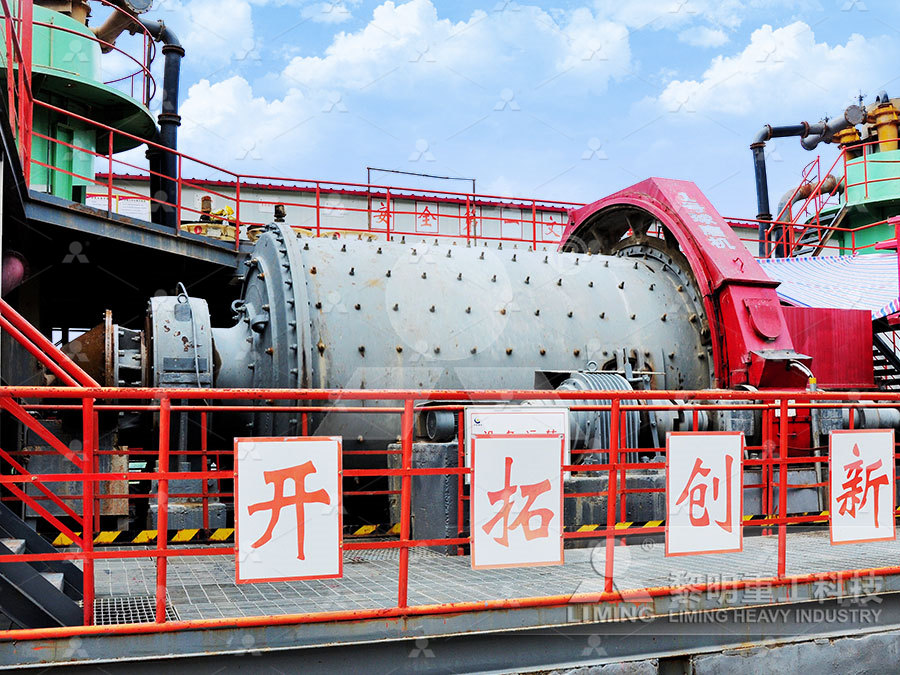

Calcium carbonate crushing station limestone crusher smelting waste slag crushing

Maximising the benefits of calcium carbonate in sustainable

2024年1月19日 Substituting Portland cement (PC) clinker with limestone has been demonstrated to effectively reduce CO 2 emissions while enhancing the properties of cement 2014年12月1日 Environmental impacts of precipitated calcium carbonate manufacturing are estimated Alternative production methods are compared using a partial life cycle assessment Cradletogate life cycle assessment of precipitated calcium 2018年2月10日 This study addresses four research themes: (1) waste cement recovery from two types of waste concrete, (2) calcium extraction efficiency from waste cement by hydrochloric Recovery and carbonation of 100% of calcium in waste concrete There are two broad pathways for release of CO2 from carbonates: calcination and the acidinduced release of CO2 The primary process resulting in the release of CO2 is the calcination CHAPTER 2 MINERAL INDUSTRY EMISSIONS IGES

.jpg)

Production of Precipitated Calcium Carbonate from Steel

2014年1月1日 They utilized wastewaters from metal industries as a solvent, aiming at simultaneous reduction of the alkalinity of the slag and of the wastewater Calcium carbonate 2023年3月21日 Using Ca (CH 3 COO) 2 (prepared from limestone waste) as a calcium source resulted in a 3187% lower MICP cost compared to using CaCl 2 An unconfined compressive Feasible Utilization of Waste Limestone as a Calcium Source for 2023年1月6日 In our studies, we used Cabearing industrial waste (ie, construction and demolition waste) as the feedstock to produce highpurity calcium carbonates We aim to Upcycling Construction and Demolition Waste into Calcium 2021年7月14日 While minimizing CO 2 emissions is a goal of the utmost importance, research into sustainable building materials must also tackle the issue of raw material depletion Use of Waste Calcium Carbonate in Sustainable Cement

.jpg)

Effect of Steam Injection during Carbonation on the Multicyclic

2022年1月6日 Steam injection has been proposed to improve the CO 2 uptake capacity of CaObased sorbents when the calcination and carbonation loops are carried out in CCS conditions: Limestone and dolomite, after being pretreated thermally at high temperatures (1000 or 1100 °C), showed a substantial increase in calcium utilization over many calcination/carbonation cycles LongTerm Calcination/Carbonation Cycling and Thermal 2023年11月10日 Generally, when configuring wearing parts, the configuration ratio of the three is 3:2:1 By replacing these wearing parts on time, we can effectively avoid damage to other components of the crushing station during the crushing process Extend the overall service life of the crushing station (machine) Impact crusher in stone crushing plantImpact crusher PF1315 Aggregate Rock Crushing Equipment2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and Limestone crushing technology and equipment SBM

