HOME→How many ore grinding mills from China should be equipped with 1314's prepowdered vertical grinding powder vertical grinding fine sand powder equipment

How many ore grinding mills from China should be equipped with 1314's prepowdered vertical grinding powder vertical grinding fine sand powder equipment

Energy Use of Fine Grinding in Mineral Processing

Fine grinding is usually performed in highintensity stirred mills; several manufacturers of these stirred mills exist Two frequently used stirred mills include the Isamill, produced by 展开CITIC HIC grinding mills are recognized as China's Manufacturing Industry Single Champion Product CITIC HIC is responsible for setting the national standards of semiautogenous mills Grinding Mills Mineral Processing Equipment CITIC HIC2017年9月1日 The objective of this work is to assess the influence of fine grinding in ball mills and stirred mills on valuable mineral liberation and particle shape characteristics of UG2 ore, a Fine grinding: How mill type affects particle shape characteristics 2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, (PDF) A comprehensive review on the grinding process:

.jpg)

How to Choose the Right Crushing and Grinding Equipment for

2024年10月12日 Choosing the right crushing and grinding equipment for metal ore processing involves understanding the characteristics of the ore, production requirements, and 2023年6月1日 The main parameters of grinding and classification process include measurement of millfeeding quantity, mill load measurement, measurement of ore slurry density, Online Measurement and Control for Ore Grinding and ClassificationUsed in mining applications for the last 30 years, HPGR technology has streamlined the transition between mineral grinding and crushing by accepting largersized particles compared to ball Our Dynamic HPGR Technology for Mineral Grinding Weir2015年3月15日 Verticalrollermills (VRM) are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principle Results of extensive test Research of iron ore grinding in a verticalrollermill

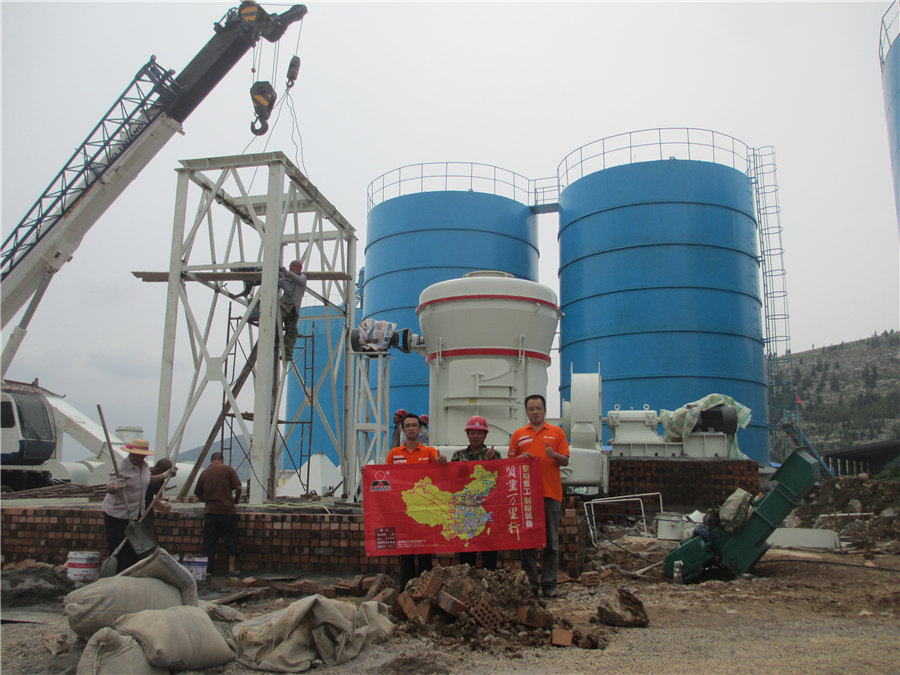

Grinding Mills, Ultrafine Mills, Powder Processing Equipment

As a manufacturer of industrial silicon powder processing equipment, Guilin Hongcheng has Raymond mill, vertical mill and ring roller mill to choose from The grinding process and 2017年1月17日 Other process activities, such as spraying the ore with water for dust control or the fact that runofmine ore moisture is approximately 2%5% are not generally considered (Bleiwas, 2012a)Breaking down energy consumption in industrial DIFFERENT MILLS REQUIRE DIFFERENT AMOUNTS OF MEDIA •BASED UPON WORKING VOLUME OR TOTAL VOLUME •Mills such as the Immersion Mill have a fixed amount determined by size of the basket •Steel Ball Mill 333% •Open Head Sand Mill 3545% •Ceramic Pebble Ball Mill 50% •Dry Grind Batch Attritor 4560% •Wet Grind Batch Attritor 3845% •Continuous How to Choose the Correct GRINDING MEDIA PCI MagCITIC HIC grinding mills are recognized as China's Manufacturing Industry Single Champion Product CITIC HIC is responsible for setting the national standards of semiautogenous mills (SAG mills) and ball mils, supported by powerful Grinding Mills Mineral Processing Equipment CITIC

