coal ignition buildup at thermal power plants which has been viewed as a very dangerous waste globally Though specific gravity does not influence the concrete quality, it is good to distinguish changes in other CFA propertiesFull article: A comprehensive review on coal fly ash and its

Fly Ash – Properties, Types, Mechanism and Uses

Physical Properties of Fly Ash The physical properties of fly ash are, 1 Fineness of Fly Ash As per ASTM, the fineness of the fly ash is to be checked in both dry n wet sieving The fly ash sample is sieved in 45 micron sieve and the percentage of retained on 2016年11月1日 Fly ash is one of the most common waste materials created by burning of coal It is composed of smaller particles, consisting mainly of aluminosilicateglass, mullite and quartz, which are (PDF) Laboratory testing of fly ash ResearchGate2023年5月24日 The two ash types are distinguished by their physical properties Fly ash is a fine powdery material, while bottom ash is a coarser, heavier material Composition of Fly Ash and Bottom Ash FLY ASH Fly ash is composed of tiny particles of ash carried up the smoke stack by the hot gasses created during coal burningThe Difference Between Fly Ash and Bottom Ash Powder Bulk 2023年2月11日 Fly ash powder affects the environment, but it has a different direct impact on the human body Figure 5 summarizes the effects of fly ash powder on the environment and the human body The figure shows that due to rain in the landfill and ash ponds leads to the leaching of various toxic metals such as lead, cadmium, arsenic, mercury, etc, pollutes the A Review of Coal Fly Ash Utilization to Save the Environment

Effect of fly ash to watercement ratio on the characterization of

2021年1月16日 Fly ash (FA) is burning coal product which is used as supplementary cementitious materials (SCM) as the conjunction with cement The use of FA is considered by its pozzolanic properties ie SiO 2 2015年2月6日 For instance, a 2009 study, “Fly Ash Properties and Mercury Sorbent Affect Mercury Release from Curing Concrete,” performed by chemists at Ohio State University, discovered that concrete made with a 55% fly ash replacement emitted basically the same trace amount of mercury vapor during curing as concrete made without fly ash, according to Alan The Truth About Fly Ash Green Builder Media