Limestone crushing, sand making and grinding process

2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other Calcium carbonate is a common mineral that is widely used in various industries such as construction, paper, plastics, and agriculture Calcium carbonate crusher is a specialized equipment used to crush calcium carbonate into small particles to facilitate its use in various applications This paper will discuss the importance of calciumCalcium Carbonate Crusher CM Mining MachineryLimestone Crusher for Efficient Limestone Crushing Plant Limestone is a versatile nonmetallic mineral with widespread applications in construction, agriculture, environmental protection and more As the primary raw material for cement production, reliable limestone supplies are critical for sustainable infrastructure development globallyLimestone Crusher for Efficient Limestone Crushing PlantMining crushing stations are unique, cost efficient and modular solutions that provide significant resource and time savings for your mining operation Mining Crushing Stations combines legacy and expertise to bring unique, costefficient and modular solutionsMining crushing stations Metso

.jpg)

High efficiency 100t construct waste concrete crushing station

High efficiency 100t construct waste concrete crushing station plant limestone mobile jaw crusher, Complete stone kaolin calcium carbonate powder 3r raymond grinding mill plant gypsum 4r raymond mill price with dust collector 110t/h mobile construct waste jaw crusher plant limestone crushing plant for sale $50,00000 Min order: 1 setWilliams Patent Crusher is committed to designing and manufacturing the most durable and efficient limestone crusher machines on the market We’ve held that commitment for over 150 years Additionally, since the mid1980s, we’ve developed extensive experience in Circulating Fluidized Bed (CFB) technology and our limestone mills have proven themselves as an Limestone Mills Limestone Crushers Pulverizers Williams Crusher2024年1月23日 Limestone is a common sedimentary rock, primarily composed of calcium carbonate It is widely distributed in different regions of the Earth, forming extensive rock layers The color of limestone can vary due to impurities, including white, gray, yellow,hellip;Limestone crushing and screening production line introduction2022年2月26日 In China, slag crushed stone can replace natural stone for highway, airport, foundation engineering, railway ballast, concrete aggregate and asphalt pavementIt can be used for: preparing slag crushed stone concrete, applying in soft foundation, paving asphalt pavement with slag crushed stone as base material, which is bright and has good antiskid performance, What is Blast Furnace Slag and How to Process It?

The Complete Guide to Primary Crushing, Secondary

2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the 2024年1月11日 The limestone sandmaking plant process mainly includes three stages: coarse crushing, fine crushing, and sand making The finished sand and gravel aggregate made of limestone can provide industrial raw materials for Limestone Crushing And SandMaking Plant2017年5月19日 The effect of calcium oxide on the crushing strength, reduction, and smelting performance of highchromium vanadium–titanium magnetite pellets (HCVTMP) was studied in this workEffect of Calcium Oxide on the Crushing Strength, 2024年1月19日 Beyond limestone extraction, quarrying, and crushing, To maximise the benefits of calcium carbonate derived from alkaline waste A reaction device for fixing CO 2 in flue gas using waste slagMaximising the benefits of calcium carbonate in sustainable

Choosing the right primary crusher for limestone crushing Baichy

2024年7月10日 Slag Grinding Mill Plant; Feldspar Grinding Mill Plant; Beneficiation Plant Choosing the right primary crusher for limestone crushing 14:51:44 Baichy Consulting Service Overview Of Limestone And Its Uses Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3), First of all, the mobile crushing station is equipped with a jaw crusher and combined into a mobile jaw crushing plant It can be directly driven to mineral waste residue site to work, which can reduce the pollution problem caused by the drop of waste residue during transportationSlag Crushing Plant Track Mounted Mobile Slag Crusher Machine2023年3月2日 Discover the benefits, types, and applications of Slag Crusher Machines in the steel industry Learn how these machines work, the types of slag they can crush, and the maintenance required for optimal performance Maximize the benefits of steel recycling and contribute to a more sustainable future with this comprehensive guideWhat is a Slag Crusher Machine and How Does it Work?2022年3月9日 This setup is a 500tph complete limestone crushing plant, the max input size is 1020mm, output sizes are 05mm, 519mm, 1925mm,2550mm It is configured with hopper, vibrating feeder DN6015, primary jaw crusher PE1200*1500, 2 sets impact crusher PF1520,4 sets vibrating screen 2YD3072, and 12 pcs belt conveyors Flowchart Explanation 1 The 500TPH Limestone Crushing Plant JXSC Machine

Construction Brick Slag Crushing And Recycling Plant

2024年2月2日 2 Mobile brick slag crushing plant The mobile brick slagcrushing plant is suitable for dealing with various complex and harsh working environments The equipment crushes the materials at the site, and after crushing, it can quickly rush to the other work site, saving material transportation time and costs2024年5月26日 Mineral carbonation is one of the known methods for carbon capture, utilization, and storage (CCUS) Slag from the steel industry is studied as a common source of CaCO3 via mineral carbonation owing to its high Ca content Despite numerous preliminary studies, the optimal factors governing the mineral carbonation of steelmaking slag, such as extraction and Experimental study on indirect mineral carbonation using five 2022年4月20日 The processing of limestone is mainly to crush, classify and produce quicklime, slaked lime, precipitated calcium carbonate, ultrafine (nano) calcium carbonate, carbon dioxide, etc Limestone generally adopts dry Limestone crushing and grinding production line2020年2月18日 Limestone is a fundamental raw material in various industrial sectors It is formed due to biochemical precipitation of calcium carbonate, and further compaction over long periods of time(PDF) Environmental Hazards of Limestone Mining