.jpg)

Grinding Mill an overview ScienceDirect Topics

These mills are mostly used for wet grinding They are really vertical ball mills where balls are not tumbling but moved by a stirrer, or by vibrating the mill The balls or media are typically smaller, especially for fine grinding, all the way down to sand mills used for dispensing paint pigments in Iron Ore, 2015 831 Grinding equipmentGuilin HCM Machinery, Guilin Hongcheng Mining Equipment Manufacture Co, Ltd is one of China leading Powder Milling Equipment Plants, Supplying Raymond Mill, Vertical Roller Mill, Micro Powder Mill HCM Machinery has whole production line for Raymond Mill, Vertical Roller Mill, Micro Powder MillGrinding Mills, Ultrafine Mills, Powder Processing Equipment2017年9月1日 With the continual depletion of high grade simple ore bodies, more complex, finely disseminated ore bodies are being processed, which has led to an increase in the prevalence of fine grinding (Sinnott et al, 2006)This has been evident in the platinum group element (PGE) industry in South Africa, where the Bushveld Complex hosts 70% of global Fine grinding: How mill type affects particle shape characteristics 2017年5月8日 For lifter mills, or mills grinding materials giving a high coefficient of friction, the functional relationships should be read from the dotted line of Fig 37 It has been suggested by Bond , that for values of the ratio (D/d) greater than about 80 the ball charge “slumps” and, thus, the curve of Fig 37 falls for values of the ratio greater than this figureGrinding Mill Power 911Metallurgist

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 Grinding Mills and Pulverizers Grinding mills and pulverizers are the second level of material reduction equipment after crushers Mills and pulverizers transform materials through pressure or blades to grind, cut or crush it As there is with crushers, there are many different types of grinding mills and pulverizers availableMetso Select™ horizontal grinding mills are a preengineered range of classleading horizontal grinding mills, designed from industry leading experience and expertise The preengineered package eliminates time and costs usually spent in the engineering and selection stages Learn more about the Select™ horizontal grinding mills >Grinding mills for mining and minerals processing MetsoSBM ultrafine powder technology co,ltd Is China's excellent ore mill supplier Our main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consultSBM Ultrafine Powder Technology Industrial Grinding Mill, 2021年10月26日 For the production of coarse powder (under 325 mesh), you can choose a highpressure powder mill or Raymond mill; for the production of fine powder above 1000 mesh, you can choose an ultra fine grinding mill, Graphite Grinding Machine Powder Mill Equipment

Energysaving and Efficient Vertical Roller Mill Fote

A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, Fine Grinding as Enabling Technology – The IsaMill Pease, JD (1), Young, MF(2), Curry, DC (1) (1) Xstrata Technology (2) Xstrata Mount Isa Mines Introduction The new generation of stirred mills like the IsaMill has fundamentally changed the economics of fine grinding This has made them enabling technology for several existing and plannedFine Grinding as Enabling Technology – The IsaMill2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills It also discusses the factors, including the design, operating parameters, and feed material properties, EnergyEfficient Advanced Ultrafine Grinding of Particles UsingJune 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process:

.jpg)

Quality Vertical Coal Mill Limestone Vertical Mill factory from China

China leading provider of Vertical Coal Mill and Limestone Vertical Mill, Slag Grinding Mill Type: Vertical Mills Capacity(t/h): 23~220 It is a nationallevel hightech enterprise and technologybased enterprise specializing in powder industry technology and equipment RD, manufacturing, Grinding Mills Manufacturers, from large stones to directly usable fine powder 80120 mesh ore crusher Ore In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer! Gemma 20211202 08:05:33 Grinding Mills Manufacturers, Factory, Suppliers from China2003年4月1日 To cope with very fine grinding to below a P80 of approximately 15 μm stirred It was shown that the vertical stirred mills Media size effect––quartz sand grinding media; (b) material Variables Affecting the Fine Grinding of Minerals Using Stirred MillsRotational speed: 100 rpm 1,100 rpm FRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding stations is designed for a broad range of Ore mill, Ore grinding mill All industrial manufacturers

.jpg)

A Review of the Grinding Media in Ball Mills for

2023年10月27日 Showing corrosion wear for (a) differential abrasion cell (b) ball mill galvanic cell Adapted from [37] 2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot PlantThere are many different types of grinding mills and many types of materials processed in them Retsch is a leading global provider of grinding mills that are used in the lab for sample preparation and characterization of solids Retsch offers a wide range of grinding mills designed to accommodate a variety of applicationsGrinding Mills for reliable size reduction tasks RETSCH2021年11月3日 Phosphate mineral powder grinding mills includes ultrafine mills, vertical roller mills, highpressure mills, etc can grind ores into a fine powder +17 [ protected]Phosphate Mineral Powder Grinding Mill SBM Ultrafine Powder

Grinding Balls Rods 911Metallurgist

2016年10月21日 The subject of grinding media (grinding balls grinding rods) is still controversial The following information is general and based upon facts gathered 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Grinding Balls 2023年10月17日 3 Ultrafine Powder Grinding Mill Ultrafine powder mill (threering / fourring mediumspeed micropowder mill) feed particle size ≤25 mm, production capacity 0545 t/h, production fineness 1503500 mesh,it is a highefficiency and lowconsumption ultrafine powder processing equipment that successfully replaces the traditional jet mill and complex process How to choose a suitable ore powder grinding mill?2016年2月29日 Some of the metallurgical relationships that must be considered from the testwork program as follows: ore grade relationship to gold recovery, crushing and grinding parameters and their relationship to the ore variability in the ore body, effect of other minerals on the process, minerals and/compounds that negatively impact processing cost such as oxidized Gold Extraction Recovery Processes 911Metallurgist2017年9月1日 In general, the efficiency of fine grinding operations can mainly be improved by either enhancing the efficiency of existing grinding equipment and developing new machines, or by improving the Fine grinding: How mill type affects particle shape ResearchGate

.jpg)

(PDF) Grinding Kinetics Adjustment of Copper Ore Grinding in

2018年8月8日 semiautogenous mills KONA Powder Part J 2002, 20, 208 An Influence of Fine Grinding Operations on Flotation Effectiveness The research was conducted in a batch copper ore grinding2024年3月21日 Embracing the future of grinding technology, the HGM UltraFine Grinding Mill sets new standards for precision and efficiency in lithium ore processing With its ultrafine grinding capabilities and advanced control systems, the HGM Mill enables precise control over particle size distribution, unlocking new possibilities for lithium productionLithium Ore Grinding Mills2017年1月17日 Other process activities, such as spraying the ore with water for dust control or the fact that runofmine ore moisture is approximately 2%5% are not generally considered (Bleiwas, 2012a)Breaking down energy consumption in industrial DIFFERENT MILLS REQUIRE DIFFERENT AMOUNTS OF MEDIA •BASED UPON WORKING VOLUME OR TOTAL VOLUME •Mills such as the Immersion Mill have a fixed amount determined by size of the basket •Steel Ball Mill 333% •Open Head Sand Mill 3545% •Ceramic Pebble Ball Mill 50% •Dry Grind Batch Attritor 4560% •Wet Grind Batch Attritor 3845% •Continuous How to Choose the Correct GRINDING MEDIA PCI Mag

Grinding Mills Mineral Processing Equipment CITIC

CITIC HIC grinding mills are recognized as China's Manufacturing Industry Single Champion Product CITIC HIC is responsible for setting the national standards of semiautogenous mills (SAG mills) and ball mils, supported by powerful These mills are mostly used for wet grinding They are really vertical ball mills where balls are not tumbling but moved by a stirrer, or by vibrating the mill The balls or media are typically smaller, especially for fine grinding, all the way down to sand mills used for dispensing paint pigments in Iron Ore, 2015 831 Grinding equipmentGrinding Mill an overview ScienceDirect TopicsGuilin HCM Machinery, Guilin Hongcheng Mining Equipment Manufacture Co, Ltd is one of China leading Powder Milling Equipment Plants, Supplying Raymond Mill, Vertical Roller Mill, Micro Powder Mill HCM Machinery has whole production line for Raymond Mill, Vertical Roller Mill, Micro Powder MillGrinding Mills, Ultrafine Mills, Powder Processing Equipment2017年9月1日 With the continual depletion of high grade simple ore bodies, more complex, finely disseminated ore bodies are being processed, which has led to an increase in the prevalence of fine grinding (Sinnott et al, 2006)This has been evident in the platinum group element (PGE) industry in South Africa, where the Bushveld Complex hosts 70% of global Fine grinding: How mill type affects particle shape characteristics

.jpg)

Grinding Mill Power 911Metallurgist

2017年5月8日 For lifter mills, or mills grinding materials giving a high coefficient of friction, the functional relationships should be read from the dotted line of Fig 37 It has been suggested by Bond , that for values of the ratio (D/d) greater than about 80 the ball charge “slumps” and, thus, the curve of Fig 37 falls for values of the ratio greater than this figure2017年6月2日 Grinding Mills and Pulverizers Grinding mills and pulverizers are the second level of material reduction equipment after crushers Mills and pulverizers transform materials through pressure or blades to grind, cut or crush it As there is with crushers, there are many different types of grinding mills and pulverizers availableHow it Works: Crushers, Grinding Mills and PulverizersMetso Select™ horizontal grinding mills are a preengineered range of classleading horizontal grinding mills, designed from industry leading experience and expertise The preengineered package eliminates time and costs usually spent in the engineering and selection stages Learn more about the Select™ horizontal grinding mills >Grinding mills for mining and minerals processing MetsoSBM ultrafine powder technology co,ltd Is China's excellent ore mill supplier Our main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consultSBM Ultrafine Powder Technology Industrial Grinding Mill,