.jpg)

Calcium carbonate Wikipedia

Calcium carbonate shares the typical properties of other carbonatesNotably it reacts with acids, releasing carbonic acid which quickly disintegrates into carbon dioxide and water:; CaCO 3 (s) + 2 H + (aq) → Ca 2+ (aq) + CO 2 (g) + H 2 2024年7月11日 After the limestone material is crushed by the impact crusher for the second time, the limestone pebbles discharged from the impact crusher outlet are screened by the vibrating screen on the mobile impact crusher, which can be screened into different aggregate specifications according to demand, such as 05mm sand, 520mm crushed stone, and 20 Limestone aggregate crusher plant stationary and mobile type2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each Stage1 Firststage Crushing The Limestone raw material is transported to the jaw crusher by the vibrating feeder for coarse crushing 2 Secondstage Crushing Screening After coarse crushing, the Limestone enters the impact crusher for fine crushing and then uses a vibrating screen for screening operation, and the qualified materials flow into the next process, and the Limestone Aggregate Crushing JXSC Machine

Limestone Crushing Plant Supplier – Limestone Crusher For Sale

320t/h Construction Waste Material Crushing Station; 250t/h Limestone Mobile Crushing Plant; The jaw crusher crushes the limestone in the first stage Output: 700800t/h: 500600t/h: 300350t: 100t/h Slag Mobile Crushing Plant; Blog; About; Contact Us +86 ne 19F, About Limestone Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3) in the form of the mineral calcite or aragonite It is a kind of stone widely found in nature Limestone can be directly processed into stone using crushing equipment and fired into quicklime Quicklime absorbs moisture or adds water to become hydrated limeLimestone Crushing Process JXSC Mineral2022年11月1日 China has the largest output of steel and iron in the world (Zhang et al, 2022)In 2021, China's average annual pig iron output arrived at about 869 million ton (Stewart et al, 2021) and crude steel arrived at about 103 billion tons (Zhao et al, 2022)Meanwhile, the output of steel solid waste keeps at a high level and generally the production of one ton steel will generate Life cycle assessment of melting reduction treatment for iron and 2016年2月22日 In this work, different separation processes, including washing, filtering, and drying, were tested on two calcium carbonate slurries produced from steel converter slag and CO2 by a laboratory Performance of Separation Processes for Precipitated Calcium Carbonate

Impact crusher PF1315 Aggregate Rock Crushing Equipment

2023年11月10日 Generally, when configuring wearing parts, the configuration ratio of the three is 3:2:1 By replacing these wearing parts on time, we can effectively avoid damage to other components of the crushing station during the crushing process Extend the overall service life of the crushing station (machine) Impact crusher in stone crushing plant2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and Limestone crushing technology and equipment SBM 2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other Limestone crushing, sand making and grinding processCalcium carbonate is a common mineral that is widely used in various industries such as construction, paper, plastics, and agriculture Calcium carbonate crusher is a specialized equipment used to crush calcium carbonate into small particles to facilitate its use in various applications This paper will discuss the importance of calciumCalcium Carbonate Crusher CM Mining Machinery

.jpg)

Limestone Crusher for Efficient Limestone Crushing Plant

Limestone Crusher for Efficient Limestone Crushing Plant Limestone is a versatile nonmetallic mineral with widespread applications in construction, agriculture, environmental protection and more As the primary raw material for cement production, reliable limestone supplies are critical for sustainable infrastructure development globallyMining crushing stations are unique, cost efficient and modular solutions that provide significant resource and time savings for your mining operation Mining Crushing Stations combines legacy and expertise to bring unique, costefficient and modular solutionsMining crushing stations MetsoHigh efficiency 100t construct waste concrete crushing station plant limestone mobile jaw crusher, Complete stone kaolin calcium carbonate powder 3r raymond grinding mill plant gypsum 4r raymond mill price with dust collector 110t/h mobile construct waste jaw crusher plant limestone crushing plant for sale $50,00000 Min order: 1 setHigh efficiency 100t construct waste concrete crushing station Williams Patent Crusher is committed to designing and manufacturing the most durable and efficient limestone crusher machines on the market We’ve held that commitment for over 150 years Additionally, since the mid1980s, we’ve developed extensive experience in Circulating Fluidized Bed (CFB) technology and our limestone mills have proven themselves as an Limestone Mills Limestone Crushers Pulverizers Williams Crusher

Limestone crushing and screening production line introduction

2024年1月23日 Limestone is a common sedimentary rock, primarily composed of calcium carbonate It is widely distributed in different regions of the Earth, forming extensive rock layers The color of limestone can vary due to impurities, including white, gray, yellow,hellip;2022年2月26日 In China, slag crushed stone can replace natural stone for highway, airport, foundation engineering, railway ballast, concrete aggregate and asphalt pavementIt can be used for: preparing slag crushed stone concrete, applying in soft foundation, paving asphalt pavement with slag crushed stone as base material, which is bright and has good antiskid performance, What is Blast Furnace Slag and How to Process It?